ShopMaster MILL TURN User guide

SHOPMASTER

SETUP MANUAL

COPYRIGHT SHOPMASTER 1981-2017

DUPLICATION PROHIBITIED WITHOUT

WRITTEN CONSENT OF SHOPMASTER

Dear owner, thank you for choosing SHOPMASTER. This owner’s manual is

being sent to you in .PDF format prior to the delivery of your machine so that you can

be prepared for it’s setup upon arrival. As the owner, you may print out a hard copy of

this manual or have a bound copy done at a local office supply house for your personal

use. Copying or printing the manual for sale or distribution to others is prohibited.

INSPECTION OF CRATE UPON ARRIVAL

Your machine will arrive at your destination by truck freight. The driver

will ask you to sign the delivery slip. Before you sign, please inspect the

crate carefully for any signs of rough handling such as holes, broken pieces

etc. Because the machines travel a great distance from the factory to you,

scuff marks, scratches and small chips in the crate are normal. However

there should not be any panels broken loose or holes punched through the

wood exterior. The machine sits on 3 steel tube skids, designed to allow

movement by forklifts and some dents on the edges are normal. However,

any skids that appear to be bent over or compressed are an indication of the

unit having been dropped. The slight dents will not show once the bench

assembly is completed. After you have inspected the machine, and if you

find anything you feel is out of the ordinary, make a note on the delivery slip

when you sign and also document the issues with photos.

OPENING THE CRATE AND TAKING INVENTORY

You will see that the wood crate has bend-over metal locking tabs holding

the components together. Using a screwdriver and pliers, straighten out the

tabs and remove the top first, followed by both ends. The sides of the crate

are secured to the bench legs with 10 mm bolts. You will need a ratchet and

socket (17 MM or 11/16) to remove the bolts. Set the bench panels aside and

save the bolts. You will find the rear sheet metal panels and the front doors

for the bench wrapped and secured inside the machine. Remove them and

set them aside. The 2 end panels are already attached. You can now see that

the bench leg assembly is mounted upside down on the base, which allows it

to form a strong support for the crate.

At his point you should look over the machine for any signs of damage

that may not have been apparent while it was crated and document them by

photos. You will find the PC and monitor in a box along with the keyboard,

mouse, power cable and laser tachometer. The tooling is in a separate box as

are the vise and CNC rotary table.

Open the boxes and compare the contents to the list of standard accessories

that was posted on our website before you placed your order. Make a note

of any missing items and send us an e-mail detailing those and any damage

you may have found.

ASSEMBLING THE BENCH

Now its time to remove the bench leg assembly which is held in place by 6

bolts threaded up from below the bench pan into the 6 legs. Remove these 6

bolts and the leg assembly can be lifted off the pan. The leg assembly is not

heavy, but due to its size, its best to have someone help you so you can lift it

straight up and off the machine. Be cautious here that you do not bang the

leg assembly against the machine and chip the paint or break any of the

control knobs. Once the leg assembly is clear of the machine, flip it over so

that it is sitting on the 6 leveling pads. Be sure that it is resting solidly on the

pads, not on the casters. Also be sure to orient the leg assembly so that when

you lift the machine onto it, the front portion faces the front of the machine.

You will see that on one side, the center leg has 2 tabs welded in place on

each side and the outer legs have the door hinge pins welded on, so this leg

should face the front of the machine. Take the 2 doors from their wrapping

and install them on the front of the bench. You will note that the door hinge

pins slide in from the top, so that when the machine is placed on the leg

assembly, they cannot be removed. Now it’s time to lift the machine up onto

the legs. If you have a forklift, it will be easy to just pick the machine up and

slide the legs under it. If you are using an overhead hoist or a roll around

“cherry picker” style hoist, then you will need to place your straps or chains

under the bench pan and get them secured in position so that the machine is

balanced when lifted. Protect the machine finish by placing towels between

the straps or chains and the machine. Also be sure none of the lifting straps

bind against handles, sheet metal etc. At this point, move with care and

caution as you raise the machine up. Do not get your hands or feet under

the machine and keep others away while you proceed. Once the machine is

high enough, slide the leg assembly under it, again noting the position of the

front of the bench. Slowly lower the machine down until it is almost resting

on the legs and then thread the 6 bolts down through the bench pan into the

legs. Lower the machine down completely until it is resting solidly on the

legs and remove your lifting mechanisms. Leave the 6 bolts just finger tight

for now. Don’t be concerned if the assembly seems a bit unsteady at this

point.

In your box of accessories you will find a bag of fasteners for the rear

panels. Place each panel in place and get all the bolts started, but not tight.

Now you may go around and begin tightening all the fasteners for the sheet

metal panels, all the while checking for squareness and even gaps. Once

done, your doors should open and close freely and the latches should catch

the tabs on the center leg when closed. You will also now see that the

assembly has taken on a very strong and solid feel. Now you can tighten

each of the 6 bolts holding the bench pan to the legs, but first, put a bead of

silicone sealer around each hole to prevent leaks if you use a coolant system.

Once those 6 bolts are sealed and tightened, your bench should be rock solid.

Finally, open the front doors and double check the tightness of the 6 bolts

holding the machine to the bench pan. The bolts are accessed by holes in the

3 skids. These holes are sealed at the factory against leaks, but it’s possible

that they may have vibrated loose during transportation.

ADDING SHELVES AND DRAWERS

While your machine is still in the open and accessible from all sides, you

may want to add some shelves and/or drawers. A lower shelf is easy to

measure and cut, and by removing one end sheet metal panel it can be

slipped into place. You can even use the crate material by gluing 2 panels

together and stacking some cinder blocks on them while the glue dries and

then cutting them to size. You can also buy drawer assemblies, or use one of

those low cost toolbox units sold at discount stores placed inside the cabinet

and resting on the lower shelf. There are plenty of variations of shelves and

drawers to suit your own style. The openings behind the doors are 24” wide,

25” tall and 25” deep.

If you install toolboxes with drawers, you may leave the doors in place

to utilize their locking feature, or simply leave them off for fast access to

your tools.

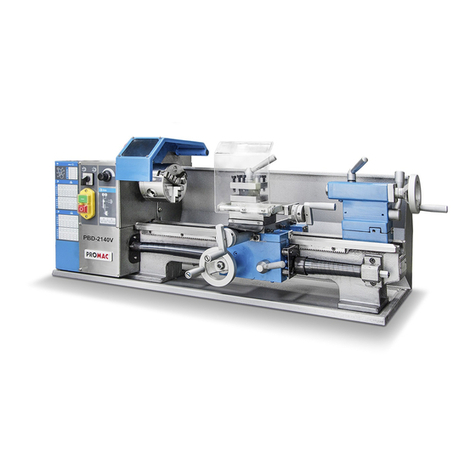

MILL TURN AND TURNADO BENCH ARE THE SAME

picture shows doors removed and toolboxes installed

CHOOSING A LOCATION AND WIRING

Now that your machine is all prepared to move into place, you need to

decide on its placement. Keep in mind access for future maintenance and

cleaning. Ideally, you should be able to walk around the machine, but we

know that many of these machines are going into home garages where space

is limited. With the casters, you can easily move the machine around should

the need arise. Keep in mind that the access panel for your electronics is on

the left as you face the machine and should you be turning long parts in the

lathe which protrude through the spindle, you will need some space on the

left side. You definitely do not want to place the left side in a corner. Once

you have chosen your location, its time to run your wiring. The machine

comes with a 6’ long cord wired to a NEMA 6-15 220 volt plug. The NEMA

6-15 is a common plug found at any home improvement store and you can

find the corresponding outlet as well. You will only need a single 15 amp 220

volt circuit and plug for the machine.

The computer and DRO that come with the machine are 220 volt only and

their cords are hard wired into the control box of the machine.

CAUTION: DO NOT PLUG THE COMPUTER OR DRO INTO A 110

VOLT OUTLET.

The cord comes out the back of the machine on the left side about 36” from

the floor. Measure out your location and have your outlet wired so the cord

can reach. (Use of a 3-4’ extension cord of sufficient wire gauge is

acceptable if necessary) The outlet should be about 48” from the floor. You

will also need a 110 volt outlet near the machine for any lights, fans etc. you

may want to use.

MOVING INTO PLACE AND LEVELING

Now that you are all wired and ready to move the machine into place,

screw the adjustable legs up into the bench legs until the machine is resting

on the casters. Now one person can easily roll the machine around.

However, be careful and move slowly because the machine is very top heavy,

and even a small nut or bolt could stop the caster and cause the machine to

tip over if rolling too fast. Sweep up your entire area before beginning the

move. If you are mounting the machine close to the back wall, be sure to

release the computer mount and swing it out toward the front of the

machine before getting up close to the wall. Once you are in the chosen

place, begin screwing the adjustable levelers out of the bench legs until the

machine is lifted off the casters. Most shops have concrete floors, but in the

unlikely event you are on a wood floor, you should cut some 6” X 6” steel

pads to place beneath the levelers to spread the load. Mark the place on the

floor with paint or sharpie so you can always return there if you should need

to move the machine. If you have a machinist’s level, that is great, but a

good quality carpenter’s level will work as well. Place the level on the top

carriage of the machine and begin to adjust the levelers until you are level

left to right, forward to back and at 45 degrees to both positions. The

machine castings are very rigid, and there is little chance of distortion as

long as all 6 legs are planted firmly on the ground.

REVIEWING THE CONTROLS

For now, leave the machine unplugged from the wall and take some time

to review the controls. You will notice that the DRO display was mounted

upside down during shipping in order to clear the bench legs. At this point

you can remove the nut from the mounting stud and turn the display right

side up. The functions and features of the DRO are covered in the DRO

manual itself. The mill head was placed at its lowest level for shipping, so

you can now unfold the handle from the wheel and move the mill head

upwards manually. There is no lock on the travel, as the stepper motors

lock it into place when at rest. You can also move the Y axis forward and

back and the X axis left and right, but be sure to loosen the carriage locks.

On the front panel to the left are all the controls for the spindles and CNC.

Your machine PC has been pre-configured as well as the VFD inverter, so

your machine will be fully functional when you get ready to turn it on.

Toward the top of the front left panel is the VFD keypad and display. In the

delivered setup, all the functions of the VFD are controlled through Mach 3,

and the display will simply read the Hz reading going to your motors. Please

note, this is not the RPM of the spindle, that will read on your Mach 3

screen. This key pad can also be configured for manual control with the

small knob and the buttons. There is a decal telling how to change the codes

between manual and Mach 3 control. This is all covered in the V-8 manual.

Below the VFD Key pad are the machine controls. The top left switch is for

selecting which spindle will run. Later on you will note that when selecting

either lathe or mill, you will hear a snap sound from the inside of the panel-

that is the magnetic contactor engaging. To the right of this switch is your

main power switch for the VFD inverter and the spindle motors. When this

switch is on, you will also have the red light on. Below these switches in the

center is the E-Stop switch. This switch shuts off all power to the VFD

inverter as well as the stepper motors, so in the event of a crash, all you need

to do is push the red button in. To re-engage the switch you just turn it

clockwise, but be sure to read the instruction and turn off all other switches

first. Below the E-Stop and to the left is the power switch for the Gecko

drive. When this switch is on, your CNC system is activated. To its right is

the stepper motor switch. With the CNC on and the stepper switch on, the

stepper motors are locked in position and can only be moved by Mach 3. If

you want to move the carriages manually, you must turn the stepper switch

off. Check each switch and watch to be sure it is properly “clocked” so the

white stripe points to the proper place on the decal. On the panel at 90

degrees to the switches you will find the flow regulator for the air coolant

system. You will note the air exits through a flex nozzle on a magnetic base

which can be used as a coolant for the cutting tools. Opposite the controls on

the rear of the panel you will find the inlet for the coolant air.

Above the air inlet is the Gecko drive to which the computer and stepper

motors are attached. You will see that Z and X axes are not hooked up, and

A and Y axes are open for use with other CNC tools like the CNC toolpost.

You will also see a small slide switch marked CHARGE PUMP. This should

remain in the ON position. The charge pump is a safety feature that prevents

the machine from moving suddenly if you forget to boot the computer prior

to turning on the CNC power. Above the Gecko drive you will find 3 plugs

marked pins 2,3,4. These are input pins for the Gecko to be used if you want

to attach home and limit switches. The corresponding male plugs are

included in your accessories. Just above these plugs is the auxiliary coolant

fan inlet. The system has 3 fans altogether to keep the operating

temperature at the proper levels.

INSPECTING THE ELECTRONICS

Before plugging the machine into the power, it’s a good idea to look inside

the control cabinet. This will give you an idea what’s inside and how it all

works. Remove the 4 bolts holding the panel in place. Looking inside and

starting at top left you will see the auxiliary cooling fan which pulls air from

outside, blows it across the electronic components and then it exits out down

over the X axis stepper motor. Just below the fan is the Gecko drive with

wires running to the inverter, switches and power supply. To the right of the

fan is the VFD inverter which takes the 220 volt single phase input and

converts it to 220 volt 3 phase out put for the motors. The inverter also

accepts signals from Mach 3 to control the spindle speeds, forward, reverse,

etc. To the right of the inverter are the 2 magnetic contactors that engage the

lathe and mill spindle motors. To the right of the contactors is the CNC

power supply. This converts 220 volts AC into 48 volts DC for the Gecko

drive. Just below the gap between the contactors and the power supply is

the module for the spindle sensors which send signals to Mach 3 for RPM

reading, threading, tapping etc. To the right of the CNC power supply is the

back side of the VFD keypad with the ribbon cable running back to the VFD

inverter. The inverter and the power supply each have their own cooling

fans as well as temperature sensors that shut down in case of overheating.

You will also see the air coolant piping going to the flow regulator. In the

central panel where the lathe spindle and drive belt are located you can see

the lathe spindle sensor mounted to its bracket. Note that this section is

sealed off to prevent any chips or debris from belt wear entering the

electronics components. To the far right you see the backs of the control

switches and you can see the white tab which allows the switch portion to

disconnect from the knob should you need to do maintenance. At the

bottom right you see the Z axis stepper motor and drive belt going to the

pulley on the end of the Z axis ball screw.

While the end panel is open and power disconnected you should check the

drive belt tension, stepper belt tension and adjust any switch knobs that are

not properly “clocked”. When done replace the panel.

NOTE: While the machine is unplugged, we strongly suggest you check

all the wire connections for tightness. Spending 10 minutes now could

save time later should there be a loose wire that becomes disconnected

as the machine is running.

CABLE CONNECTIONS FOR STEPPERS

AND DRO

To prevent any damage to the cables and the Gecko drive, and due to

the position of the DRO display in shipping, the cables are left

unconnected but are labelled for proper connection to the machine.

All cables must be securely attached with the holding screws, because a

loose connection can cause Mach 3 to fault out during a program.

CAUTION- Always turn off the CNC Power

switch before disconnecting a cable.

DRO CABLES

The DRO has 2 modes for lathe and mill, but when first powered up it

should go into the default Mill mode. So just plug the cables into the

display and then watch which display is reading when you move the X

axis and move that cable to the X axis port on the display. The same

procedure for Z. The CNC toolpost will attach to the A axis. You can

swap DRO cables with power on with no problem. Once the cables are

in their proper positions, secure them with the screws.

TEST RUN THE MACHINE

To begin the first test run of the machine, move the Z and X carriages to

their mid travel points, this will give you plenty of clearance for your first

moves. Bring the computer mount around and adjust it to a comfortable

position. Hook up the keyboard and mouse and the monitor and Parallel

port cables. Plug the PC power cable in to the 220 volt wall outlet. Turn the

PC on. It should boot up and on your desktop screen you should have

several icons. RECYCLE BIN, MACH LOADER. Double click Mach

Loader and then select LATHE. If you have some extra selections in the

Mach loader, such as Plasma, Mach3Turn and Mach3Mill, just delete them,

as they are default XML files from the Mach 3 installation and do not have

the correct settings for your machine. Also, delete any extra icons from the

Desktop for Mill, Turn or Plasma and just use the Mach Loader. The Mach

3 screen should load up at this point. Now make sure all your switches on

the machine panel are in the OFF position and plug your 220 cord into the

220 outlet. Be sure your E-Stop switch is engaged by twisting it. Set the

selector switch to LATHE mode and turn on the SPINDLE POWER switch.

You should get a red light and hear the auxiliary cooling fan running. Turn

on the CNC POWER switch and you should get a red light and also hear the

power supply fan running. Turn on the STEPPER switch and you should

hear the steppers jump to locked position. You should not be able to turn

the handles at this point. The DRO display may or may not light up at this

point. It is hard wired into the power switch, but also has a separate ON-

OFF switch on the back of the display. On the lower left of the Mach 3

screen you will see a reset button flashing- click on this to reset. Note- every

time you turn off the stepper switch, the reset will flash and you will need to

reset it. Once the reset button is reset, go to the top of the screen and select

MDI (Manual Data Input). A bar will open up for data entry. First type

G91 and hit enter. G91 is the code for incremental moves. Now type G0 Z1

and hit enter. The carriage should move up 1” to the right. Now try G0 Z-1

and hit enter. The carriage should move 1” to the left. Try the same

commands for X axis according to the chart on the right sheet metal shield.

When testing any axis, if you hear a whining noise and there is no motion,

don’t worry- that is just the stepper stalling and it won’t hurt anything.

Contact us for help with diagnosing the problem.

PLEASE NOTE: The command is G “ZERO” not G “OH”

Now try a spindle command- type M3 S200 and hit enter. The lathe spindle

should turn at 200 RPM. Type M5 and enter to stop the spindle. Type M4

S200 and the spindle should rotate the opposite direction. Always use M5 to

stop the spindle.

If the carriages or spindle move the wrong direction go to the bottom of this

file for instructions.

As your spindle is running, on the Mach 3 screen you will have a display that

shows the RPM you requested and another display showing the true rpm as

read from the spindle sensor. These should be very close, but can be

adjusted in the CONFIG files. At this point you are ready to begin the final

adjustments of the spindle rpm, steps per inch and backlash compensation.

We have included a number of files for these operations on our website. We

have set the adjustments as close as possible, but every machine will be

slightly different and once installed in its final location these fine

adjustments must be completed by the operator. The functions of each of

the VFD codes are set forth in the V-8 VFD manual which we have on our

website. Following are a few of the more common adjustments used in daily

operations.

Codes P0-02 and P0-03 and P0-11 allow you to change from Mach 3 control

of your spindles to manual control according to the settings on the decal.

Codes P0-08 and P0-10 are the Hz settings which control your maximum

spindle speeds. Please note, when adjusting these settings, the 2 code settings

must always match. The factory default setting is the maximum allowable of

120.

Codes P0-18 and P0-19 control the rate in seconds of the acceleration and

deceleration of the spindles. If the setting is too low (.5) it will cause a fault

error as the motor cannot accelerate or decelerate that fast. We recommend

1.5 as the setting.

The V-8 inverter allows you to select the proper settings to match your

motor. These settings are done at the factory according to the nameplate on

the motor. However you may want to compare the inverter settings to the

name plate on your motors. These codes are found in P1-00 through P1-05.

POSSIBLE ISSUES:

1. Stepper motors run the wrong direction according to the

machine decal.

The steppers have 2 wires that are interchangeable in the plug, and

occasionally we find motors with them reversed. Changing the

direction is a simple Mach 3 adjustment-

Go to CONFIG>PORTS & PINS> MOTOR OUTPUTS and find

the column marked DIR LOW ACTIVE - simply change the

check mark from red to green or vice versa to reverse the motor

direction.

Your machine comes with an operating demo version of Mach 3

which will run up to 500 lines of G-code. In order to use more lines

or the special wizards, you will need to purchase the full Mach 3

license.

You can purchase the full license from

DMAUCH@SEANET.COM

DRO updates:

Machines after serial # 15066 on have a new DRO feature unique

to the Shopmaster. Because the axes designations for Lathe and

Mill are different, normal DRO displays require you to remember

which mode you are reading. For example, when in Mill mode, the

X axis is the carriage travelling along the main bed toward and

away from the chuck. But in Lathe mode it is called the Z axis.

This can be confusing when trying to remember which is which.

On those machines after 15066 we have re-designed the DRO

display, and now by pressing the EDM button twice, the display

switches between Mill and Lathe mode so your readings are always

correct.

5C COLLET SET

4 JAW CHUCK

FOLLOW REST

STEADY REST

TOOL TRAY

The CNC toolpost setup manual will be sent as a separate

document.

SETTING STEPS PER INCH AND BACKLASH

COMPENSATION

To get the best results from your machine these settings must be done

to the best possible settings. Because the machine is new, it will wear

in a bit after a certain amount of run time and may loosen up. We

suggest that your first step is to take some time to run all your axes

back and forth their full travel for about an hour. After this

procedure is done, check your gib adjustments and the adjustments on

your thrust bearings to be sure there is no looseness from the assembly

grease having been displaced.

SETTING STEPS PER INCH

1. Go to CONFIG> NATIVE UNITS and set to INCH

2. Go to BACKLASH and be sure it is not enabled

3. In your MANUAL screen, choose an axis to start and put a slight

amount of drag on your carriage lock. First give a G91 command

for incremental mode. Move the axis in any direction –this will

take out any inherent lash in the screw.

4. Now Zero your DRO in Mach 3 and also your machine DRO. Now

give your Mach 3 a G code command to go 1 inch ( G0 X1 )

5. Read the actual motion on your DRO. If the travel was less than 1

inch, you need to add steps in your steps per inch settings in

MOTOR TUNING. If the travel was more than 1 inch, then you

need to subtract steps.

6. Suppose your 1” command resulted in a true motion of only 0.999”

that means you were one thousandth short, so you need to add

enough steps to increase the travel by 0.001”. Go to

CONFIG>MOTOR TUNING and you will find the steps per inch

box. For example, Z axis is set to 20314steps. You need one

thousandth more, or 20314 divided by 0.001 = 20.314steps ( 20 in

round numbers)

7. Add the 20 steps to the factory setting and set the steps to 20334, hit

the SAVE SETTINGS button and go back to your MDI screen.

8. Move your carriage back PAST the start point, then forward to the

start point to take out any inherent lash again and repeat the

procedure. Once you have the steps per inch set such that the travel

matches your command, move on to the other axes and repeat the

procedure.

BACKLASH COMPENSATION

Once you have the steps per inch adjusted on all 4 axes, you can now

measure your backlash and set the compensation.

1. Go to BACKLASH and enable the backlash compensation

2. Using the same procedure as before, move your carriage to a start

point taking out the inherent backlash. Set your DRO to Zero and

give the carriage a command to go 1”. If your steps per inch settings

are correct, it should go exactly 1”.

3. Now give the carriage a command to go 1” in the opposite direction

and read the result on your DRO. If the return move was only

0.998”, then you have 0.002” backlash.

4. Go to CONFIG>BACKLASH and select the axis and put in the

backlash amount, SAVE SETTINGS and repeat the test until your

carriage moves exactly 1” in both directions when given the

command. Repeat this procedure for both axes.

SETTING SPINDLE PULLEYS

1. Set the Hz settings in your VFD to your preference from 50 to a

maximum of 120. ( the factory setting is 120)

2. Follow the instructions in your Laser Tachometer manual for testing the

spindle RPM.

3. Set your Hz setting to its maximum amount and read the spindle RPM

with your tachometer.

4. Go to CONFIG>SPINDLE PULLEYS

5. In the Minimum speed set it to ZERO

6. In Maximum speed put in the reading from your tachometer. Set the

Pulley Ratio to 1.

7. Now test your spindle with various M3S commands( M3S500, M3S750

etc.) and check the spindle RPM with your tachometer and compare to the

spindle speed and STrue readings on your Mach 3 screen.

With some tweaking of the MAX speed settings you should be able to get

the Mach 3 screen settings within a few RPMs of your tachometer reading.

NOTE: If you change the Hz amount in your VFD, you will need to test your

RPM again with the tachometer and adjust the Max speed in your settings.

This manual suits for next models

1

Table of contents