SETUPELECTRICAL MAINTENANCE SERVICE PARTS

OPERATIONS

SAFETYINTRODUCTION

USE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

Contents

INTRODUCTION ..................................................................................................2

Woodstock Technical Support ............................................................................ 2

About Your New 6" x 10" Mini-Lathe..................................................................... 2

Specifications ............................................................................................... 2

SAFETY ............................................................................................................4

Standard Safety Instructions ............................................................................. 4

Additional Safety Instructions for 6" x 10" Mini-Lathes .............................................. 6

Avoiding Potential Injuries................................................................................ 7

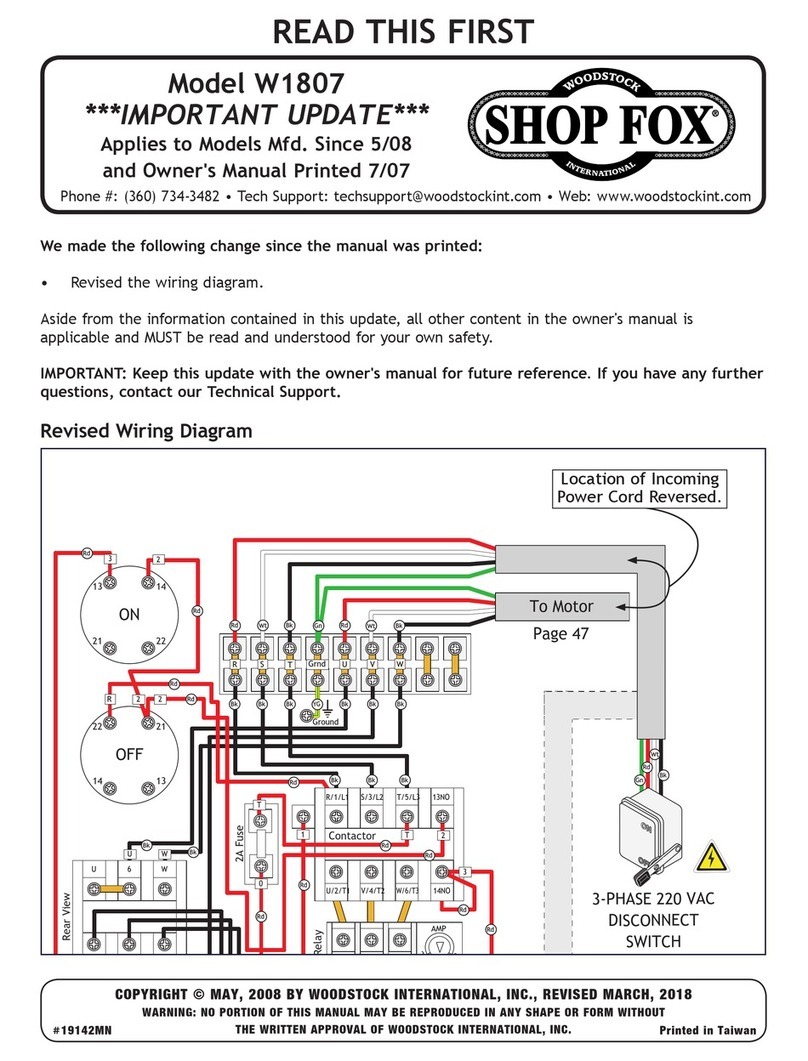

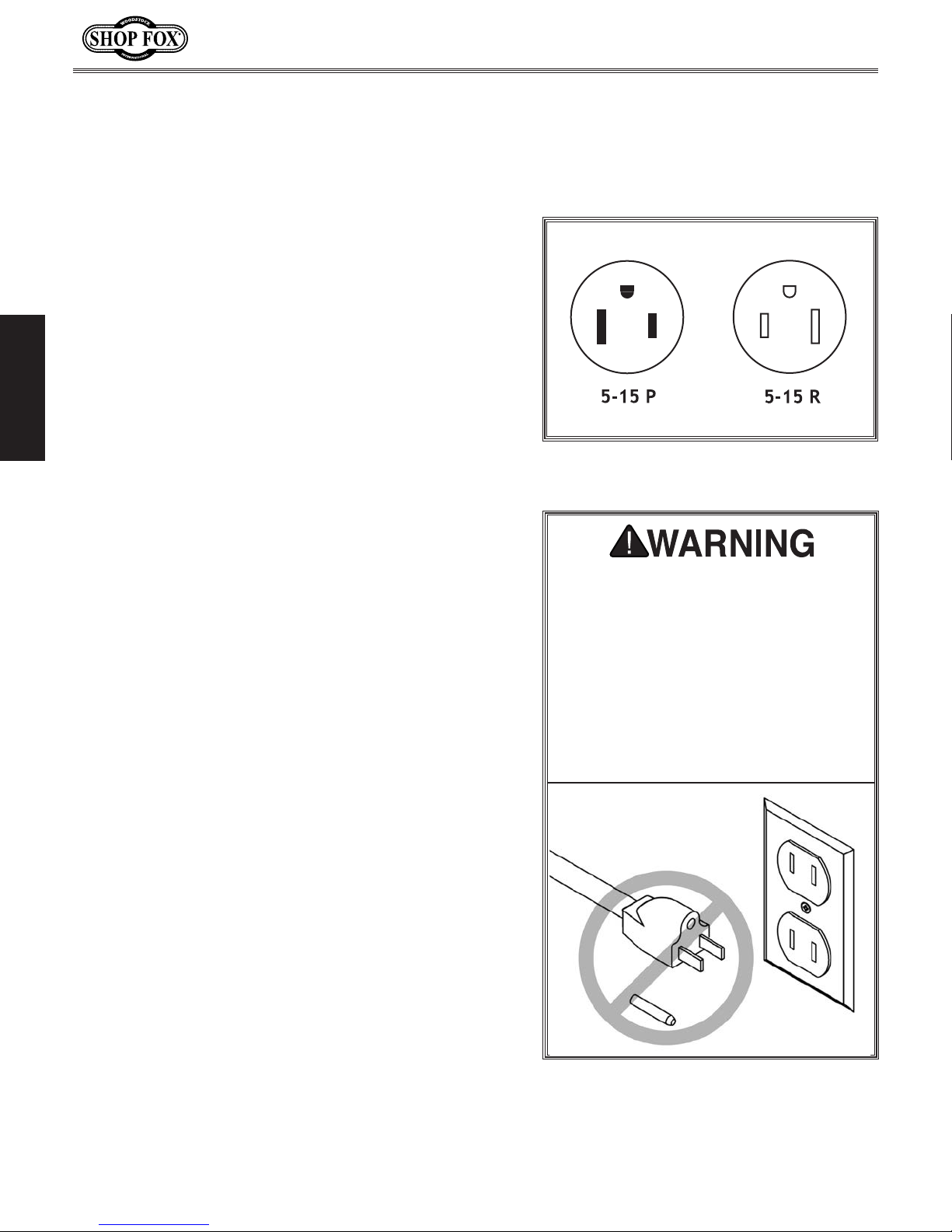

ELECTRICAL ......................................................................................................8

110V Operation ............................................................................................. 8

Grounding ................................................................................................... 8

SET UP ............................................................................................................9

Unpacking ................................................................................................... 9

Inventory .................................................................................................... 9

Cleaning the Lathe....................................................................................... 10

Machine Placement ...................................................................................... 10

Mounting the Lathe ...................................................................................... 11

Chuck Installation ........................................................................................ 12

Replacing Jaws ........................................................................................... 14

Tailstock Alignment ...................................................................................... 15

Centers..................................................................................................... 16

OPERATIONS ................................................................................................... 17

General .................................................................................................... 17

Test Run, Start-up, and Lathe Break-in............................................................... 18

Loading a Workpiece .................................................................................... 19

Using the Cross Slide and Tool Holder ................................................................ 19

Auto and Manual Feed................................................................................... 20

Setting RPM ............................................................................................... 21

TPI and Gear Selection.................................................................................. 22

Feed Rate and Gear Selection ......................................................................... 23

MAINTENANCE ................................................................................................. 24

General .................................................................................................... 24

Cleaning and Lubrication ............................................................................... 24

SERVICE ......................................................................................................... 25

General .................................................................................................... 25

Cross Feed and Saddle Backlash ....................................................................... 25

Replacing Belt ............................................................................................ 26

Replacing Motor Brushes ................................................................................ 27

Replacing Electrical Controls........................................................................... 27

Troubleshooting........................................................................................... 28

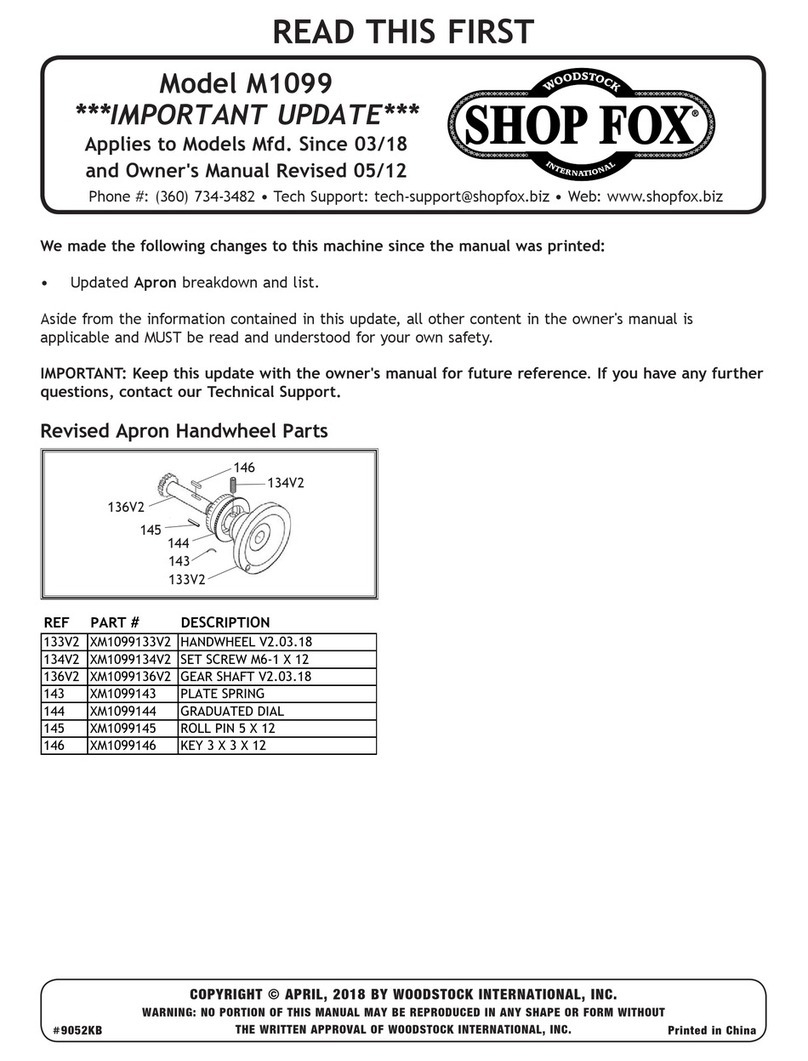

PARTS ........................................................................................................... 30

Parts List................................................................................................... 30

Parts Diagram ............................................................................................. 30

Parts List................................................................................................... 31

Notes ....................................................................................................... 32

Warranty................................................................................................... 34