HARWI 130 User manual

1

MANUAL

130

Harwi Holland BV

Lage Dijk 28

5705 BZ Helmond

the Netherlands

Tel. 31 (0) 543355

Fax 31 (0) 522305

Email inf[email protected]l

2

CONTENTS

APPLIANCE ........................................................................................................................................................................... 3

GENERAL INDICATIONS/SAFETY REGULATIONS ............................................................................................................... 4

GENERAL INFORMATION ..................................................................................................................................................... 5

MANUFACTURER.............................................................................................................................................................. 6

MACHINE........................................................................................................................................................................... 6

EU DECLARATION OF CONFORMITY FOR MACHINERY................................................................................................. 6

SPECIFICATIONS.................................................................................................................................................................. 7

NOISE INFORMATION ...................................................................................................................................................... 7

SETTING UP THE MACHINE ................................................................................................................................................. 8

MOVING ............................................................................................................................................................................ 8

INSTALLING THE MACHINE.............................................................................................................................................. 8

DUST EXTRACTION.......................................................................................................................................................... 8

CONNECTING THE ELECTRIC SUPPLY ............................................................................................................................... 9

MACHINE CONNECTION .................................................................................................................................................. 9

DIRECTION OF SPINDLE ROTATION ................................................................................................................................. 10

PROPER DIRECTION IS CLOCKWISE............................................................................................................................ 10

WRONG DIRECTION IS ANTI CLOCKWISE.................................................................................................................... 10

CHANGING THE SAW-BLADE............................................................................................................................................. 11

ADJUSTING THE RIVING KNIFE ......................................................................................................................................... 12

OPERATING THE MACHINE................................................................................................................................................ 13

RIPPING .......................................................................................................................................................................... 13

MITRING WITH THE MITRE FENCE................................................................................................................................ 14

HEIGHT ADJUSTMENT SAW-BLADE.............................................................................................................................. 15

ANGLE ADJUSTMENT SAW-BLADE ............................................................................................................................... 15

FINE ADJUSTMENT......................................................................................................................................................... 15

MALFUNCTIONS ................................................................................................................................................................. 16

SAW CUT IS NOT SQUARE (ADJUSTING 0°STOP)................................................................................................... 16

SAW CUT IS NOT 45°(ADJUSTING STOP 45°) .......................................................................................................... 16

RIP FENCE NOT PARALLEL TO SAW-BLADE. ............................................................................................................... 17

WOOD CLAMPS BETWEEN FENCE EN SAW-BLADE. ................................................................................................... 17

WOOD CLAMPS ON RIVING KNIFE................................................................................................................................ 18

BRAKE DOES NOT WORK.............................................................................................................................................. 18

SAW-BLADE DOES NOT ROTATE .................................................................................................................................. 18

MAINTENANCE.................................................................................................................................................................... 19

CLEANING, LUBRICATING AND GREASING .................................................................................................................. 19

40 PRODUCTIVE HOURS ........................................................................................................................................... 19

160 PRODUCTIVE HOURS.......................................................................................................................................... 19

1000 PRODUCTIVE HOURS........................................................................................................................................ 19

WIRING DIAGRAM .............................................................................................................................................................. 20

3

APPLIANCE

The sawbench type 130 is only to be used for

cutting wood and wood-like panels (e.g.

chipboard, block board, MDF etc.)

Maximum panel sizes:

Height: 110 mm

Between saw-blade and

rip fence: 1250 mm

Length (not supported): 1000 mm

Cutting of other materials with the standard

saw-blade is prohibited. Cutting other materials

with a special saw-blade only with permission of

manufacturer.

All other appliances except for the above are

improper use of the machine and therefore

prohibited. The producer cannot be held

responsible for damage as a result of improper

use. Damage will be recovered from the user

The machine may not be operated, used or

maintained by persons not acquainted with the

risks of the machine.

Permission for operating, using and maintaining

the machine have to be clearly described by a

person or persons responsible within the

organisation.

Maintenance has to be performed by the

manufacturer or customer service.

One has to be acquainted and comply with the

country's applicable safety regulations.

Only original Harwi parts are to be used.

We cannot give warranty or be held responsible

for damage caused by using non-original Harwi

parts.

The manufacturer cannot be held responsible

for damage caused by changes made to the

machine by the user.

REMAINING RISKS

If the machine is completely used according

to all safety regulations there still will

remain some risks:

Touching of the saw-blade with the

sawing area.

Touching of the saw-blade when the lid is

opened

Breaking of the saw-blade or parts of the

saw-blade hurtling out of the guard.

Touching of parts under voltage while

junction box or switch is opened.

Damage to the hearing by constant use

of the machine without ear protection.

Throw out of harmful dusts or vapours by

using a dust extractor with bad

performance or no dust extractor at all.

4

GENERAL INDICATIONS/SAFETY REGULATIONS

Harwi Holland B.V. has bestowed great care

on compiling this manual. Before operating the

machine read the complete manual carefully.

Persons under the age of 18 are not allowed to

work on or with circular sawing machines.

Except for a training program on a legal basis.

The machine may only be operated by

educated personnel or under supervision of

educated personnel.

To avoid touching with rotating saw-blades

make sure that:

Clothing fits tightly to the body

Work with closed fingers

No rings or other jewellery are worn.

A hairnet is used by long hair.

Be careful when changing the saw-blades.

They are sharp and cause injuries.

Do not remove woodchips when the saw-blade

is running. Stop the machine first.

Broken saw-blades or blades or deformed

blades are not to be used. Neither are HSS

blades

The applied saw-blade is to be used and

sharpened according to the directions of the

manufacturer.

Sharpening only by competent craftsmen.

Stick to max. admissible r.p.m. mentioned on

the blade. Preferably use noise-reduced saw-

blades.

Flexible hoses of the dust extractor have to be

from a highly inflammable quality (according to

DIN 4102).

The safety guard and other safety equipment

may not be removed or put out of order.

Assembling or repairs are only to be performed

if the machine cannot be switched on. The

switch or the main switch are to be switched off

and locked with for instance a padlock.

Repairs to the electricity supply are only to be

executed by skilled craftsmen.

When leaving the working area make sure that

incompetent persons cannot switch on the

machine. It is obligatory to wear dust-mask, ear

protection and safety glasses.

Take care of a clean working area.

The machine has to be lighted. When using

strip lighting take into account the stroboscopic

effect. A rotating saw-blade seems to be

standing still.

5

GENERAL INFORMATION

6

MANUFACTURER

HARWI Holland B.V.

Lage Dijk 28

5705 BZ Helmond, the Netherlands

Tel: 00 31 492-54 33 55

Fax: 00 31 492-52 23 05

MACHINE

Sawbench

Type:.....................................................

Machine number:..................................

Manufactured:......................................

EU DECLARATION OF CONFORMITY FOR MACHINERY

(according to Annex II A of the Machinery Directive)

We HARWI Holland B.V. Lage Dijk 28, 5705 BZ Helmond, the Netherlands herewith declare, on our

own responsibility, that the product:

HARWI SAWBENCH TYPE 130, MACHINE NUMBER..........................,

which this declaration refers to, is in conformity with the following standards;

2006/42/EG meets requirements EMV 2004/108/EG.

Meets requirements, resulting from supplement 4 of the Machinery directive, against

Holz – BG 0392

For Construction and Building EN-1870-1

Netherlands, Helmond, d.d.

……………………………………name

…………………………………….signature

7

SPECIFICATIONS

MEASURES AND WEIGHTS

Height of cut (standard) mm

0-110

Height of cut (max.)

mm

135

Width of cut mm

625 of 1250

Diam. saw-blade (standard) mm

∅

400

Diam. saw-blade (max.) mm

∅450

Saw-blade bore mm

∅

30

Angle adjustment

0-45°

Distance saw-blade centre to

front table

mm

580

Table size

mm

965*1125

Table height

mm

850

Motor power kW

5.5

hp

7.5

Voltage V

380

Spindle speed

rpm

2800

Weight

kg

320

Used saw-blades have to be conform to prEN 847-1.

Maximum thickness of saw-blade 3.6 mm.

NOISE INFORMATION

Used saw-blade: :Leuco proline 101420/10005 ∅400

Z=48 d=30.

A-weighed Equivalent Continuous Noise Pressure

Idle dB(A) :81.0 dB(A)

Loaded dB(A) :84.4 dB(A)

Measuring performed according to DIN 45635 part 1659. Measured when cutting chipboard thickness

18 mm, length 2 meters.

Safe deviation can be approx. 3 db(A).

The above-mentioned values are radiated noise pressures and not necessarily noise pressures to

work safely with this machine. Supplementary measures for ear protection can be necessary. The

following can be of influence:

duration of operations

working area

other noises

Maximum value may vary per country. Above information can be used for better valuation of dangers

and risks subsequent to using this machine.

8

SETTING UP THE MACHINE

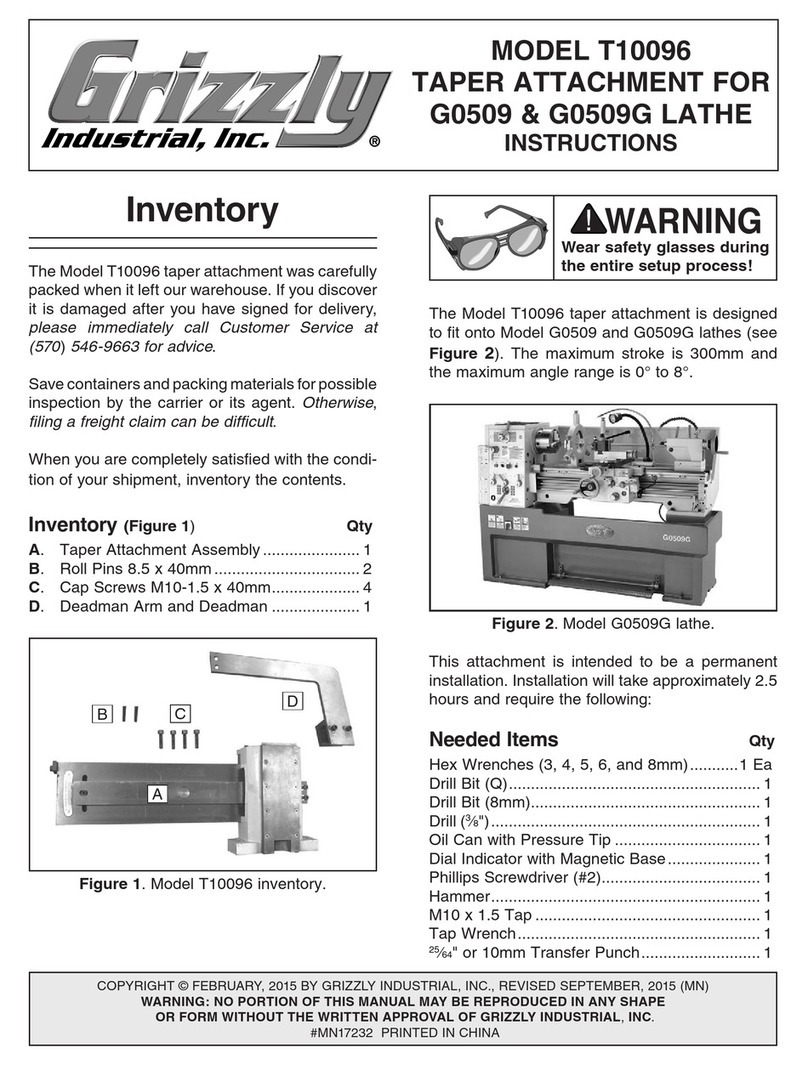

MOVING

Move the machine with a forklift truck or a

pallet truck with forks of max. 550 mm and a

minimum length of 600 mm (Fig. 1). Minimum

capacity of 500 kilograms. Put the forks at the

left side far enough under the machine to avoid

tilting.

INSTALLING THE MACHINE

The machine has to be put on a solid floor,

which has to be flat, dry and not slippery.

DUST EXTRACTION

The machine has to be connected to a dust

extraction.

Connection for dust extracting hose of ∅120

mm. Connection of the safety guard is ∅80

mm.

The extracting capacity has to be calculated in

such a way that a minimum air speed of 20 m/s

is reached at the connection. Air speed is 1500

m3 at a depression bigger than 450 Pa.

Figure 1

45

40

35

30

25

20

15

10

5

0

9

CONNECTING THE ELECTRIC SUPPLY

A skilled craftsman may only do connecting the

machine.

MACHINE CONNECTION

380 V- 3 PHASE

(see wiring diagram)

1 Disconnect mains supply.

2 Open switch at the backside of the

machine (fig. 2).

3 Connect the 5-core cable at the same

points.

Black (1] = Phase

Black [2] = Phase

Brown [3] = Phase

Bleu [4] = Zero

Yellow/green [5] = Earth

the 3 phases L1. L2, L3

- MP for the zero

- PE for the earth

4 Close the switch.

Notice: Use cartridge fuses of min. 25 Ampere.

Notice: Check the rotation of the saw (see

chapter DIRECTION OF SPINDLE

ROTATION).

Figure 2

10

DIRECTION OF SPINDLE ROTATION

Disconnect the mains supply with the main

switch at the backside of the machine.

Remove the table insert, the saw nut, the

flanges and the saw-blade (see chapter

CHANGING THE SAW-BLADE).

0 Put the motor in the highest position.

PROPER DIRECTION IS CLOCKWISE

(Looking from the front side of the spindle to the

motor, fig. 3).

1 Connect the mains supply.

2 Switch motor on and off.

3 Check if direction is clockwise.

4 Disconnect the mains supply with the

main switch.

5 Put saw-blade, flanges and saw nut back

(see chapter CHANGING THE SAW-

BLADE).

6 Put table insert back.

WRONG DIRECTION IS ANTI

CLOCKWISE

(Looking from the front side of the spindle to the

motor fig. 3).

1 The spindle turns anti clockwise.

2 Disconnect the mains supply.

3 Open the switch at the backside of the

machine and interchange two phases.

4 Check the rotation again.

5 Disconnect the mains supply with the

main switch.

6 Put the saw-blade, the flanges and the

saw nut back on.

7 Put table insert back.

Figure 3

11

CHANGING THE SAW-BLADE

Notice: Before changing the saw-blade

disconnect the main switch at the backside

of the machine and secure it against

switching on with a lock.

Noise reduced saw-blades are preferred. Use

a suitable saw-blade. Enquiries at you supplier

or the manufacturer.

1 Remove the table insert with the 4 mm

Allen key..

2 Block the saw-blade with the spanner at

the front side of the saw spindle (fig.4 ).

3 Remove the flange.

4 Remove the saw-blade.

5 Clean the flanges, the thread of the

spindle and the nut.

6 Put the saw-blade and flange back again.

Notice: spindle rotation is clockwise.

7 Check the position and the thickness of

the riving knife.

8 Put the table insert back.

Saw-blades have to be sharpened by experts.

Figure 4

12

ADJUSTING THE RIVING KNIFE

Check the thickness and the measures of

the riving knife. The riving knife has to be

thicker than the blade body but thinner than

the tooth thickness.

1 Disconnect the mains supply at the main

switch and secure it against switching on.

2 Remove the table insert.

3 Put the saw-blade in its highest position.

4 Loosen the bolt of the riving knife

fastening.

5 Adjust the riving knife in such a way that

the distance between the knife and the

teeth sticking out above the tabletop is

maximum 3 mm. The highest point of the

riving knife has to be 3-5 mm under the

highest point of the teeth (fig. 5).

6 Fasten the bolt of the riving knife

fastening tightly.

7 Put the table insert back.

8 Connect the mains supply.

Figure 5

13

OPERATING THE MACHINE

RIPPING

SAFETY

When ripping solid wood, put the saw-blade

as high as possible. The sub-fence max. 10

mm past the point where the blade cuts the

wood at full height.

Adjusting the sub-fence properly prevents

the return shock of the wood or a part of it.

Use a push stick when cutting small wood.

Adjusting the riving knife (fig. 6).

1 Adjust the rip fence with the sub-fence at

the desired measure.

2 Check if the saw-blade can rotate freely.

3 Switch on the motor.

4 After cutting switch off the motor

immediately.

5 Remove the material after the saw-blade

has stopped.

Notice: If the saw-blade stops because of

clamping of the wood, switch off the motor.

Hold the piece of wood tightly!

Notice: Never stand in the line of the saw-

blade. In case of a return shock you might

get hit.

Figure 6

14

OPERATING THE MACHINE

MITRING WITH THE MITRE FENCE

SAFETY

When mitring NEVER use the ripping fence

as a stop.

1 Put the saw-blade in its highest position.

2 Put the material on the machine (fig. 7).

3 Push the wood against the fence.

Notice: Support the wood properly.

4 See to it that the wood and the fence do

not touch the saw-blade.

5 Switch on the motor.

6 Move the fence and the wood forward at

a constant speed and cut the material.

7 Switch off the motor.

8 Remove the material after the saw-blade

has stopped.

Notice: If the saw-blade stops because of

clamping of the wood, switch off the motor.

Hold the piece of wood tightly!

Notice: Never stand in the line of the saw-

blade. In case of a return shock you might

get hit.

Figure 7

15

OPERATING THE MACHINE

HEIGHT ADJUSTMENT SAW-BLADE

0 The hand wheel of the height adjustment

is at the front side of the machine (fig. 8)

1 The saw-blade rises by turning the wheel

to the left (anti-clockwise).

2 The height can be adjusted accurately by

using a folding rule.

Notice: the saw-blade must have stopped.

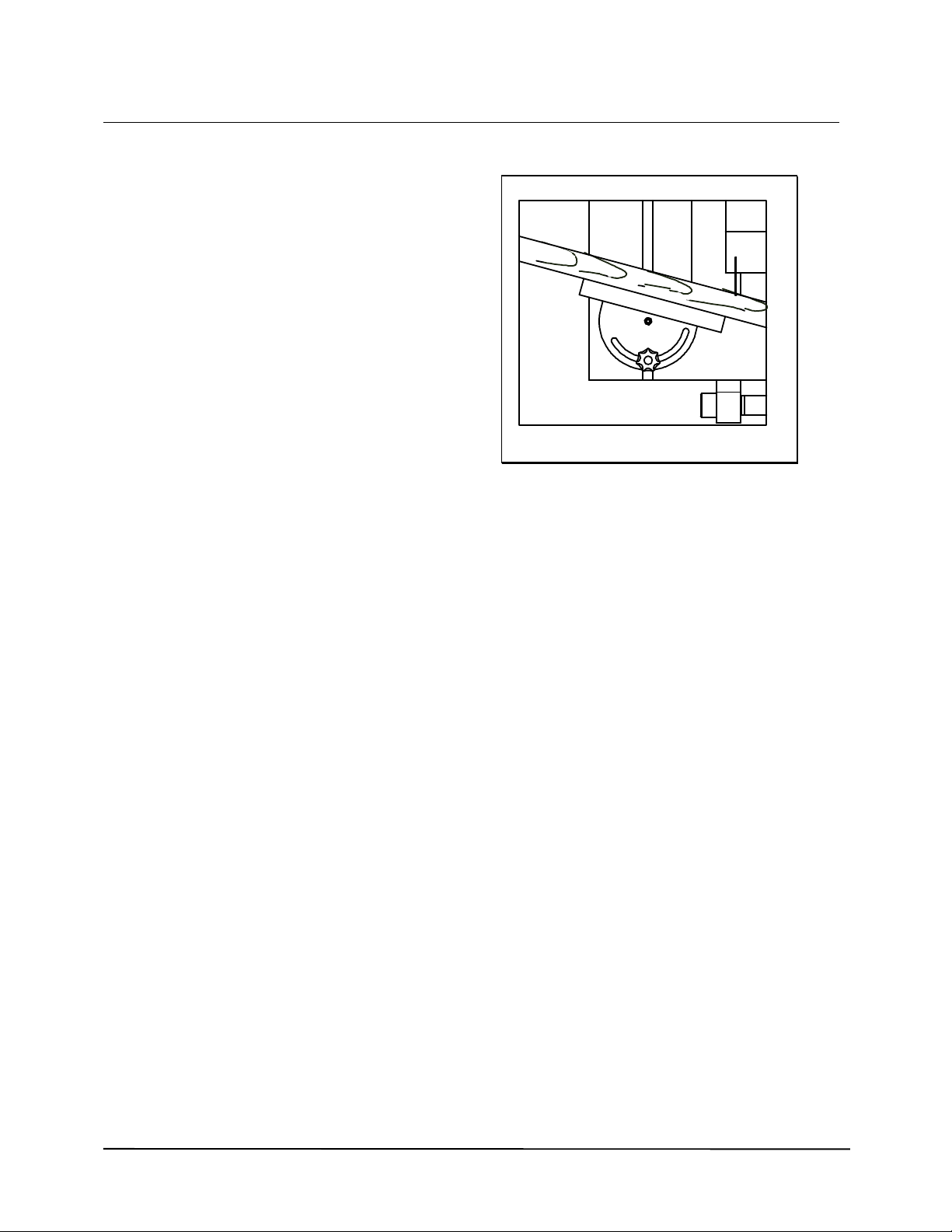

ANGLE ADJUSTMENT SAW-BLADE

0 The hand wheel of the angle adjustment

is at the left side of the machine (fig. 9).

1 By turning the wheel to the left (anti-

clockwise the saw-blade moves from 0°to

45°.

2 Measure scale is at the front side of the

machine.

Notice: the saw-blade may not touch the

fence or the sub-fence.

FINE ADJUSTMENT

1 Adjust the rip fence at the approximately

needed measure.

2 Block the fence with the knob at the front

side.

3 Adjust the exact measure between sub-

fence and saw-blade at the left side of

the fence rail (fig. 10).

Figure 8

Figure 9

Figure 10

45

40

35

30

25

20

15

10

5

0

45

40

35

30 25 20 15

16

MALFUNCTIONS

Safety

Disconnect the machine of the mains supply

before adjusting the machine or removing

malfunctions.

See to it that all damaged parts are replaced

before operating the machine.

MALFUNCTION:

SAW CUT IS NOT SQUARE (ADJUSTING

0°STOP)

1 Put the saw-blade in its highest position

2 Set the saw-blade with a square.

3 Remove the panel at the left side of the

machine.

4 Loosen the nuts that clamp the threaded

spindle to the frame.

5 Put it against the stop fitted to the

trapezium threaded nut.

6 Fasten the two nuts tightly to the frame

(fig. 11).

MALFUNCTION:

SAW CUT IS NOT 45°(ADJUSTING STOP

45°)

1 Put the saw-blade at an angle of 45°.

2 Set the saw-blade exactly with a square.

3 Remove the panel at the left side of the

machine.

4 Adjust the nuts closest to nut with

trapezoidal thread (fig. 12).

Figure 11

Figure 12

17

MALFUNCTIONS

Safety

Disconnect the machine of the mains supply

before adjusting the machine or removing

malfunctions.

See to it that all damaged parts are replaced

before operating the machine.

MALFUNCTION

RIP FENCE NOT PARALLEL TO SAW-

BLADE.

WOOD CLAMPS BETWEEN FENCE EN

SAW-BLADE.

CHECK RIP FENCE, ADJUST AGAIN

0 Put the saw-blade in the highest position,

angle adjustment at 0°.

Example:

Distance between fence and saw-blade is

bigger at the back than at the front side of the

fence.

1 Put a wooden lath to the right side of the

saw-blade.

2 Push the fence without the sub-fence

against the lath and block the fence.

3 Loosen the right hexagon nut of the

fence with a 17 mm key.

4 Turn the right adjusting screw with an

Allen key till the fence and lath are

parallel (fig. 13).

5 Fasten the hexagon bolt tightly.

6 Check if lath and fence are parallel.

Figure 13

Example:

Distance between fence and saw-blade is

bigger at the front than at the backside.

1 Loosen the hexagon nut of the fence with

a 17 mm key.

2 Turn the left adjusting screw with an

Allen key till the fence and lath are

parallel (fig. 13).

3 Fasten the hexagon bolt tightly.

4 Check if lath and fence are parallel.

18

MALFUNCTIONS

Safety

Disconnect the machine of the mains supply

before adjusting the machine or removing

malfunctions.

See to it that all damaged parts are replaced

before operating the machine.

MALFUNCTION:

WOOD CLAMPS ON RIVING KNIFE

0 Check thickness, measure and position

of riving knife (see chapter : ADJUSTING

RIVING KNIFE).

MALFUNCTION:

BRAKE DOES NOT WORK

0 Switch off the machine and contact you

dealer or the producer how to adjust the

brake.

MALFUNCTION:

SAW-BLADE DOES NOT ROTATE

1 Disconnect mains supply.

2 Check if the saw-blade can run freely.

3 Check if the saw-blade is fitted properly

(see chapter: CHANGING SAW-BLADE).

4 Check if the saw-blade is mounted

properly between the front and back

flange.

Have you checked all this, but the problems is

not solved contact you dealer.

19

MAINTENANCE

CLEANING, LUBRICATING AND

GREASING

40 PRODUCTIVE HOURS

Perform following maintenance every 40

productive hours.

1 Clean the tubes of the height adjustment

and also the spindle. Lubricate slightly.

2 Clean the rail fence and the knob of the

fine adjustment.

3 Clean the spindle and the stop of the

angle adjustment. Lubricate slightly.

4 Brush the air inlet and parts of the motor

and check if it is not obstructed.

5 Remove plates at front and back side of

table. Clean segments and blow clean.

Lubricate slightly. Mount plates again.

160 PRODUCTIVE HOURS

Perform following maintenance every 160

productive hours.

5 Wear and tear of cables.

6 Broken or torn parts of the electric circuit.

7 Brake time of saw-blade (has to be less

than 10 seconds).

8 Operation and condition of safety guard.

9 Free outlet of dust collector to dust

extractor.

1000 PRODUCTIVE HOURS

Perform following maintenance every 1000

productive hours.

10 The bolt connections of the height and

angle adjustment.

11 Check saw spindle for backlash.

12 The bolt and nut connections of the

motor.

20

WIRING DIAGRAM

The diagram is in the switchbox

Table of contents