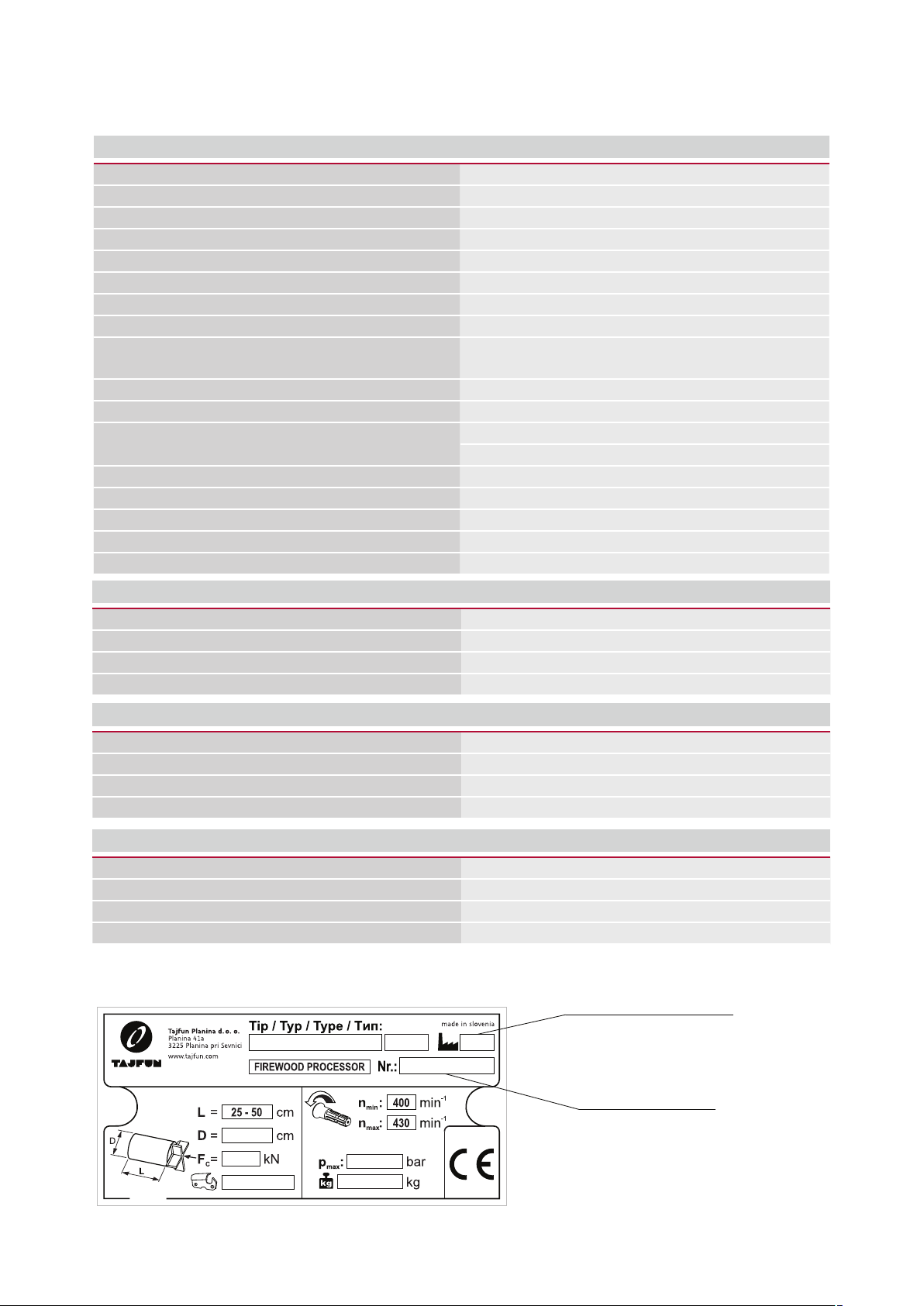

2.2. ADDITIONAL SAFETY INSTRUCTIONS FOR THE

FIREWOOD PROCESSOR

2.1. GENERAL SAFETY INSTRUCTIONS

• Machine operation and maintenance may be carried out only by individuals who have the

knowledge about machine’s operation, work-related dangers and operating instructions.

• Machine operation and maintenance may not be carried out by people under the influence of

alcohol, drugs or medicinal products that affect people’s psychophysical abilities.

• The machine can be operated by one person only. Please, make ensure that nobody is standing

in the near vicinity (in the 3 m radius) of the machine’s operating area!

• Machine operation and maintenance may be carried out only by qualified personnel over 18

years of age!

• Before starting the operation place the machine in a stable position in accordance with the

machine’s installation instructions!

• Use only PTO shafts of appropriate strength (min. 25 kW) with undamaged exterior plastic

protective cover!

• Never use damaged, cracked or deformed cutting chains, chain sprockets and saw bars!

• All protective parts of the machine (safety nets, saw shield, covers, etc.) must be fixed in place

during the machine’s operation. Any modification of these protective parts is prohibited!

• Always wear personal protective equipment (safety glasses, hearing protectors, gloves and

forestry boots)!

• When troubleshooting, replacing the chain, cleaning or any other service procedure always

disengage the PTO shaft and shut down the power unit (tractor) or unplug the power cord from

the mains (EP 12)!

• Do not wear loose clothing!

• Keep the operating area clean and tidy!

• Always use caution when operating the machine! Moving parts can cause serious injuries in case

of improper use of the machine!

• During the running of the machine never leave the machine unsupervised!

• Do not reach into the working area during the operation of the machine!

• Before removing any wedged pieces of wood shut down the machine’s drive or turn off the

machine.

• For transportation of the machine via public roads install lights on the rear end of the machine!

• For personal safety use only original spare parts and accessories approved by the manufacturer!

• The damaged power cord or plug must immediately be replaced.

UVOD

2. SAFETY INSTRUCTIONS

6

• The manufacturer,Tajfun Planina d.o.o., provides the declaration of conformity and risk estimation

only for the machines operated by a single person that has sufficient overview over the entire

surrounding area, and applies to the machine’s entire operating area.

• Personal protective equipment and protective parts, which must always be used when operating

the machine, are included in the scope of delivery.

• Never reach within the chain saw or splitting cylinder working area during the machine’s

operation. Never remove cut pieces and other wood residues from the sawing and splitting area

during the machine’s operation.

• For outdoor use only. When operating the machine indoors it is necessary to install a suction

device on the machine, which is supplied as part of the accessories.

• Ensure regular machine maintenance and cleaning. Regularly remove the sawdust and wood

residues.

• The operating pressure of the hydraulic system must not exceed 230 bars.