Shopsmith MARK V 505 User manual

MARK V MODEL 505/510

ROUTER TABLE

522155

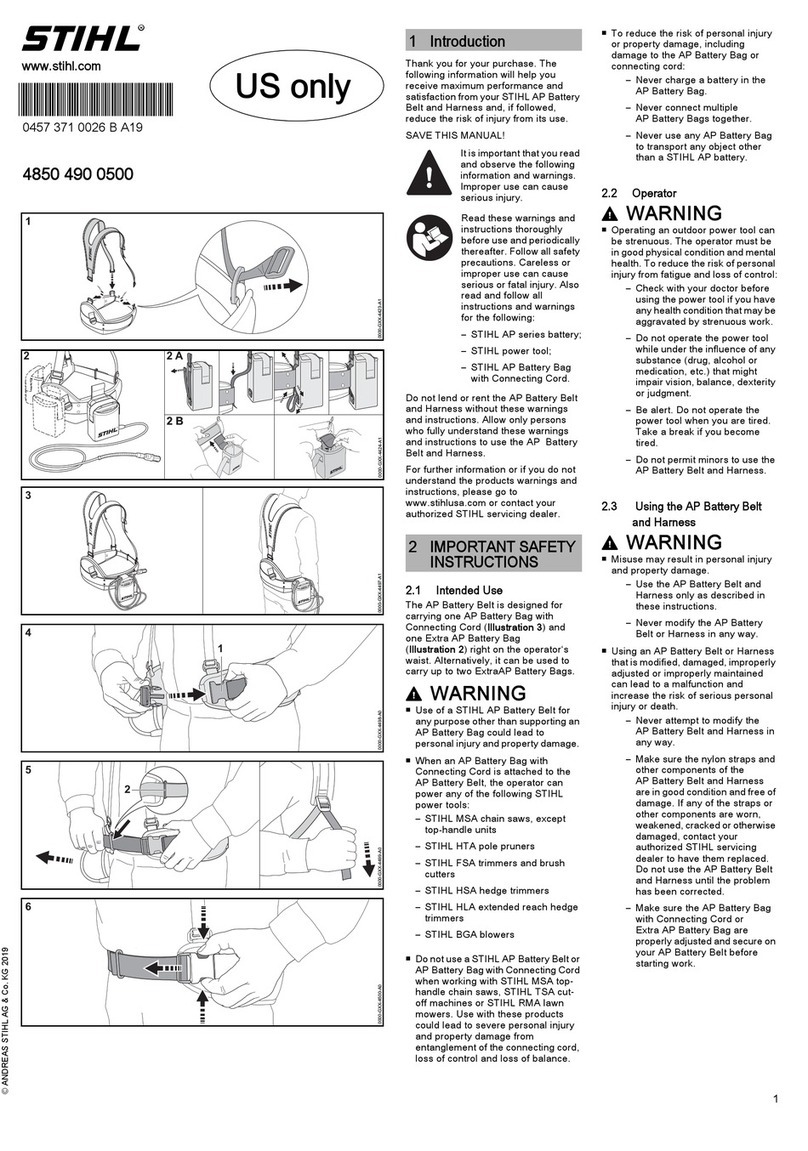

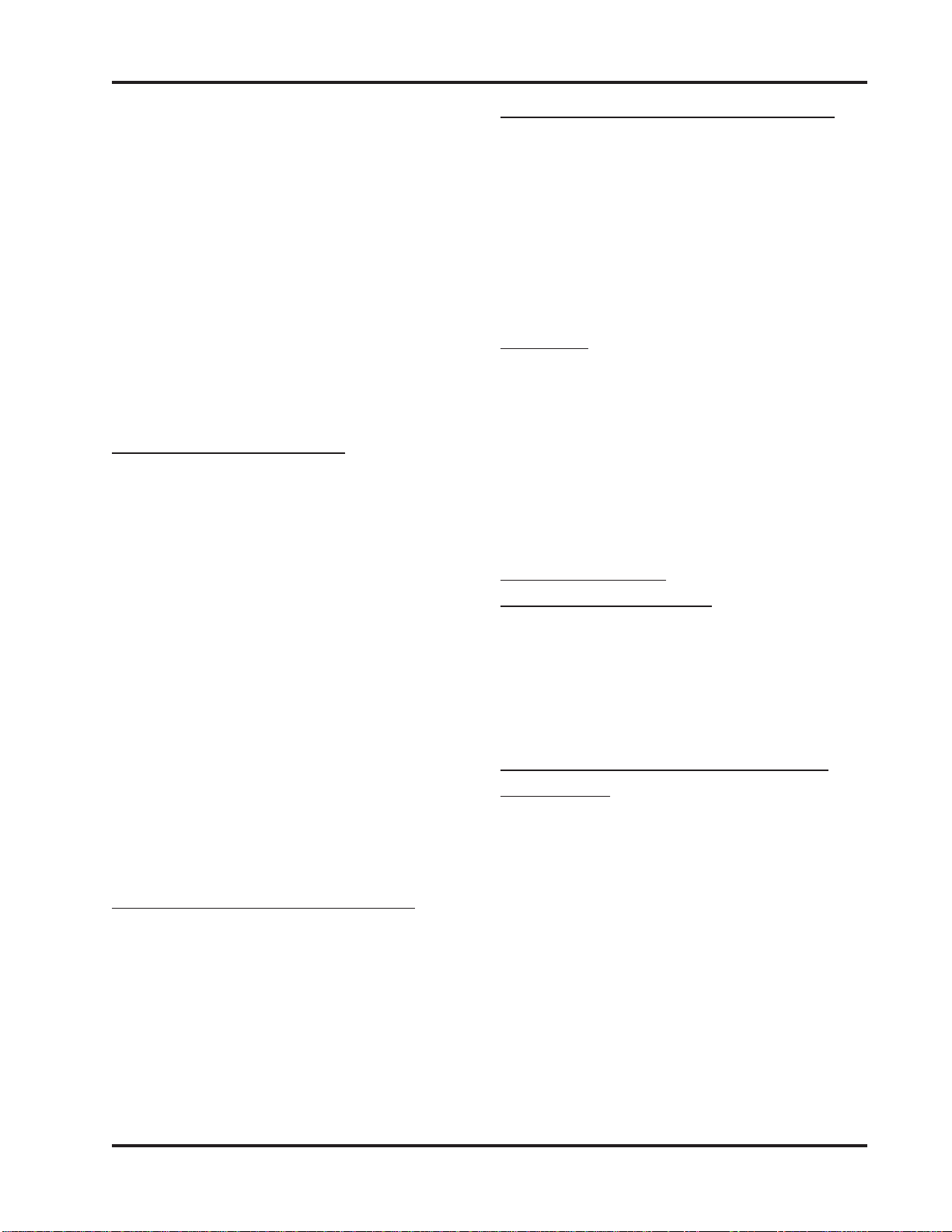

EXPLODED VIEW

Ref. Part Item

No. No. Description Qty.

PARTS LIST

— 522155 Router Table Package

—522150 . Table Assembly (Inc. 1-9) ................ 1

1522180 . . Router Table With Label (Inc. 2) ... 1

2522014 . . . Warning Label .......................... 1

3514667 . . Table Tube ................................. 2

4514440 . . Jackscrew.................................. 4

5522136 . . Table Spacer ............................. 6

6515294 . . Keps Nut ................................... 6

7522134 . . Bracket ...................................... 2

8120380 . . Split Lock Washer ..................... 6

9521692 . . Button Head Screw ................... 6

10 521991 . Router Plate & Hardware (Not Shown) 1

Ref. Part Item

No. No. Description Qty.

2

1

7

8

94

3

6

5

MARK V MODEL 505/510 ROUTER TABLE 522155

Page 2

INTRODUCTION

The Router Table can be used with the

Shopsmith MARK V Model 505 & 510.

This instruction manual covers safety, assem-

bly, alignment, operations and care of the

Router Table. Read through the entire manual

before assembling and operating the Router

Table.

SAFETY

TheMARKVModel505/510RouterTablehas

many built-in safety-features, but the effec-

tiveness of them depends on you. Power Tool

safety requires good common sense. Misuse

of this tool can cause serious injury.

Throughoutthismanual,welistWARNINGS,

CAUTIONS,andNOTES.Weadvisethatwhen

you come to one of these headings that you

read them until fully understood.

Their meanings are:

WARNING

AWARNINGisgivenwhenfailuretofollow

thedirections is likely to result in injury, loss

of limb, or life.

CAUTION

A CAUTION is given when failure to follow the

directionsislikelyto resultindamagetothe equip-

ment.

NOTE

A NOTE is used to highlight an important

procedure, practice, or condition.

WARNING

To protect yourself from injury:

• READ,UNDERSTAND, AND FOLLOW

ALL THE INFORMATION IN THE IN-

STRUCTION MANUAL.

• ALSO, READ, UNDERSTAND AND

FOLLOW ALL the information that came

with your Router Motor and the Router

Table Plate Package.

• Read the Safety section, complete the

Assembly procedures and check the

Alignment, before operating any acces-

soriesthatworkwiththeMARKVModel

505/510 Router Table.

GENERAL SAFETY RULESGENERAL SAFETY RULES

GENERAL SAFETY RULESGENERAL SAFETY RULES

GENERAL SAFETY RULES

• Know your power tool. Read the instruc-

tion manual. Learn its application and

limitations as well as specific potential

hazards peculiar to this tool.

• Ground all tools (unless double insu-

lated). If the tool is equipped with an

approved 3-conductor cord and a 3-prong

grounding type plug to fit the proper

groundingtype receptacle, the green con-

ductor in the cord is the journeying wire.

Never connect the green wire to a live

terminal.

• Wear proper eye and ear protection. Also,

wear a dust mask.

• Keep all safety guards in place. Always

keep the guards in working order, in

proper alignment, and in proper adjust-

ment. Most injuries occur on unguarded

power tools.

• Removealladjusting keys and wrenches.

• Wear proper apparel. Do not wear loose

clothing, ties, gloves, rings, or other jew-

elry. Roll long sleeves up above your

elbows, wear nonslip footwear, and tuck

Page 3

522155 MARK V MODEL 505/510 ROUTER TABLE

long hair under a hat.

• Avoiddangerous environments.Don'tuse

power tools in damp, wet, or explosive

atmospheres.

• Keep works area well lit, clean, and free

from clutter.

• Do not force the tool. It will do the job

betterandsaferattherateforwhichitwas

designed.

• Use the right tool. Do not force a tool or

accessory to do a job for which it was not

designed.

• For directional feed, ALWAYS feed the

workpieceinto the cutter against the rota-

tion of the cutter. NEVER feed the

workpiece into the cutter with the rota-

tion of the cutter.

• Check for damaged parts. A damaged

guard or part must be properly repaired

or replaced before further use of the tool.

If a strange noise or vibration develops,

immediately turn off the power, unplug

the machine and correct the problem.

Never operate a power tool that is not

functioning properly.

• Secure workpieces. Use clamps, fixtures

and other devices to hold workpieces

when practical. It's safer than using your

hands and frees your hands to operate

the tool.

• Do not overreach. Keep proper footing

and balance at all times.

• Turnoffthe tool and wait until it comes to

a complete stop before removing

workpieces and scraps.

• Do not try to stop the tool by grabbing the

workpiece or any part of the tools. Turn

off the tool and let it come to a complete

stop by itself.

• Donotleavethetool running unattended.

Turn off the power. Don't leave the tool

until it comes to a complete stop.

• Avoid unintentional starting. Make sure

the switch is in the "off" position before

plugging in or unplugging the tool.

• Disconnect tools. Turn off and unplug

toolsbeforechangingaccessories,setups,

making adjustments, performing main-

tenance, or repairs.

• Do not stand or lean on the tool. You

could fall into the tool or it could tip over

injuring you and/or the tool.

• Maintaintools. Keeppartsandtoolssharp,

clean, and maintained according to the

instruction manual.

• Make your workshop child proof. Use

padlocks, master switches and remove

starter keys.

• Keep children away. All visitors must

stay a safe distance from power tools, and

wear ear and eye protection.

• Do not permit anyone who is inexperi-

enced to use your power tools without

proper supervision.

MARK V MODEL 505/510MARK V MODEL 505/510

MARK V MODEL 505/510MARK V MODEL 505/510

MARK V MODEL 505/510

RR

RR

ROUTEROUTER

OUTEROUTER

OUTER TT

TT

TABLE SAFETYABLE SAFETY

ABLE SAFETYABLE SAFETY

ABLE SAFETY

RULESRULES

RULESRULES

RULES

• Be sure to read and understand this en-

tire instruction manual before using the

MARK V Model 505/510 Router Table.

Also, do not use the MARK V Model 505/

MARK V MODEL 505/510 ROUTER TABLE 522155

Page 4

510 Router Table unless you are sure it is

assembled properly, all safety devices

are installed, and you understand the

operations you are attempting.

• Keep the Guard in place and in working

order.Always set the Guard no more than

1/4" above the workpiece.

• Keep your hands, fingers, and other parts

of your body at least 3" away from the

rotating bit.

• Use a Push Stick, Push Block, Feather

Board(s), fixtures, or other safety devices

to maneuver a workpiece into a rotating

bit. If a kickback occurs, these devices

help to protect your hands and fingers.

• Use only Shopsmith Parts and Accesso-

ries on your MARK V Model 505/510

RouterTable.NEVERusenon-Shopsmith

Replacement Parts or Accessories. They

are not designed like Shopsmith Parts.

Using non-Shopsmith Parts may create a

hazardous condition and will void your

warranty. Follow your Router Motor

manufacturer's recommendations as to

Replacement Router Motor Parts.

• Donotroutsecondhand lumber. If youhit

a nail, screw, or other foreign object, you

could be hit by pieces of metal or there

could be kickback.

• Do not "freehand" rout stock less than 12"

x 12" or equivalent.

• Support long boards and sheet materials

with a Roller Stand(s) placed 1' to 4' from

the Worktable.

• Always use a Fixture, Fence, Miter Gauge

with Safety Grip, and/or Starter and

GuidePinsto help control the workpiece.

• Always feed the workpiece against the

rotation of the bit, not with it. Otherwise,

thebitwillgrabandthrowtheworkpiece.

• Keep a firm grip on the workpiece at all

times and never hold the workpiece with

your hands in line with the Router Bit.

• Always use a Feather Board Assembly or

other devices to hold or guide narrow

workpieces. Also, use a long piece of

scrap stock to feed narrow workpiece

underneath the Guard to complete a cut.

• Cut with the grain of the wood instead of

against it. You will get a smoother cut and

the operation will be safer.

• Avoid standing in-line with the

workpiece being fed. In the event of a

kickback you could be hit.

• Feed the workpiece slowly. Use extra

care in routing workpieces that contain

figured grain of knots, as these may cause

kickbacks.

• Whenyouareroutingstockupto10" wide

across the grain, use your Miter Gauge

withSafetyGripto control the workpiece.

The workpiece must extend 5-1/2" away

from the router bit.

• When stop routing, always you a Stop

Block(s) to control the length of cut. Fail-

ure to use Stop Blocks could cause the bit

to grab and throw the workpiece.

• When routing oversized stock, always

use a least one Push Block to help control

the workpiece firmly against the fence.

• Donotworkwithstockthatistoosmallor

too large to handle safely; that is warped,

bowed, or cupped; or that has loose knots

or other defects.

Page 5

522155 MARK V MODEL 505/510 ROUTER TABLE

• Plan the operation before you begin. If

you are in doubt about how to complete

an operation safely, do not attempt it,

contact a Shopsmith Service Representa-

tive for advice.

• Freefreehand routing use a Guide Pin, do

not rout a workpiece which has less than

a 4" radius.

• The minimum length of stock should be

no less than 8". You should also use a

PushStickand/or Push Blockonanystock

between 8" to 18" long.

EYE PROTECTIONEYE PROTECTION

EYE PROTECTIONEYE PROTECTION

EYE PROTECTION

Always wear eye protection when you use

power tools. Use Goggles, Safety Glasses or

a Face Shield, to protect your eyes.

• Gogglescompletelysurroundandprotect

your eyes. Many Goggles will also fit

over Regular Glasses. Be sure your

Goggles fit closely, but comfortable.

• Safety Glasses don't fog as easily as

Goggles and can be worn at all times.

Regular Glasses normally have only im-

pact resistant lenses. They are not Safety

Glasses.

• A Face Shield protects your entire face,

not just your eyes.

HEARING PROTECTIONHEARING PROTECTION

HEARING PROTECTIONHEARING PROTECTION

HEARING PROTECTION

Prolonged exposure to high intensity noise

from high-speed power tools can damage

your hearing.

• Hearing Protectors screen out noise lev-

els that can damage your ears, and are

recommended for ALL uses with Routers

mounted in Router Tables.

GUGU

GUGU

GUARDING FOR RARDING FOR R

ARDING FOR RARDING FOR R

ARDING FOR ROUTINGOUTING

OUTINGOUTING

OUTING

Most shop accidents happen to woodwork-

ers who fail to follow instructions, or fail to

use Guards and Safety Devices. Although

proper use of Guards and Safety Devices

often requires additional setup, the protec-

tionforyou and your family is well worth the

effort.

DRESSDRESS

DRESSDRESS

DRESS

Loose hair and clothing, which could be en-

tangled in rotating bits, are very hazardous.

• Tuck long hair under a hat or tie it up

above the shoulders. Do not wear ties,

gloves, loose clothing, rings or other jew-

elry. Roll sleeves up above your elbows.

ELECTRICALELECTRICAL

ELECTRICALELECTRICAL

ELECTRICAL

REQUIREMENTSREQUIREMENTS

REQUIREMENTSREQUIREMENTS

REQUIREMENTS

Follow the electrical requirements that ap-

pear in the instruction manual that cam with

your Router Motor. Do not overload your

electrical circuits

UNDER-TUNDER-T

UNDER-TUNDER-T

UNDER-TABLE MOUNTEDABLE MOUNTED

ABLE MOUNTEDABLE MOUNTED

ABLE MOUNTED

ROUTERROUTER

ROUTERROUTER

ROUTER

TheRouterisnotincludedwiththeMARKV

Model 505/510 Router Table. You will have

to purchase a Router or use one that you

already own. Any UL approved router can be

used.

The specifications for the router that you can

use are:

• Use only UL approved Routers

• The Router switch is best located so that

it can face toward the operators position

This manual suits for next models

1

Table of contents