Shopsmith 555812 User manual

CHISEL SHARPENER

555812

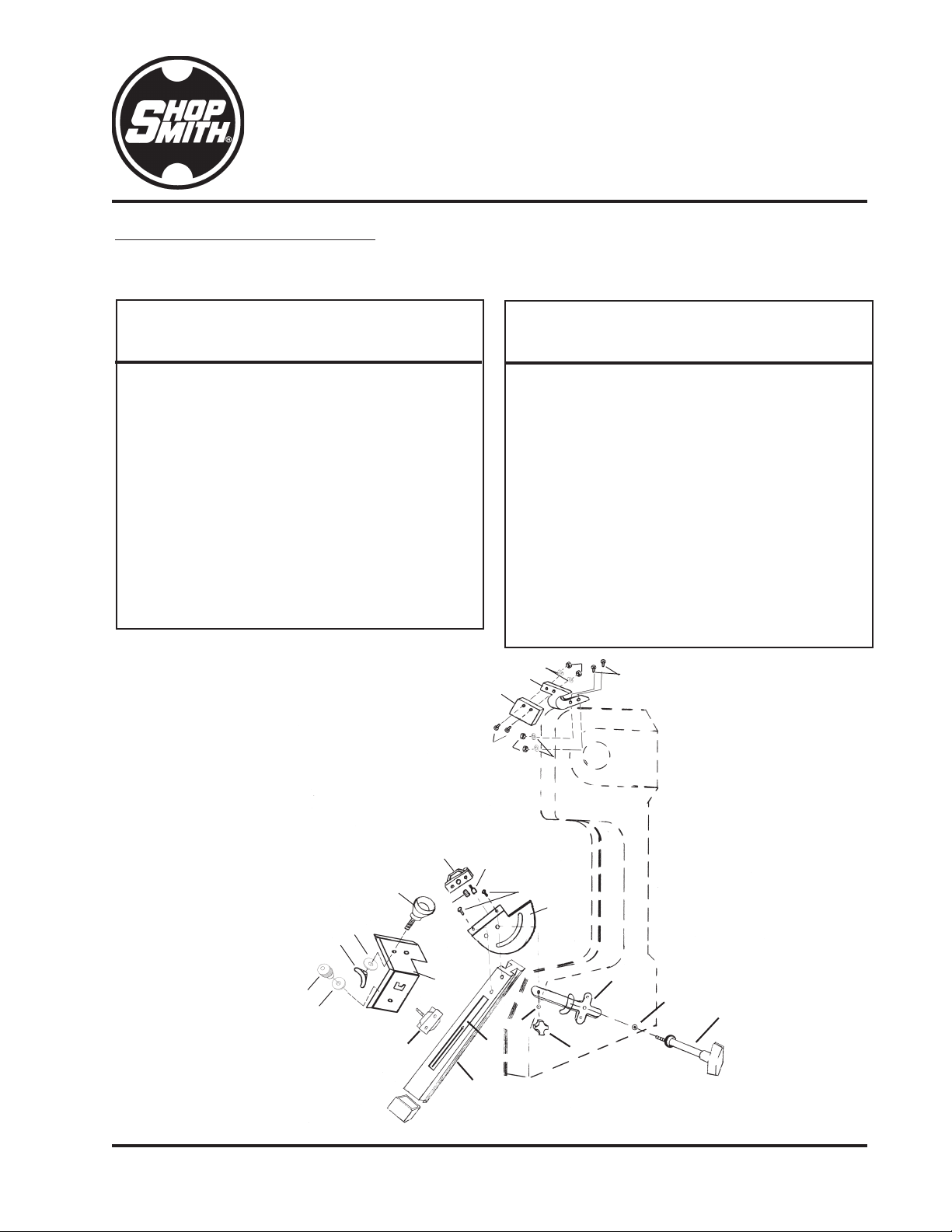

PARTS EXPLOSION

Parts List

Ref Part Item

No. No. Description Qty

— 555812 Mark V Chisel Sharpener

1 120392 . Flat Washer.................................. 2

2 126315 . Carriage Bolt, 1/4-20x1 ............. 1

3 274737 . Nut, 10-24 .................................... 4

4 436691 . Pan Head Machine Screw ......... 2

5 436732 . Philips Screw, 10-24x1/2 ........... 4

6 502973 . Split Washer ................................ 4

7 513216 . Wing Nut ..................................... 1

8 513739 . Flat Washer.................................. 1

9 514491 . T-Nut ............................................ 1

10 515318 . Eye Shield .................................... 1

11 521662 . Knob ............................................. 1

12 521768 . Knob ............................................. 1

13 521846 . Chisel Bracket ............................. 1

14 521847 . Chisel Protractor......................... 1

15 521849 . Support Angle ............................. 1

16 521853 . Set Screw ...................................... 1

17 521854 . Chisel Stud .................................. 1

18 521855 . T-Nut Assembly ......................... 1

—521903 . Arm & Label Assembly ............. 1

19 521856* . . Arm ............................................. 1

20 521899 . . Warning Label, Rotation ......... 1

21 521859 . Cup Assembly ............................. 1

22 521879 . Bracket, Eye Shield ...................... 1

23 521881 . Sharpening Plate (not shown) ... 1

24 521898 . Warning Label, Dust Collection 1

* Not available as a service part.

Ref Part Item

No. No. Description Qty

From your

Strip Sander

2

12

1

13

19

20

18

1

21

8

7

11

15

4

14

17

9

16

56

3

22 65

3

10

CHISEL SHARPENER 555812

Page 2

INTRODUCTION

The Chisel Sharpening Attachment allows

you to sharpen various sizes and shapes of

chisels. Straight -edged chisels, curved edge

chisels, steep-angle lathe scraping tools, and

low angle carving chisels can all be sharpened

in a flash. It is as simple as replacing the Strip

Sander table with the sharpening attachment,

changing the platen, and placing the Strip

Sander on your Mark V.

NOTE

To operate the Strip Sander Abrasive Belt in

an upward direction, the Strip Sander must

be mounted on the Quill End of the Mark V.

SAFETY

WARNING

Throughout this manual, we list WARN-

INGS, CAUTIONS, and NOTES. We advise

that when you come to one of these list-

ings, please read and understand it fully.

Their meanings are:

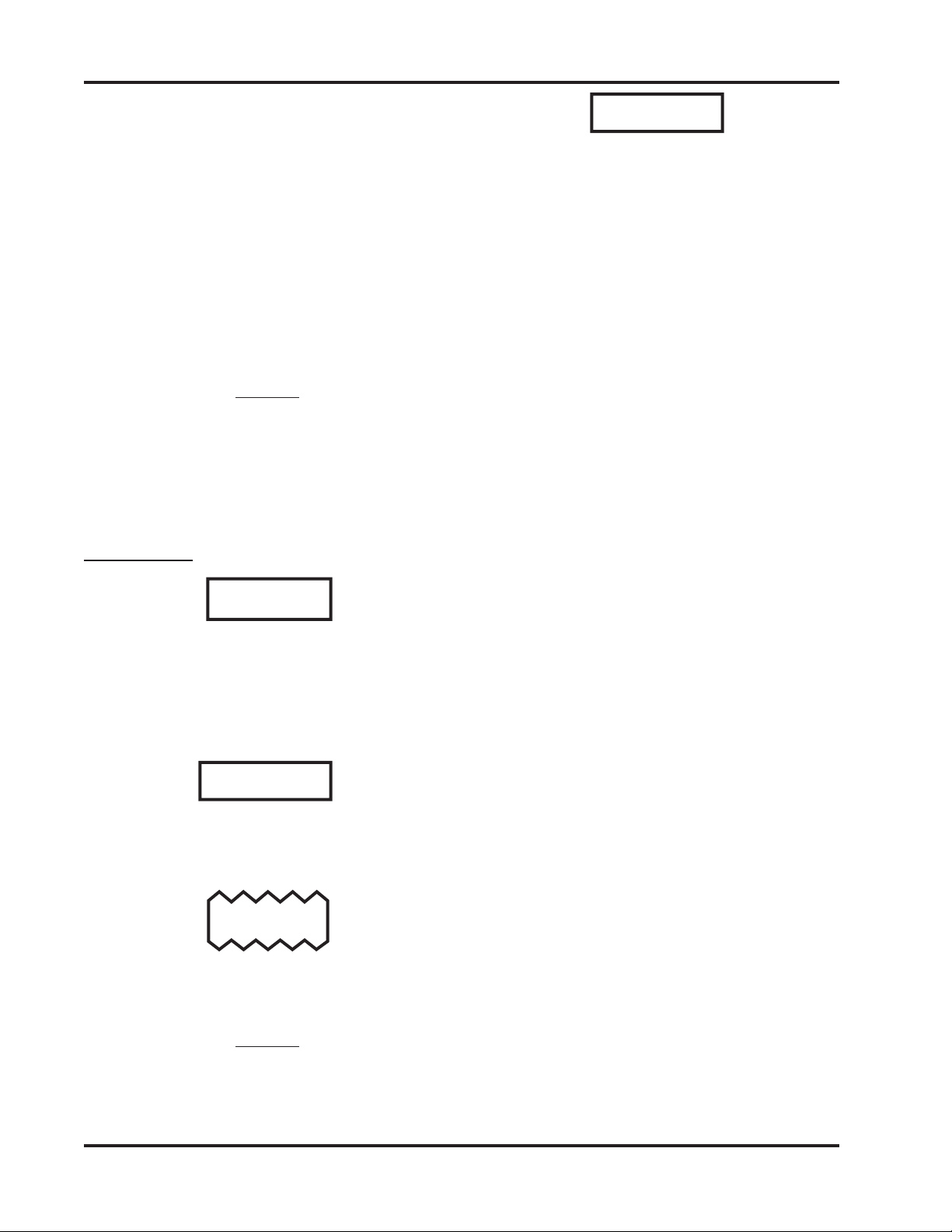

WARNING

A WARNING is given when failure to follow

the directions is likely to result in injury,

loss of limb, or life.

CAUTION

ACAUTIONisgivenwhenfailuretofollowthedirec-

tionsislikelyto result in damage to the equipment.

NOTE

A NOTE is used to highlight an important

procedure, practice or condition.

WARNING

General Safety

•Wear proper eye and ear protection.

Also, wear a dust mask.

•Keep guards in place. Always keep

guards in working order and in proper

alignment and adjustment. Most inju-

ries occur on unguarded power tools.

•Remove adjusting keys and wrenches.

•Wear proper apparel. Do not wear loose

clothing, ties, gloves, rings or other jew-

elry. Roll sleeves up above your el-

bows, wear nonslip footwear, and tuck

long hair under a hat.

•Do not operate power tools if you are

tired, taking medication, or under the

influence of alcohol or drugs.

•Avoid dangerous environments. Don’t

use power tools in damp, wet or explo-

sive atmospheres.

•Keep work areas well-lit, clean, and free

from clutter.

•Do not force the tool. It will do the job

better and safer at the rate for which it

was designed.

•Use the right tool. Don’t force a tool or

accessory to do a job for which it was

not designed.

•Check damaged parts. A damaged guard

or part should be properly repaired or

replaced before further use. If a strange

noise or vibration develops, immedi-

ately turn off the power, unplug the

machine and correct the problem. Never

Page 3

555812 CHISEL SHARPENER

operate a power tool that is not function-

ing properly.

•Do not overreach. Keep proper footing

and balance at all times.

•Do not leave the tool running unattended.

Turn off the power. Don’t leave the tool

until it comes to a complete stop.

•Avoid unintentional starting. Make sure

the switch is in the “off” position before

plugging in or unplugging the tool.

•Disconnect tools. Turn off and unplug

tools before changing accessories and

setups, making adjustment, and per-

forming maintenance and repair.

•Do not stand or lean on the tool. You

could fall onto the tool or it could tip

over injuring you and/or damaging the

tool.

•Maintain tools. Keep parts and tools

sharp, clean and maintained according

to the instruction manual.

•Make your workshop childproof. Use

padlocks, master switches or remove

starter keys.

•Keep children away. All visitors should

stay a safe distance from power tools,

and wear eye and ear protection.

•Do not permit anyone who is inexperi-

enced to use your power tools without

supervision.

To protect yourself from injury:

•READ, UNDERSTAND and FOLLOW ALL

the information in this Owner’s Manual.

•ALSO READ, UNDERSTAND and FOL-

LOW ALL the information in the instruc-

tion manuals, which came with your

MARK V and Strip Sander.

•Read the Safety section and complete

the Assembly and Setup procedures

before operating your Mark V Chisel

Sharpener.

•DO NOT USE the Mark V Chisel Sharp-

ener to sharpen knives.

•Rotation of the belt must be up against

the platen and away from the cutting

edge.

•DO NOT USE Dust Collection while grind-

ing metal.

•Clean Sawdust from Strip Sander prior

to grinding metal. Sparks from grinding

will ignite sawdust deposits.

TOOLS REQUIRED

5/32" Allen wrench

3/8” Wrench

#2 Phillips Screwdriver

For Strip Sanders Purchased

before January 1, 2001.

3/16” Drill bit

Electric Hand Drill

Center Punch

Hammer

ASSEMBLY

NOTE

The arm comes with the trunnion, t-nut,

pivot,end cap,and warninglabelassembled.

Set this aside.

CHISEL SHARPENER 555812

Page 4

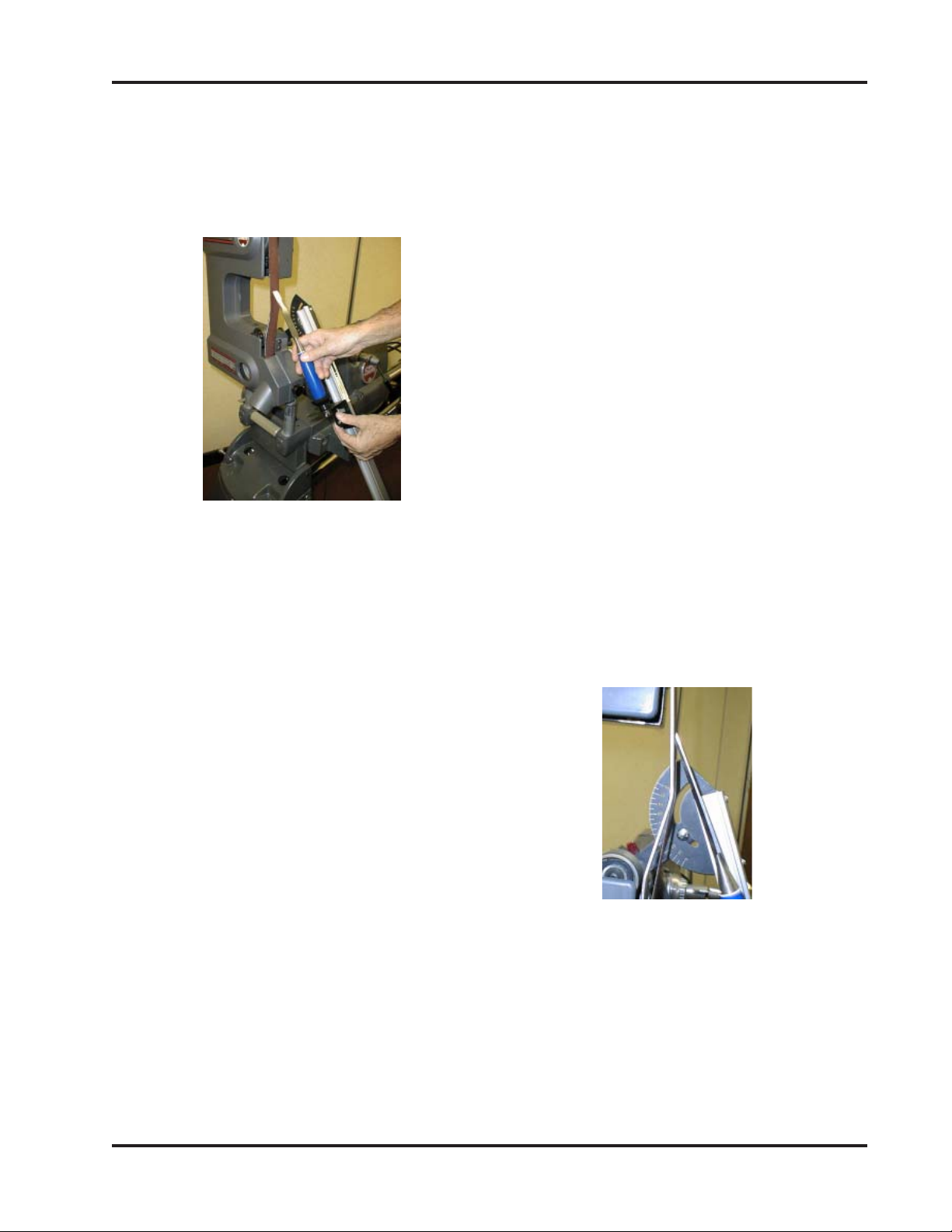

1. Pick up bracket (15), with bent tab down

slide stud of t-nut asm. (18) up through

the round hole. With t-nut asm. parallel,

add washer (8) and knob (11), as shown in

Figure 1. Do not tighten completely.

(5), as shown in Figure 4.

NOTE

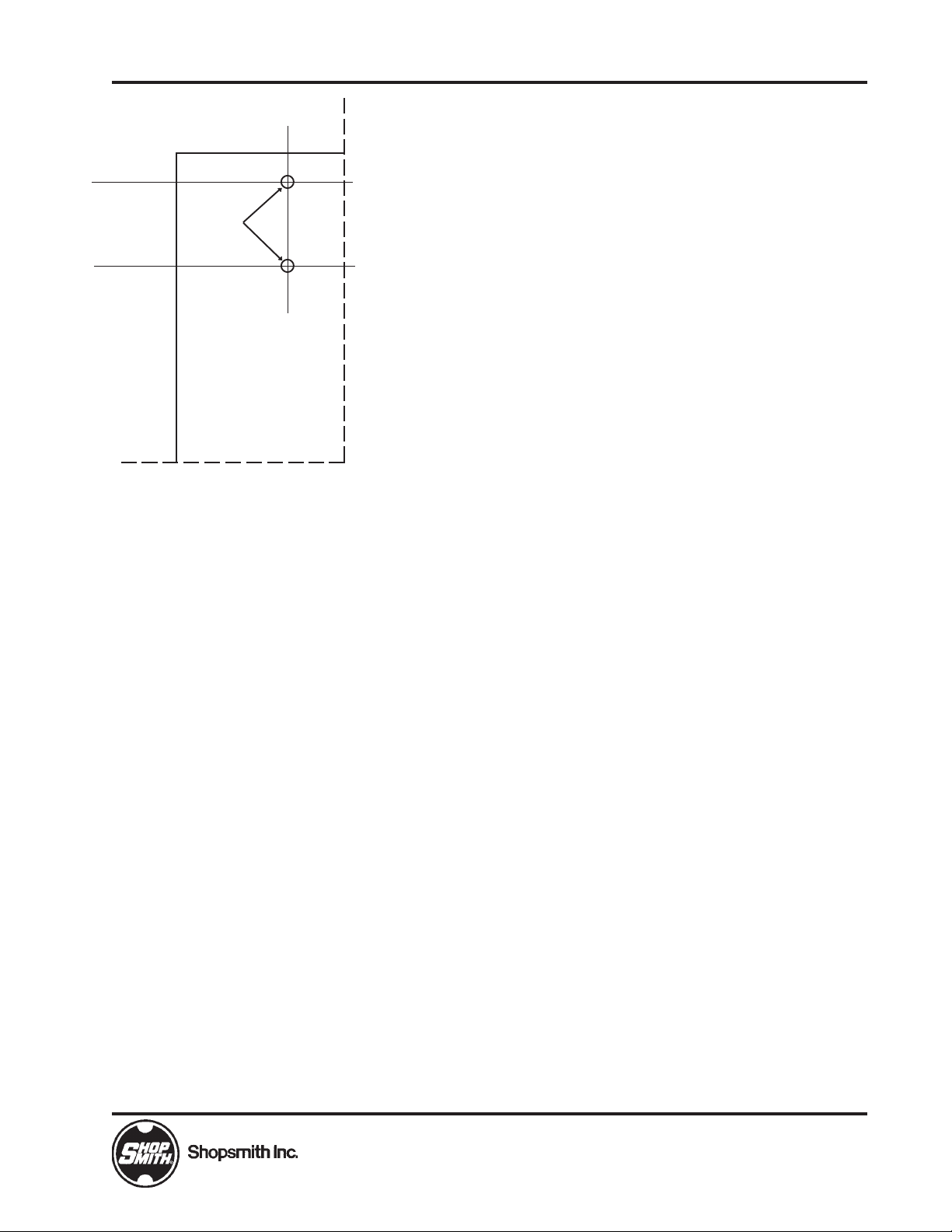

ForStrip Sandersmade afterDecember 2000,

skip steps 5-7 and continue on with step 8.

For Strip Sander prior to 2001.

NOTE

There is a drilling template included with

this Owner’s Manual, you will need to lo-

cate and cut out.

5. Tape template on top of Strip Sander,

align line “A” with edge of cover perpen-

dicular to the Upper wheel and line “B”

with the side edge of cover. Hold in place

with masking tape.

6. Place tip of center punch on the center

lines of the holes and strike it with a

hammer to mark the Strip Sander.

7. Remove template. Use 3/16” Drill bit in

an Electric Drill to drill 2 holes through

the casting where marked.

Figure 1

Figure 3

Figure 4

2. Turn bracket assembly so bottom of t-nut

is vertical and surface with the two holes

is down. Slide cup assembly (21) up

through center hole. Add washer (1) and

wing nut (7) on threads, as shown in

Figure 2. Finger tighten, this is your sup-

port assembly.

3. Place arm assembly on bench with trun-

nion scale facing up. Slide t-nut of sup-

port assembly into t-rail arm asm. (19), as

shown in Figure 3. Tighten knob when

support assembly is half way down arm.

Figure 5

4. Assemble guard to bracket with 2 screws

Figure 2

Page 5

555812 CHISEL SHARPENER

SETUP

WARNING

Make sure the Mark V is set to slow speed,

turned off, and unplugged before begin-

ning setup or operations.

1. Mount the Mark V in similar manner as

shown in Strip Sander Owners manual

for wood sanding, except that in this case

the Strip Sander is mounted in the base

arm of the Mark V and coupled to the

quill in headstock. DO NOT mount the

Strip Sander in the headrest or coupled to

the upper auxillary spindle.

8. Openthe StripSander cover,hold bracket

and guard assembly against the top of the

frame. Slip screw through the hole in the

bracket and through the casting. See Fig-

ure 5. Add lock washer and nut to screw

andtighten withPhillips screwdriverand

3/8” wrench. Repeat this step for other

screw.

Mount Chisel Sharpening

Attachment on Strip Sander

9. Pick up Dust Collection Warning label

(24), remove backing and place on the top

of the dust collection outlet on your Strip

Sander.

WARNING

Read and Follow information on the warn-

ing label. Failure to follow label warning

will result in fire damage to you strip sander,

dust collector, and other personal prop-

erty.

10. Remove abrasive belt from Strip Sander,

by pressing the idler wheel down and

slipping the belt off sideways.

11. Remove table from Strip Sander by re-

moving knob and bolt from slot in table,

then unscrew and remove tilt knob from

Strip Sander.

12. Removeplaten fromStripSander, byloos-

ening the three socket head cap screws

with 5/32" Allen wrench.

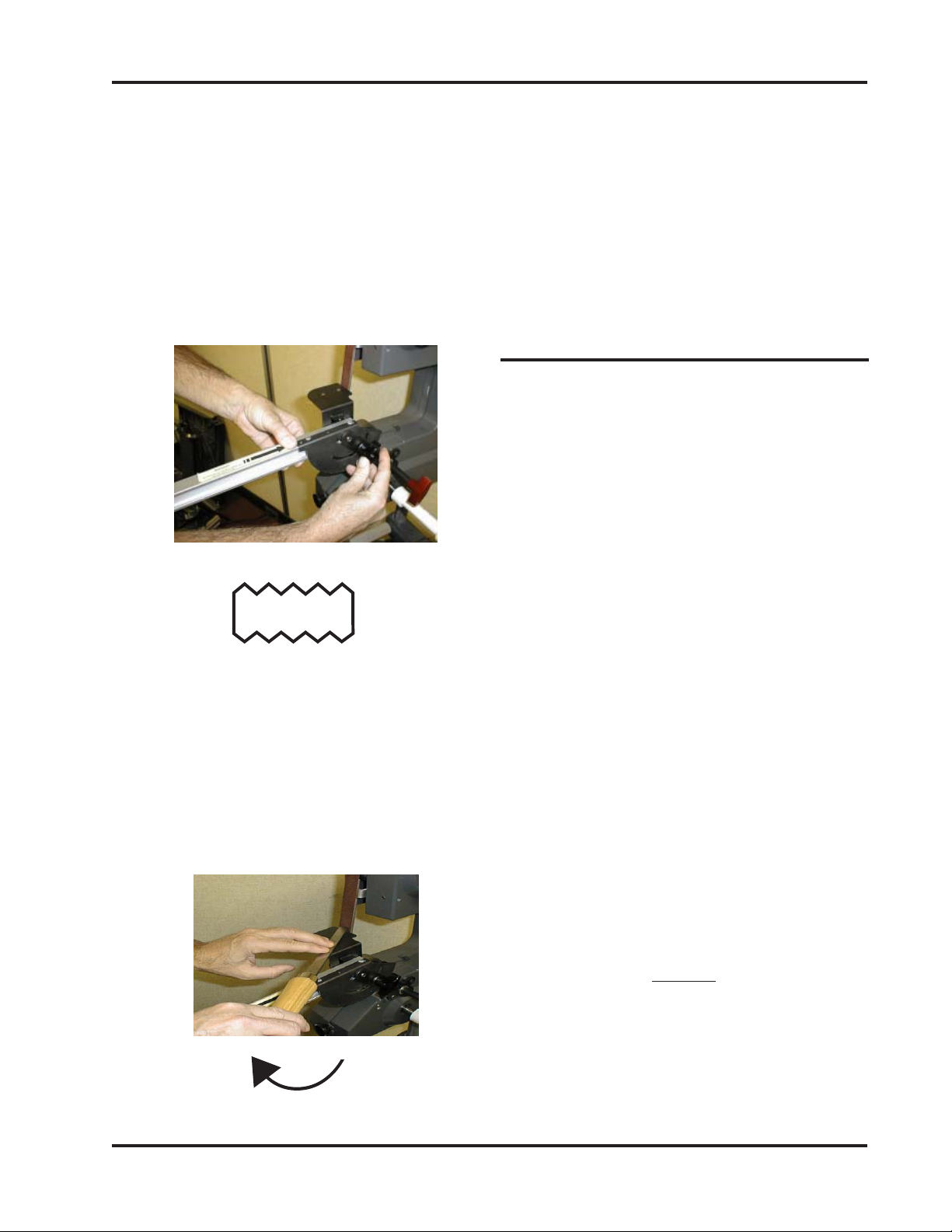

13. Slip trunnion support bracket over trun-

nion support and hold in place with

washer and knob assembly that was used

to hold table in place, as shown in Figure

6. Tighten by hand. Mount the chisel

sharpening platen and install the desired

abrasive belt.

14. Place arm assembly with angle degrees to

left against left side of trunnion support

bracket,so pivotscrewprotrudes through

pivot hole in end of trunnion support

bracket.Insert carriagebolt throughtrun-

nion and trunnion support bracket from

left. Add washer and knob, as shown in

Figure 7.

Figure 6

Figure 7

CHISEL SHARPENER 555812

Page 6

WARNING

Failure to mount Strip Sander (as described

in Step 1) will cause the abrasive belt to run

in the wrong direction, and will cause the

tool to gouge into the belt, damaging both

and throwing the tool.

2. Be sure that you have mounted the hub

with5/8" diameterholeandfour (4)spline

grooves on quill. Position the headstock

as far to the right as possible and lock.

3. Slide the coupler on the Strip Sander hub

and extend the quill until the quill hub

engages in coupler. Lock quill.

OPERATIONS

Basic Operations

CAUTION

Tooltemperatureisveryimportanttothelifeofyour

cutting tools. Cool the tool frequently in water dur-

ing the sharpening process.

1. The recommended speed is “I” (1750

RPM) on your Mark V Speed Dial.

2. In order to keep the hardness and tough-

ness properties of the steel in your cutting

tool, you must overheat the tool while

grinding, sharpening, or honing it. If you

can not touch the tool without burning

your finger, it is too hot. Cool the tool

frequently in water during the sharpen-

ing process.

NOTE

The finer the abrasive you use and/or the

more pressure you exert on the tool the more

heat will be generated. If your cutting tool

gets hot very quickly, you are either using

too much pressure or the belt has become

dull and needs replaced. Finer belts will

wear quickest and will need to be replaced

most often.

Grinding, Sharpening & Honing

1. Grinding - Use coarser grits 60, 80, 100 to

reshape the tools bevel or remove large

nicks in the cutting edge.

2. Sharpening - Use medium grits 100, 150,

220 to remove burrs, small nicks and

sharpen very dull tools.

3. Honing - Use finest grits 320, 400, 600 to

dress and improve the cutting edge of

tools that do not have any nicks or burrs

and only require a light touch-up to keep

them razor sharp.

Tool Care

Most new cutting tools will require at least

sharpening with medium grits and final hon-

ing with finest grit sanding belts. Lathe chis-

els intended for scraping only need grinding

with coarse grits. The burr left on the cutting

edge will help cut. Other lathe, carving, and

bench chisels must be used razor sharp and

are easiest to use when kept that way.

Setting the Tool Angle

The tool angle is a function of both the arm

angle and the cup position. The trunnion scale

is an approximate guide and is only accurate

when the metal shank of the tool being sharp-

ened is exactly parallel to the arm.

NOTE

To set the proper angle, you must first de-

cide whether you are going to copy the tool’s

bevel angle or change it.

Page 7

555812 CHISEL SHARPENER

To Copy the Tool’s Bevel

1. Place a 100, 150, or 220 grit abrasive belt

on the Strip Sander. Refer to Strip Sander

Owner’s Manual for belt installation in-

structions.

7. If the scratches are only at the tool’s tip,

then turn speed on speed dial to “slow”

and turn off the headstock. Loosen the

trunnion lock knob, lower the arm

slightly, lock trunnion lock knob and re-

peat until scratches follow full bevel

length.

8. Repeat with the next finer grits.

To Change the Bevel Angle

1. Place a 60, 80, or 100 grit abrasive belt in

the Strip Sander, refer to the Strip Sander

Owner’s Manual for belt installation in-

structions.

2. Set the chisel handle in the cup, loosen the

support lock knob. Slide the support un-

til the tool’s bevel rests against the belt

and tighten the support lock knob.

3. Loosen the trunnion lock knob and tilt

arm until the cutting tool’s bevel is at the

new angle against the abrasive, as shown

in Figure 9. Lock the trunnion lock knob.

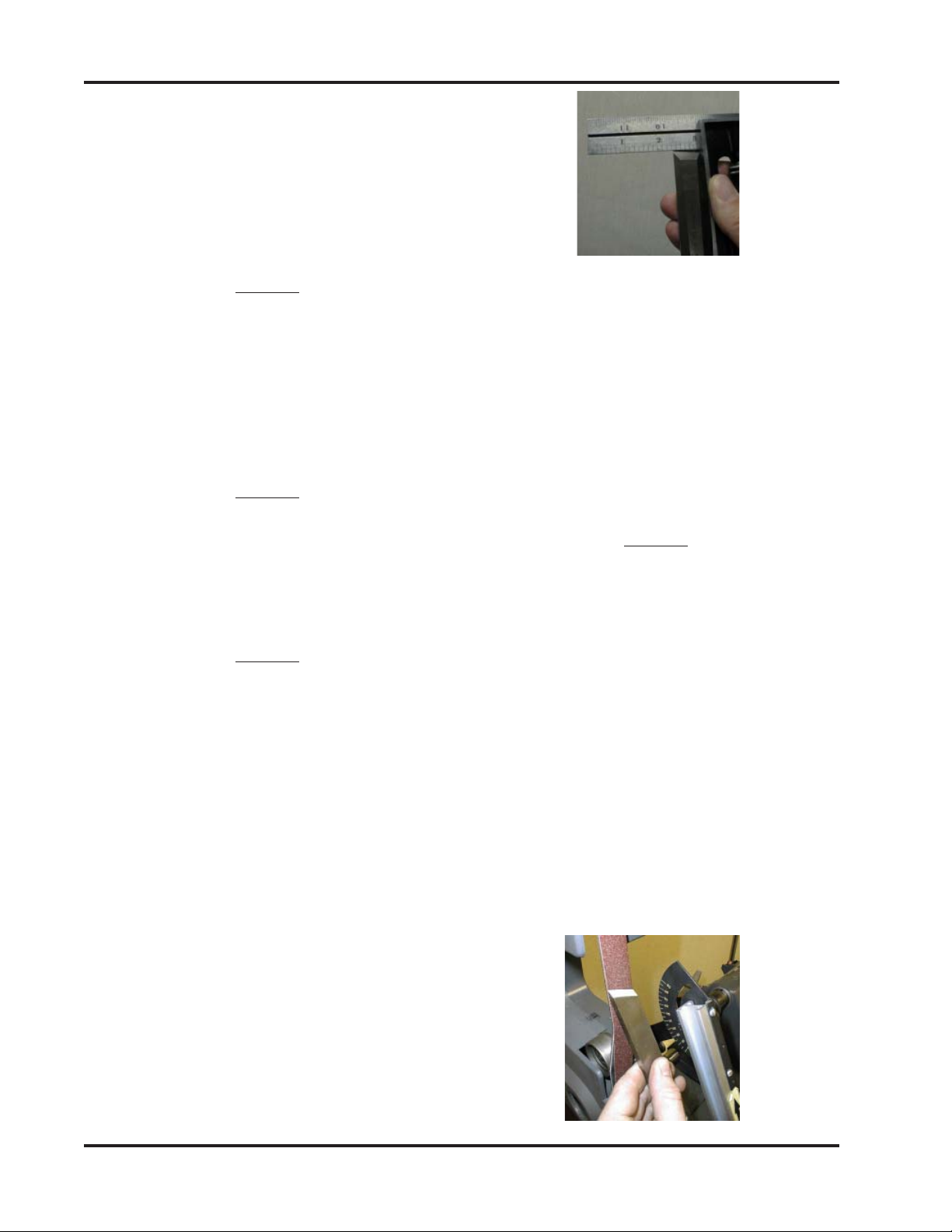

Figure 8

2. Set the chisel handle in the cup, loosen the

support lock knob. Slide the support until

the tool’s bevel rests against the belt and

tighten the support lock knob, as shown

in Figure 8.

3. Loosen the trunnion lock knob and tilt

arm until the cutting tool’s bevel lays flat

against the abrasive belt and the tools

steel shank is parallel to the arm. Lock the

trunnion lock knob.

4. Final minor adjustments to align the tool

shank parallel to the arm should be made

by moving the support on the arm.

5. Remove the chisel from the cup, turn the

headstock on at “slow” speed setting,

check the belt tracking and adjust if neces-

sary. Set speed to “I” (1750 rpm) on the

Mark V speed dial.

6. Place the tool handle in the cup and gen-

tly touch the bevel against the moving

belt and remove. Look for flat, consistent

scratches along the bevel.

4. Final minor adjustments to align the tool

shank parallel to the arm should be made

by moving the support on the arm.

5. Remove the chisel from the cup, turn the

headstock on at “slow” speed setting,

check the belt tracking and adjust if nec-

essary. Set speed to “I” (1750 rpm) on the

Mark V speed dial.

Figure 9

Figure

Figure 8

CHISEL SHARPENER 555812

Page 8

6. Place the tool handle in the cup and grind

the new bevel against the moving belt.

7. After the initial bevel grind is completed,

turn down and turn off the Mark V. Open

the Strip Sander, remove the belt and

install the next finer grit.

NOTE

Each progressively finer grit belt will re-

movescratches andburrsformprevious grits.

8. After changing each belt to a finer grit,

repeat steps 4-6, until you achieve the

sharpnessdesired.

NOTE

A final honing will be required on the in-

side of gouges with a slip stone.

Sharpening a Bench Chisel

NOTE

This is probably the easiest tool to sharpen

and a good tool to use to learn this accessory.

1. Select appropriate abrasive belt and in-

stall on Strip Sander.

2. Set angle as described previously. Turn

on the machine to Speed “I” (1750 rpm)

on your Mark V speed dial.

3. Set the chisel handle in the cup and hold

the chisel against the moving belt with

light, even pressure.

4. Check your progress often and check

chisel temperature. Cool in water as

needed.

5. Use a square to make sure the new cutting

edgeisperpendicular totheside,as shown

in Figure 10. If it is not square, grind more

from the high side by applying more

pressure against that side.

6. Repeat steps 3-5 with progressively finer

abrasives. As you progress to finer and

finer abrasive belts the burr will become

smaller and eventually be removed.

Sharpening a Skew

NOTE

This is very similar to sharpening the bench

chisel, except that you must evenly grind a

bevel on both sides of the tool.

1. Select appropriate abrasive belt and in-

stall on Strip Sander.

2. Set angle as described previously. Turn

on the machine to Speed “I” (1750 rpm)

on your Mark V speed dial.

3. Set the chisel handle in the cup and hold

the chisel against the moving abrasive

belt with light, even pressure. See Figure

11. This time the chisel is rotated slightly

at a skew angle.

Figure 10

Figure 11

Page 9

555812 CHISEL SHARPENER

6. Use a square to make sure the new cutting

edge is perpendicular to the side. If it is

not square, grind more from the high side

by applying more pressure against that

side.

7. You may proceed to finer grits if you

desire, but many woodturners who use

the scraping technique prefer to leave the

burr on the chisel. They believe the burr

cuts smoother than a burr-free edge.

Sharpening a Gouge

1. Select appropriate abrasive belt and in-

stall on Strip Sander.

2. Set angle as described previously. Turn

on the machine to Speed “I” (1750 rpm)

on your Mark V speed dial.

3. Hold the chisel against the moving abra-

sive belt with light, even pressure. Rotate

the chisel in the cup to grind the curved

bevel, as shown in Figure 14.

4. Checkyourprogressoften andcheckchisel

temperature. Cool in water as needed.

5. Turn the skew chisel over and grind the

opposite side, checking that the bevel is a

constant width on both sides. If it is not

consistent, grind more from the narrow-

est part of the bevel by applying more

pressure against that area.

6. Checkthatthe anglesat theheal andtoe of

the chisel are equal, see Figure 12.

Figure 12

7. Repeat steps 3-6 with progressively finer

abrasives. As you progress to finer and

finer abrasive belts the burr will become

smaller and eventually be removed.

Sharpening a Parting Tool

1. Select appropriate abrasive belt and in-

stall on Strip Sander.

2. Set angle as described previously. Turn

on the machine to Speed “I” (1750 rpm)

on your Mark V speed dial.

3. Set the chisel handle in the cup and hold

the chisel against the moving abrasive

belt with light, even pressure, as shown

in Figure 13.

4. Grindboth edgesof theparting toolso the

bevels are the same length and the point

is exactly centered at the widest part of

the sides.

5. Check your progress often, check chisel

temperature,and coolin wateras needed.

Figure 13

Figure 14

Heal

Toe

CHISEL SHARPENER 555812

Page 10

Figure 15

4. Check your progress often to check chisel

temperature. Cool in water as needed.

5. To grind a pointed gouge for spindle

turning, more grinding is done on either

side, see Figure 15.

Figure 17

NOTE

The angle scale is no longer accurate with

the cup set in the inner hole. You must

estimate your bevel angle.

3. Sharpen your chisel as described previ-

ously, refer to the appropriate section.

Sharpening Low Angle Curved

or Straight Scarping Chisels

NOTE

To sharpen scraping chisels you must make

somechanges tothe sharpeningguide setup.

1. Remove the cup and loosen the support

bracket lock knob several turns.

2. Rotate the support bracket 90oclockwise

looking at the knob, so it’s two holes are

approximately parallel to the arm. As

shown in Figure 18,the tab that was pre-

viously in the arm is now above the arm.

6. To grind a square gouge for roughing,

less grinding is done on either side, as

shown in Figure 16.

7. Repeat steps 3-5 with progressively finer

abrasives. As you progress to finer and

finer abrasive belts the burr will become

smaller and eventually be removed.

Sharpening a Long Angle

Carving Gouge, Skew, or

Paring Chisel

NOTE

To grind angles less than 10oon carving

chiselsthe cup thatsupports thechisel handle

must be moved to the inner position.

1. Remove the wing nut and washer, repo-

sition the threads on the cup in the hole

closest to the machine.

2. The new cup position will now allow you

to grind the very long bevels required on

some carving chisels. See Figure 17.

Figure 16

Back

Front

Front

Back

Figure 18

Page 11

555812 CHISEL SHARPENER

3. Slide the support bracket up the arm until

its edge is even with the top end of the

armand tightenthesupport bracketknob.

4. Loosen the trunnion lock knob and rotate

the arm to the 90oposition.

5. Loosen the support bracket lock knob.

Slide and pivot the support bracket to-

ward the abrasive belt. Set your desired

angle, as shown in Figure 19.

Figure 19

CAUTION

Position the support bracket no further than 1/4"

away from the abrasive belt.

6. Turn on the Strip Sander, hold the chisel

flat on support bracket with light even

pressure and slide it toward the belt. For

curved scraping chisels pivot the chisel

from left to right to create the desired

profile on the end of the chisel, as shown

in Figure 20. For straight tools hold the

Figure 20

Right Left

cutting edge against the bent without

rotating the chisel.

7. Check your progress often to check chisel

temperature. Cool in water as needed.

8. You may proceed to finer grits if you

desire, but many woodturners who use

the scraping technique prefer to leave the

burr on the chisel. They believe the burr

cuts nicer than a burr-free edge.

NOTE

If you have further questions or need help,

call our Customer Service Department: Toll

Free 1-800-762-7555 or visit our website at

www.shopsmith.com.

CHISEL SHARPENER 555812

6530 Poe Avenue

Dayton, Ohio 45414

www.shopsmith.com All Rights Reserved

Printed In U.S.A.

RLFSHOP, LLC.

845515 Rev. B 01-10

NOTES

555812 CHISEL SHARPENER TEMPLATE

6530 Poe Avenue

Dayton, Ohio 45414

www.shopsmith.com

845518 Rev. 12/00

All Rights Reserved

Printed In U.S.A.

LINE “A”

LINE “B”

3/16” Diameter

Table of contents

Other Shopsmith Power Tools manuals

Popular Power Tools manuals by other brands

ELORA

ELORA 2034 operation instruction

P.Lindberg

P.Lindberg 9039281 manual

BGS technic

BGS technic 8496 instruction manual

Kurtz Ersa

Kurtz Ersa X-TOOL VARIO operating instructions

Roland

Roland DWX-51D Setup guide

Johnson & Johnson

Johnson & Johnson DePuy Synthes Small Battery Drive II Manual and Mechanical Cleaning Instructions