Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 www.shorelandr.com 0004224

Page 8 of 11 8/17/2010

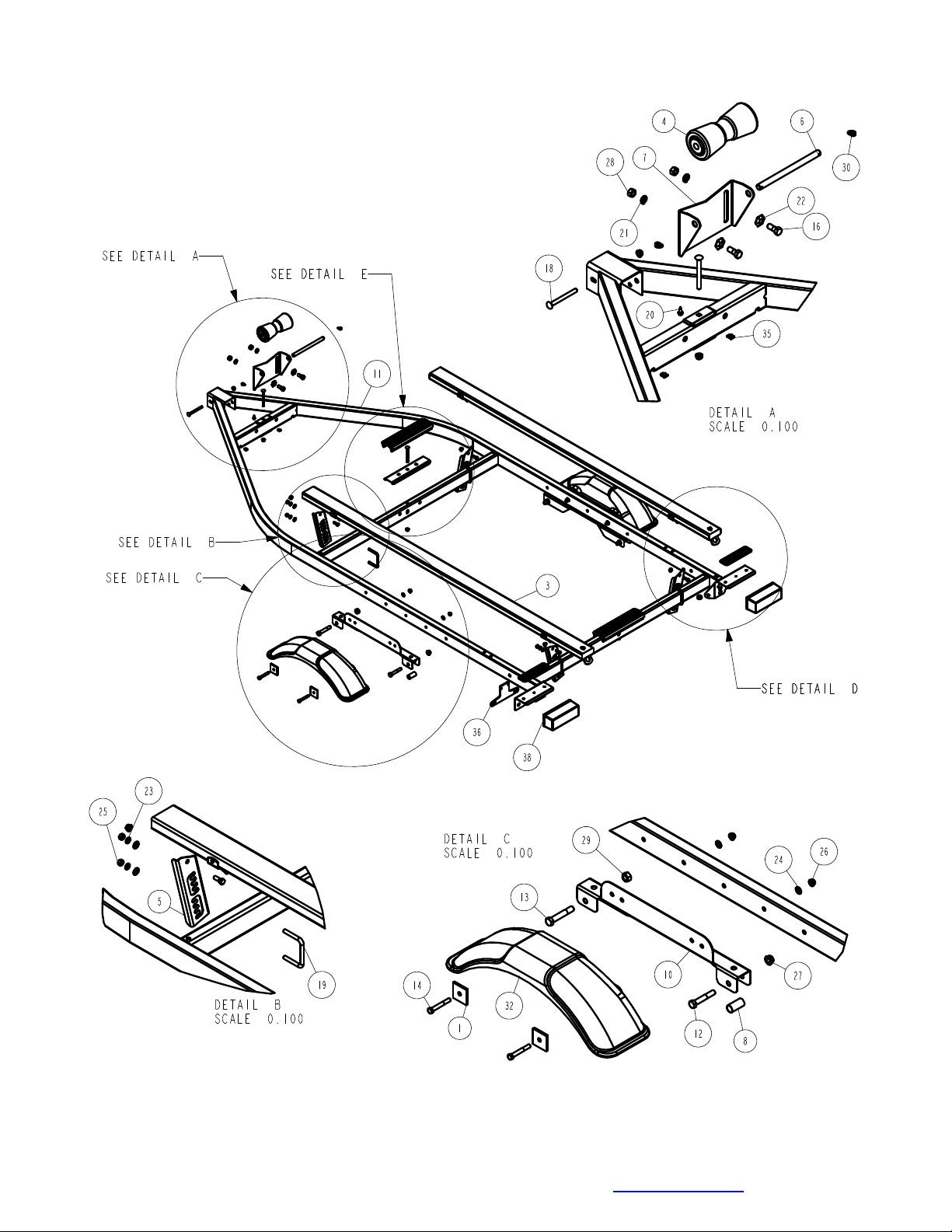

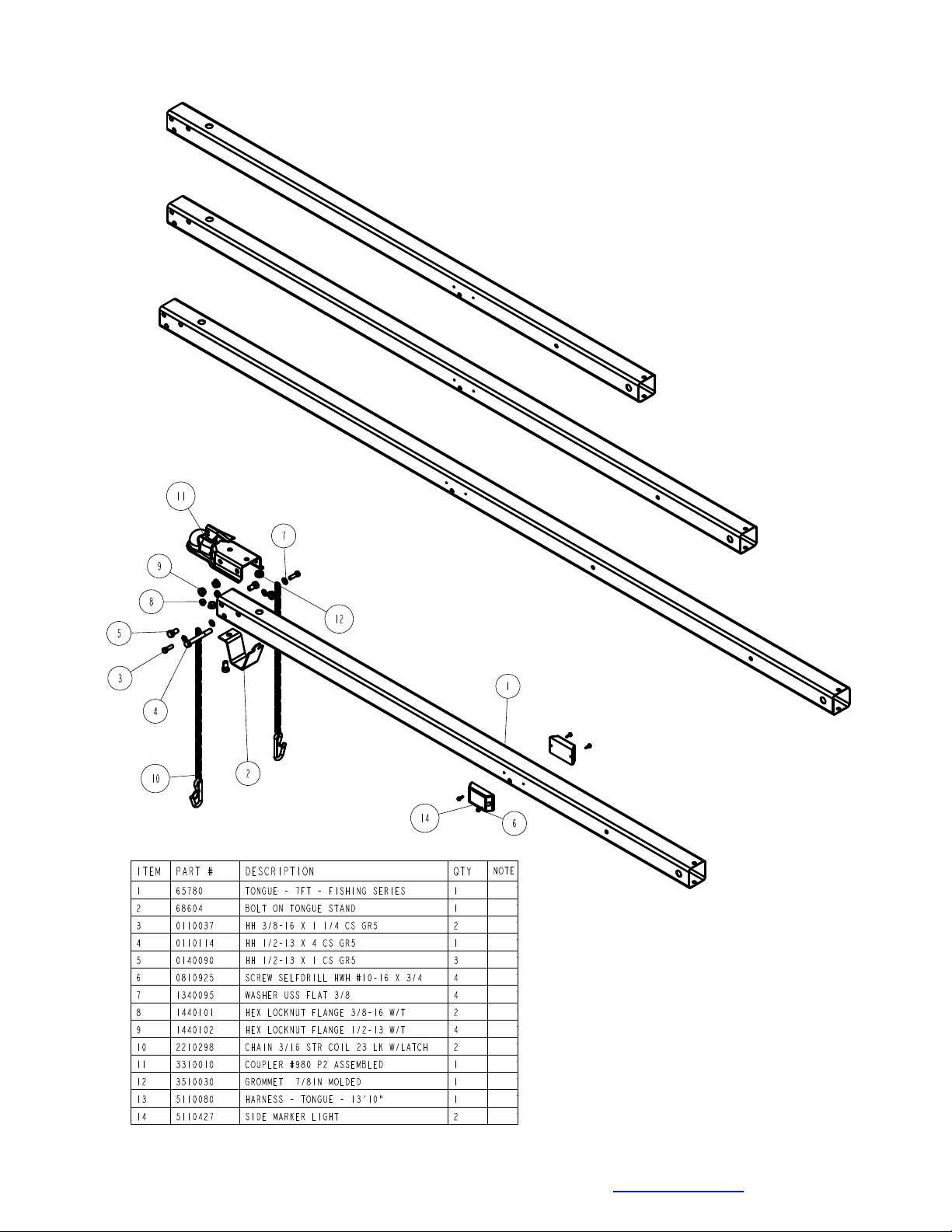

TONGUE ASSEMBLY

Place the frame to be assembled on saw horses or stands to assist in the assembly. Remove all items

that are banded to the frame. Sort the items in the hardware box by item and the hardware by size.

Locate the tongue for the trailer. Note that there are three different lengths of tongues designed to fit

this particular frame. The length of tongue will determine the length of boat that can be placed on the

trailer when assembled. The 7’ tongue will accommodate boats 12-14 feet in length, the 8’-6” tongue

will fit boats 14’ - 16’ 6” in length and the 10’ tongue is used for boats 15’ 6”- 18’ long.

Once the proper tongue is identified place it on the stands so it can be prepared for installation into the

frame. Locate the two amber side marker lights shipped in the hardware box. Uncoil the wire and insert

the plug end into the larger, center hole that is drilled in the side of the tongue. As the wire is inserted

into the hole direct the wire so that it will go to the forward end of the tongue. Pull the wire out the front

of the tongue. It will be connected to the tongue harness at a later time. Attach the light to the tongue

using two (2) No. 10 x 3/4” self-tapping screws provided. Repeat this process on the other light on the

other side of the tongue.

Locate the tongue wire harness. Insert the end of the harness with the small plug into the hole located

in the top of the tongue. Pull the wire backward through the tongue until the end comes out the rear of

the tongue. As the wire harness is inserted note that there are two single bullet wires towards the front

plug of the tongue wire harness. Pull these wires forward as the wire harness is inserted into the

tongue. Plug the single wires from the side marker lights installed earlier into the two single bullets of

the tongue harness. Push the additional back into the front of the tongue to keep it from damage during

use. Place a rubber grommet around the wire harness and in the hole in the top of the tongue to protect

the wires from damage during use.

Route the harness plug at the rear of the tongue through the hole provided in the side of the tongue.

Pull both the plug and the white ground wire out the hole. They will be attached later once the tongue is

installed in the frame.

Look at the bottom side of the tongue and locate the slotted key slot hole in the tongue. Note that one

end of the tongue stand has a dart or arrow shaped end. With the tongue stand positioned 90 degrees

to the centerline of the tongue, insert the dart or arrow end of the tongue stand into the key slotted hole.

Once it is inserted, turn the tongue stand 90 degrees so that it now is in line with the centerline of the

tongue. Attach the front end of the tongue stand to the tongue using a 1/2” x1” hex bolt and flange lock

nut. Tighten.

Locate the safety chains. Place a 3/8” flat washer on a 3/8” x 1-1/4” hex bolt. Insert the bolt through the

last link in the safety chain and then into the lower hole provided in the front of the tongue. Secure with

a 3/8” flange lock nut. Tighten. Repeat on the other chain.

Place the coupler on the top of the tongue. Align the holes in the coupler with the holes in the tongue.

Place a 1/2” x 4” hex bolt through the back holes of the coupler and the tongue. Secure with a 1/2”

flange lock nut but do not tighten at this point.

Place a 1/2” x 1” hex bolt through the front hole on one side of the coupler and the tongue so that the

head of the bolt is to the outside. Place a 1/2” flange lock nut on the bolt inside the tongue. Repeat this

process on the other side of the tongue. Once the bolts are installed, tighten all nuts left loose at this

time.

Insert the tongue assembly through the front channel of the frame far enough so the rear of the tongue

is inserted into the front cross member. Align the cross hole in the front channel and the tongue and

insert a 3/8” x 4” carriage bolt. Secure with a 3/8” flange locknut. Place a second 3/8” x 4” carriage bolt

down through the hole in the rear of the tongue and the front cross member. Place on a 3/8” flange lock

nut. Tighten.

Connect the tongue wire harness into the side frame harness of the trailer by matching plugs. Attach

the white ground wire of the tongue harness to the frame using a No. 10 x 3/4” self-tapping screw

provided so that a good ground connection is made between the frame of the trailer and the tow

vehicle. Push all extra wires used to make the connection back inside either the side frames of the

trailer or else into the tongue. Place a second rubber grommet into the hole where the wires exit the

tongue to protect them from damage during normal use.