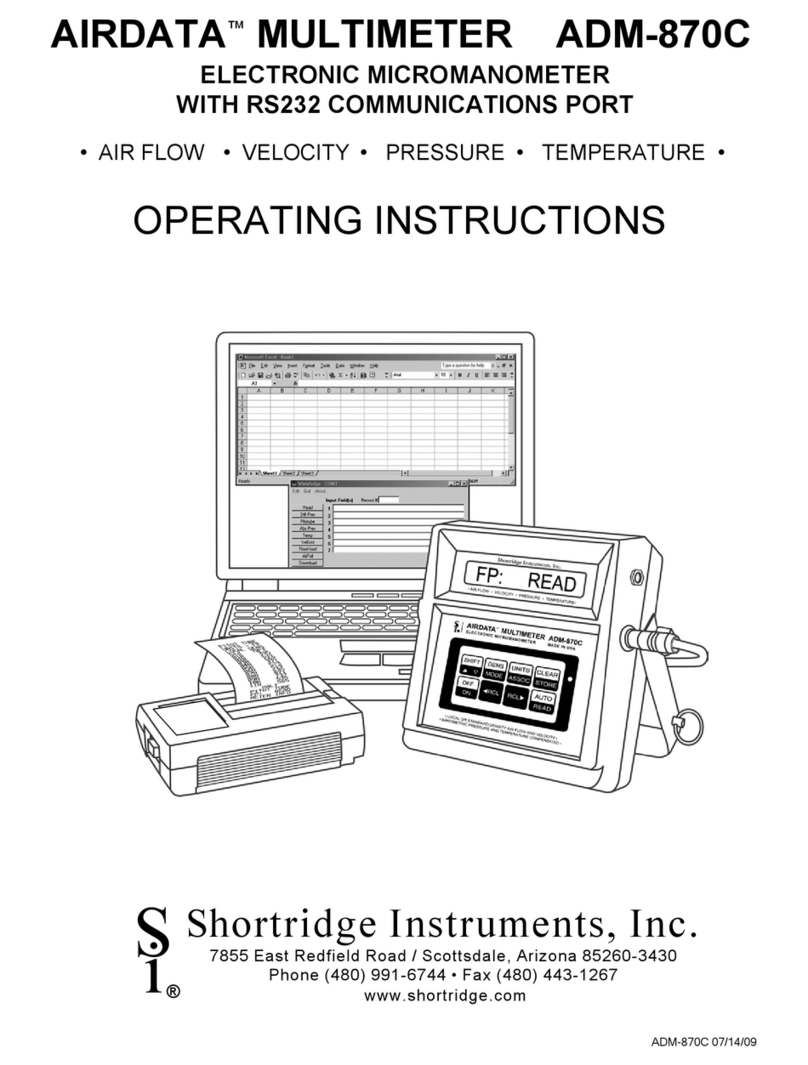

Shortridge Instruments Airdata ADM-870 User manual

ADM-870 05/23/08

Shortridge Instruments, Inc.

7855 East Redfield Road / Scottsdale, Arizona 85260-3430

Phone (480) 991-6744 • Fax (480) 443-1267

www.shortridge.com

S

i

AIRDATA™MULTIMETER ADM-870

ELECTRONIC MICROMANOMETER

AIR FLOW • VELOCITY • PRESSURE • TEMPERATURE

OPERATING INSTRUCTIONS

®

ADM-870 05/23/08i

CONTENTS

1.0 INTRODUCTION 1

2.0 SPECIFICATIONS 2

3.0 EXTERNAL FEATURES 4

3.1 KEYPAD 4

3.2 FEATURES ON SIDES AND BACK OF METER 4

4.0 DISPLAY MESSAGES AND PROMPTS 7

4.1 READ PROMPTS 7

4.2 MEASUREMENT READOUTS 7

4.3 FUNCTION READOUTS 8

5.0 USING THE AIRDATA MULTIMETER 12

5.1 AUTOMATIC READINGS 12

5.2 MEMORY/AVERAGE/TOTAL FUNCTION 12

5.2.1 MEMORY OPERATION 12

5.2.2 RECALL 13

5.2.3 DISCARD READING 13

5.2.4 CLEAR MEMORY 13

5.2.5 ERROR 13

5.3 AUTOMATIC READING MEMORY 13

5.4 SPEED-READ FEATURE 13

5.4.1 SPEED-READ OPERATION 14

6.0 VELOCITY MEASUREMENT 15

6.1 VELOCITY CORRECTION FACTORS 15

6.2 PITOT TUBE VELOCITY MEASUREMENT 16

6.3 AIRFOIL PROBE 17

6.3.1 DUCT VELOCITY USING AIRFOIL PROBE 18

6.3.2 FUME HOODS AND SAFETY CABINETS - AIRFOIL 18

6.3.3 EXHAUST HOODS - AIRFOIL PROBE 19

6.3.4 LAMINAR FLOW WORKSTATIONS - AIRFOIL PROBE 19

6.4 VELGRID AIR VELOCITY 19

6.4.1 CHEMICAL EXHAUST HOODS - VELGRID 20

6.4.2 LAMINAR FLOW WORKSTATION - VELGRID 20

6.4.3 AIR FLOW CALCULATION FROM VELGRID VELOCITY 20

6.5 VELOCITY: LOCAL DENSITY VS STANDARD DENSITY (MASS FLOW) 22

7.0 PRESSURE MEASUREMENT 23

7.1 DIFFERENTIAL PRESSURE 23

7.1.2 PITOT TUBE "VELOCITY PRESSURES" 23

7.1.3 PITOT TUBE "STATIC PRESSURES" 23

7.1.4 PITOT TUBE "TOTAL PRESSURES" 24

7.2 ABSOLUTE PRESSURES 24

8.0 TEMPERATURE MEASUREMENT 25

8.1 TEMPROBE 25

8.2 AIRDATA MULTITEMP 25

9.0 AIR FLOW MEASUREMENT 27

9.1 FLOWHOOD FUNCTION 27

9.2 BACKPRESSURE COMPENSATION 27

10.0 FLOWHOOD ASSEMBLY 28

10.1 UNPACKING 28

10.2 FRAME CHANNELS 28

10.3 FABRIC TOPS 28

10.4 SUPPORT ASSEMBLY 28

10.5 HANDLE 29

11.0 FLOWHOOD OPERATING PROCEDURE 34

11.1 AIR FLOW - NONBACKPRESSURE COMPENSATED READINGS 34

11.2 AIR FLOW - BACKPRESSURE COMPENSATED READINGS 34

11.2.1 ERROR 35

ADM-870 05/23/08ii

12.0 SPECIAL BALANCING PROCEDURES 36

12.1 PROPORTIONAL BALANCING 36

12.2 LARGE RETURN AIR GRILLES 36

12.3 KITCHEN EXHAUST HOODS 36

12.3.1 RANGE EXHAUST FILTERS AND GREASE EXTRACTORS 36

12.4 CONSTANT VOLUME CONTROLLERS 36

12.5 LINEAR SLOT DIFFUSERS 37

12.6 SIDEWALL REGISTERS 37

12.7 14"x14"x14" SHORT TOP SET 37

12.8 SYSTEM PROBLEMS 37

13.0 CORRECTION FACTORS AND CONVERSION FORMULAS 38

13.1 BAROMETRIC PRESSURE DENSITY CORRECTION - LOCAL DENSITY 38

13.2 TEMPERATURE DENSITY CORRECTION 38

13.4 RELATIVE HUMIDITY CORRECTION 38

13.5 HOT WIRE ANEMOMETER VERSUS AIRDATA MULTIMETER 38

14.0 METER ACCURACY FIELD TESTING 40

14.1 METER ZERO FUNCTION 40

14.2 DIFFERENTIAL PRESSURE FUNCTION 40

14.3 ABSOLUTE PRESSURE FUNCTION 40

14.4 AIR FLOW ACCURACY 40

14.5 DUCT TRAVERSE COMPARISONS, INCLINED MANOMETER, MICROMANOMETER 40

14.6 DUCT TRAVERSE USING THE AIRDATA MULTIMETER 41

14.7 BACKPRESSURE COMPENSATED COMPARISON READINGS 41

14.8 NONBACKPRESSURE COMPENSATED COMPARISON READINGS 41

15.0 METER & FLOWHOOD MAINTENANCE 42

15.1 METER MAINTENANCE 42

15.2 FLOWHOOD MAINTENANCE 42

16.0 RECALIBRATION AND REPAIR INFORMATION 43

AIR BALANCE MANUALS & TRAINING PROGRAMS 43

WARRANTY 44

APPENDIX A - NIST VELOCITY TESTING 45

APPENDIX B - LABORATORY DIFFERENTIAL PRESSURE TEST 46

APPENDIX C - BATTERY TEST PROCEDURE 47

REPLACEMENT PARTS LIST 49

ADM-870 INDEX 51

Copyright © Shortridge Instruments, Inc., 2008. All rights reserved. This information may

not be reproduced or duplicated in any manner, or for any purpose, without

permission in writing from Shortridge Instruments, Inc.

ADM-870 05/23/08iii

ILLUSTRATIONS

3.1 ADM-870 METER FRONT AND BACK 6

6.1 PITOT TUBE 17

6.2 AIRFOIL PROBE 18

6.4 VELGRID ASSEMBLY 21

7.1 STATIC PRESSURE PROBE 23

8.1 ADT442 TEMPROBE 25

8.2 AIRDATA MULTITEMP 26

10.1 FRAME STORAGE 30

10.2 FLOWHOOD IN CASE 30

10.3 FLOWHOOD ASSEMBLY 31

10.4 2X2 FRAME ASSEMBLY 32

10.5 1X4 FRAME ASSEMBLY 32

10.6 2X4 FRAME ASSEMBLY 32

10.7 1X5 FRAME ASSEMBLY 33

10.8 3X3 FRAME ASSEMBLY 33

ADM-870 05/23/081

1.0 INTRODUCTION

You will find these instructions much easier to follow if you have the meter in front of you as you read through

them. You can note the various connections and press the keys, observing the displayed results as you read

through the various procedures. The operation of the meter is quite simple and straightforward, as will

become apparent after a little practice.

The AirData Multimeter performs the following essential functions. This meter measures air velocity when

used with a pitot tube, AirFoil probe, or VelGrid and automatically corrects for density variations due to local

temperature and barometric pressure. Velocity ranges are 0-29,000 fpm using a pitot tube, 0-5,000 fpm using

the AirFoil probe, and 0-2500 fpm using the VelGrid.

When used with the Series 8400 FlowHood System, this unit measures air flow and may compensate for

density and backpressure effects, allowing direct air flow readings from 0-2500 cfm. Accurate differential

pressure measurements can be obtained from 0.0001 in wc to 60.00 in wc. Absolute pressure measurements

range from 10-40 in Hg. Temperatures can be measured from -67/F to 250/F, either individually, or in

conjunction with an air flow or velocity measurement.

The Model ADM-870 AirData Multimeter performs these additional functions which greatly simplify the

complex technical requirements of highly demanding test and balance projects. This model features an

automatic mode which registers repeated measurements for any capability, with sequential storage and recall

of up to 100 automatically or individually obtained measurements, with sequence tags for each value. Recall

of the sum and average of the stored sequence is available at any point, without terminating the process.

Flow and velocity measurements may be displayed in either local air density or the standard density (mass

flow) sea level equivalent.

Internal calibration and zeroing of the AirData Multimeter are fully automatic. No external adjustments are

ever needed. This instrument is extremely tolerant of overpressure, and is unaffected by position or by

ambient temperatures from 40/F to 140/F.

It is recommended that the AirData Multimeter kit be returned to the factory at least every two years for

recalibration and software update. This preventive maintenance program will assure that the original accuracy

of the meter is maintained throughout the life of the meter.

ADM-870 05/23/082

2.0 SPECIFICATIONS

AIR VELOCITY: Measured in feet per minute (fpm), or meters per second (m/s), corrected for local or

standard air density. The measurement range is 25 to 29,000 fpm with a pitot tube, and 25 to 5,000 fpm with

the Shortridge Instruments, Inc. AirFoil probe. The measurement range using the VelGrid is 25 to 2500 fpm.

Accuracy is ± 3% of reading ± 7 fpm from 50 to 8000 fpm. Pitot tube velocity readings from 8,000 fpm to

29,000 fpm are based on compressible isentropic flow theory and are not certified NIST traceable.

DIFFERENTIAL PRESSURE: Measured in inches of water column (in wc) or Pascals (Pa). The

measurement range is from 0.0001 to 60.00 in wc. Maximum safe pressures are 20 psid (900% full scale)

and 60 psia common mode. Accuracy is ± 2% of reading ± 0.001 in wc from 0.0500 to 50.00 in wc.

ABSOLUTE PRESSURE: Measured in inches of mercury (in Hg) or bars with reference to a vacuum. The

measurement range is 10-40 in Hg. Maximum safe pressure is 60 psia. Accuracy is ± 2% of reading ±

0.1 in Hg from 14 to 40 in Hg.

TEMPERATURE: Accuracy is ± 0.5/F from 32/F to 158/F with a resolution of 0.1/F using the ADT442,

ADT443, ADT444, ADT445 or ADT446 TemProbes. Meter will display readings from -67.0/F to 250.0/

F. Safe exposure range for TemProbe is -100/F to 250/F. Do not expose the plastic base of the

TemProbe or the extension wand to temperatures above 200/F.

AIR FLOW: Measured in cubic feet per minute (cfm) or litres per second (L/s), corrected for air density. This

function requires the use of the Shortridge Instruments' Series 8400 Backpressure Compensating

FlowHood System. The measurement range is 25 to 2500 cfm supply and 25 to 1500 cfm exhaust.

Accuracy is ± 3% of reading ± 7 cfm from 100 to 2000 cfm (nonbackpressure compensated readings).

AIR DENSITY CORRECTION: The air density correction range is 14-40 in Hg and 32/F to 158/F for

correction of air flow and velocity measurements. The readings represent either local density air flow or

standard density sea level equivalent (mass flow) for air flow or velocity. Readings are corrected for the

density effects of temperature and absolute pressure.

MEMORY: 100 readings with sequential recall of each reading with average and sum.

RESPONSE TIME: Five seconds or less at pressures greater than .002 in wc (180 fpm), and up to eight

seconds at less than .0003 in wc (70 fpm). SPEED-READ mode provides continuous readings in as little

as two second intervals. (Accuracy specifications do not apply).

READOUT: Eight digit, 0.5 inch, liquid crystal display (LCD).

METER HOUSING: High impact, molded, "T" grade ABS.

WEIGHT: 36 ounces, (1.02 kg) including batteries.

SIZE: 6.0" x 6.4" x 2.7" (15.2 x 16.3 x 6.9 cm).

BATTERY LIFE: Normally two working days of heavy use, or 2000 readings per charge. A set of

rechargeable type AA NiCad batteries is supplied in each meter. Batteries may be recharged up to 500

times before replacement. If rechargeable batteries are not available in a field situation, the batteries may

be replaced with 12 non-rechargeable "AA" pen cell batteries. WARNING: Do not plug the charger in

if any non-rechargeable batteries are in the meter. The meter may be seriously damaged along with the

batteries and charger.

BATTERY CHARGER: The battery charger requires 120V, 60Hz, 6W. Batteries recharge in a maximum of

10 hours, and may be left on charge for an unlimited time without harm. The temperature of the

instrument during charge should be kept between 40/F and 113/F (5/C to 45/C). The meter is fully

operational during recharge.

OPERATIONAL TEMPERATURE LIMITS: The specified accuracy for measurements is maintained over a

meter exposure temperature range of 40/F to 140/F (5/C to 60/C).

STORAGE TEMPERATURE LIMITS: -4/F to 140/F (-20/C to 60/C).

ADM-870 05/23/083

AIR BLEED: Each pressure measurement allows a small volume of air to pass through the meter. The

pressure source must be capable of supplying this volume without significant depletion to assure accurate

measurements. Bleedthrough (typ) 0.0004 cu in/in wc/measurement. Quiescent bleedthrough (max)

0.0005 cu in/in wc/minute.

TUBING: The maximum recommended length of pneumatic tubing for the measurement of air flow, velocity,

or differential pressure is 18 feet. Minimum tubing size is 3/16 inch internal diameter. The VelGrid is used

with the two eight foot lengths of 3/16 inch ID tubing furnished with the kit.

ADM-870 05/23/084

3.0 EXTERNAL FEATURES

3.1 KEYPAD

The meter keypad has eight keys. Each key may include multiple functions that may be activated, either

alternately, or by pressing the shift key followed by the function key. The instructions will often refer to

a key by only one of the functions shown on the key.

A. Upper half of keys SILVER - active only after pressing "SHIFT" key.

Control name Function

SHIFT Shifts control from lower to upper half of keys and vice versa.

UNITS Alternate action for English or metric units.

DENS Alternate action for local or standard density.

CLEAR Clears memory, auto-read and average functions.

OFF Turns the meter off.

AUTO Automatic repeat reading.

B. Lower half of keys BLACK - always active except following SHIFT.

Control Name Function

MODE Sequential action for all measurement modes (air flow, velocity, pressure and

temperature).

ASSOC Recalls associated temperature and pressure for flow and velocity

STORE Activates memory mode, then alternate action for average and for total. (This key was

labeled "MEM" prior to May, 1993).

ON Turns the meter on.

=RCL Recalls stored readings in reverse order.

RCL <Recalls stored readings in entry order.

READ Initiate measurement, and SPEED-READ or halt automatic readings.

3.2 FEATURES ON SIDES AND BACK OF METER

BATTERY CHARGER JACK

When viewed from the front, the battery charger jack is on the right side of the meter toward the top. The

battery charger plug is to be connected here.

EXTERNAL READ JACK

When viewed from the front, the external read jack is on the left side of the meter toward the top. The

plug for the external thumbswitch is connected here. This feature allows the operator to trigger air flow

measurements from the FlowHood or VelGrid handgrip while working overhead or in awkward

circumstances. The thumbswitch performs exactly the same function as the READ key.

FLAPS JACK

The flaps jack is on the back of the meter, in the upper right hand corner. The flaps plug on the FlowHood

is connected here.

TEMPERATURE INPUT JACK

The temperature input jack is centered on the back of the meter, slightly toward the top. The flexible

ADM-870 05/23/085

TemProbe sensor must be connected to this receptacle whenever temperature density correction is

desired for either flow or velocity measurements. A retractile cord connects the TemProbe or the

MultiTemp to the temperature input jack for remote temperature sensing.

OFF/RESET SWITCH

The off/reset pushbutton switch is on the back of the meter in a recess near the upper left corner. This

switch is used to reset the meter in the unlikely event that the microprocessor becomes lost in its program.

This may occur if the meter is dropped, and may cause the keypad to become nonfunctional until the

meter is reset. If the meter continues to fall into "lockout", it may have been damaged, and should be

returned for repair.

PNEUMATIC PRESSURE INLETS

Two pneumatic pressure inlets positive (+) and negative (-) are centered on the back of the meter at the

top edge and may be connected to various pressure sources for the measurement of air velocity, flow,

or pressure. Sources include the FlowHood, AirFoil probe, VelGrid, pitot tubes, static pressure probes,

or any other pressure source not exceeding the safe limits for the meter. The negative (-) inlet senses

the static pressure during flow or velocity measurements, and also is used for direct absolute pressure

measurements.

ADM-870 05/23/086

External Read Jack for

Pushbutton Handle Plug

Pushbutton Reset Switch

8 Digit, 0.5" LCD Display

SHIFT Activates Upper Half of Keys

Battery Charger Jack

DENS Local Density/Standard Density

MODE Flow/Pres/Temp/VLG/AFP/Pitot/Abs

UNITS English/Metric

ASSOC Associated Pressure & Temperature

CLEAR Clear for Memory and Speed-Read

STORE Memory/Average/Total

AUTO Automatic Readings

READ Read/Hold for Speed or Halt

RCL <Recall in Entry Order

=RCL Recall in Reverse Order

OFF Power Off

ON Power On

Positive (+) Pressure Port

Negative (-) Pressure Port

Flaps Jack for FlowHood Flaps Plug

Threaded Insert for Attachment to FlowHood with

Captive Screw

Calibration Label with Serial Number & Date

Temperature Input Jack for TemProbe,

Retractile Cord or MultiTemp

Battery Compartment Cover - Remove the 8 Small

Phillips Head Screws to Test or Replace the

Batteries (12 AA NICAD)

Four Large Phillips Head Screws That Hold

the Meter Case Together - DO NOT REMOVE

FIGURE 3.1 ADM-870 METER FRONT AND BACK

ADM-870 05/23/087

4.0 DISPLAY MESSAGES AND PROMPTS

4.1 READ PROMPTS

The following ten prompts all include the term READ, which is a signal for the operator to press the READ key

to trigger the actual measurement.

English Units

CF: READ

This display indicates that the meter has been placed in the air flow function (cfm) and will appear

automatically upon power up if the flaps plug of the FlowHood is connected to the meter.

/F: READ

This display indicates that the meter has been placed in the temperature function (/F).

FP: READ

This display indicates that the meter has been placed in a velocity function (fpm).

Hg: READ

This display indicates that the meter has been placed in the absolute pressure function (in Hg) with

reference to a vacuum.

IN: READ

This display indicates that the meter has been placed in the differential pressure function (in wc).

Metric Units

BAR READ

This display indicates that the absolute pressure readings will be displayed in bars (1 bar = 100 kPa) with

reference to a vacuum.

/C: READ

Display indicates that the temperature readings will be displayed in degrees Celsius /C).

LS: READ

This display indicates that the meter has been placed in the air flow function and will read in litres per

second (L/s).

/S: READ

This display indicates that the velocity readings will be displayed in meters per second (m/s).

PA: READ

This display indicates that differential pressure readings will be displayed in Pascals (Pa).

4.2 MEASUREMENT READOUTS

In the following 12 examples, n indicates a number in the displayed result. If no sign is displayed, the result is

a positive number. A negative sign indicates a negative number. English and metric units are shown for each

example.

English Units

CF:c± nnnn

Indicates that the result represents an air flow measurement (cfm). "C" indicates that the result has been

compensated for backpressure effects.

CF:u± nnnn

Indicates that the result represents an air flow measurement (cfm). "U" indicates that the result has not

been compensated for backpressure effects.

FP: ± nnnnnn

Indicates that the displayed result represents a velocity measurement (fpm).

/F: ± nnn.n

Indicates that the displayed result represents a temperature measurement (/F).

Hg: ± nn.n

Indicates that the result represents an absolute pressure measurement (in Hg).

ADM-870 05/23/088

IN: ± nnnnn

Indicates that the result represents a differential pressure measurement (in wc).

Metric Units

BAR n.nnn

Indicates that the result represents an absolute pressure measurement (bar). (One bar = 100 kPa).

/C: ± nnn.n

Indicates that the displayed result represents a temperature measurement (/C).

LS:c± nnnn

Indicates that the result represents an air flow measurement (L/s). "C" indicates that the result has been

compensated for backpressure effects.

LS:u± nnnn

Indicates that the result represents an air flow measurement (L/S). "U" indicates that the result has not been

compensated for backpressure effects.

PA: ± nnnnn

Indicates that the result represents a differential pressure measurement (Pa).

/S: ± nnnnnn

Indicates that the displayed result represents a velocity measurement (m/s).

4.3 FUNCTION READOUTS

The following prompts and messages are listed in alphabetical order.

8.8:8.8.8.8.8.8

A sequence of eights will be flashed briefly to test the operation of the display each time the meter is turned

on.

ABS PRES

This signal will be flashed when the absolute pressure mode is selected, and also each time the READ key

is pressed when in the absolute pressure mode.

AIRFOIL

This signal will be flashed when the AirFoil probe mode is selected and also upon each subsequent

operation of the READ key.

AUTOSTOR

This message indicates that the meter has been placed in the automatic memory mode, which integrates

the automatic reading function with the sequential storage function, and permits recall of the readings, sum

or average at any point. Press the READ key to initiate the actual reading process. Press and hold the

READ key until HALT is displayed in order to stop the automatic reading sequence.

AUTO RDY

This message indicates that the meter has been placed in the automatic reading function. Press the READ

key to initiate the actual measurement and hold the READ key down to halt the process.

CAL

When the meter is first turned ON, it will perform a self-calibration process that takes a few seconds. The

display will read CAL during this period and the operating controls will be inhibited. No READ operations

or function changes may be made during the CAL period. The meter will also perform a brief CAL cycle

about once every thirty seconds throughout normal operation.

CALC

This message indicates that the measurement sampling period has been completed, and that the

calculations are in process. When CALC has been displayed, the sensors, or the FlowHood, may be

removed from the measurement position without affecting the result.

CF: CORR

This message indicates that the air flow measurement being performed will be backpressure compensated.

ADM-870 05/23/089

CF: UNCORR

This message indicates that the air flow measurement being performed will not be backpressure

compensated.

CLEAR

This signal is flashed as the memory, auto, or SPEED-READ function is cleared.

DIF PRES

This signal will be flashed when the differential pressure mode is selected, and also upon each subsequent

operation of the READ key.

ENGLISH

This message indicates that the readings will be in English units. Pressing the SHIFT key and then the

UNITS key will switch the meter to metric units. The meter automatically starts up in English units when first

turned on. Metric startup is available if requested.

ERROR

This message advises the operator that the backpressure compensated air flow measurement, which is in

process, is invalid because the numerical ratio of the two parts of the measurement sequence exceeds the

predetermined limits. Normally this means, either that the operator has made a procedural error, or that a

dynamic change (such as a changed damper setting) has occurred between the two parts of the

backpressure compensated air flow measurement process. ERROR will also be displayed during a memory

sequence, either manual or automatic, that has been interrupted by an alteration in the meter set up, such

as the connection of the flaps plug or temperature probe.

FLO-HOOD

This message will be flashed when the FlowHood mode is selected, or when the meter is first turned on if

the flaps plug is connected.

HALT

This message will be displayed when an automatic reading sequence has been halted manually by holding

down the READ key. The individual readings, or the average and total of the readings, may now be

displayed if the memory mode is active.

LOCAL

This message indicates that flow or velocity readings will be corrected for local air density. The meter

automatically starts up in the local density mode.

LOCHARGE

This message indicates that the battery cells are nearing the end of their useful charge. The meter will

function normally for approximately one more hour of operation before recharge is required.

LS: CORR

This message indicates that the air flow measurement will be backpressure compensated.

LS: UNCORR

This message indicates that the air flow measurement will not be backpressure compensated.

METRIC

This message indicates that the readings will be in metric units as selected by first pressing the SHIFT key

and then the UNITS key.

NEGPITOT

This message indicates an invalid, negative, pitot tube velocity reading. This may result from reversed tube

connections to the meter, or from other conditions described in the section on VELOCITY MEASUREMENT,

PITOT TUBE.

NO FLAPS

This message advises that the flaps plug on the FlowHood has not been connected to the meter for air flow

measurements. The meter senses the position of the flaps through the flaps plug.

NO PROBE

This message appears when the operator has neglected to install the TemProbe sensor prior to initiating

ADM-870 05/23/0810

a temperature measurement. This term is also displayed if the TemProbe or extension cord has been

damaged so as to create an open circuit.

OPEN FLAP

This message advises that the operator has attempted to perform a nonbackpressure compensated air flow

measurement at greater than 500 cfm with the flaps closed. The flaps must be opened to proceed.

OVERANGE

This display advises the operator that the measurement being attempted is beyond the range of the meter.

OVERANGE may also be displayed if internal voltage settings or linearity is out of proper range. (Contact

factory if meter continues to read OVERANGE at inappropriate times).

PITOTUBE

This signal will be flashed when the Pitot tube mode is selected, and also upon each subsequent operation

of the READ key.

PROBE

Flashes during the actual temperature measurement to confirm TemProbe function.

READING

This term is displayed during differential pressure measurements, and also during the first reading period

of some automatic reading sequences.

RECHARGE

This message signals that the batteries have reached the end of their useful charge, and must be

recharged. The meter will turn off following the display of RECHARGE.

SHIFT

This message is displayed when the upper half of the keys are activated by pressing the SHIFT key.

SPEED

The meter will display SPEED when the SPEED-READ mode is initiated by holding the READ key down

throughout any measurement. SPEED is also displayed when SPEED readings are restarted from a HALT

condition. NOTE: Accuracy specifications do not apply to SPEED readings.

STD 70/F

This message will be flashed during air flow or velocity measurements performed without the TemProbe.

The resulting flow or velocity value will be calculated using the standard temperature, 70/F. The correction

for the ambient barometric pressure will still occur.

STORFULL

This message indicates that the number of readings in memory has reached the storage capacity of 100

readings.

STOR RDY

This message indicates that the meter has been placed in the memory mode, and that selective, individually

obtained readings may be sequentially entered into storage by pressing the STORE key, or by taking

another reading. This function permits recall of readings with the RCL keys, or of their sum and average

by pressing the STORE key, at any point.

STANDARD

This message indicates that readings will be calculated to display standard density sea level equivalent

(mass flow) as selected by the DENS key. It will also be displayed during the actual measurement interval.

TOO HOT or TOO COLD

If the internal temperature of the meter exceeds its operational limits, it will display TOO HOT or TOO COLD

and shut down. However, if there are readings in memory, the meter will continue to display TOO HOT or

TOO COLD, and will retain the readings in memory. The meter must be cooled down or warmed up, as the

case may be, before normal operation can resume.

If the meter has displayed OVERANGE after displaying either TOO HOT or TOO COLD, but has not shut

down, this message indicates that the TemProbe sensor was being exposed to temperature levels beyond

the proper operating range. Also, if TOO HOT/OVERANGE has been displayed, but the meter has not shut

down, the TemProbe sensor may have become short circuited.

ADM-870 05/23/0811

VELGRID

This signal will be flashed when the VelGrid mode is selected, and also upon each subsequent operation

of the READ key.

ADM-870 05/23/0812

5.0 USING THE AIRDATA MULTIMETER

The meter is automatically set to read in English units and local density. The SHIFT key must be pressed,

followed by the desired units or density key, to shift the meter into either the metric units function, the standard

density function, or both. The meter will revert to English units and local density each time it is turned off.

After being turned on, the meter will flash a full set of eights to test the display, and will display CAL while

performing a brief internal calibration test. If the FlowHood flaps plug is plugged into the meter, the meter will

display FLO-HOOD and then CF: READ. If the flaps plug is not plugged in, the meter will display DIF PRES and

then IN: READ and is then ready for differential pressure measurements. The functions shown in the lower dark

colored section of each key may be activated directly by pressing the desired key. The SHIFT key must be

pressed prior to the selection of any of the functions shown in the light colored upper half of each key. When

the MODE key is pressed, the selected function will be briefly displayed, immediately followed by display of the

two letter abbreviation for the function being used, combined with READ; for example, CF: READ.

After the READ key is pressed, the selected function will again be briefly displayed. READING will be displayed

during the measurement period, followed by CALC during the calculation period. Then the measurement result

will be displayed.

Each successive measurement is triggered by pressing the READ key, which also clears all previous data from

the display. The meter remains in the previously selected units and function.

The meter will turn off automatically if it has not been used for eight consecutive minutes, except when readings

have been entered into memory; or if performing measurements in the SPEED-READ mode or the automatic

reading mode.

5.1 AUTOMATIC READINGS

Automatic sequential readings are initiated by first pressing the function and units keys required, then pressing

the SHIFT key and the AUTO/READ key. The meter will display AUTO RDY. Pressing the READ key starts

the actual measurement process. The automatic reading sequence may be interrupted by holding the READ

key down until the reading in process has been completed. Release the READ key when HALT is displayed.

The automatic reading sequence will be resumed if the READ key is pressed again when the display reads

HALT. The automatic reading function may be exited by pressing the SHIFT key, followed by the CLEAR key.

5.2 MEMORY/AVERAGE/TOTAL FUNCTION

The memory/average/total function may be used with any of the measurement modes and allows the storage

of up to 100 individual readings for later recall of each reading, the average and sum of the readings. This

capacity may be used to facilitate such tasks as pitot tube duct traverses, VelGrid face velocity measurements,

and the recording of outlet readings. These functions also assist in the averaging of coil face velocities and

temperatures, static pressures, and pressure drop readings.

The STORE key is used only with the memory related functions and serves several purposes. The STORE key

is first used to place the meter in the memory function, and then is used to alternately display the average and

the sum of the readings, after the readings have been entered into memory. This key is also used to interrupt

the memory entry process. The last reading of a sequence is entered into memory by pressing the STORE key.

The memory is cleared by pressing the SHIFT key and then the CLEAR/STORE key.

5.2.1 MEMORY OPERATION

Press the MODE key. The meter will flash the selected function followed by a READ prompt. Press the STORE

key (MEM key prior to April, 1993). The meter will display STOR RDY. When the READ key is pressed, the

meter will display the selected function during the measurement. (If the TemProbe is not in place during flow

or velocity measurements, the meter will flash STD 70/F prior to the display of the result). When the READ key

is pressed again, the reading that is on display will be entered into memory as the next reading is being taken.

The meter will briefly flash the sequence number of the reading being placed in memory. A reading will not be

entered into memory until READ is pressed for the next reading, or STORE is pressed to interrupt the sequence.

The reading and memory entry process will continue as long as you continue to take readings. When the

reading shown on the display is the last reading desired, or if you wish to check the average and sum to that

point, press the STORE key. The last reading will be entered into memory, and the number of readings that

have been taken, along with the average of the readings will be displayed: such as 07:395. The first two digits

are the number of readings taken (reading 100 is displayed as 00:nnn). The digits following the colon are the

average of the readings. Press the STORE key again to display the sum of the readings. The number of

readings in memory will not be displayed with the sum. The measurement sequence may be resumed by

pressing the READ key, and may be interrupted at any point by pressing the STORE key.

ADM-870 05/23/0813

If the meter's full capacity of 100 readings has been reached, STOR FULL will be displayed. Press the STORE

key to alternately display the average and sum, or one of the RCL keys for recall of the individual readings. The

memory must be cleared before a new reading sequence begins.

5.2.2 RECALL

The RCL keys are used to sequentially recall all readings that are in memory, and in general are used after the

STORE key has been pressed. A brief press of a RCL key will advance the display one number at a time.

Holding a recall key down will fast forward or fast reverse the display through all the numbers that are in memory.

5.2.3 DISCARD READING

A displayed reading may appear to be abnormal, may have been taken at the wrong time, or with an improperly

positioned sensor. If a RCL key is pressed while a reading is still on display, that reading will be bypassed, and

discarded, and will not be entered into memory. The interrupted sequence may be resumed by pressing the

READ key. The readings taken after pressing the recall key to discard a reading will be integrated with the

readings already in memory.

5.2.4 CLEAR MEMORY

The memory is cleared by pressing the SHIFT key followed by the STORE key. This sequence removes all

readings from memory. Press the STORE key a second time and a new averaging sequence will be initiated.

NOTE: Readings are still in memory after the SHIFT key has been pressed. Pressing the SHIFT key a second

time will return the meter to the previous mode and the existing readings will remain in memory.

The measurement mode or other conditions may not be changed while the meter is in the memory function. The

meter may not be turned off, either automatically or manually, after the first reading has been placed in memory

unless the SHIFT key is first pressed, followed by the CLEAR key. This feature reduces the risk of accidental

loss of readings from memory.

5.2.5 ERROR

ERROR will be displayed if the TemProbe is inserted or removed during an averaging sequence for flow or

velocity readings. That is, if the first reading in memory was taken with the TemProbe installed, then all following

readings must be taken with the TemProbe in place.

5.3 AUTOMATIC READING MEMORY

The automatic reading function and the memory function may be combined to gain the increased resolution

afforded by the increased time base of the measurement interval. This function permits the operator to store

up to 100 fully automatic, repeated readings for the same function. This measurement and storage process

will continue until interrupted by the operator, or until the meter registers STORFULL at 100 readings.

The auto-reading memory sequence is initiated by first pressing the function and units keys required. Then

press the SHIFT key, followed by the AUTO/READ key, then press the STORE key. The meter will display

AUTOSTOR, at which point the actual measurements are initiated by pressing READ.

The auto-reading memory sequence may be interrupted by holding the READ key down until the measurement

in process has been completed. Release the READ key when HALT is displayed. The auto-reading memory

sequence will be resumed if the READ key is pressed again. When the auto-reading memory sequence has

been completed or interrupted, press the STORE key. The number of readings and the average will be

displayed. Press the STORE key a second time to display the sum of the readings, or press one of the RCL

keys to recall individual readings. This function may be exited by holding the READ key down until the display

reads HALT, then pressing the SHIFT key followed by the CLEAR key.

5.4 SPEED-READ FEATURE Note: Accuracy specifications do not apply to SPEED readings.

The SPEED-READ feature is used for fast automatic readings. This mode may be used for all primary functions

and is especially useful for proportional air balance, which requires that the damper positions be adjusted while

the air flow is being measured at the outlet. One person using the FlowHood set for SPEED-READ, can very

quickly relay the required damper changes to another person who is adjusting the dampers. Damper

adjustments must always be made on a proportional, percentage change basis when using the SPEED-READ

feature, since these readings are not compensated for backpressure.

SPEED-READ is also useful for monitoring or averaging any measurements that are changing rapidly, such as

fluctuating or "hunting" damper or temperature controls. Velocity readings at turbulent locations can also be

quickly averaged by using the memory mode.

SPEED-READ must not be used for tasks which require moving a probe or the FlowHood from one location to

another. Examples of improper uses are pitot tube traverses, preliminary and final outlet readings using the

ADM-870 05/23/0814

FlowHood, and very low readings of building or room air pressures.

The first reading taken after moving a sensor is not valid when using SPEED-READ and must not be relied upon.

At least two or three more readings would have to be taken to assure a stable readout. It is faster to take

individually triggered readings whenever the process requires changing positions.

5.4.1 SPEED-READ OPERATION

Hold the READ key down until SPEED is displayed. Release the READ key immediately when SPEED is

displayed and automatic fast readings will begin and continue until the sequence is interrupted by pressing the

READ key until HALT is displayed. (Release the READ key immediately when HALT is displayed or the reading

process will begin again). Pressing the READ key again will restart the SPEED-READ process. The SPEED-

READ function may be terminated while HALT is displayed by pressing the SHIFT key, followed by the CLEAR

key, or by turning the meter off.

The memory function may be activated while HALT is being displayed by pressing the STORE key. AUTOSTOR

will be displayed. Press the READ key and up to 100 subsequent readings will be entered into memory.

Backpressure compensated air flow measurements can not be made in the SPEED-READ function. Also, the

SPEED-READ function can not be entered directly following a change in the flaps position. This limitation is

designed to prevent accidental initiation of the SPEED-READ function while backpressure compensated

readings are being taken with the FlowHood.

SPEED-READ can not be entered when the flaps are closed, or when the meter is already in the memory mode.

However, SPEED readings can be made with the flaps closed by first starting SPEED-READ with the flaps open

and then closing the flaps. This allows very low flow readings during the proportional balancing process.

ADM-870 05/23/0815

6.0 VELOCITY MEASUREMENT

Air velocity measurements obtained with the AirData Multimeter are automatically corrected for the density effect

of barometric pressure. The TemProbe must be used to obtain readings corrected for the density effect of

temperature. If the TemProbe has not been connected to the meter, STD 70/F will be flashed during the

calculation time, and all data will be processed using the standard temperature of 70/F.

An optional temperature value associated with the previous velocity measurement (associated temperature) may

be recalled, without leaving the velocity mode, by pressing the ASSOC key after the velocity reading has been

displayed (if the TemProbe was connected during the reading). The associated differential pressure value may

also be displayed by pressing the ASSOC key again.

6.1 VELOCITY CORRECTION FACTORS

Prior to the development of capture hoods for measuring air flow directly, face velocity and jet velocity

measurements were used to calculate air flow. Since the primary interest was in determining accurate

volumetric air flow, obtaining accurate velocity measurements was not a priority. Only the repeatability of the

velocity readings was considered to be important.

The manufacturers of the various air movement devices developed what became known as Akor "area

correction factors". These Akfactors actually corrected for the variations in velocity reading for the different

types of instruments being used to measure velocity. It was necessary to develop different Akfactors for each

type of test instrument used to test velocity, because each type is affected differently by the configuration of a

given air movement device (AMD).

Use of the terms Akor area constant diverted attention from the fact that average face velocity readings taken

with different instruments on the same AMD were not the same, nor were readings taken with the same

instrument likely to be the same on two or more AMDs with identical areas, but with different configurations.

We continue to use Akfactors when calculating the air flow for very large diffusers and other special applications.

The use of an Akfactor is not appropriate, however, in the measurement of face velocities, work zone velocities

or in calculating air flow from velocity measurements at most air movement devices such as Clean Room HEPA

filters, chemical exhaust hoods, safety cabinets, laminar flow work stations, coil and filter face velocities, kitchen

exhaust hoods or any air movement device that affects velocity measuring instruments by its shape or

configuration.

Various air measurement instruments will display differing readings when used on various (AMD) air movement

devices, but the resultant calculated velocity or flow will be the same if the correct "k" factor is used for each

particular instrument on that device. This correction factor is not an area correction factor,"Ak" (and never really

was), but is actually a "Kv" velocity correction factor which must be applied to the velocity readings obtained with

a specific instrument used in a specific manner on a specific AMD.

The area of the AMD is the gross active face area (frame to frame actual face area, plus leakage or bypass

areas). The measured velocity multiplied by the correct "Kv" results in a corrected velocity reading that

represents the true average face velocity relative to the gross active area. The measured velocity, multiplied

by the "Kv", multiplied by the active face area, results in a calculated volumetric flow in cfm, l/s, etc.

Ideally, the manufacturers of the various air movement devices (AMD) will eventually develop and provide Kv

correction factors and procedures to be used with each of their products and various velocity measurement

instruments.

In the meantime, Kv factors will have to be established through field testing of AMDs in the following manner:

1. Determine the gross active area of the filter, coil, grille, opening or exhaust hood. Be sure to deduct

the area of all obstructions to air passage such as support bands, T-bars, glue line and repaired

areas on HEPA filters. The total intake area of an exhaust hood includes all areas of air entry,

including the space behind and around the sash, under the threshold, and through service openings.

It is accepted practice to assume that the velocity through these additional areas is the same as that

of the sash opening area.

2. Determine the "actual" volumetric air flow through the given AMD air movement device. Pitot tube

duct traverse is likely the most reliable means of determining the actual air flow. Direct air flow

measurements can also be used in areas where duct air velocity measurements are not practical,

by using the FlowHood with custom designed tops.

ADM-870 05/23/0816

3. Calculate the effective average face velocity (fpm) by dividing the actual air flow measured in Step

#2 (cfm) by the gross active face area (sq ft) calculated in Step #1.

4. Measure the average face velocity at the AMD using the VelGrid, AirFoil probe or other velocity

instrument being tested for a Kv. Document the procedure used to obtain the average face velocity

including all factors such as: the instrument used, the sensing probe positions, spacing of the velocity

sample points and the number of readings taken to obtain the average for each measurement

location. Always record the instrument type and any specific set up conditions such as whether

readings were taken in local or standard air density, and whether or not the correction included

temperature.

5. Calculate the velocity correction factor "Kv" for this particular AMD by dividing the effective average

velocity obtained in Step #3 above by the measured velocity obtained in Step #4 above. This "Kv"

factor should now be used routinely as a required multiplier to correct velocity readings taken at this

specific AMD design, model and size. The specific procedures developed for measuring air

velocities at a given AMD must always be used to obtain the air velocity measurements.

This "demanding" five step procedure seems to leave little room for the "art" of Testing and Balancing. This is

not altogether true. The measurement of the air velocity in Step #4 is affected by the position and orientation

of the air velocity measuring probe. By selective experimental positioning of the sampling point locations, a

procedure can be developed which will result in a Kv for this particular AMD very near or equal to 1.0.

The face velocity test procedure should be included in the AMD test report. The result is a documented,

repeatable face velocity measurement that can be confirmed by a trained technician using the proper

instrumentation and following the test procedure. This procedure may also be used by laboratory personnel to

retest the air flow at periodic intervals to confirm that the flow still conforms to test report data.

6.2 PITOT TUBE VELOCITY MEASUREMENT

The pitot tube is primarily used to obtain air velocity measurements in ductwork. A pitot tube is stainless steel

with a 90 degree bend at one end and two connectors at a 90 degree angle located near the base. The

measurement range of the AirData Multimeter with the pitot tube is 25 to 29,000 fpm. (calibration accuracy is

certified to 8,000 fpm.) The stainless steel pitot tube included in the AirData Multimeter kit is suitable for use in

temperatures up to 1500/F. A "traverse" of the duct is obtained by taking multiple air velocity readings at equal

area locations within the duct cross-section. See the section on AIR BALANCE MANUALS AND TRAINING

PROGRAMS for sources of detailed information on performing duct traverses and other air balance procedures.

Connect one of the tubing sections from the positive (+) port of the meter to the total pressure connection (in line

with the main shaft) on the pitot tube and connect the negative (-) port to the static pressure connection

(perpendicular to the main shaft). If the hoses are connected incorrectly the readings will show as negative air

velocity and the meter will display NEGPITOT. All passages and connections must be dry, clean, and free of

leaks, sharp bends and other obstructions.

After turning the meter on, press the MODE key until PITOTUBE is displayed. Use the retractile cord to connect

the TemProbe to the meter. Insert the pitot tube and the TemProbe into 3/8" holes drilled into the side of the

duct, being careful to align the point of the pitot tube so that it is facing directly into the airstream. If the negative

(-) connection of the pitot tube is exactly parallel to the duct, the point of the pitot tube should be facing directly

into the airstream. The shaft of the pitot tube is marked at one inch intervals to make it easier to control the

location of the pitot tube within the duct.

Press the READ key to obtain the air velocity measurement. As soon as the display reads CALC, the pitot tube

may be moved to the next traverse position.

The accuracy of pitot tube results depends heavily upon uniformity of air flow and completeness of the duct

traverse. Careful technique is critical to good results. Pitot tubes are available in several different sizes and

configurations to simplify different applications which may be encountered.

When a pitot tube is used in internally insulated ducts, small particles of fiberglass may be dislodged and

become caught in the openings of the tube. This will effect the accuracy of the readings and eventually clog the

tube. Remove the connections to the meter and blow compressed air through the bottom of the inside tube to

discharge fiberglass particles from the tip of the pitot tube.

Table of contents

Other Shortridge Instruments Multimeter manuals

Popular Multimeter manuals by other brands

Chauvin Arnoux

Chauvin Arnoux C.A 5210 G user manual

Triplett

Triplett MM300 user manual

Faithfull

Faithfull FAI DETMULTI instruction manual

Conrad Electronic

Conrad Electronic VC-227 manual

Gossen MetraWatt

Gossen MetraWatt METRA HIT 27EX operating instructions

Maxwell Digital Multimeters

Maxwell Digital Multimeters 25211 user manual