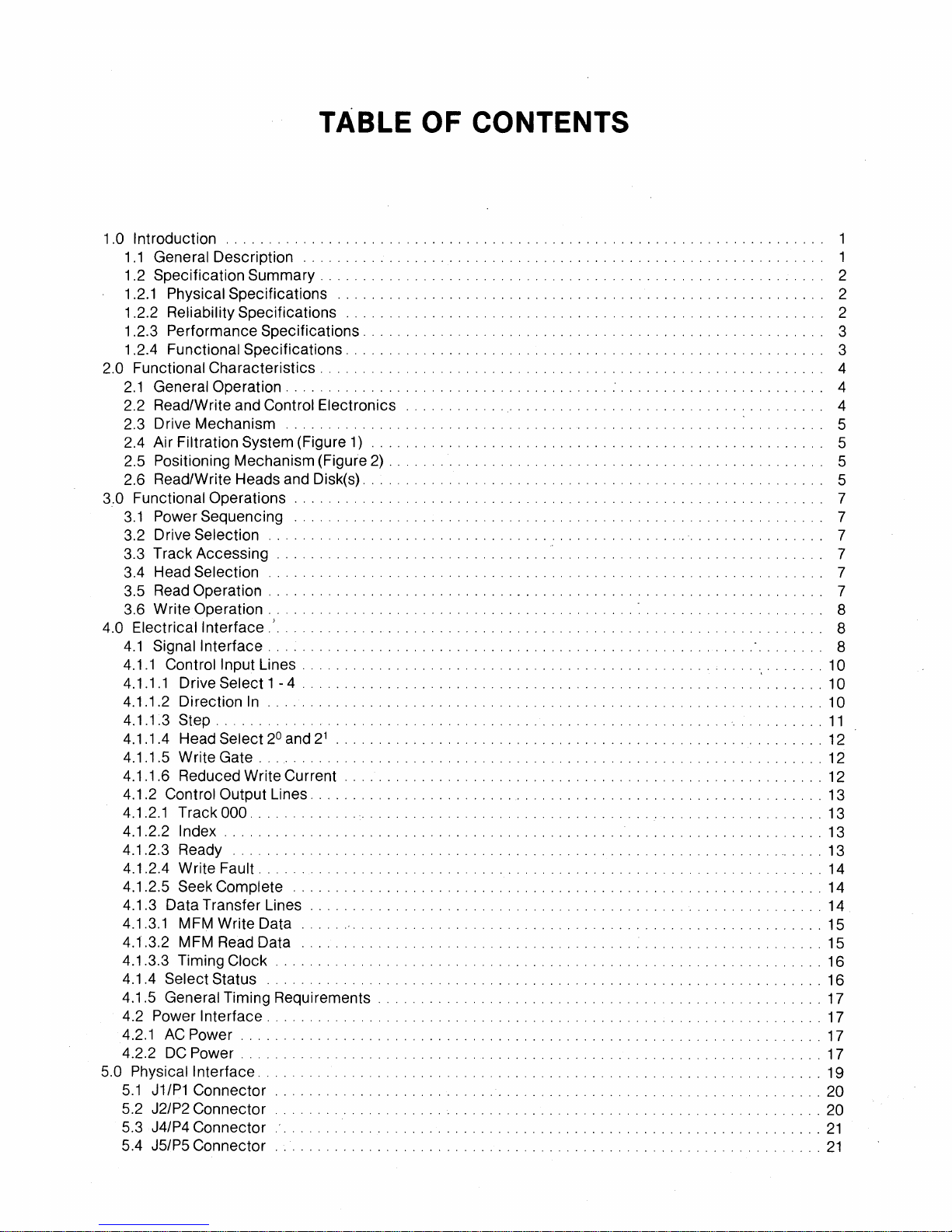

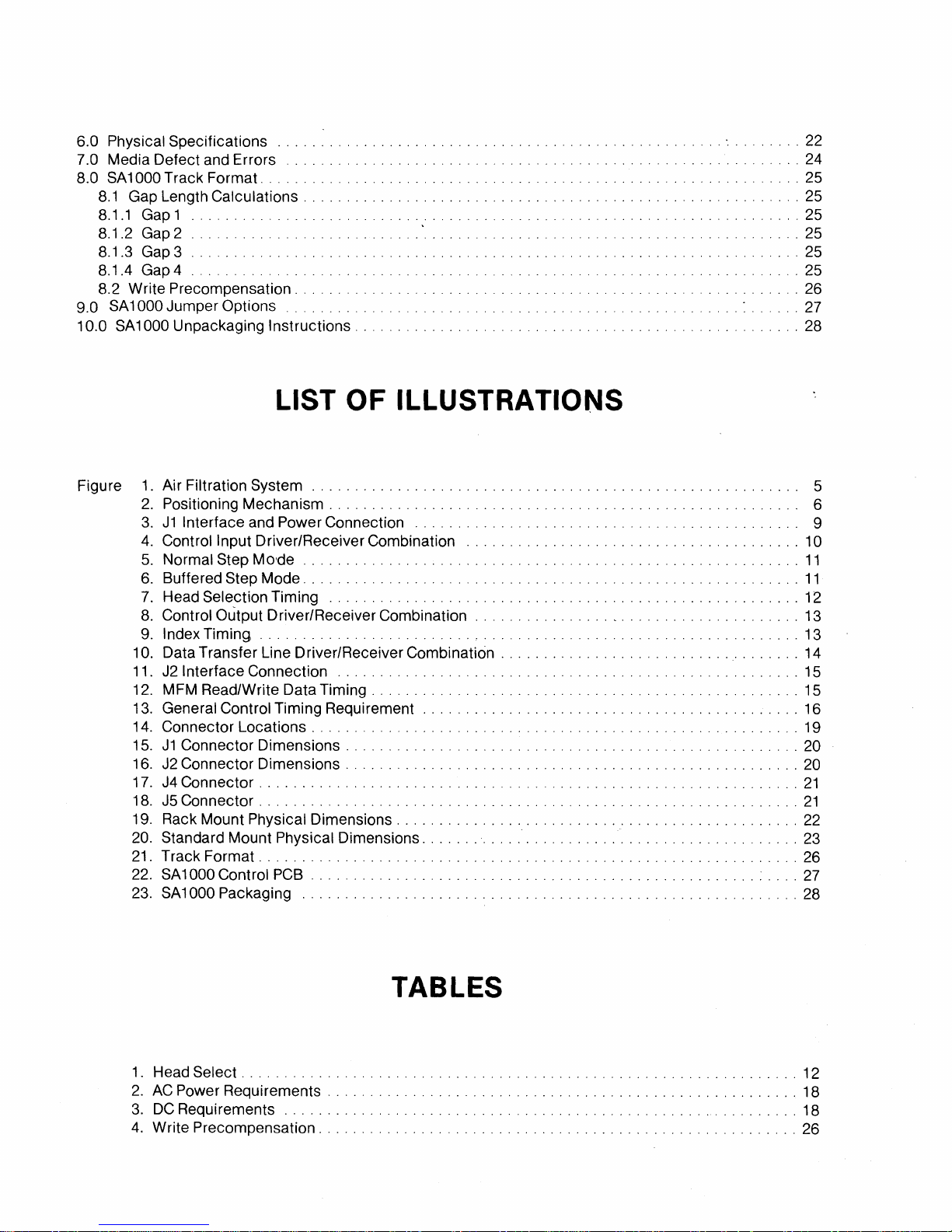

TABLE OF CONTENTS

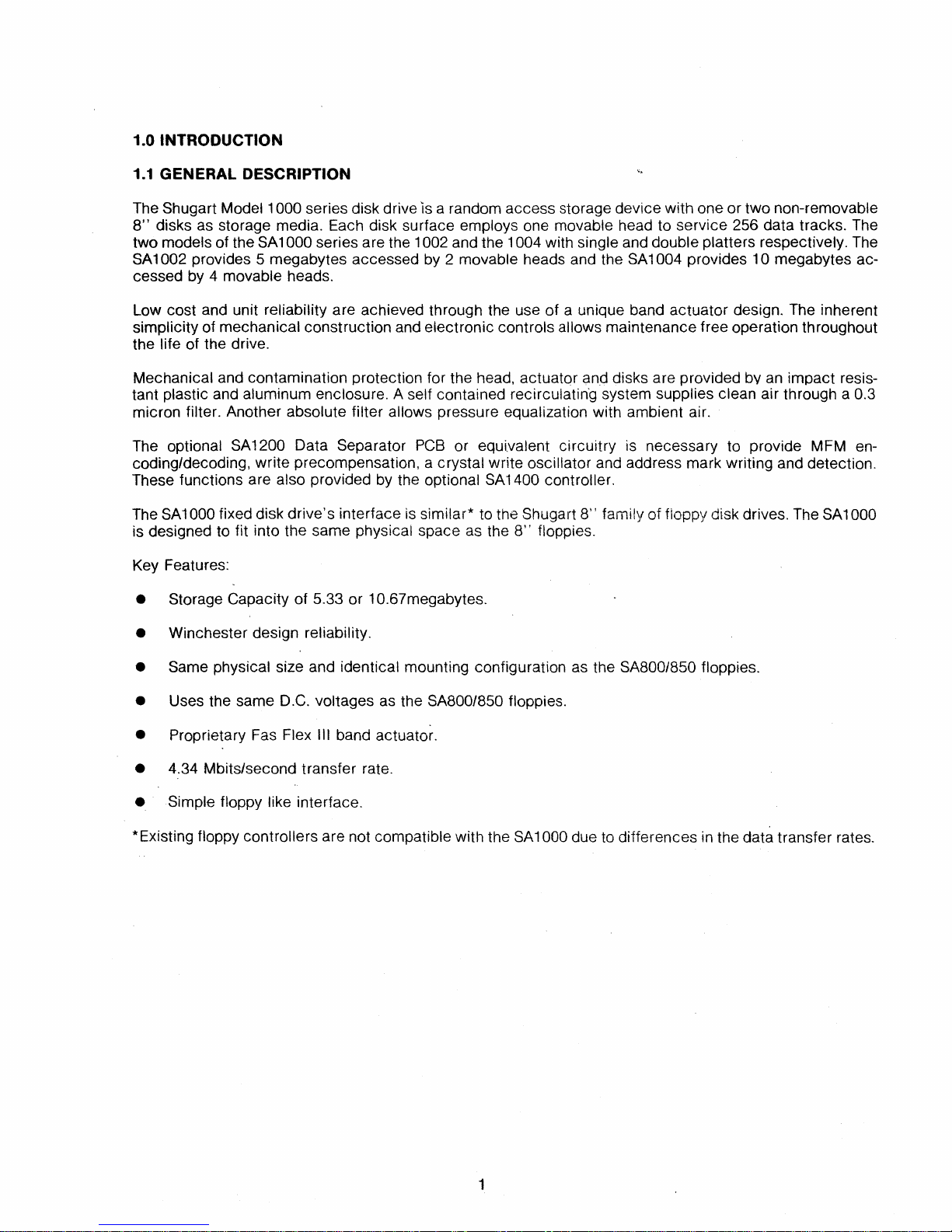

1.0 Introduction

.....................................................................

.

1.1

General Description

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1

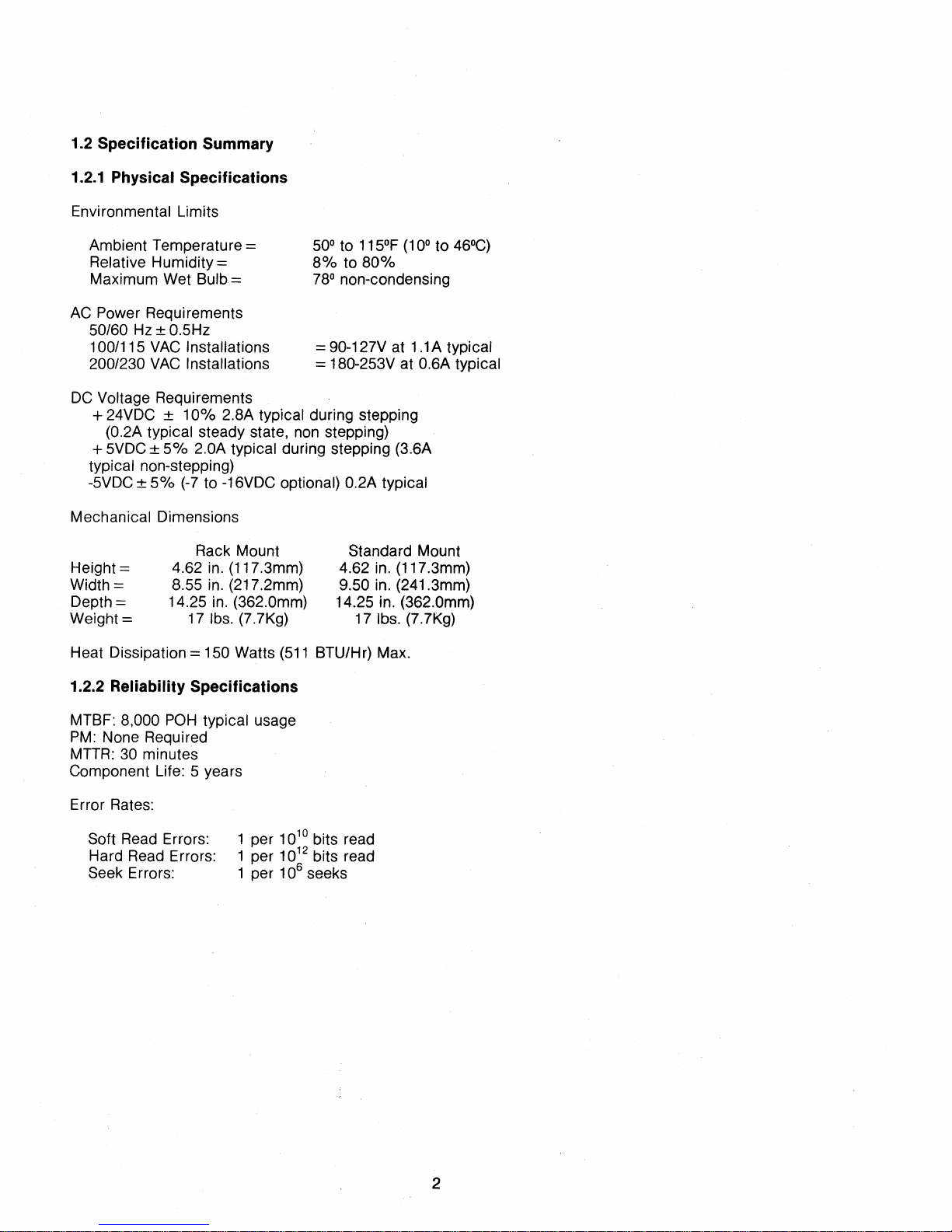

1.2 Specification Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2

1.2.1

Physical Specifications

................................

. . . . . . . . . . . . . . . . . . . . . . .

..

2

1.2.2 Reliability Specifications

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2

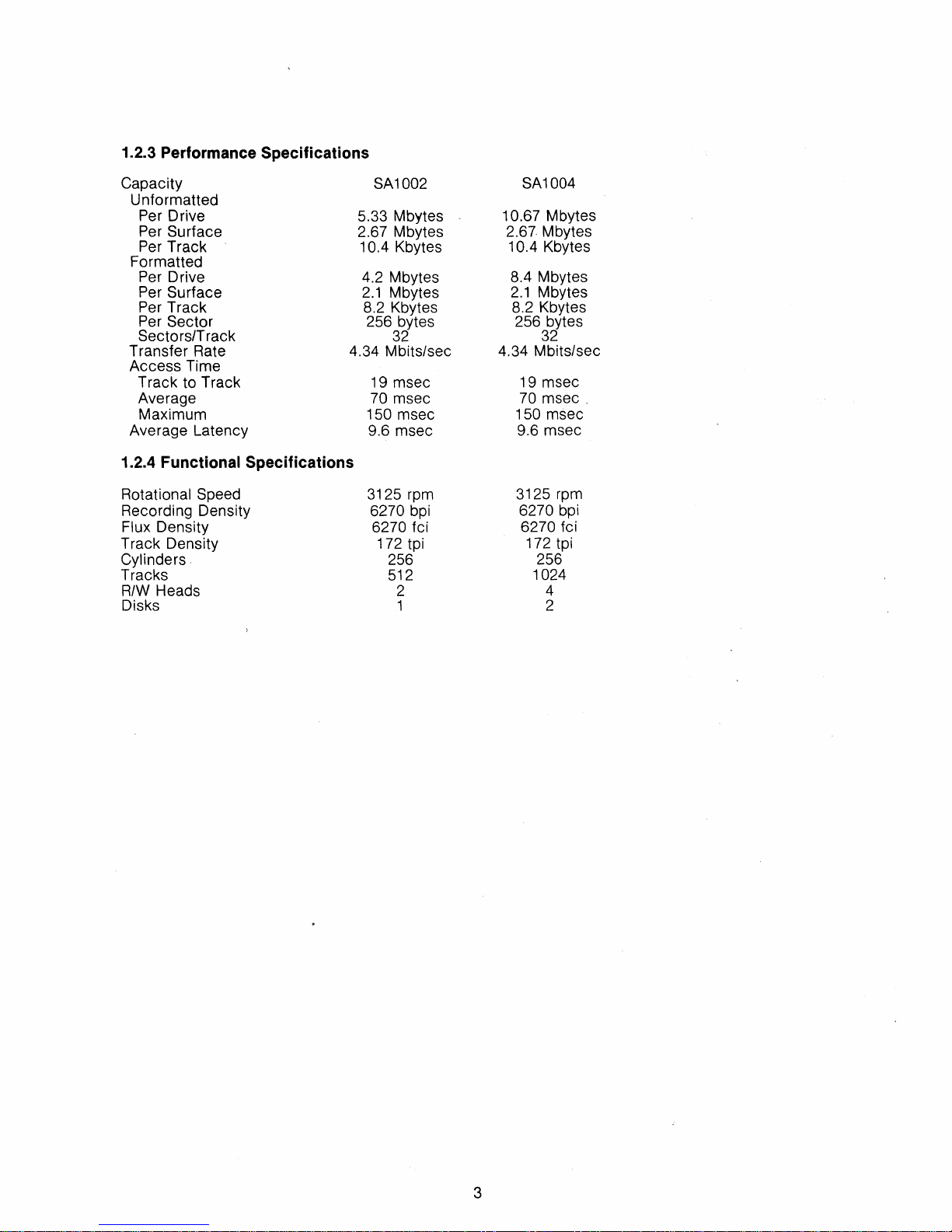

1.2.3 Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3

1.2.4 Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

3

2.0 Functional Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4

2.1

General Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4

2.2 Read/Write and Control Electronics

........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4

2.3 Drive Mechanism

.....................................................

: . . . . . . .

..

5

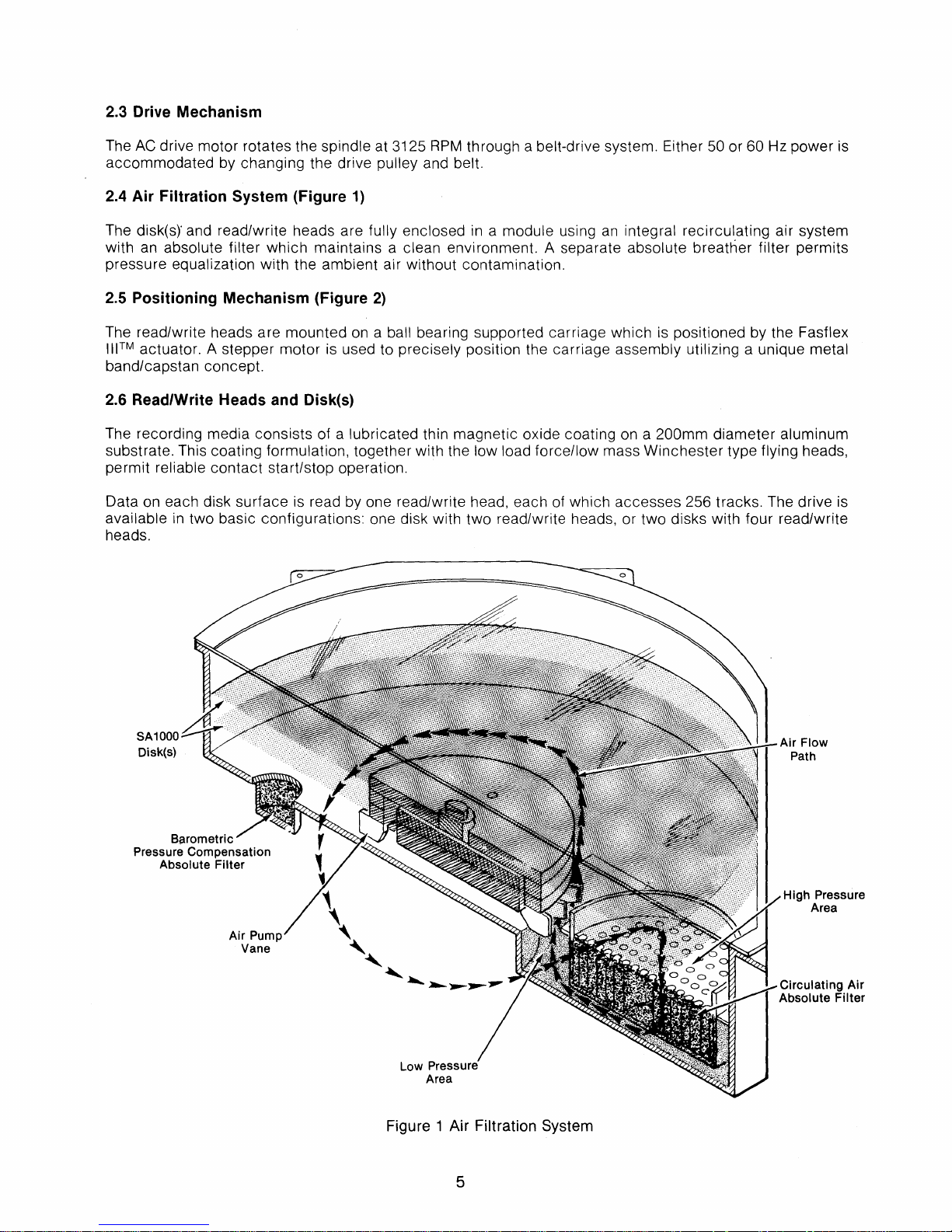

2.4 Air Filtration System (Figure

1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5

2.5 Positioning Mechanism (Figure

2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5

2.6 Read/Write Heads and Disk(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

5

3.0 Functional Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

3.1

Power Sequencing

..............................................................

7

3.2 Drive Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . .

..

7

3.3 Track Accessing

................................

'.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

3.4 Head Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

3.5

Read

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

3.6 Write Operation

...........................................

'.

. . . . . . . . . . . . . . . . . . .

..

8

4.0 Electrical Interface .

J.

. . . . . . . . . • • • • . • . . . • • . • . • • • • . . • . . . . • • • . . . . . . . . • • . . . . . . . • • . . . • •

..

8

4.1

Signal Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8

4.1.1

Control Input Lines

.....................................................

"

.......

10

4.1.1.1

DriveSelect1-4

.............................................................

10

4.1.1.2 Direction

In

.................................................................

10

4.1.1.3 Step

.......................................................................

11

4.1

.1.4 Head Select 2° and

21

.........................................................

12

4.1.1.5 Write Gate

...

,

..............................................................

12

4.1.1.6 Reduced Write Current

........................................................

12

4.1.2 Control Output Lines

............................................................

13

4.1.2.1 Track 000

...................................................................

13

4.1.2.2 Index

......................................................................

13

4.1.2.3 Ready

............................................................

13

4.1.2.4 Write Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......

14

4.1.2.5 Seek Complete

..............................................................

14

4.1.3 Data Transfer Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

......

14

4.1.3.1 MFM Write Data

......

'

.......................................................

15

4.1.3.2 MFM Read Data

.............................................................

15

4.1.3.3 Timing Clock

................................................................

16

4.1.4 Select Status

.................................................................

16

4.1.5 General Timing Requirements

....................................................

17

4.2 Power Interface

.................................................................

17

4.2.1

AC

Power

....................................................................

17

4.2.2

DC

Power

....................................................................

17

5.0 Physical Interface

..................................................................

19

5.1

J1/P1

Connector

................................................................

20

5.2 J2/P2 Connector

................................................................

20

5.3 J4/P4 Connector

...........................................................

21

5.4 J5/P5 Connector

..........................................................

21