SIATA V360 User manual

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 1 of 25

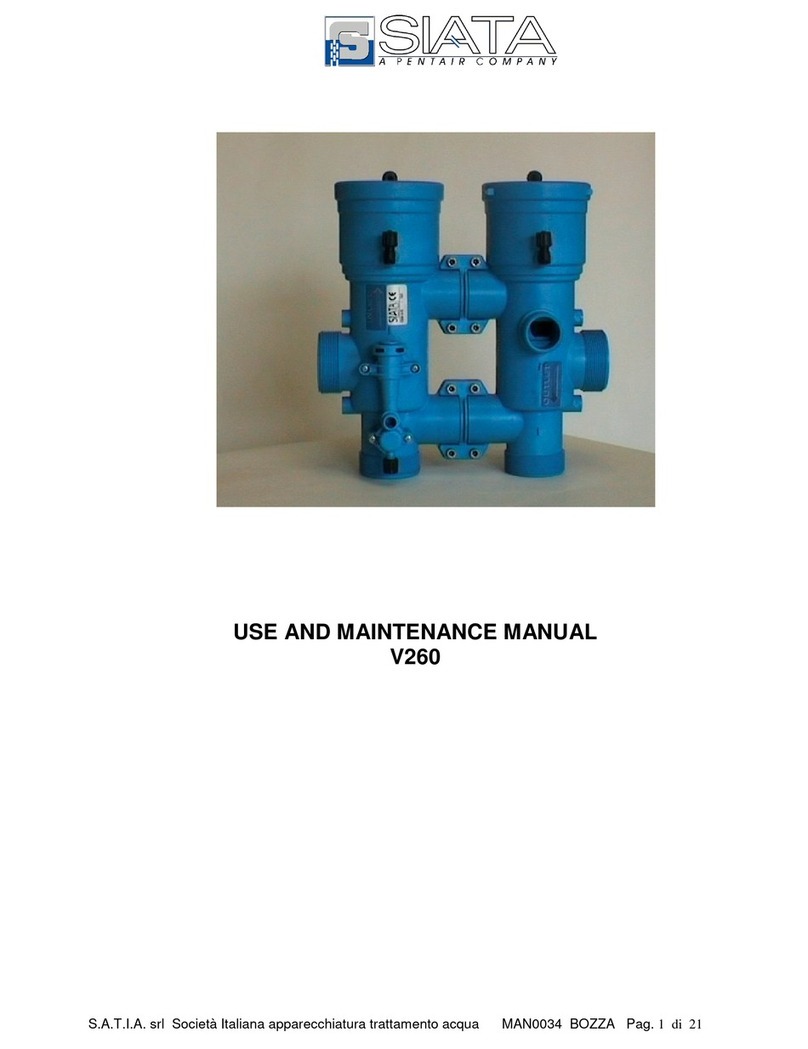

USE AND MAINTENANCE MANUAL

V360

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 2 of 25

Document Revision Revision note Date

MAN0031 A Draft

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 3 of 25

INDEX

GENERAL CHARACTERISTICS – TECHNICAL SPECIFICATIONS 4

COUNTERCURRENT AND FAST RINSE LOADS 5

DIMENSIONS 6

FUNCTIONAL DIAGRAMS 7-9

FUNCTIONAL DIAGRAMS (with countercurrent flow regulator) 10

USE VARIATIONS 11-13

USE SPECIFICATIONS 14

VALVE/TIMER CONNECTIONS 15-18

INJECTOR TABLES 19

FLOW CONTROL PREVIEW V360 20

TIMERCHOICETABLE 21

BASIC VALVE COMPONENTS SOFTENING AND DEMINERAL. 22

BASIC STANDARD FILTER COMPONENTS 23

NORMAL MAINTENANCE OPERATIONS 24

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 4 of 25

GENERAL CHARACTERISTICS – TECHNICAL SPECIFICATIONS

The “360” valves represent an essential element for the realisation of systems of various types and for

various uses.

Softening – single, duplex, or on more columns for domestic industrial or laboratory use.

Demineralisation and decarbonisation – single, duplex, for laboratory and industrial use and for all uses

which require water with guaranteed quality characteristics.

Filtration – single or duplex for all applications shown above.

The valves are made from materials which guarantee the maximum durability and quality.

The valves are available with a wide range of timers, for the control of all operative phases of service and

regeneration, from the simplest electromechanical timer with a weekly timer, to the sophisticated electronic

timers in various models which allow for volume and volume/time controls, controls of salinity in

microsiemens/cm etc.

With the electronic systems, all the times of the operative phase operations are programmable, relative to

the type and dimensions of the system.

For the specific characteristics of the timers, see the relevant manual.

TECHNICAL SPECIFICATIONS

Running pressure : 2 - 6 bar

Max. Running load : 45m3/h

For variables of the value see graph : -

Countercurrent rinse load : max. 12 m3/h

Equicurrent fast rinse load : 480-1300 l/h

Equicurrent fast rinse load : max. 18 m3/h

Static resistance to pressure : 22 bar

Max quantity regenerable resin : 1200 l.

Running temperature : 5 - 40° c

Basic materials of principal components : abs + fv

Entry/exit attachments : 2” female gas

LOAD LOSS GRAPH

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 5 of 25

COUNTERCURRENT LOAD GRAPH

FAST RINSE LOAD GRAPH

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 6 of 25

DIMENSIONS

1Connection for cylinder opening

Top column

6 Exit

2Connection for cylinder closure

Top column

7 Connection top column

3Connection for cylinder opening

bottom column

8 Connection bottom column

4Connection for cylinder closure

bottom column

9 Connection for suction Ø 1”

5Entry 10 Connection for male drain Ø ISO 40

11 Connection for pilot timer control

364-A 1” ½ GAS

364-B 2” GAS

364-C 2” ½ GAS

364-D 3” GAS

364-E01 ISO 50 GLUED

364-F01 ISO 63 GLUED

364-G01 ISO 75 GLUED

364-N01 Ø60.4 GLUED

364-P01 3” NPT GLUED

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 7 of 25

FUNCTIONAL DIAGRAMS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 8 of 25

FUNCTIONAL DIAGRAMS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 9 of 25

FUNCTIONAL DIAGRAMS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 10 of

25

FUNCTIONAL DIAGRAMS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 11 of

25

VARIATIONS FOR SINGLE

SYSTEMS USE

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 12 of

25

VARIATIONS FOR DUPLEX

SYSTEMS USE

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 13 of

25

VARIATIONS FOR

DEMINERALISATION AND FILTRATION SYSTEMS USE

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 14 of

25

USE SPECIFICATIONS

Referring to the paragraph VERSIONS seen above, the various possibilities for the uses of this

valve in the various applications may be examined.

1) Single softening: the system consists of a basic valve V360A-05/05 with or without bypass,

and a timer complete with a minimum of 2 external pilots in different solutions, with which the

system may be personalised as desired.

In particular, varying the number of external pilots, it is possible to obtain the following

personalisations:

I. 2 pilots controls only the movement of the pistons of the valve

II. 3 pilots controls also an additional use closure valve

III. 4 pilots controls a use closure + a suction closure

2) duplex softening: the system is made on two columns, each of which is run by a V360A-05/05

valve. This is controlled, with water or air, by a timer with a minimum of 2 pilots per valve. The

alternating duplex systems (one column is in service while the other is in regeneration or not in

use), may be controlled by the AQUA CUBIC timer, which may be supplied in two standard

versions:

I. 5 pilots (AC5-02/05), run by volume. The system allows for use of two brine

valves plus a use closure valve

II. As a variation on this system, it is possible to substitute the two brine valves

with two on-off hidro-pneumatic valves for the closing/opening of the suction

duct(see valve V1 page 10), using an AQUA CUBIC 7-pilot timer. (AC7-

02/05)

3) Demineralisation and Decarbonisation: this is the applicative sector in which the

characteristics of the V360 valve may be best appreciated in the models V360D-04/05 & V360D-

05/05. The timer predisposed for demineralisation is electronic with external pilots, capable of

controlling an anionic and cationic column, can control the level of conductibility showing a valve in

µsiemens/cm at the exit of the system, and regenerate the system automatically. The number of

pilots of the timer is determined by the type of system required

I. AQUA IONIC 5 pilots ( AI5-02/05 ) controls the two columns + an on-off hydro-

pneumatic use closure valve

II. AQUA IONIC 7 pilots ( AI7-02/05 ) controls the two columns+ an on-off hydro-

pneumatic use closure valve+ two on-off hydro-pneumatic valves for the

closing/opening of the regenerator suction.

4) Filtration: the considerations made regarding softening are valid both for single and duplex

systems, with the exception that in this case the suction of the regenerator does not need to be

controlled.

. For further details regarding the timers, see the table of timer choice (page 23).

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 15 of

25

VALVE/TIMER CONNECTIONS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 16 of

25

VALVE/ TIMER CONNECTIONS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 17 of

25

VALVE / TIMER CONNECTIONS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 18 of

25

VALVE / TIMER CONNECTIONS

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 19 of

25

INJECTOR TABLES V360

S.I.A.T.A. S.r.l Società Italiana apparecchiature trattamento acqua MAN0031 BOZZA Pag. 20 of

25

FLOW CONTROL V360

PREVIEW

Table of contents

Other SIATA Control Unit manuals