Exhausto EBC12 Series User manual

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

3001434-2006-09-01.fm Product Instruction

EBC12-EU-01

GB

3001434-2006-09-01.fm 2/12

1P

ro

d

uc

t

i

n

f

orma

ti

on ____________________________________________________________________________

3

2Installation ___________________________________________________________________________________ 4

2.1 Fitting .................................................................................................................................................................. 4

2.2 Wiring.................................................................................................................................................................. 4

2.2.1 Connection examples.............................................................................................................................. 5

2.2.2 Example 1 - Voltage signal (fig. 5)........................................................................................................... 5

2.2.3 Example 2 - Voltage free contact (fig. 6) ................................................................................................. 6

2.2.4 Example 3 - Extra fail-safe supervision with pressure differential switch (fig. 7)..................................... 7

2.2.5 Example 4 - Continuous chimney fan operation (fig. 8) .......................................................................... 8

2.3 Installation........................................................................................................................................................... 9

2.3.1 Dipswitch setting (fig. 9-A)....................................................................................................................... 9

2.4 Commissioning ................................................................................................................................................. 10

3 Fault finding ________________________________________________________________________________ 11

4 Technical data ______________________________________________________________________________ 12

3001434-2006-09-01.fm 3/12

1 Product information

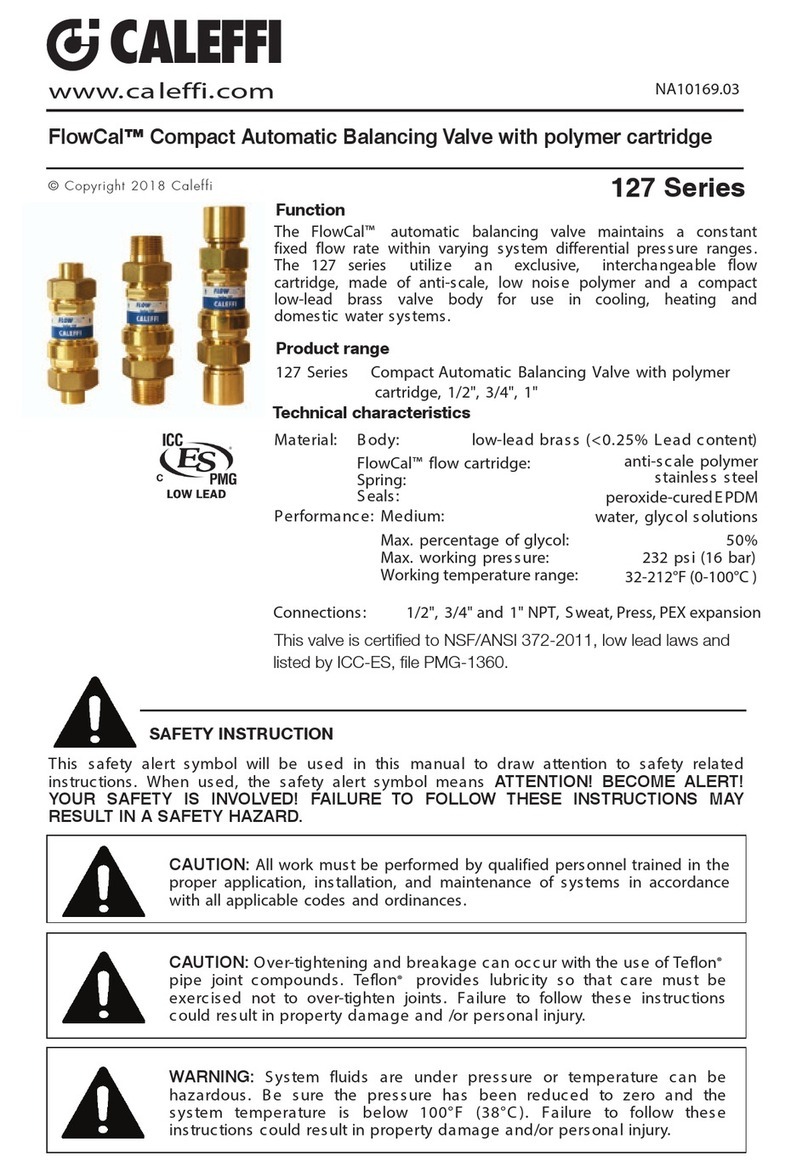

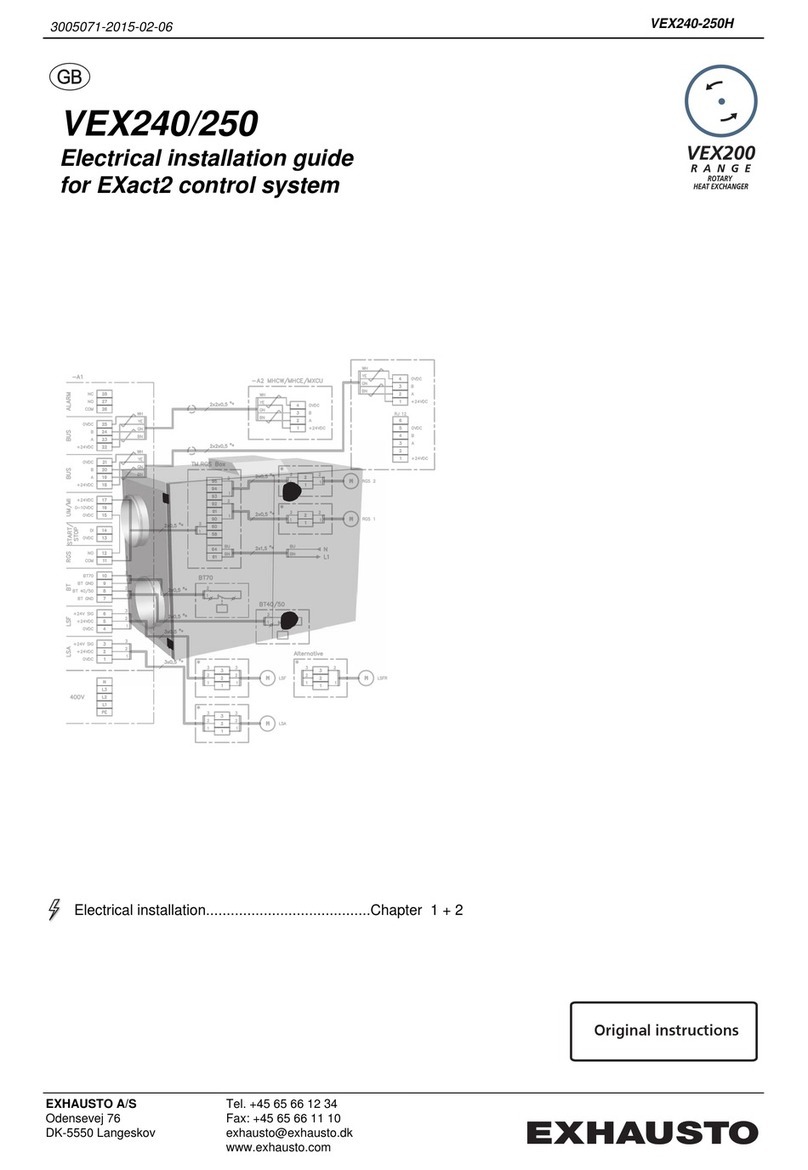

EBC12 (fig. 1) is an automatic control unit with con-

stant pressure regulation of EXHAUSTO chimney

fans. EBC12 is used for multiple systems and for boil-

ers with a modulating burner. The automatic controls

the chimney draught and cut out the boilers in case of

a fault. The automatic control unit is used for both

atmospheric gas boilers and for boilers with a forced

draught burner for oil and gas.

Function

When the boiler thermostat calls for heat, the chim-

ney fan starts at full voltage. When the faile-safe

supervision confirms sufficient chimney draught, the

burner is released and the voltage to the chimney fan

is regulated to match the draught selected (the value

can be read from the display by pushing a button, fig.

1-B).

If the draught is in adequate for more than 12 se-

conds, the burner will cut out. Inadequate draught

means that the pressure is less than 64% of the

selected value, corresponding less than 80% flow.

When the boiler cuts out, the chimney fan stops, too.

However, it is possible to select a 3-minute post-run

period by means of the POST PURGE dipswitch (fig.

1-H). Alternatively, the controls can be wired so the

chimney fan run continuously.

All in- and outputs have an LED for fail-safe supervi-

sion and servicing the system (fig. 1-I).

Additional function

The controls have two extra safety functions which

can be selected on the dipswitch (fig. 1-H), where this

is prescribed by local regulations

• MANUAL RESET after power failure and

draught fault.

• PDS-CHECK, only used for extra fail-safe func-

tion (pressure differential switch/PDS).

• EBC12 has a 0-10V output signal for controlling

several chimney fans via a frequency converter

or a motor power relay.

Accessories

EBC12 comes with a pressure transducer (XTP-sen-

sor), a tube and a probe.

Fig. 1A: Fuse holder

Fig. 1B: Setpoint button

Fig. 1C: Reset button

Fig. 1D: Potentiometer for adjusting the setpoint

Fig. 1E: Display showing the current under pressure

or setpoint

Fig. 1F: Alarm LED (red)

Fig. 1G: Up/down regulation LEDs (yellow)

Fig. 1H: Dipswitch block

Fig. 1I: ON/OFF LEDs (green)

1

3001434-2006-09-01.fm 4/12

2 Installation

2.1 Fitting

Fit the control and the pressure transducer in the

boiler room. The XTP-sensor’s probe (fig. 2-A) must

be mounted in the boiler’s fluepipe or manifold. If the

boiler is atmospheric the probe must always be

placed after the hood. When mounted outdoor the

sensor is to be mounted safe from wind and weather

influences. The sensor can be mounted in a box with

a hole (Ø2 mm) in the bottom, mainly to ensure cor-

rect reference pressure, but also to prevent water

penetration.

If the sensor is mounted to that insects have direct

access to the free (+) tube we recommend that a sin-

ter filter is mounted.

Do not enclose the pressure transducer, as the

atmospheric pressure is the reference pres-

sure.

NB! Remember to turn the pressure transducer cor-

rectly (fig. 3).

2.2 Wiring

The control terminals are spring-loaded. Use a suita-

ble size of screwdriver for fitting the conductors.

Fig. 4 shows how to fit the wires.

2

3

4

RD10139

3001434-2006-09-01.fm 5/12

2.2.1 Connection examples

The controls can be connected to a voltage signal as

well as a voltage free set of contacts - see connection

example 1 or 2. It is recommended to contact the

boiler manufacturer to ensure correct connections to

the boiler automatic control unit.

Connection example 3 shows an EBC12 connected

to a separate pressure differential switch (PDS).

When the pressure differential switch has been con-

nected, the boiler system has doubled its draught fail-

safe function (the pressure differential switch is an

accessory).

Connection example 4 shows continuous operation of

the chimney fan.

2.2.2 Example 1 - Voltage signal (fig. 5)

The example shows how a voltage signal (10-230V

AC/DC) from the boiler control is connected to the

EBC12.

• Connect the power supply to terminals 1-3.

• Connection to the boiler automatic:

• Connect the burner start signal (L) to termi-

nal 6.

• Loop terminals 7 and 14.

• The start signal to the burner will now come

on terminal 15.

• Connect Neutral to terminal 4.

• Connect the chimney fan to terminals 19-21.

• Connect the pressure transducer (XTP) to

terminals 22-24.

Terminals (fig. 5)

1 Supply L1

2 Supply N

3 Supply PE

4-5 Boiler thermostat. Opto coupler (-)(10-230V)

6-7 Boiler thermostat. Opto coupler (+)(10-230V)

8 24V DC supply to voltage free contact (boiler

thermostat)

9 0V DC supply to voltage free contact (boiler

thermostat)

14 Burner relay switch Common (max. 230V AC

8A)

15 Burner relay switch Normally Open (max.

230V AC 8A)

16 PDS-C (Common) pressure differential switch

17 PDS-NC (Normally Closed) pressure differen-

tial switch

18 PDS-NO (Normally Open) pressure differential

switch

19 Chimney fan L1

20 Chimney fan Nreg

21 Chimney fan PE

22 XTP 0V supply (pressure transducer)

23 XTP 24V supply (pressure transducer)

24 XTP 0-10V signal (pressure transducer)

25 Control signal 0V

26 Control signal 0-10V

5

3001434-2006-09-01.fm 6/12

2.2.3 Example 2 - Voltage free contact (fig. 6)

The example shows how a voltage free contact from

the boiler control is connected to the EBC12.

• Connect the power supply to terminals 1-3.

• Connection to the boiler automatic:

• Connect the voltage free contact to termi-

nals 4 and 9.

• Loop terminals 7 and 8.

• Connect the burner start signal to terminals

14 and 15.

• Connect the chimney fan to terminals 19-21.

• Connect the pressure transducer (XTP) to

terminals 22-24.

Terminals (fig. 6)

1 Supply L1

2 Supply N

3 Supply PE

4-5 Boiler thermostat. Opto coupler (-)(10-230V)

6-7 Boiler thermostat. Opto coupler (+)(10-230V)

8 24V DC supply to voltage free contact (boiler

thermostat)

9 0V DC supply to voltage free contact (boiler

thermostat)

14 Burner relay switch Common (max. 230V AC

8A)

15 Burner relay switch Normally Open (max.

230V AC 8A)

16 PDS-C (Common) pressure differential switch

17 PDS-NC (Normally Closed) pressure differen-

tial switch

18 PDS-NO (Normally Open) pressure differential

switch

19 Chimney fan L1

20 Chimney fan Nreg

21 Chimney fan PE

22 XTP 0V supply (pressure transducer)

23 XTP 24V supply (pressure transducer)

24 XTP 0-10V signal (pressure transducer)

25 Control signal 0V

26 Control signal 0-10V

6

3001434-2006-09-01.fm 7/12

2.2.4 Example 3 - Extra fail-safe supervision with pres-

sure differential switch (fig. 7)

The example shows how a pressure differential

switch (PDS) must be connected to an EBC12. The

pressure differential switch carries out extra fail-safe

supervision. With a PDS fitted, the boiler will not be

released, until both the pressure differential switch

(PDS) and the pressure transducer (XTP) have regis-

tered sufficient draught.

• Connection to the pressure differential switch

(PDS):

• Remove the factory-fit loop between termi-

nals 16 and 18.

• Connect the pressure differential switch to

terminals 16-18.

• Connect the chimney fan to terminals 19-

21. Chimney fans with an integral pressure

differential switch (PDS) must be connected

to terminals 16-21 according to the instruc-

tions enclosed with the chimney fan.

• The remaining terminals should be connected as

in example 1 or 2.

Below the connections of example 1 are shown.

Terminals (fig. 7)

1 Supply L1

2 Supply N

3 Supply PE

4-5 Boiler thermostat. Opto coupler (-)(10-230V)

6-7 Boiler thermostat. Opto coupler (+)(10-230V)

8 24V DC supply to voltage free contact (boiler

thermostat)

9 0V DC supply to voltage free contact (boiler

thermostat)

14 Burner relay switch Common (max. 230V AC

8A)

15 Burner relay switch Normally Open (max.

230V AC 8A)

16 PDS-C (Common) pressure differential switch

17 PDS-NC (Normally Closed) pressure differen-

tial switch

18 PDS-NO (Normally Open) pressure differential

switch

19 Chimney fan L1

20 Chimney fan Nreg

21 Chimney fan PE

22 XTP 0V supply (pressure transducer)

23 XTP 24V supply (pressure transducer)

24 XTP 0-10V signal (pressure transducer)

25 Control signal 0V

26 Control signal 0-10V

7

3001434-2006-09-01.fm 8/12

2.2.5 Example 4 - Continuous chimney fan operation

(fig. 8)

This example shows how the EBC12 is to be con-

nected if continuous chimney fan operation is

required.

• Connect the power supply to terminals 1-3.

• Loop terminals 4 and 9.

• Loop for terminals 6 and 8.

• Connect the release signal to terminals 14 and

15.

• Connect the chimney fan to terminals 19-21.

• Connect the pressure transducer (XTP) to

terminals 22-24.

Terminals (fig. 8)

1 Supply L1

2 Supply N

3 Supply PE

4-5 Boiler thermostat. Opto coupler (-)(10-230V)

6-7 Boiler thermostat. Opto coupler (+)(10-230V)

8 24V DC supply to voltage free contact (boiler

thermostat)

9 0V DC supply to voltage free contact (boiler

thermostat)

14 Burner relay switch Common (max. 230V AC

8A)

15 Burner relay switch Normally Open (max.

230V AC 8A)

16 PDS-C (Common) pressure differential switch

17 PDS-NC (Normally Closed) pressure differen-

tial switch

18 PDS-NO (Normally Open) pressure differential

switch

19 Chimney fan L1

20 Chimney fan Nreg

21 Chimney fan PE

22 XTP 0V supply (pressure transducer)

23 XTP 24V supply (pressure transducer)

24 XTP 0-10V signal (pressure transducer)

25 Control signal 0V

26 Control signal 0-10V

8

3001434-2006-09-01.fm 9/12

2.3 Installation

Before installation, read through item 2.3.1.

'If the boilers are not connected to an electronic

sequencer or management system we recommend

the EXHAUSTO Relay Box ES12-EU-01 to interface

a maximum of 4 boilers, use multiple relay boxes for

more boilers. Please refer to the Instruction Manual

on ES12-EU-01 for wiring details.

2.3.1 Dipswitch setting (fig. 9-A)

Before starting up the system, check that the

dipswitch setting corresponds to the required operat-

ing mode.

Factory setting: All OFF

*) Must always be in OFF position if the extra pres-

sure differential switch (PDS) has not been con-

nected.

If the factory setting is to be changed, the black top

plate must be removed to get access to the dipswitch

block (see fig. 9).

1. Remove the 4 serrated screws and lift the top

plate off the PCB.

2. Change the dipswitch setting.

Dip-

switch

Name OFF ON

1 MANUAL

RESET

Automatic reset

after mains drop-

out and draught

fault

Manual reset

after mains

drop-out and

draught fault

2POST

PURGE

No post-purge 3-minutes post-

purge

3*) PDS

CHECK

No control indicat-

ing that the pres-

sure differential

switch has been in

position NC before

starting up.

The pressure

differential

switch must be

in position NC

before starting

up

9

3001434-2006-09-01.fm 10/12

2.4 Commissioning

Commissioning must be carried out on the EBC12 to

ensure a correct draught from the system.

Proceed as follows:

1. Provisional setting of draught.

Push the setpoint button (fig. 10-B). The

selected value will be shown on the display. By

means of the potentiometer (fig. 10-C), adjust-

ments are carried out, until the required under

pressure is shown on the display (fig. 10-D).

Release the setpoint button (Fig. 10-B).

2. Start the system and wait until the boiler thermo-

stat (fig. 10-A) switches on and the draught has

stabilised (up/down adjustment LEDs are not lit).

The current draught is shown on the display (fig.

10-D).

3. Final setting of draught.

Check the draught on the boiler and adjust as

above if required.

4. Check that the fail-safe system cuts out the

boiler. Faults can be simulated by removing the

tube that goes to ’negative’ on the pressure

transducer (XTP).

The LED (fig. 10-E) is turned off and the alarm

LED (fig. 10-F) is turned on.

5. Check the start function after completing the ini-

tial adjustment. This is done by restarting the

system.

Concerning setpoint values please refer to the data of

each boiler, anyway the following may be considered

as typical values.

• Boilers with forced draught: Typical 20 - 30 Pa

• Boilers with atmospheric burner:

Typical 5 - 10 Pa

10

3001434-2006-09-01.fm 11/12

3 Fault finding

Some systems require a special start-up procedure after a safety cut-out. Follow this procedure before

pressing the RESET button (fig. 11-C).

Observation Fault type Solution

The supply LED (fig.11-A) is not lit. Defective fuse or no

mains connection.

1) Check the fuse (fig. 11-B) and the chimney fan.

2) Check the wiring.

Permanent light in LED for Upwards

regulation (fig. 11-D)

System fault. 1) Check that the probe is connected to the negative

probe on the XTP pressure transducer.

2) Check that the probe has not been clogged up.

WARNING: Do not blow into the XTP pressure

transducer.

3) Check that the chimney fan is running

4) The selected value is higher than the chimney fan

capacity. Check the setpoint setting.

5) Check the initial adjustment of the system.

6) Check the flue pipe duct and chimney for leaks.

7) Check the wiring of the XTP pressure transducer.

Permanent light in LED for Downwards

regulation (fig. 11-E)

System fault. 1) The natural draught in the chimney prevents

downwards regulation to the required setpoint.

Check the setpoint setting.

2) The probe is in an unfortunate position. The probe

may be moved to a better position.

Permanent light in ALARM LED (fig. 11-H).

- No light in chimney fan LED (fig. 11-G)

- (Only occurs if MANUAL RESET is ON

(fig. 11-F)).

Mains drop-out (Cur-

rent failure).

Press the RESET button for 1 sec. (fig. 11-C) -

See warning.

Permanent light in ALARM LED (fig. 11-H)

- Light in chimney fan (fig. 11-G).

No draught. 1) Press the RESET button for 1 sec. (fig. 11-C) -

See warning.

2) Check the repair switch for the chimney fan.

3) Check the flue, chimney and chimney fan for any

blocking items.

Flashing ALARM LED (fig. 11-H).

- (Only occurs if PDS CHECK is ON (fig. 11-F)).

Failure in fail-safe

supervision (PDS).

1) Check that a pressure differential switch has been

fitted.

2) Check the setting of the fail-safe system (natural

draught prevent cut-out/alternatively PDS-

CHECK can be deselected on the dipswitch (fig.

11-F).

3) Check the connection to the pressure differential

switch and the pressure differential switch itself.

11

3001434-2006-09-01.fm Product Instruction

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel.: +45 6566 1234

Fax: +45 6566 1110

exhausto@exhausto.dk

www.exhausto.dk

EXHAUSTO GmbH

Am Ockenheimer Graben 40

D-55411 Bingen-Kempten

Tel.: +49 6721 9178-0

Fax: +49 6721 9178-99

info@exhausto.de

www.exhausto.de

EXHAUSTO AB

Verkstadsgatan 13

S-542 33 Mariestad

Tel.: +46 501 39 33 40

Fax: +46 501 39 33 41

info@exhausto.se

www.exhausto.se

EXHAUSTO Ltd.

Unit 3 Lancaster Court

Coronation Road

Cressex Business Park

High Wycombe HP12 3TD

Tel.: +44 1494 465166

Fax: +44 1494 465163

info@exhausto.co.uk

www.exhausto.co.uk

EXHAUSTO NORGE A/S

Lilleakerveien 4

N-0283 Oslo

Tel.: +47 2412 4200

Fax: +47 2412 4201

post@exhausto.no

www.exhausto.no

EXHAUSTO Inc.

1200 Northmeadow Parkway

Suite 180

Roswell, GA 30076 USA

Tel.: +1 770 587 3238

Fax: +1 770 587 4731

service@exhausto.com

www.us.exhausto.com

4 Technical data

EBC12

Height x width x depth: 125mm x 175mm x 75mm

Degree of protection/material: IP54/ABS box and polycarbonate cover

Supply voltage: 230V ± 10%

Fuse: T5 A H 250V sand-filled

Ambient temperature: -20°C to 50°C

Boiler output relay: max. 8A/230V

Chimney fan output (AC3): max. 3A/230 V

Control signal 0-10V: max. 10 mA

Supply 0-24V (terminals 8-9): max. 10 mA

Regulating range: 5 - 150 Pa

XTP-Sensor

Height x width x depth: 74mm x 92mm x 49mm

Degree of protection: IP54

Ambient temperature: -20°C to 60°C

This manual suits for next models

1

Table of contents

Other Exhausto Control Unit manuals

Exhausto

Exhausto MCCW User manual

Exhausto

Exhausto VEX260 User manual

Exhausto

Exhausto EBC 10-P Installation instructions

Exhausto

Exhausto VEX200 series User manual

Exhausto

Exhausto OJ GreenZone Module A User manual

Exhausto

Exhausto OJ GreenZone Module M User manual

Exhausto

Exhausto OJ GreenZone User manual

Popular Control Unit manuals by other brands

Hagerman

Hagerman HagClock manual

GEM

GEM N085 Installation, Operating and Maintenance Instruction

ICP DAS USA

ICP DAS USA M-7019Z quick start guide

Allen-Bradley

Allen-Bradley ControlNet 1786-RPFM installation instructions

Freescale Semiconductor

Freescale Semiconductor TWR-K21F120MA user manual

Watts

Watts Series 709 installation instructions