SIATA V260 User manual

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 1 di 21

USE AND MAINTENANCE MANUAL

V260

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 2 di 21

DOCUMENT REVISION REVISION NOTE DATE

MAN0034 DRAFT

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 3 di 21

INDEX

GENERAL CHARACTERISTICS .................................................................................................................................4

RUNNING LOAD .............................................................................................................................................................4

RINSE LOAD IN COUNTERCURRENT ......................................................................................................................5

FAST RINSE LOAD .....................................................................................................................................................5

DIMENSIONS...................................................................................................................................................................6

FLOW DIAGRAM ...........................................................................................................................................................7

VERSIONS ........................................................................................................................................................................9

USE SPECIFICATIONS ................................................................................................................................................11

TIMER – VALVE CONNECTIONS.............................................................................................................................12

FLOW CONTROL SYSTEMS......................................................................................................................................16

V260 BASIC COMPONENTS .......................................................................................................................................17

V260 INJECTOR ............................................................................................................................................................18

SPARE PARTS ...............................................................................................................................................................19

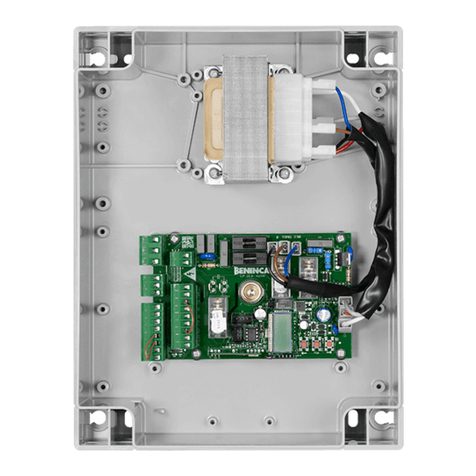

TIMER .............................................................................................................................................................................20

MAINTENANCE ADVISE ............................................................................................................................................21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 4 di 21

GENERAL CHARACTERISTICS

The “V260” valves represent an essential element for the realisation of systems of various types and for

various uses

a) SOFTENING (decalcification)- single, duplex or on more columns for domestic or industrial use

b) DEMINERALISATION single o duplex, for all uses which require water with guaranteed quality

characteristics.

The valves are made from materials which guarantee the maximum durability and quality.

The valves are available with a wide range of timers, for the control of all operative phases of service and

regeneration. These sophisticated electronic timers in the various models;by time, by volume, by

volume/time, allow for the programming of all operative phases of water treatment systems covered by the

types specified .

TECHNICAL SPECIFICATIONS

Running pression : 1.5 - 6 bar

Running load : 21 mc/h

Countercurrent rinse load : 12 mc/h

Slow rinse load : 300 - 1000 l/h

Equicurrent fast rinse load : 14 mc/h

Static resistance to pressure : 22 bar

Max.quantity regenerable resin : 500 l

Running temperature : 5 - 40°c

Basic materials of principal components : abs + fv

Entry/exit attachments : 2” ¼ male gas

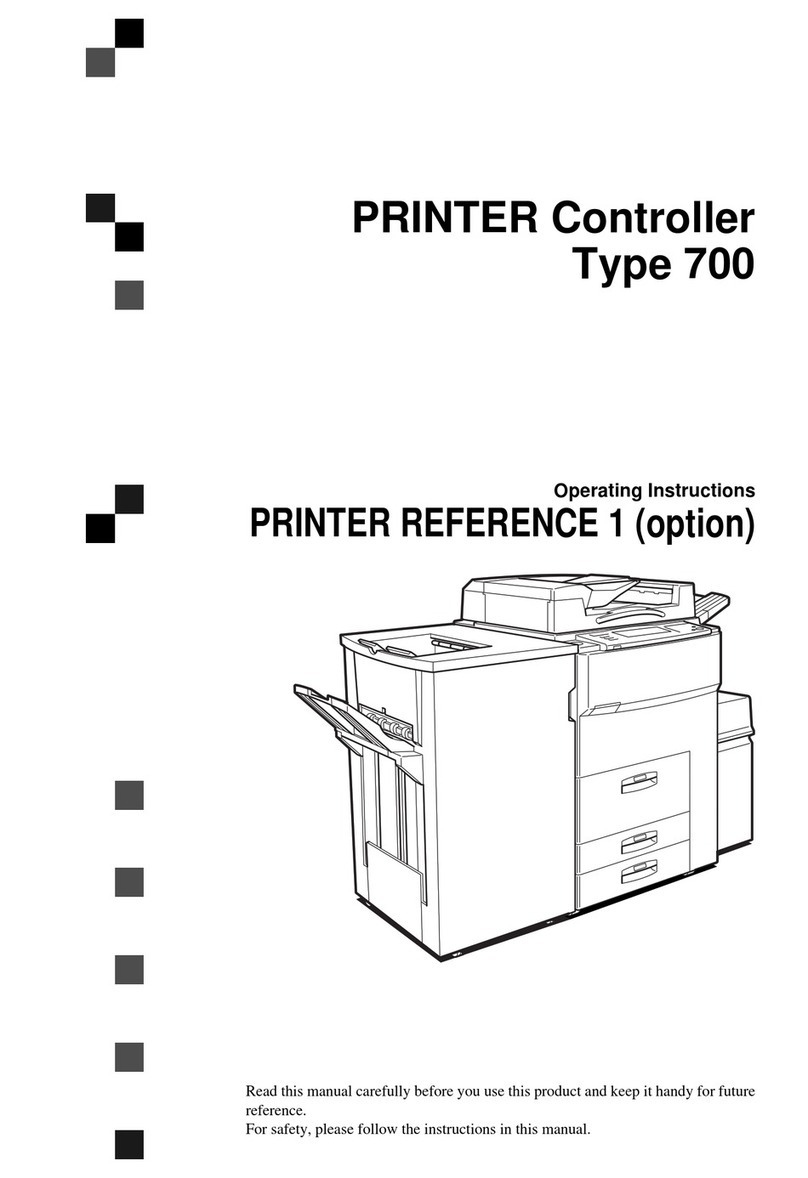

RUNNING LOAD

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 5 di 21

RINSE LOAD IN COUNTERCURRENT

FAST RINSE LOAD

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 6 di 21

DIMENSIONS

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 7 di 21

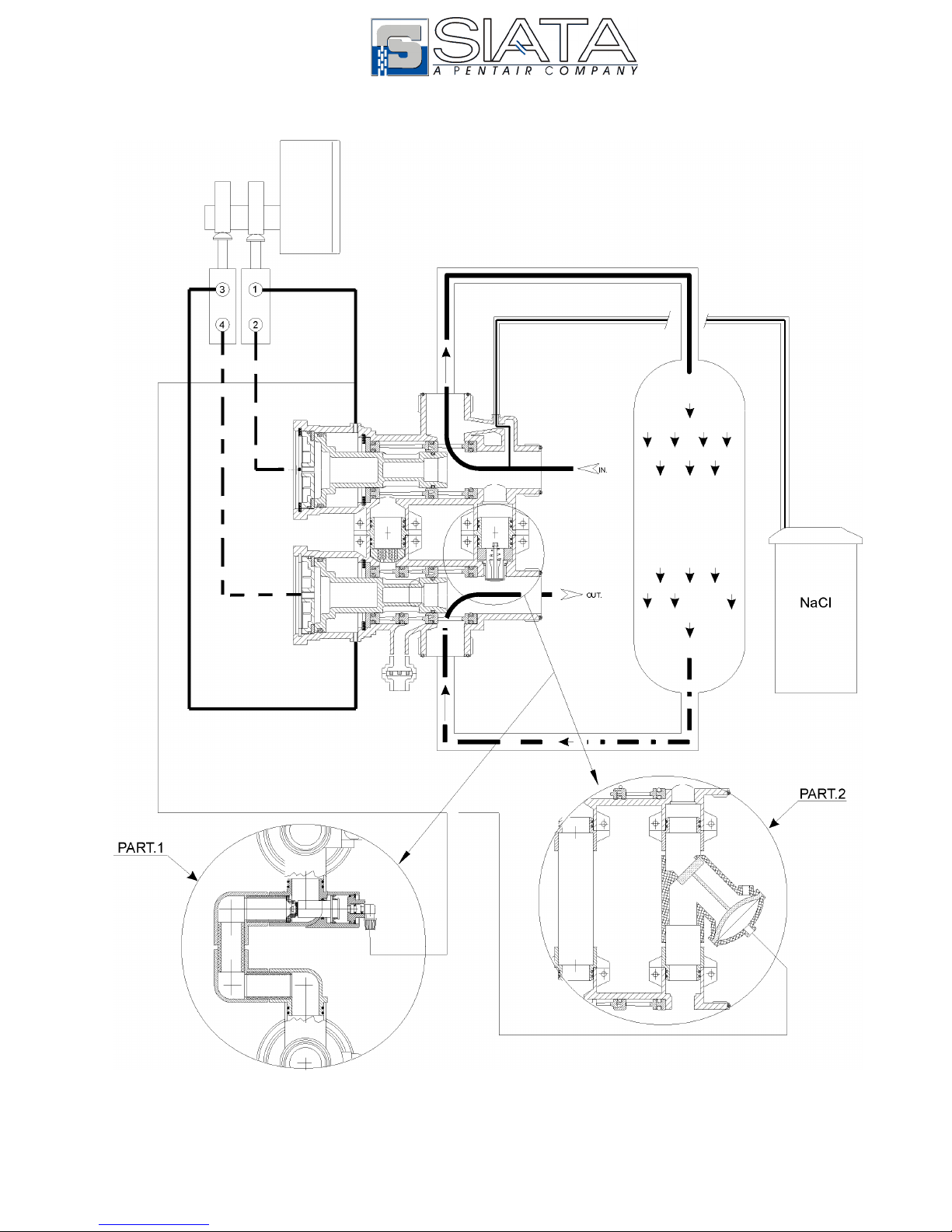

FLOW DIAGRAM

SERVIZIO / SERVICE

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 8 di 21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 9 di 21

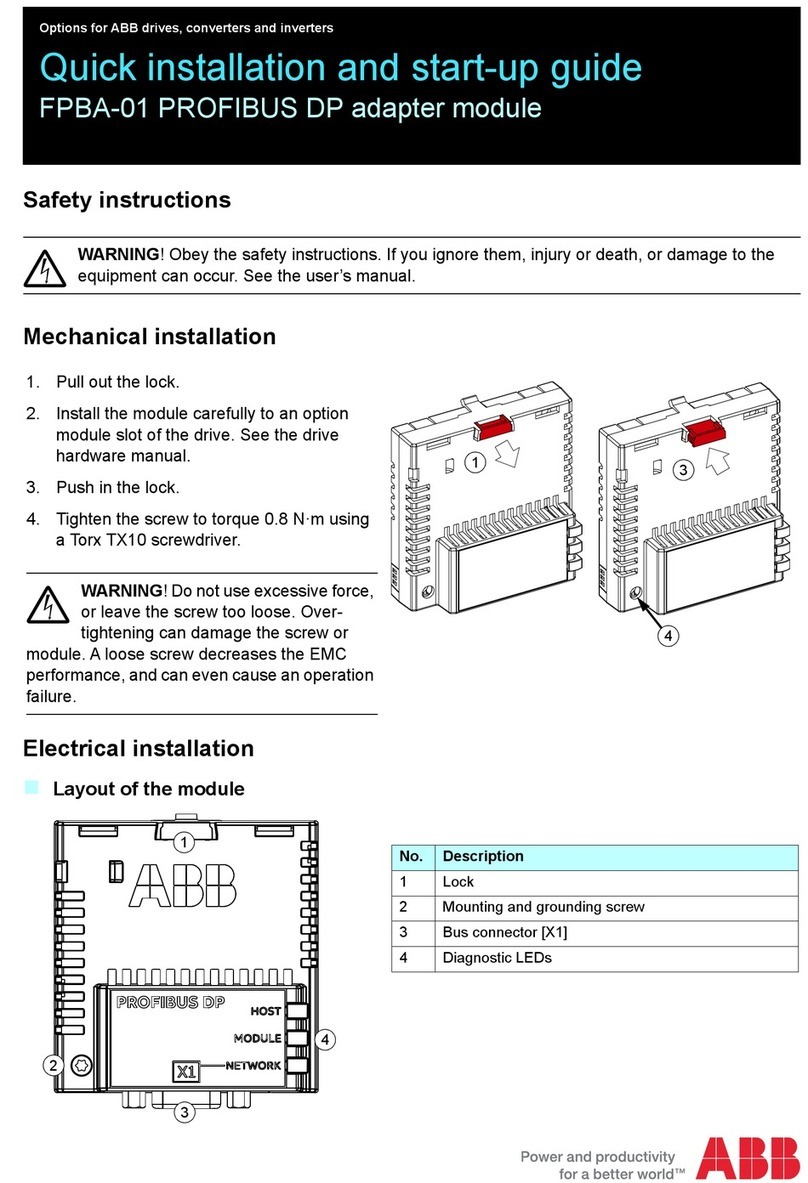

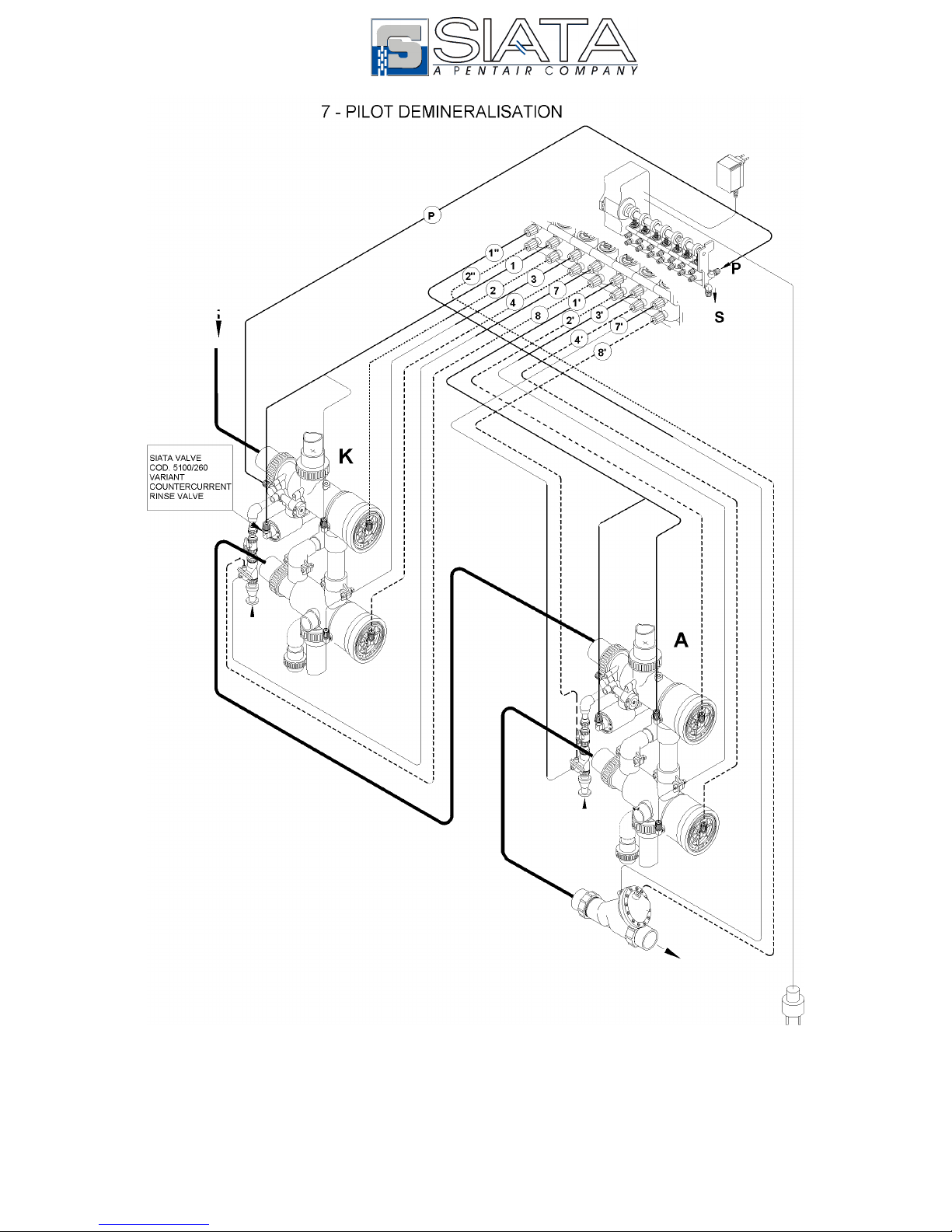

VERSIONS

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 10 di 21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 11 di 21

USE SPECIFICATIONS

Referring to the paragraph “VERSIONS” seen above, the various possibilities for the uses of this

valve in the various applications may be examined.

1) Single softening: the system consists of a basic valve V260A-?/05 (the question mark should

be substituted with the colour of the injector required), and a timer complete with a minimum of 2

external pilots in different solutions, with which the system may be personalised as desired.

In particular, varying the number of external pilots, it is possible to obtain the following

personalisations:

I. 2 pilots controls only the movement of the pistons of the valve

II. 3 pilots also controls an additional use closure valve

III. 4 pilots controls a use closure + a suction closure

2) Duplex softening: the system is made on two columns, each of which is run by a V260A-?/05.

This is controlled, with water or air, by a timer with a minimum of 2 pilots per valve.

The alternating duplex systems (one column is in service while the other is in regeneration or not in

use), may be controlled by the AQUA CUBIC timer, which may be supplied in two standard

versions:

I. 5 pilots (AC5-02/05), run by volume. The system allows for the use of two brine valves plus

a use closure valve

II. As a variation on this system, it is possible to substitute the two brine valves with two on-off

hydro-pneumatic valves for the closing/opening of the suction duct, using an AQUA CUBIC

7-pilot timer . (AC7-02/05)

1) Demineralisation and Decarbonisation: this is the applicative sector in which the

characteristics of the V260 valve may be best appreciated. In particular the V260 for

demineralisation is supplied in two different solutions: (see the demineralisation versions page

10)

A) The V260D consists of a separated top column and base column, both however supplied

with a two Ø 1” connectors, allowing the installer the possibility to choose the length of the

most suitable connecting pipe.

B) The V260D-BV with backwash valve, (eliminites bypass water during regeneration)

consists of a top and base column, as well as kit 5100-260. Also in this case, the definitive

connection between the two parts must be carried out by the installer.

The timer predisposed for demineralisation is electronic with external pilots, capable of controlling

an anionic and cationic column, can control the level of conductibility showing a valve in

µsiemns/cm at the exit of the system, and regenerate the system automatically. The number of

pilots of the timer is determined by the type of system required

I. AQUA IONIC 5 pilots ( AI5-02/05 ) controls the two columns + an on-off hydro-pneumatic

use closure valve

II. AQUA IONIC 7 piloti ( AI7-02/05 ) controls the two columns + an on-off hydro-pneumatic

use closure valve+ two on-off hydro-pneumatic valves for the closing/opening of the

regenerator suction.

4) Filtration: the considerations made regarding softening are valid both for single and duplex

system, with the exception that in this case the suction of the regenerator does not need to be

controlled.

. For further details regarding the timers, see the table of timer choice (pag. 21)

N.B. Among the accessories of the V260, note the kit code 5100-260 of the backwash valve, the

bypass of unpurified water towards use, during the regeneration phase, can be avoided.

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 12 di 21

TIMER – VALVE CONNECTIONS

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 13 di 21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 14 di 21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 15 di 21

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 16 di 21

FLOW CONTROL SYSTEMS

The S.I.A.T.A. flow control system is composed of 3 parts, see page 1:

1. The flow delivery with 2 or 4 drill holes cod. 5124 or 5124-4

2. The flow cod. 70-* (with various dimensions)

3. The flow delivery part cod 5228

In the solution proposed in fig. 3, it may be operated easily as a drain flow control of a V250 valve using a

normal adaptor Ø 40 ISO F – 1” ½ G.F..

The solution in fig.1 may be used instead as a flow control of the countercurrent, see fig.4. For the

calculation of the load which are to be controlled, see the table below.

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 17 di 21

V260 BASIC COMPONENTS

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 18 di 21

V260 INJECTOR

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 19 di 21

SPARE PARTS

Pos. Code Description

1 5120-L V250-V260 A/C Machined body

2 5121-L V250-V260 B/C machined body

3 5141 V250- 260 piston

4 5110-AC A/C V250 – 260 linings set

5 5110-BC B/C V250 – 260 linings set

6 5150-B V250- 260 blu injector set

5150-N V250- 260 black injector set

5150-F V250- 260 filter injector set

7 5160 V250-260 complete mobile valve set

8 5180-SC V250 A/B column ring set

9 5100-250 V250 complete backwash valve

10 5130 Stopper set V250-260

11 5200-A Under valve filter for V250A (0.3 mm)

5200-F Under valve filter for V250F (0.8 mm)

12 5201-A Base filter for V250A (0.3 mm)

5201-F Base filter for V250F (0.8 mm)

S.A.T.I.A. srl Società Italiana apparecchiatura trattamento acqua MAN0034 BOZZA Pag. 20 di 21

TIMER

Table of contents

Other SIATA Control Unit manuals