N500-78-00 1 I56-1804-012

BEFORE INSTALLING

If the modules will be installed in an existing operational system, inform the

operator and local authority that the system will be temporarily out of service.

Disconnect the power to the control panel before installing the modules. This

system contains static sensitive components. Always ground yourself with a

proper wrist strap before handling any circuits so that static charges are re-

moved from the body. The housing cabinet should be metallic and suitably

grounded.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

The XP6-R Six Relay Control Module is intended for use in an intelligent alarm

system. Each module is intended for Form-C switching applications, which

do not require wiring supervision for the load circuit. A single isolated set

of dry relay contacts is provided for each module, which is capable of being

wired for either normally open or normally closed for each operation. Each

module has its own address. A pair of rotary code switches is used to set the

address of the first module from 01 to 154. The remaining modules are auto-

matically assigned to the next five higher addresses. Provisions are included

for disabling a maximum of three unused modules to release the addresses to

be used elsewhere. Each XP6-R module also has panel controlled green LED

indicators. The panel can cause the LEDs to blink, latch on, or latch off.

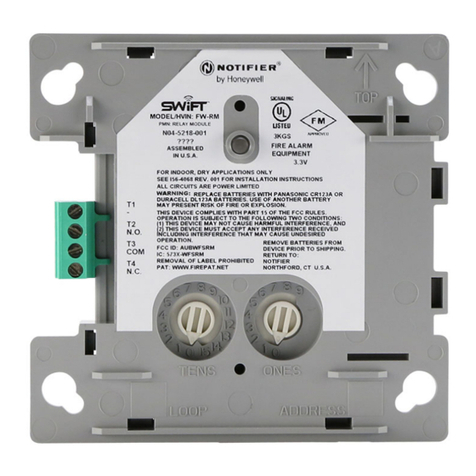

XP6-R Six Relay Control Module

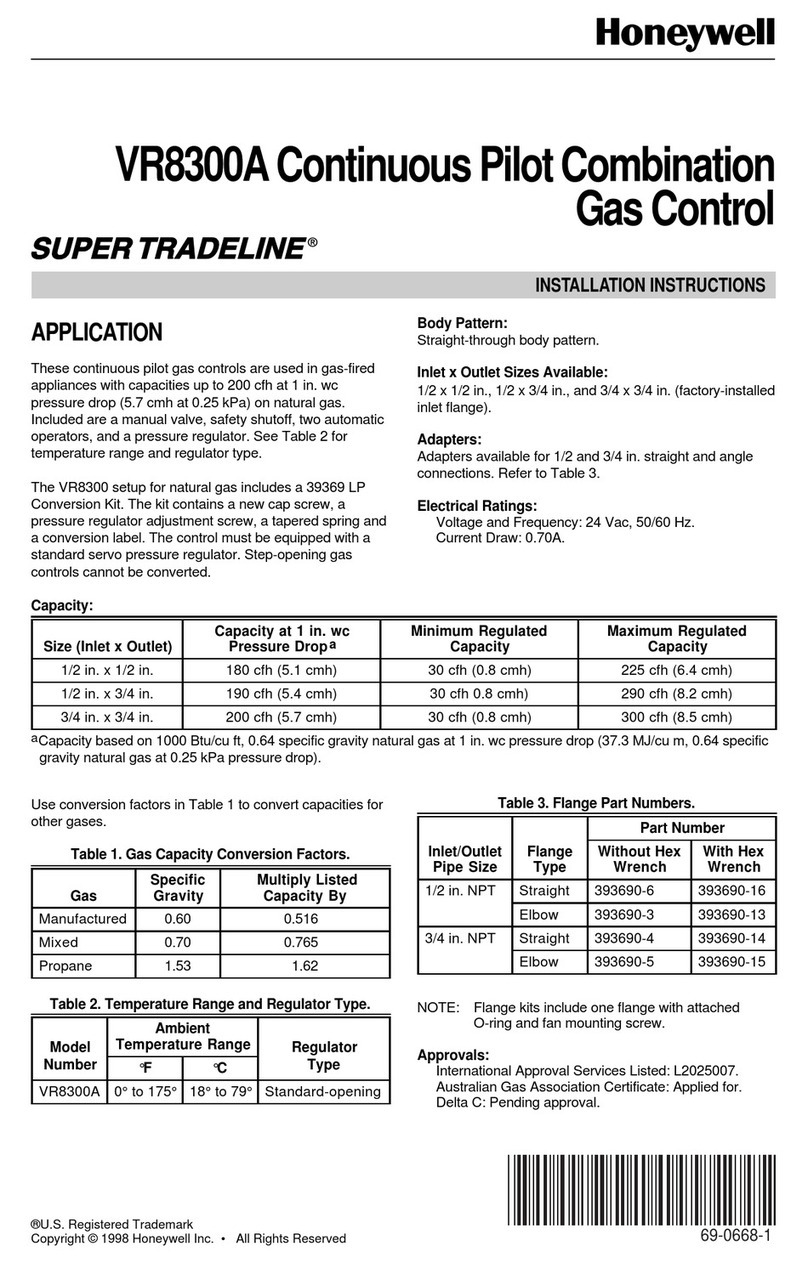

SPECIFICATIONS

Normal Operating Voltage: 15-32VDC

Stand-By Current: 1.90 mA @ 24V

Alarm Current: 32 mA (assumes all six relays have been switched once and all six LEDs solid on)

Temperature Range: 32°F to 120°F (0°C to 49°C)

Humidity: 10 to 93% Non-condensing

Dimensions: 6.8˝H × 5.8˝W × 1.0˝D

Accessories: CHS-6 Chassis; BB-25 Cabinet; BB-XP Cabinet; CAB-3 Series Cabinets; CAB-4 Series Cabinets

Wire Gauge: 12-18 AWG

Relay Current: 30 mA/Relay Pulse (15.6 mS pulse duration) pulse under panel control

CONTENTS INCLUDE:

(6) 1 × 3 Terminal Blocks

(1) 1 × 4 Terminal Blocks

(2) 11/4˝ (32mm) Stand offs

(4) Machine Screws

(2) Nuts

(1) Shunt (NOTE: For the disable position, not more than one shunt shall be

installed at the same time)

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a compatible

Notifier system control panel.

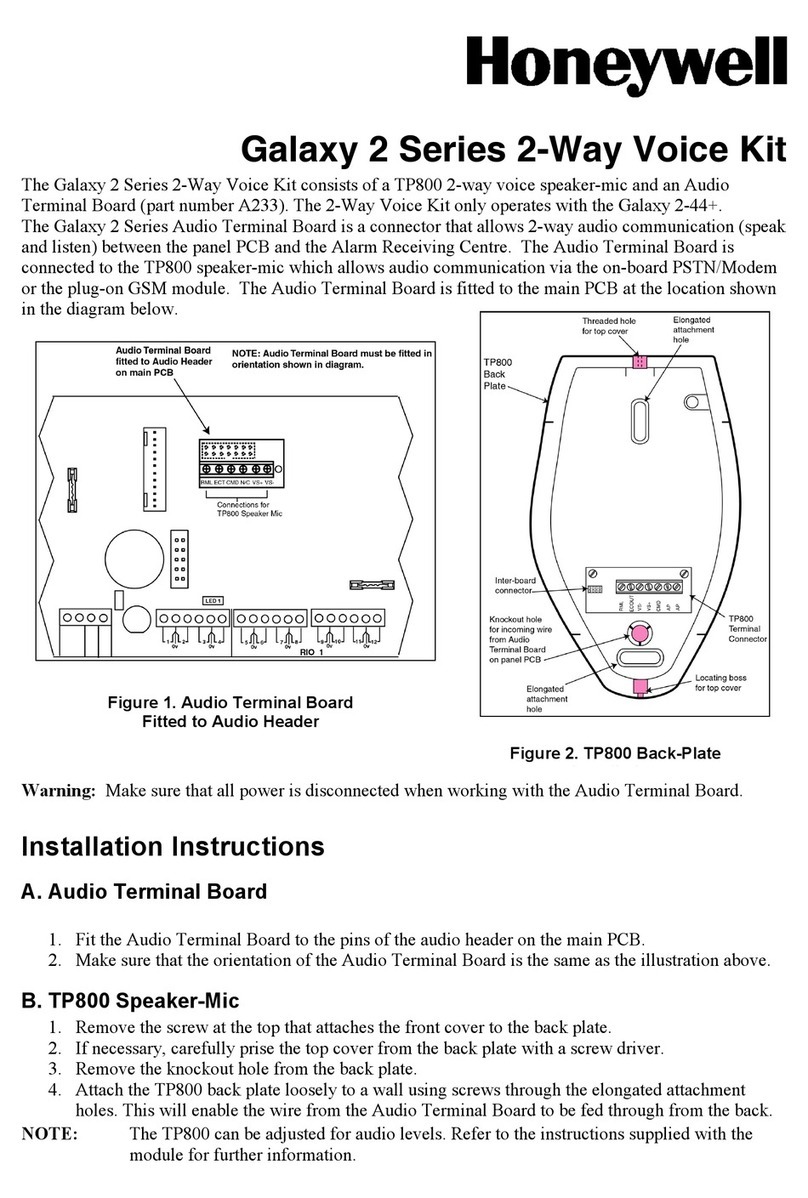

COMPONENTS

Following are descriptions of the XP6-R mounting frameworks. There are two

mounting options for XP6-R modules:

• Up to six XP6-R modules can be installed on a CHS-6 in a CAB-3, CAB-4

or BB-25 cabinet

• One or two XP6-R modules can be installed in a BB-XP cabinet

Chassis

The CHS-6 chassis is used to mount XP6-R modules in a BB-25, CAB-3 or

CAB-4 Series cabinet. It accommodates up to six XP6-R modules in a single

cabinet row three modules wide and two modules deep.

All relay switch contacts are shipped in the standby state (open) state, but may have transferred to the activated (closed) state during shipping. To ensure that

the switch contacts are in their correct state, modules must be made to communicate with the panel before connecting circuits controlled by the module.

I56-1804-012

RELAY CONTACT RATINGS:

12 Clintonville Road

Northford, CT 06472-1653

Phone: 203.484.7161

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CURRENT RATING MAXIMUM VOLTAGE LOAD DESCRIPTION APPLICATION

2 A 25 VAC PF = 0.35 Non-coded

3 A 30 VDC Resistive Non-coded

2 A 30 VDC Resistive Coded

0.46 A 30 VDC (L/R = 20ms) Non-coded

0.7 A 70.7 VAC PF = 0.35 Non-coded

0.9 A 125 VDC Resistive Non-coded

0.5 A 125 VAC PF = 0.75 Non-coded

0.3 A 125 VAC PF = 0.35 Non-coded