SIATA Aqua Timer Plus User manual

Aqua Timer Plus - 1/34

USE AND MAINTENANCE MANUAL

AQUA TIMER PLUS

y:Distributed b

37 Tannery Lane

#06-08 Tannery House

Singapore 347790

Tel: +65 6741 2994 • Fax: +65 6741 2995

S.I.A.T.A Asia Pacific Pte Ltd

Distributed by:

www.siata.com.sg

Aqua Timer Plus - 2/34

EC DECLARATION OF CONFORMITY

Producer SIATA S.r.l.

Declares that the following material:

PN

AT-PLUS2/05

Description

AQUA TIMER PLUS

Conforms to the essential pre-requisites of the following DIRECTIVES:

Electromagnetic Compatibility 89/336/CEE, 93/68/CEE

Low Voltage 73/23/CEE, 93/68/CEE

The fulfilment of the following regulations has been verified:

EN 50081-1 General Regulation on Emissions – part 1 residential, commercial and light

industry environment

EN 50082-1 General Regulation on Immunity – part 1 residential, commercial and light

industry environments

SIATA S.R.L. has a Quality System which conforms to the requirements of the

regulation:

ISO 9001/UNI EN ISO 9001-ed. 1994 (Certificate n°95.022 SGS ICS )

Managing Director

LUIGI FERRALI

Aqua Timer Plus - 3/34

Index

1 – BASIC CHARACTERISTICS .................................................................................................................................. 4

2 – TECHNICAL DATA .................................................................................................................................................. 5

3 – EXPLANATION OF THE LEDS AND OF THE KEYS ........................................................................................ 6

4 – STATES OF VISUALISATION OF THE DISPLAY ............................................................................................. 7

5 – GENERAL .................................................................................................................................................................. 7

5.1 – PACKAGING AND STORAGE ................................................................................................................................ 7

5.2 – INSTALLATION ..................................................................................................................................................... 7

5.3 – ELECTRICAL CONNECTIONS ............................................................................................................................... 8

5.4 – PROTECTION DEVICES ......................................................................................................................................... 8

6 – INSTRUCTIONS FOR USE ...................................................................................................................................... 9

6.1 – TURNING ON ......................................................................................................................................................... 9

6.2 – PROGRAMMING OF THE OPERATIVE MODALITIES ........................................................................................... 9

6.2.1 – LLL1 – LL–1 – One single column with start by time ................................................................................... 11

6.2.2 – LLL1 – LL–2 – One single column with start by volume. ............................................................................. 12

6.2.3 - LLL1 – LL–3 – One single column with mixed time / volume start. .............................................................. 14

6.2.4 – LLL2 – LL–1 – A duplex column with start by time. ..................................................................................... 16

6.2.5 – LLL2 – LL–2 – One duplex column with start by volume. ............................................................................ 18

6.2.6 – LLL2 – LL–3 – One duplex column with mixed time / volume start.............................................................. 20

6.3 – PROGRAMMING CODES .................................................................................................................................... 22

6.3.1 – Access to the programming codes ................................................................................................................. 22

6.3.2 – List of programming codes and their meaning ............................................................................................. 22

6.4 – PROGRAMMING OF THE RESERVE .......................................................................................................................... 23

6.5 – REMOTE START ..................................................................................................................................................... 24

6.6 – PROGRAMMING OF THE LITRE COUNTER DIVIDER ( PRESCALER ) ........................................................................... 24

6.7 – CALCULATION OF THE CYCLIC CAPACITY OF A SYSTEM ........................................................................................ 25

6.8 – FUNCTIONALITY OF THE REGENERATION CYCLE, FLAGS 1CL AND 2CL. ............................................................... 26

6.9 – MANAGEMENT OF THE ALARM OF END OF REGENERATIVE AUTONOMY ................................................................. 28

6.10 – PUTTING INTO SERVICE ....................................................................................................................................... 28

6.11 – CONNECTIONS ..................................................................................................................................................... 29

6.12 – MANAGEMENT OF THE INHIBIT SIGNAL. FLAG 0DL. ............................................................................................ 29

7 – WHAT TO DO IF … ................................................................................................................................................ 31

7.1 - ... AQUA TIMER PLUS DOES NOT COME ON ? .......................................................................................................... 31

7.2 - ... THE MOTORS OF THE DISTRIBUTORS DO NOT STOP ? ........................................................................................... 31

7.3 - ... THERE IS NO CURRENT TO THE UTILISERS? ......................................................................................................... 31

7.4 - ... AQUA TIMER PLUS WORKS IN AN IRREGULAR WAY? .......................................................................................... 31

APPENDIX A (GENERAL ELECTRICAL CONNECTIONS) ................................................................................. 32

APPENDIX B (ELECTRICAL CONNECTIONS FOR THE SINGLE DISTRIBUTOR) ...................................... 33

APPENDIX C (ELECTRICAL CONNECTIONS FOR THE DUPLEX DISTRIBUTOR) .................................... 34

Aqua Timer Plus - 4/34

1 – BASIC CHARACTERISTICS

Aqua Timer Plus is dedicated to the control of a SIATA multi-port valve for the realisation of water softening

systems, working on the principle of ionic exchange resins.

Aqua Timer Plus can control a hydraulic distributor which, with one or two SIATA valves, forms an

electrical/hydraulic command unit for single or duplex systems.

When Aqua Timer Plus is programmed in a duplex mode, it is possible to activate a particular regeneration cycle,

which has a stand-by position at the start of the regeneration.

Aqua Timer Plus automatically calculates the volume of treatable water based on the following parameters:

the hardness of the water

the volume of the tank

the capacity of the exchange of the resins used

The regeneration cycle is entirely programmable and may be run in three different ways:

by time (the programmed time running out sets off the regeneration)

by volume (the programmed volume running out sets off the regeneration)

mixed (this is a combination of the first two)

manually

by an external signal (remote starter)

It is also possible, by pressing the key Reset to cancel a regeneration in progress, or to jump one or more phases by

pressing the key Regener during the stop phase.

Aqua Timer Plus makes it possible to use an outlet which is activated during the second phase of the regeneration

cycle (phase 2C normally used for having the regenerants moved along the resin), which may be used to control the

supply of an electrolytic cell for chlorine or any other electrical controller.

Aqua Timer Plus is equipped with a counter of the regenerations which may be carried out with the salt introduced

into the system; the controller will emit an alarm when it is the right time to restore the salt level.

Aqua Timer Plus may be connected to a computer via RS232 using the correct cable serial cod. 881-1, so as to be able

to acquire and then analyse the progress of the work parameters.

Aqua Timer Plus is equipped with a buffer battery which allows for the work parameters to be retained in the

memory should the electricity current fail.

Aqua Timer Plus is equipped with an EEPROM memory, on which the programmed data is memorised, with the

capacity to retain data for over 10 years.

Aqua Timer Plus, like all the range of SIATA controllers, conforms to the EEC Directives and is produced in the

SIATA plant of Montespertoli which operates with the certified Quality System according to the regulation

ISO 9001 / UNI EN ISO 9001.

Aqua Timer Plus - 5/34

2 – TECHNICAL DATA

Supply voltage 230 Vac 10%

Network frequency 50 Hz 3%

Power absorbed 30 VA

Operative temperature 0° C – 55° C

Class of protection IP65

Protection from disturbances ICE 65 Trial class 4 ( 3000 V )

Reading scale 0 – 999,999 Litri

Box dimensions 240 mm x 185 mm x 115 mm

Total weight 1.5 Kg

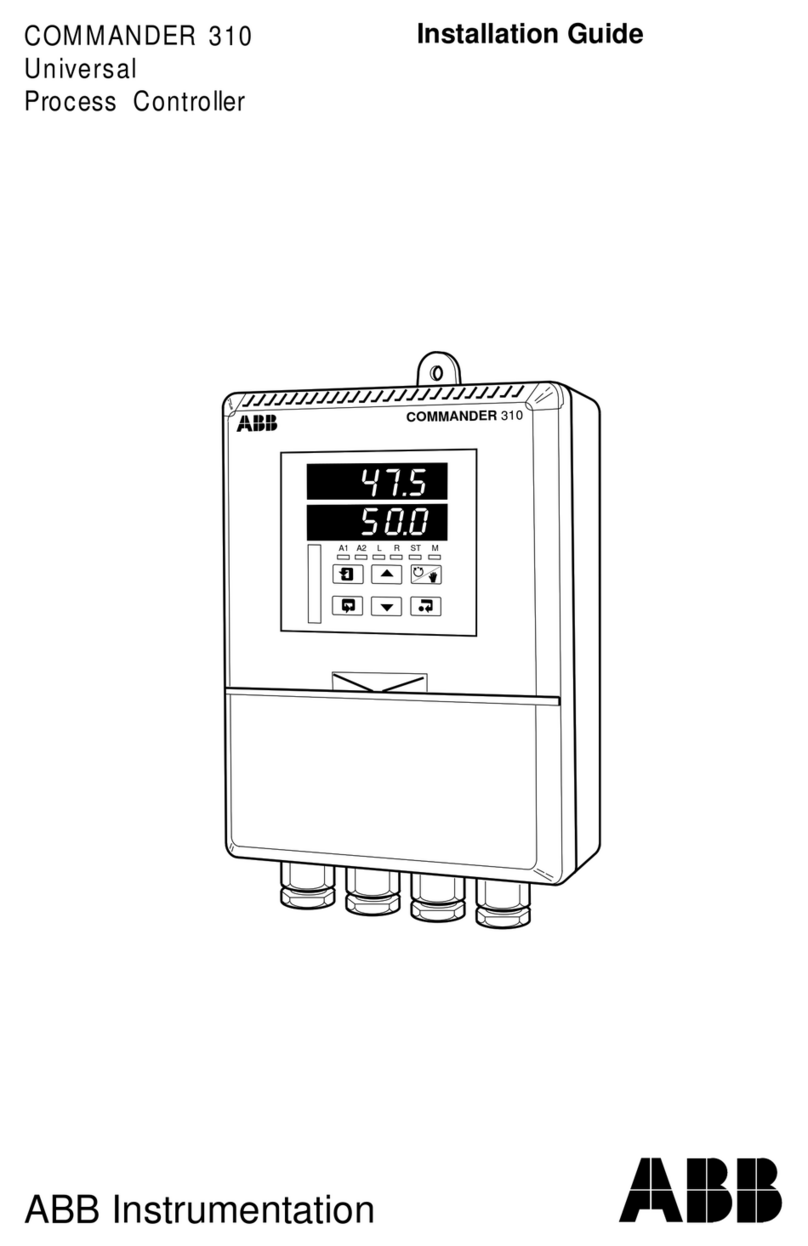

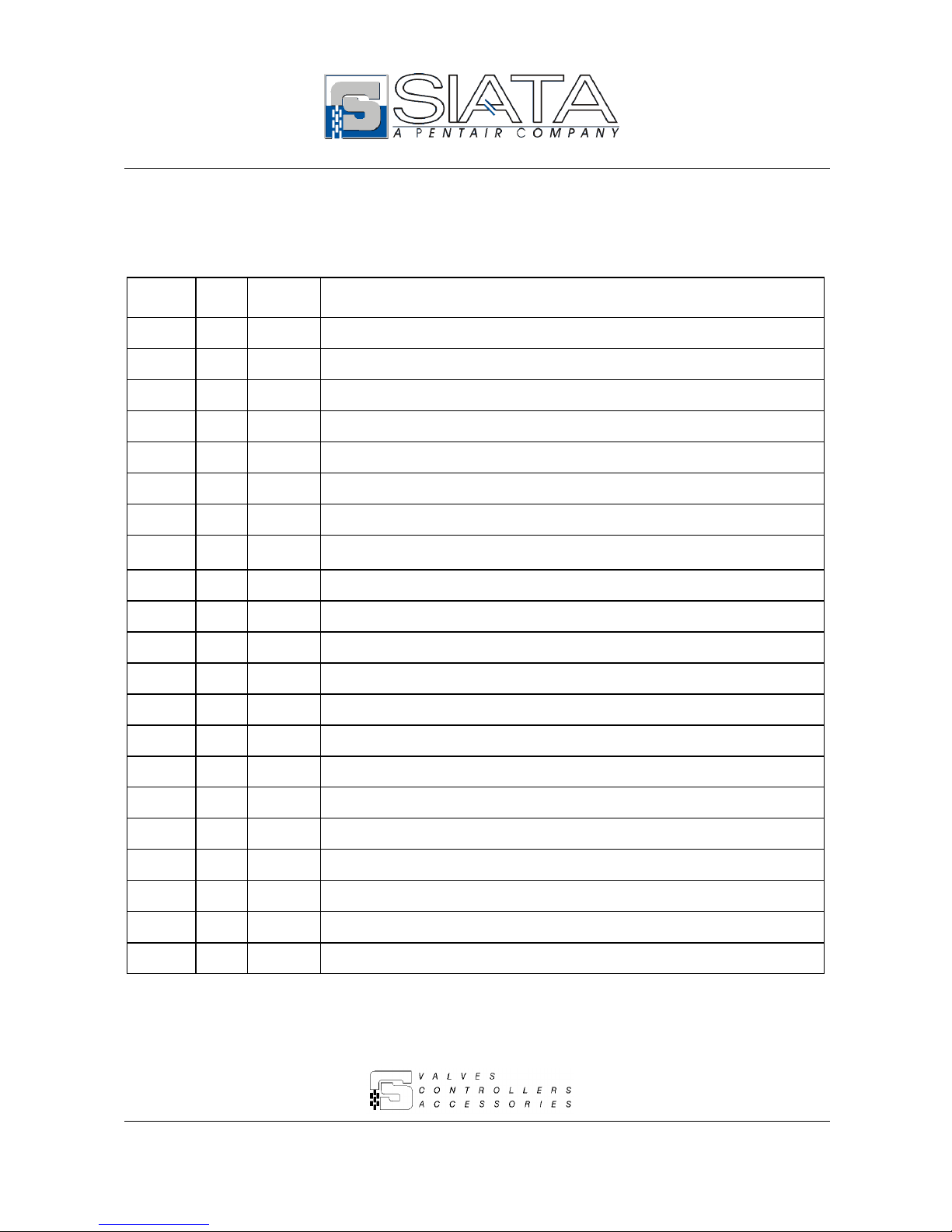

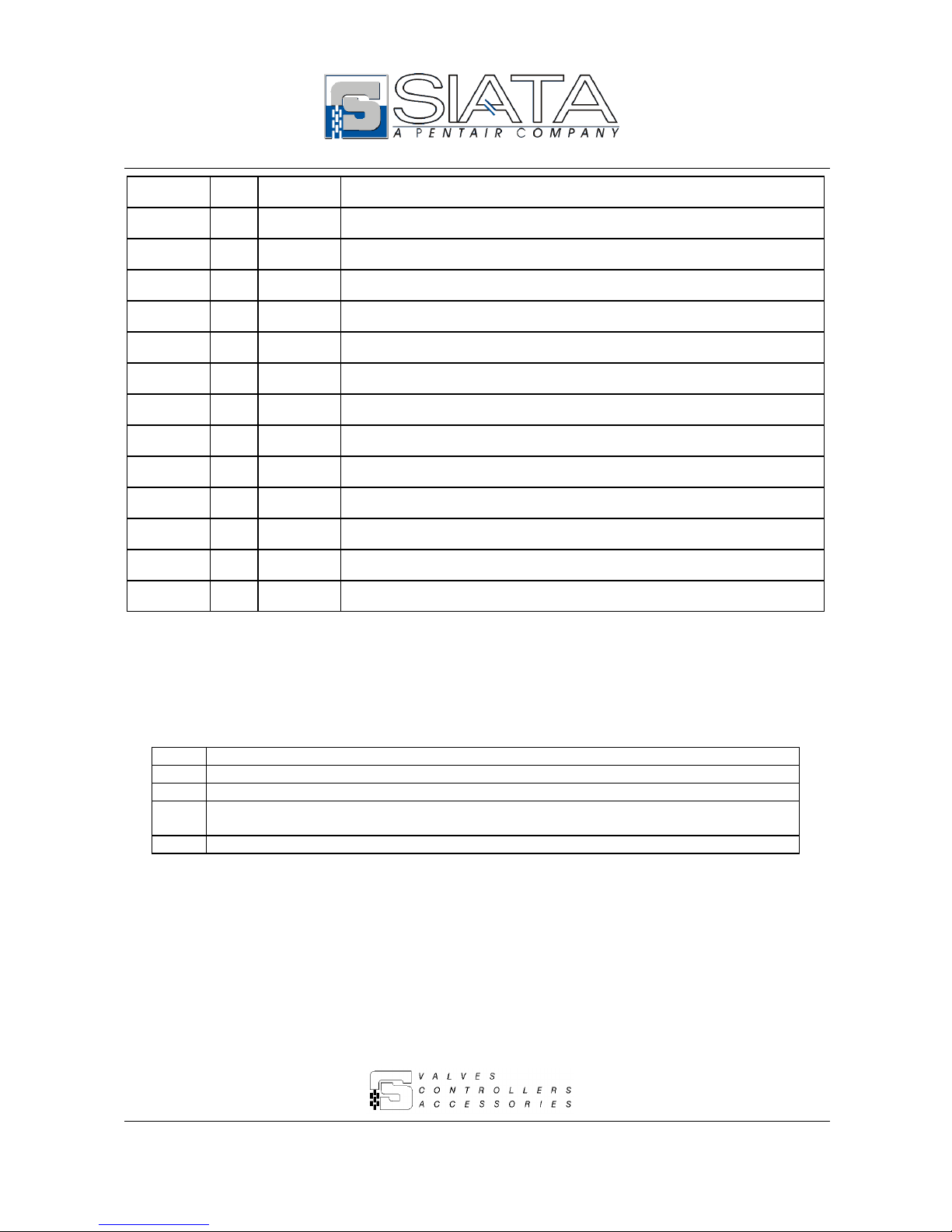

Fig. 1

Aqua Timer Plus - 6/34

3 –LEDS AND KEYS MEANING

The tabs. 1 and 2 describe the meaning respectively of the LEDs and of the keys on the front panel of the controller, and

which can be seen in fig. 1.

Tab. 1 – Functionality of the LEDs

LED

Meaning

A SERVICE

On when column A is in service

B SERVICE

On when column B is in service

WAIT. REGEN.

The controller waits until the programmed time for the regen.

ALARM

Alarm

TIME

Control of the time for the start of the regeneration

VOLUME

Control of the volume for the start of the regeneration

DUPLEX

Duplex distributor in use

SALT

Alarm when salt has run out

TIME+VOLUME

Both the LEDs on, mixed control time/volume for the regen.

Tab. 2 – Functionality of the keys

Key

Description

CODE

Access to the programming of the work parameters through the protection code.

During the programming, returns to zero the value being modified

RESET

Allows for the programming to be outleted from, without memorising the last value keyed in.

Pressed during the service, resets the counters of the management of salt alarm.

PROGRAM

MODE

Allows access to the programming functions.

REGENER.

Starts up the regeneration.

Pressed during the stop time, returns to zero the residual time and starts up the next phase.

ADVANCE

Changes the visualisation mode of the display.

In programming, increases the value being modified.

TIME OF

DAY

Resetting of the local time.

If the flag 1HL is programmed to 1, after the time the day of the week is set.

Aqua Timer Plus - 7/34

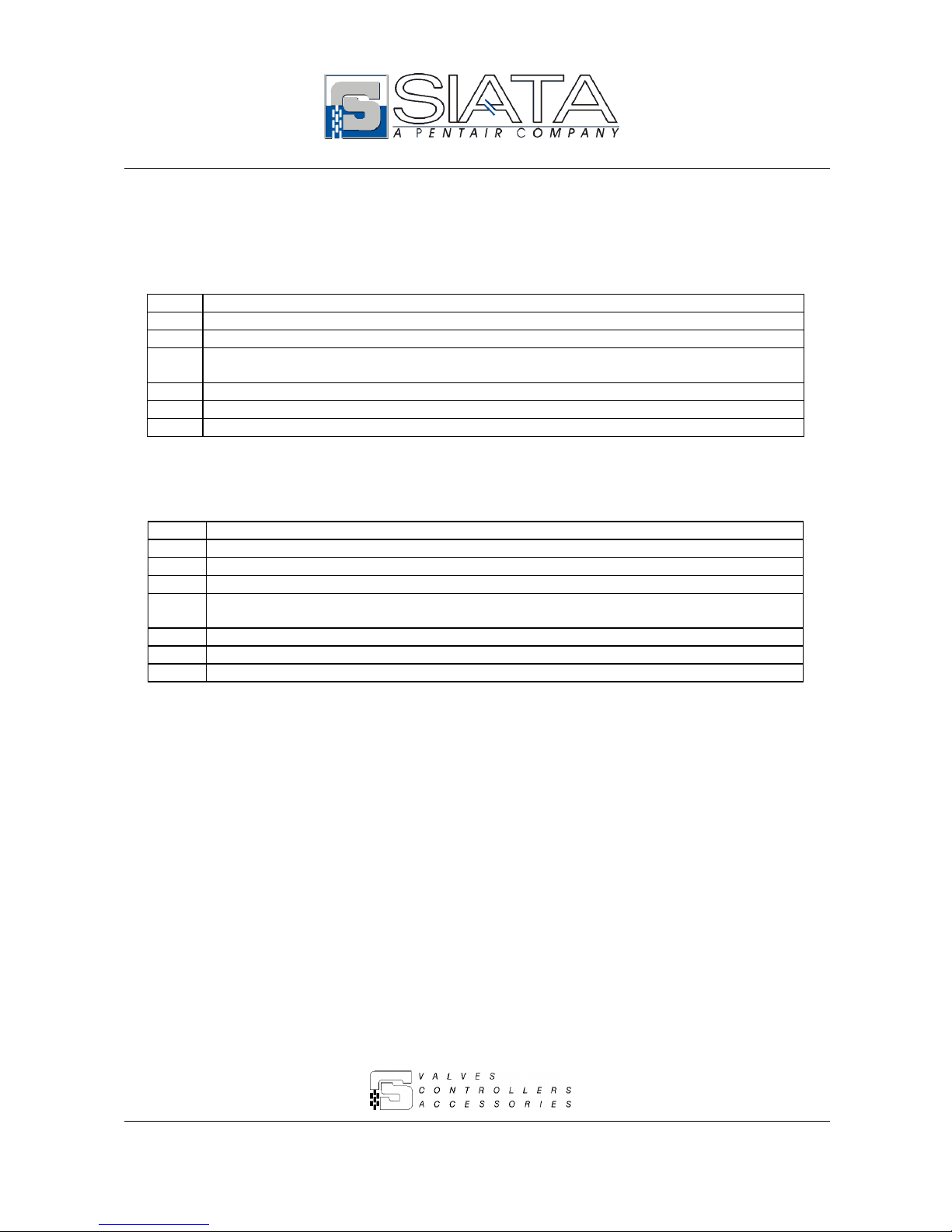

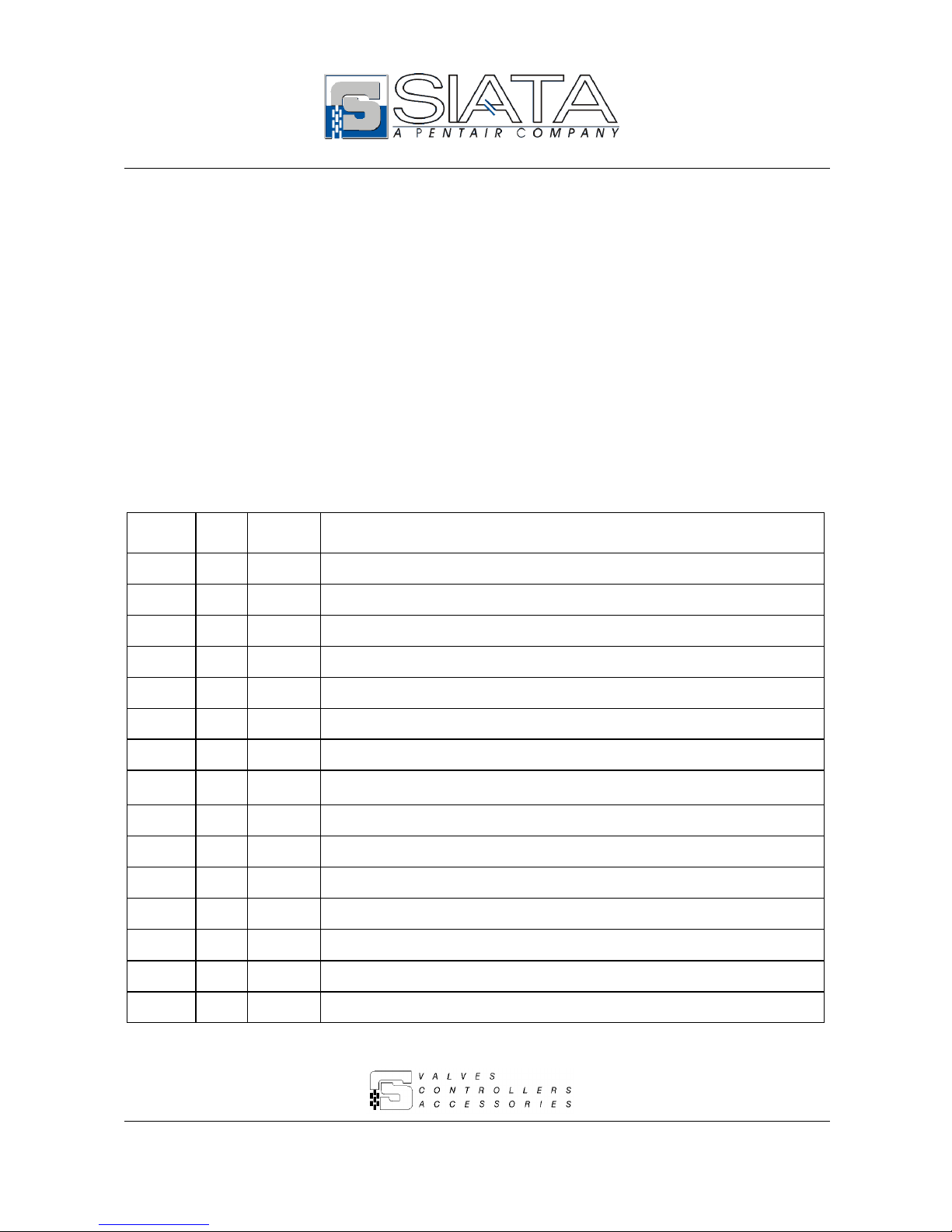

4 – STATES OF VISUALISATION OF THE DISPLAY

The display, through the key Advance, allows the different operative states and/or data to be visualised.

The LEDs A or B will indicate which to column the data visualised on the display refers.

Tab. 3 – Data visible on the display

Display

Operative state/ Data visualised

Advance

1 2 . 3 0

Local time. The central dot is flashing.

Advance

0 2 . 3 0

Time programmed for the regeneration. The central dot is not flashing.

Advance

d - 3 0

The programmed number of reserve regenerations (remains fixed).

Advance

d d 3 0

The number of regenerations before the salt runs out (is updated).

Advance

- - - -

If no regeneration is in progress, 4 lines appear

1 C 2 5

If a regeneration is in progress, the progression appears.

Advance

5 . 0 0 0

Value of the residual volume.

5 – GENERAL

The installation of the controller must be carried out by qualified personnel; the installation procedures must be carried

out when the controller is disconnected from the electricity supply

5.1 – Packaging and storage

The packaging consists of a cardboard box with a label identifying the product, carrying the following infrormation:

name of producer and PN producer AT-PLUS2/05; the quick reference guide for the installation and programming

may be found inside.

No particular procedures are necessary for the removal of the controller from the packaging.

The controller must be stored in environments with the following characteristics:

Temperature of between +0°C and +55°C;

Relative humidity of between 30 % and 95 %.

5.2 – Installation

The controller consists of a PVC box with a cover in plexi-glass which may be opened manually, giving access to the

keypad, and of a cover which may be removed by removing two screws and which gives access to the external

connection terminal board.

The box is covered by a certificate with the IP65 grade of protection, Aqua Timer Plus is therefore protected against

infiltration of dust and direct jets of water. This protection is valid when the cover is closed, and the wiring slots are of

the correct size for the cables used and are correctly assembled. If these conditions are not respected, the level of

protection falls to IP40, which gives no protection against infiltration of dust and water.

The back of the box is equipped with mechanical details which allow it to be wall-mounted.

Aqua Timer Plus - 8/34

5.3 – Electrical connections

The electrical connection of the controller must take place conforming to the conditions stated in the diagram CE0027

shown on the attached appendix A.

If the system uses a single hydraulic distributor connected with one or two valves, the relative electrical connections

must conform to that indicated in the diagram CE0028 which is shown on the attached appendix B.

If the system uses a duplex hydraulic distributor connected to one valve each, the relative electrical connections must

conform to that indicated in the diagram CE0021 which is shown on the attached appendix C.

Also follow the instructions shown in par. 6.11 on the connections.

The controller is equipped with free contact outlets with the following signals.

-Dosing pump

-End of cycle impulse

-Impulse during phase 2

-Alarm

-Regeneration in progress

Warning!!

Before carrying out any installation and/or maintenance operation, check that the controller is disconnected from the

power supply.

The supply to the controller must take place in accordance with all that is set out in the Low Voltage directive

(73/23/EEC). Aqua Timer Plus is equipped with a clip for the earth connection.

5.4 – Protection devices

The controller is protected from current overloads by a 0.6A supply retardant fuse which is assembled on the front

panel. It is also protected against disturbances originating from the electricity supply by filters mounted inside the

controller.

If the version supplied at 24 Vac is used, the fuse is 1A retardant.

An Autoreset circuit intervenes automatically if Aqua Timer Plus stops functioning after particularly strong

disturbances.

Aqua Timer Plus - 9/34

6 – INSTRUCTIONS FOR USE

6.1 – Turning on

The controller is turned on via the main switch ON (I) - OFF (0) situated on the front panel. This switch acts on both

supply conductors.

The supply voltage must be 230 Vac - 50 Hz. (on demand 24 Vac – 50 Hz. )

Check the supply voltage using the adhesive labels situated on the cover of the connections.

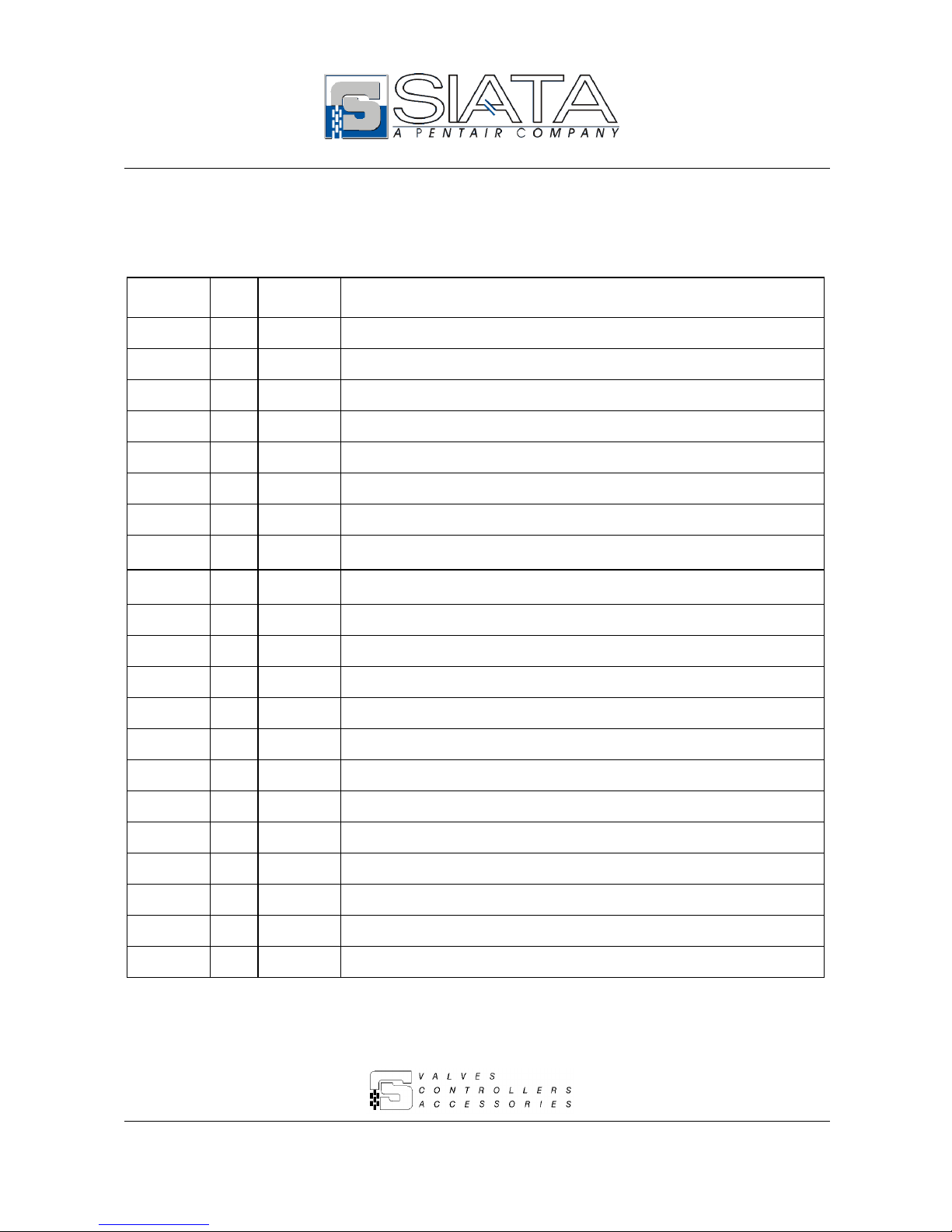

6.2 – Programming of the operative modalities

Before proceeding to the programming of Aqua Timer Plus, it must be checked that the distributor cams are positioned

at the limit cycle position. If operations are to be carried out on the controller before its installation, that is without the

distributor connected, the limit switch entry must be closed with a connection bridge. If this simple rule is not

respected, Aqua Timer Plus will accept all the new programming, but will not be able to carry out the normal

operations needed during the service.

The programming will be carried out via the keypad on the front of the controller.

Aqua Timer Plus has the following operative modalities:

Tab. 4 – Table of the operative modalities

Code

Description

Cam rotation times

L L L 1

One single column

4 stop with 50 second rotation time

L L L 2

One duplex column

4 stop with 25 second rotation time

L L L 2

One duplex column and distributor with stand-by

3 stop with 25 second rotation time

The selection takes place according to the sequence shown below:

Tab. 5 – Selection of the operative modalities

Display

Operative state / Data visualised

Program

S C - -

State of access to the insertion of the programming codes

Advance

S C 0 0

By using the Advance key the programming code is selected ( 0 9)

Advance

S C 0 9

The code for the programming of the operative modalities

Program

L L L 1

The number 1 indicates the single column

Advance

L L L 2

The number 2 indicates the duplex column

If the protection code has been programmed through the programming function SC07 (see par. 6.3), the procedure

described in tab. 5 varies as follows:

Aqua Timer Plus - 10/34

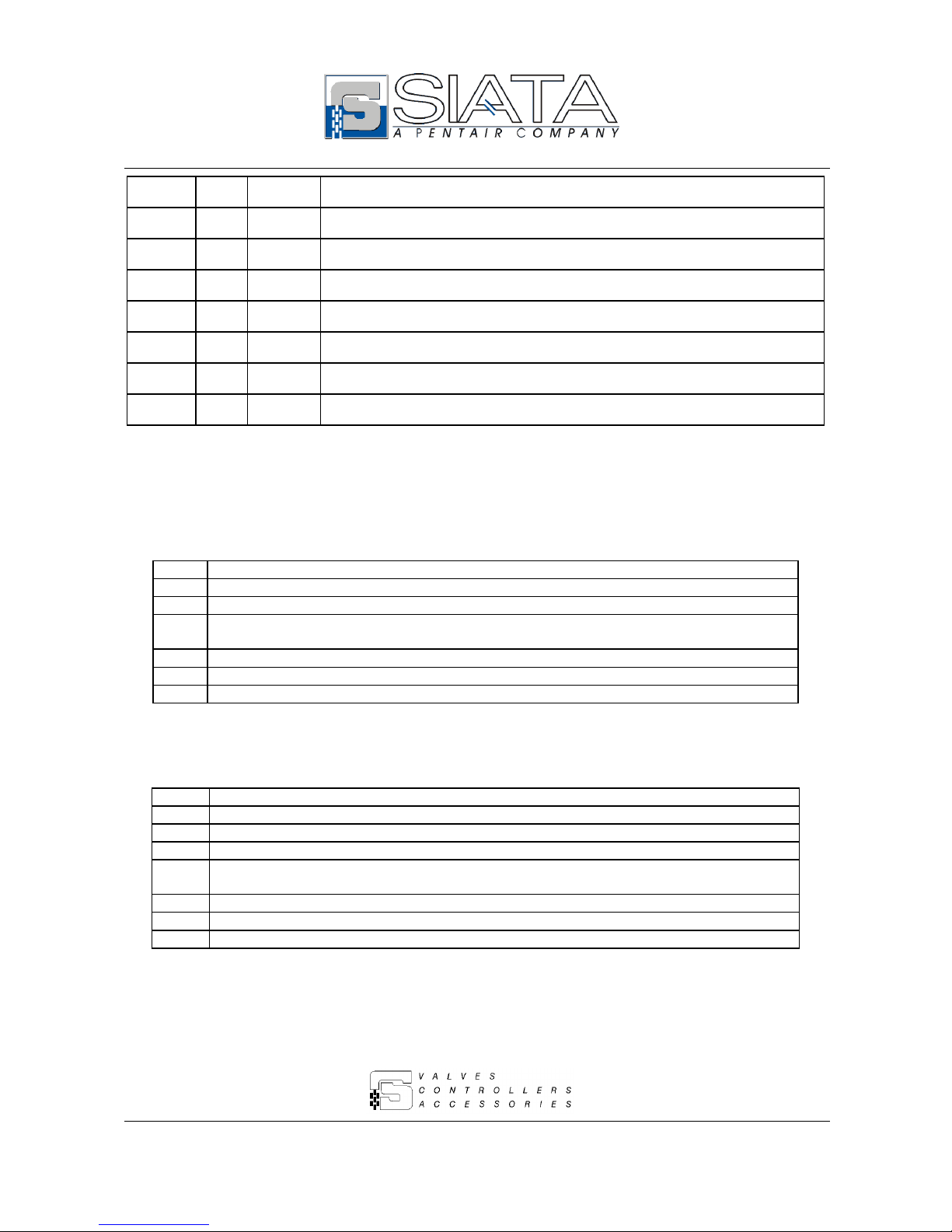

Tab. 6 – Selection of the operative modalities through the protection code

Display

Operative state / Data visualised

Code

0 0 0 0

Key in the protection code programmed with the function SC07

Advance

0 0 0 2

Key the code on the display with the keys Advance and Code

Code

S C - -

State of access to the keying in of the programming codes

Advance

S C 0 0

With the key Advance the programming code is selected( 0 9)

Advance

S C 0 9

The code for the programming of the of the operative modality

Program

L L L 1

The number 1 indicates the single column

Advance

L L L 2

The number 2 indicates the duplex column

In the same way, in all the following tables where there is the sequence

Program

S C - -

State of access to the keying in of the programming codes

the sequence

Code

0 0 0 0

Key in the protection code programmed with the function SC07

Advance

0 0 0 2

Key the code on the display with the keys Advance and Code

Code

S C - -

State of access to the keying in of the programming codes

is substituted when there is a different protection code.

IMPORTANT !!!

To remove the protection code, set the value 0000 in the function SC07.

If the protection code is forgotten, it is no longer possible to enter the programming functions. In case of need,

contact the SIATA technical service.

Pressing the key Program Mode after the selection shown in tab. 5, proceed to the selection of the regeneration start

mode, as shown in tab. 7.

Tab. 7 – Selection of the control modality of the regeneration start

Display

Operative state / Data visualised

Program

L L - 1

Regeneration by time. The LED TIME comes on on the panel

Advance

L L - 2

Regeneration by volume. The LED VOLUME comes on on the panel

Advance

L L - 3

Mixed regeneration. The LEDs TIME and VOLUME come on on the panel

Aqua Timer Plus - 11/34

6.2.1 – LLL1 – LL–1 – One single column with start by time

6.2.1.a – Operative characteristics.

In this operative modality, the regeneration starts exclusively at the programmed time, after the interval days

programmed (or on the days of the week selected).

No control on the volume or on the reserve is available.

Control on the remote start is available, which can start up the regeneration both immediately or deferred to the

programmed time based on the content of the flag 2HL.

In this operative modality it is not possible to activate the cycle with the stand-by.

6.2.1.b – FLAG Programming

The tab. 8 is to be used in the programming of the flag for the modality LLL1 – LL–1

Tab. 8 – Selection of the operative modality single column - time start

FLAG

Display

Operative state / Data visualised

Program

S C - -

State of access to the selection of the programming codes

Advance

S C 0 9

By pressing Advance key the programming code is increased up to 9

Program

L L L 1

Single column modality. If necessary modify the data with Advance

Program

L L - 1

Regeneration by time. If necessary, modify the data with Advance.

Program

0 H L

0 H L 0

FLAG not used

Program

1 H L

1 H L 0

Interval between two regenerations expressed in days. See par. 6.3.2

Advance

1 H L

1 H L 1

Regeneration to be carried out on the days of the week programmed.

Program

2 H L

2 H L 0

Immediate start up of the regeneration on the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the programmed time at the command of the remote

start

Program

3 H L

3 H L 0

FLAG not used. Leave programmed at 0

Program

0 C L

0 C L 0

Modality of the litre counter divider. Do not use. see par. 6.6

Program

1 C L

1 C L 0

FLAG not used. Leave programmed at 0

Program

2 C L

2 C L 0

FLAG not used. Leave programmed at 0

Program

3 C L

3 C L 0

Management of salt alarm disabled

Advance

3 C L

3 C L 1

Management of salt alarm enabled. See par. 6.9

Program

0 d L

0 d L 0

Normal functioning

Aqua Timer Plus - 12/34

Advance

0 d L

0 d L 1

Management of the start of the regeneration in the case of inhibit. See par. 6.12

Program

1 d L

1 d L 0

FLAG not used

Program

2 d L

2 d L 0

FLAG not used

Program

3 d L

3 d L 0

FLAG not used

Program

Fast flashing of the display. The programming is stored in eeprom.

6.2.1.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality the programming of the following

codes is recommended:

Tab. 9 – Table of the codes in one single column modality LLL1 – LL–1

Code

Meaning

SC02

Regeneration starting time and interval days between two regenerations programming

SC03

Regeneration cycle steps programming

SC05

End of cycle impulse duration and dosing pump divider programming

SC00

Initialisation of the system

6.2.2 – LLL1 – LL–2 – One single column with start by volume.

6.2.2.a – Operative characteristics.

In this operative modality the regeneration starts exclusively when the volume reaches the value 0.

The flag 0HL allows to enable the regeneration start by time. In fact, the immediate start of the cycle by finished

volume remains the same, to which the start of the cycle at the programmed time after the interval days programmed or

on the active days, is added.

The control on the reserve is not available.

The control on the remote start is available, which can start up the regeneration both immediately and deferred to the

programmed time, based on the content of the flag 2HL.

In this operative modality it is not possible to activate the cycle with the stand-by.

Aqua Timer Plus - 13/34

6.2.2.b – Programming of the FLAGs

Tab. 10 is to be used in the programming of the flags for the modality LLL1 – LL–2

Tab. 10 – Selection of the operative modality single column - start a volume

FLAG

Display

Operative state / Data visualised

Program

S C - -

State of access to the selection of the programming codes

Advance

S C 0 9

With the key Advance programming code is increased up to 9

Program

L L L 1

Single column modality. If necessary modify the data with Advance

Program

L L - 2

Regeneration by volume. If necessary modify the data with Advance.

Program

0 H L

0 H L 0

Immediate start of the regeneration only by finished volume

Advance

0 H L

0 H L 1

Immediate start of the regeneration by finished volume and by finished time

Program

1 H L

1 H L 0

FLAG not used

Program

2 H L

2 H L 0

Immediate start of the regeneration at the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the time programmed at the command of the remote start

Program

3 H L

3 H L 0

FLAG not used. Leave programmed at 0

Program

0 C L

0 C L 0

Modality of the litre counter divider. Do not use. See par. 6.6

Program

1 C L

1 C L 0

FLAG not used. Leave programmed at 0

Program

2 C L

2 C L 0

FLAG not used. Leave programmed at 0

Program

3 C L

3 C L 0

Management of management of salt alarm disabled

Advance

3 C L

3 C L 1

Management of management of salt alarm enabled. See par. 6.9

Program

0 d L

0 d L 0

Normal functioning

Advance

0 d L

0 d L 1

Management of the start of the regeneration in the case of inhibit. See par. 6.12

Program

1 d L

1 d L 0

FLAG not used

Program

2 d L

2 d L 0

FLAG not used

Program

3 d L

3 d L 0

FLAG not used

Program

Fast flashing of the display. The programming is memorised in eeprom.

Aqua Timer Plus - 14/34

6.2.2.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality the programming of the following

codes is recommended:

Tab. 11 – Table of the codes in one single column modality LLL1 – LL–2

Code

Meaning

SC03

Programming of the regeneration cycle ( stop times )

SC04

Programming of the litre counter divider ( pre-scaler )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the

dosing pump

SC06

Programming of the volume of resin, of the percentage of reserve and of the capacity of exchange

SC01

Programming of the hardness value

SC00

Initialisation of the system

If the flag 0HL has been programmed with the value 1 to also have the regeneration by time, the programming

recommended varies as follows:

Tab. 12 – Table of the codes in one single column modality LLL1 – LL–2

Code

Meaning

SC02

Programming of the time of regeneration and the interval days between two regenerations

SC03

Programming of the regeneration cycle ( stop times )

SC04

Programming of the litre counter divider ( prescaler )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the

dosing pump

SC06

Programming of the volume of resin, of the percentage of reserve and of the capacity of exchange

SC01

Programming of the hardness value

SC00

Initialisation of the system

6.2.3 - LLL1 – LL–3 – One single column with mixed time / volume start.

6.2.3.a –Operative characteristics.

In this operative modality, the regeneration starts exclusively when the interval days have passed and at the

programmed time. If the volume of water treated reaches the value calculated for the reserve, the residual days will be

ignored. It is not possible to have the immediate start of the regeneration either because the volume has run out, or

because the value of the reserve has been reached. The control on the reserve is automatic and cannot be dis-

activated.

The control on the remote start is available, and can start up the regeneration both immediately and deferred to the

programmed time, based on the content of the flag 2HL.

In this operative modality the possibility of using the cam with the stand-by is not available.

Aqua Timer Plus - 15/34

6.2.3.b – Programming of the FLAGs

Tab. 13 is to be used in the programming of the flags for the modality LLL1 – LL–3

Tab. 13 – Selection of the operative modality single column - start in mixed mode

FLAG

Display

Operative state / Data visualised

Program

S C - -

State of access to the selection of the programming codes

Advance

S C 0 9

With the key Advance the programming code is increased up to 9

Program

L L L 1

Single column modality. If necessary modify the data with Advance

Program

L L - 3

Mixed regeneration. If necessary modify the data with Advance.

Program

0 H L

0 H L 0

FLAG not used

Program

1 H L

1 H L 0

Interval between two regenerations expressed in days. See par. 6.3.2

Advance

1 H L

1 H L 1

Regeneration to be carried out on the days of the week programmed.

Program

2 H L

2 H L 0

Immediate start of the regeneration at the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the programmed time at the command of the remote

start

Program

3 H L

3 H L 0

FLAG not used. Leave programmed at 0

Program

0 C L

0 C L 0

Modality of the litre counter divider. Do not use. See par. 6.6

Program

1 C L

1 C L 0

FLAG not used. Leave programmed at 0

Program

2 C L

2 C L 0

FLAG not used. Leave programmed at 0

Program

3 C L

3 C L 0

Management of salt alarm disabled

Advance

3 C L

3 C L 1

Management of salt alarm enabled. See par. 6.9

Program

0 d L

0 d L 0

Normal functioning

Advance

0 d L

0 d L 1

Management of the start of the regeneration in the case of inhibit. See par. 6.12

Program

1 d L

1 d L 0

FLAG not used

Program

2 d L

2 d L 0

FLAG not used

Program

3 d L

3 d L 0

FLAG not used

Program

Fast flashing of the display. The programming is memorised in eeprom.

Aqua Timer Plus - 16/34

6.2.3.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality, the programming of the following

codes is recommended:

Tab. 14 – Table of the codes in one single column modality LLL1 – LL–3

Code

Meaning

SC02

Programming of the time of regeneration and of the interval days between two regenerations

SC03

Programming of the regeneration cycle ( stop times )

SC04

Programming of the litre counter divider ( prescaler )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the dosing

pump

SC06

Programming of the volume of resin, of the percentage of reserve and of the exchange capacity

SC01

Programming of the hardness value

SC00

Initialisation of the system

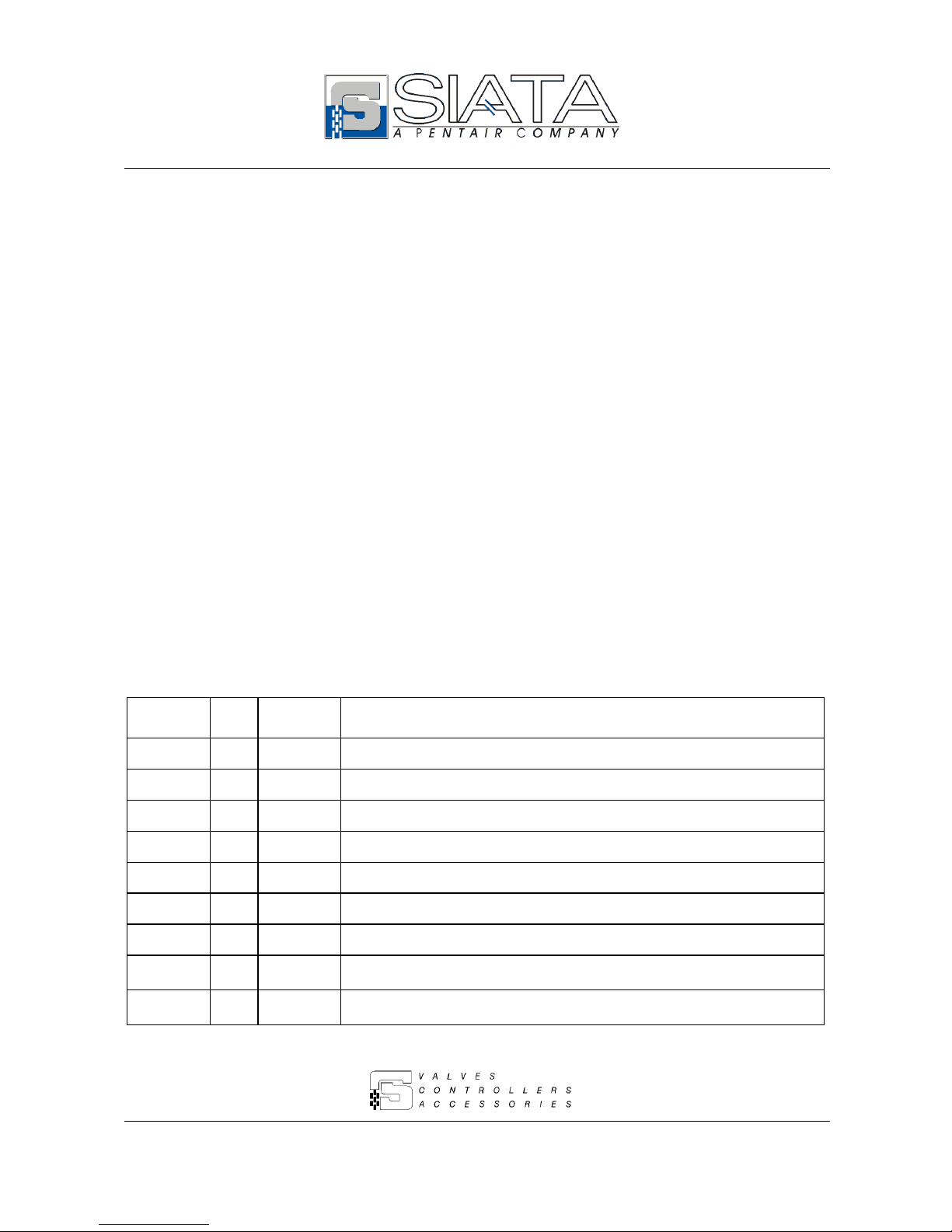

6.2.4 – LLL2 – LL–1 – A duplex column with start by time.

6.2.4.a – Operative characteristics

In this operative modality, the regeneration starts exclusively at the programmed time after the interval days

programmed ( or on the days of the week selected ). No control is available on the volume or on the reserve. Control is

available on the remote start, which can start up the regeneration both immediately and deferred to the programmed

time, on the basis of the content of the flag 2HL. It is possible to use the cam with the stand-by. (see par. 6.8)

6.2.4.b – Programming of the FLAGs

Tab. 15 is to be used in the programming of the FLAG for the modality LLL2 – LL–1

Tab. 15 – Selection of the operative modality duplex column – start by tempo

FLAG

Display

Operative state / Data visualised

Program

S C - -

State of access to the selection of the programming codes

Advance

S C 0 9

With the key Advance the programming code is increased up to 9

Program

L L L 2

Modality duplex column. If necessary modify the data with Advance

Program

L L - 1

Regeneration a tempo. If necessary modify the data with Advance.

Program

0 H L

0 H L 0

FLAG not used

Program

1 H L

1 H L 0

Interval between two regenerations expressed in days. See par. 6.3.2

Advance

1 H L

1 H L 1

Regeneration to be carried out on the days of the week programmed.

Program

2 H L

2 H L 0

Immediate start of the regeneration at the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the programmed time on the command of the remote

start

Aqua Timer Plus - 17/34

Program

3 H L

3 H L 0

FLAG not used. Leave programmed at 0

Program

0 C L

0 C L 0

Modality of the litre counter divider. Do not use. See par. 6.6

Program

1 C L

1 C L 0

Standard regeneration. See par. 6.8

Advance

1 C L

1 C L 1

Regeneration with stand-by

Program

2 C L

2 C L 0

Duplex distributor with standard cams. See par. 6.8

Advance

2 C L

2 C L 1

Duplex distributor with stand-by cams

Program

3 C L

3 C L 0

Management of salt alarm disabled

Advance

3 C L

3 C L 1

Management of salt alarm enabled. See par. 6.9

Program

0 d L

0 d L 0

Normal functioning

Advance

0 d L

0 d L 1

Management of the start of the regeneration in the case of inhibit. See par. 6.12

Program

1 d L

1 d L 0

FLAG not used

Program

2 d L

2 d L 0

FLAG not used

Program

3 d L

3 d L 0

FLAG not used

Program

Fast flashing of the display. The programming is memorised in eeprom.

6.2.4.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality the programming of the following

codes is recommended:

Tab. 16 – Table of the codes in one duplex column modality LLL2 – LL–1

Code

Meaning

SC02

Programming of the time of regeneration between two regenerations

SC03

Programming of the regeneration cycle ( stop times )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the

dosing pump

SC00

Initialisation of the system

Aqua Timer Plus - 18/34

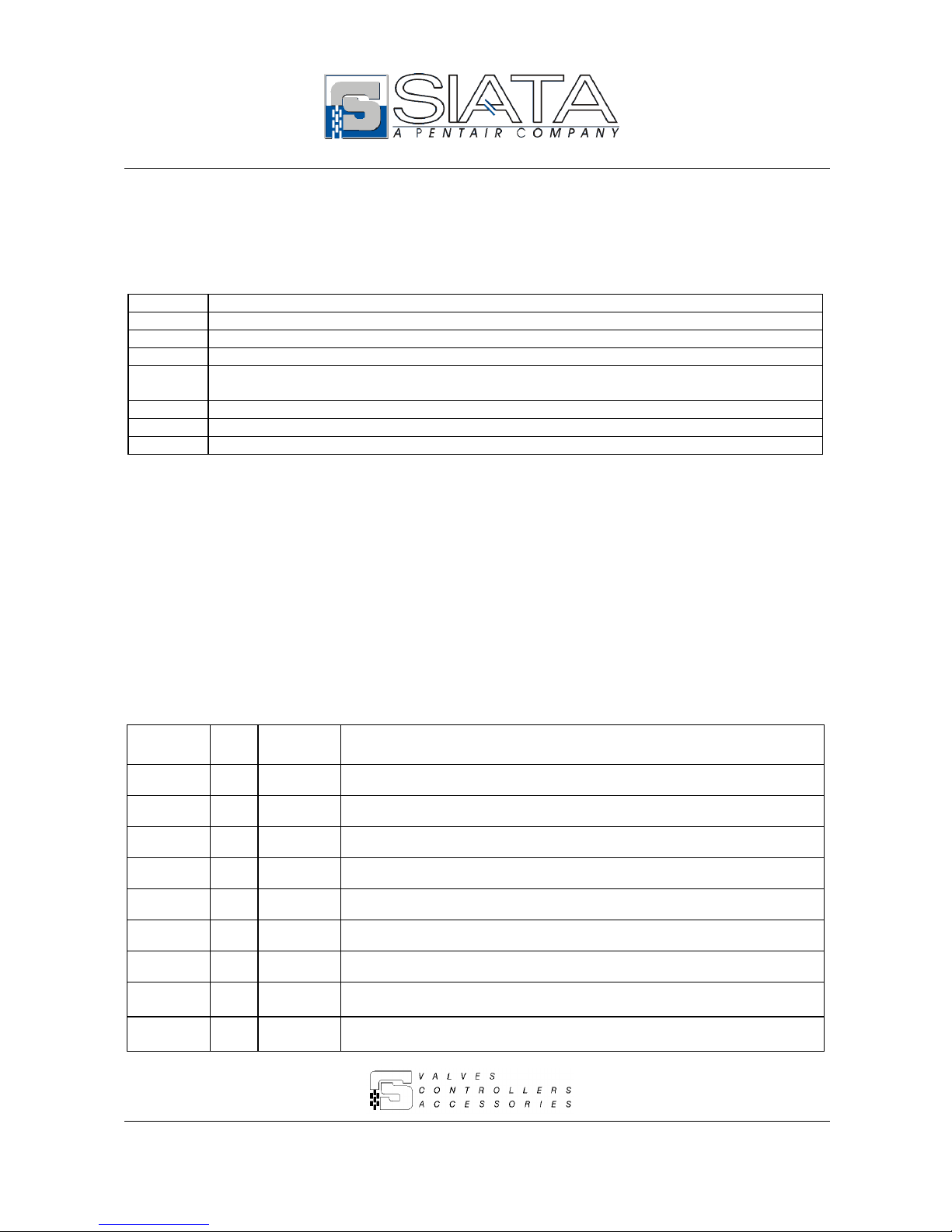

6.2.5 – LLL2 – LL–2 – One duplex column with start by volume.

6.2.5.a – Operative characteristics.

In this operative modality the regeneration starts exclusively when the volume reaches the value 0.

The flag 0HL allows for the enabling also of the start of the regeneration by time. Thus, the immediate start of the cycle

by finished volume remains unchanged to which the start of the cycle at the programmed time after the interval days

programmed or on the active days is added.

The control on the reserve is not available.

The control on the remote start is available, and can start up the regeneration both immediately and deferred to the

programmed time, on the basis of the content of the flag 2HL.

In this operative modality it is not possible to activate the cycle with the stand-by.

6.2.5.b – Programming of the FLAGs

Tab. 17 is to be used in the programming of the flags for the modality LLL2 – LL-2

Tab. 17 – Selection of the operative modality duplex column – start by volume

FLAG

Display

Operative state / Data visualised

Program

S C - -

State access to the selection of the programming codes

Advance

S C 0 9

With the key Advance the programming code is increased up to 9

Program

L L L 2

Modality duplex column. If necessary modify the data with Advance

Program

L L - 2

Regeneration a volume. If necessary modify the data with Advance.

Program

0 H L

0 H L 0

Immediate start of the regeneration only by finished volume

Advance

0 H L

0 H L 1

Immediate start of the regeneration by finished volume and by finished time

Program

1 H L

1 H L 0

FLAG not used

Program

2 H L

2 H L 0

Immediate start of the regeneration at the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the programmed time at the command of the remote start

Program

3 H L

3 H L 0

FLAG not used. Leave programmed at 0

Program

0 C L

0 C L 0

Modality of the litre counter divider. Do not use. See par. 6.6

Program

1 C L

1 C L 0

Regeneration standard. See par. 6.8

Advance

1 C L

1 C L 1

Regeneration with stand-by

Program

2 C L

2 C L 0

Duplex distributor with standard cams. See par. 6.8

Advance

2 C L

2 C L 1

Duplex distributor with stand-by cams

Aqua Timer Plus - 19/34

Program

3 C L

3 C L 0

Management of salt alarm disabled

Advance

3 C L

3 C L 1

Management of salt alarm enabled. See par. 6.9

Program

0 d L

0 d L 0

Normal functioning

Advance

0 d L

0 d L 1

Management of the start of the regeneration in the case of inhibit. See par. 6.12

Program

1 d L

1 d L 0

FLAG not used

Program

2 d L

2 d L 0

FLAG not used

Program

3 d L

3 d L 0

FLAG not used

Program

Fast flashing of the display. The programming is memorised in eeprom.

6.2.5.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality the programming of the following

codes is recommended:

Tab. 18 – Table of the codes in one duplex column modality LLL2 – LL–2

Code

Meaning

SC03

Programming of the regeneration cycle ( stop times )

SC04

Programming of the litre counter divider ( prescaler )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the

dosing pump

SC06

Programming of the volume of resin, of the percentage of reserve and of the exchange capacity

SC01

Programming of the hardness value

SC00

Initialisation of the system

If the flag 0HL has been programmed with the value 1 to have also the regeneration by time, the recommended

programming varies as follows:

Tab. 19 – Table of the codes in the one duplex column LLL2 – LL–2

Code

Meaning

SC02

Programming of the time of regeneration and of the interval days between two regenerations

SC03

Programming of the regeneration cycle ( stop times )

SC04

Programming of the litre counter divider ( prescaler )

SC05

Programming of the duration of the end of cycle impulse and of the litre counter divider of the

dosing pump

SC06

Programming of the volume of resin, of the percentage of reserve and of the exchange capacity

SC01

Programming of the hardness value

SC00

Initialisation of the system

Aqua Timer Plus - 20/34

6.2.6 – LLL2 – LL–3 – One duplex column with mixed time / volume start.

6.2.6.a – Operative characteristics.

In this operative modality the control for the start of the regeneration depends on the use or otherwise of the cam with

stand-by, that is of the programming of the flags 1CL and 2CL.

If both of the flags are programmed with the value 0, the regeneration cycle is standard in 4 phases of 25 seconds. The

start of the cycle is controlled by the running out of the interval time between two regenerations, or by the running out

of the volume. The latter condition, differently from that described in par. 6.2.3.a, does not activate a request for

regeneration to be carried out at the programmed time, but causes the immediate start of the cycle.

The same effect is obtained also by programming to 1 only the flag 2CL, that is when the standard regeneration cycle

standard with a stand-by cam is required to be carried out.

If both of the flags are programmed with the value 1, the controller carries out the regeneration with stand-by. In this

case, the running out of the volume causes a request for regeneration which will be carried out at the programmed time.

The controller will immediately position the cam in the stand-by position, that is it will carry out the exchange of the

columns. The regeneration will start from the stand-by position.

The control on the reserve is not available.

The control on the remote start is available, and this can start up the regeneration both immediately and deferred to the

programmed time, on the basis of the content of the flag 2HL.

6.2.6.b – Programming of the FLAGs

Tab. 20 is to be used for the programming of the flags for the modality LLL2 – LL-3

Tab. 20 – Selection of the operative modality duplex column - start in mixed mode

FLAG

Display

Operative state / Data visualised

Program

S C - -

State of access to the selection of the programming codes

Advance

S C 0 9

With the key Advance the programming code is increased up to 9

Program

L L L 2

Duplex column modality. If necessary modify the data with Advance

Program

L L - 3

Mixed regeneration. If necessary modify the data with Advance.

Program

0 H L

0 H L 0

FLAG not used

Program

1 H L

1 H L 0

Interval between two regenerations expressed in days. See par. 6.3.2

Advance

1 H L

1 H L 1

Regeneration to be carried out on the days of the week programmed.

Program

2 H L

2 H L 0

Immediate start of the regeneration at the command of the remote start.

See par. 6.5

Advance

2 H L

2 H L 1

Start of the regeneration at the programmed time on the command of the remote

start

Table of contents

Other SIATA Controllers manuals