SIATA AQUA CUBIC MULTIPLEX User manual

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 1/33

USE AND MAINTENANCE MANUAL

AQUA CUBIC MULTIPLEX

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 2/33

EC DECLARATION OF CONFORMITY

Producer S.I.A.T.A. S.r.l.

address Via Virginio 370/372

50025 Montespertoli-Florence (ITALY)

Declares that the following material:

PN

AC-MULT/05

Description

AQUA CUBIC MULTIPLEX

Conforms to the essential pre-requisites of the following DIRECTIVES:

• Electromagnetic Compatibility 89/336/CEE, 93/68/CEE

• Low Voltage 73/23/CEE, 93/68/CEE

The fulfilment of the following regulations has been verified:

EN 50081-1 General Regulation on Emissions – part 1 residential, commercial and light

industry environment

EN 50082-1 General Regulation on Immunity – part 1:residential, commercial and light

industry environments

S.I.A.T.A. S.R.L. has a Quality System which conforms to the requirements of the

regulation:

ISO 9001/UNI EN ISO 9001-ed. 1994 (Certificate n°95.022 SGS ICS )

Date Director

LUIGI FERRALI

03.03.1998

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 3/33

Summary

1 – INTRODUCTION .........................................................................................................................5

2 – TECHNICAL DATA.....................................................................................................................6

3 – EXPLANATION OF THE LEDs AND OF THE KEYS.............................................................7

4 – STATES OF VISUALISATION OF THE DISPLAY .................................................................7

5 – GENERAL.....................................................................................................................................8

5.1 – Packaging and storage........................................................................................................................ 8

5.2 – Installation........................................................................................................................................... 8

5.3 – Electrical connections ......................................................................................................................... 8

5.4 – Protection devices................................................................................................................................ 8

6 – INSTRUCTIONS FOR USE ........................................................................................................9

6.1 – Turning on ........................................................................................................................................... 9

6.2 – Programming of the operative modalities ........................................................................................ 9

6.2.1 – PPP0 – One single column............................................................................................................................ 10

6.2.1.a – Operative characteristics....................................................................................................................... 10

6.2.1.b – Programming of the flags ...................................................................................................................... 11

6.2.1.c – List of codes to be programmed ............................................................................................................. 12

6.2.2 – PPP1 – Three single columns. ...................................................................................................................... 12

6.2.2.a – Operative characteristics....................................................................................................................... 12

6.2.2.b – Programming of the flags ...................................................................................................................... 14

6.2.2.c – List of codes to be programmed ............................................................................................................. 15

6.2.3 – PPP2 – Two alternated single columns......................................................................................................... 15

6.2.3.a – Operative characteristics....................................................................................................................... 15

6.2.3.b – Programming of the flags ...................................................................................................................... 17

6.2.3.c – List of codes to be programmed............................................................................................................. 18

6.2.4 – PPP4 – One duplex column. ......................................................................................................................... 18

6.2.4.a – Operative characteristics....................................................................................................................... 18

6.2.4.b – Programming of the flags ...................................................................................................................... 20

6.2.4.c – List of codes to be programmed ............................................................................................................. 21

6.2.5 – PPPA – Two single columns in parallel........................................................................................................ 21

6.2.5.a – Operative characteristics....................................................................................................................... 21

6.2.5.b – Programming of the flags ...................................................................................................................... 22

6.2.5.c – List of codes to be programmed ............................................................................................................. 23

6.3 – Programming codes .......................................................................................................................... 24

6.3.1 – Access to the programming codes ................................................................................................................ 24

6.3.2 – List of programming codes and their use...................................................................................................... 24

6.4 – Programming of the reserve ............................................................................................................ 26

6.6 – Programming of the litre counter divider (prescaler) ................................................................... 27

6.7 – Calculation of the capacity of a system ........................................................................................... 28

6.8 – Putting into service ........................................................................................................................... 28

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 4/33

6.9 – Connections ....................................................................................................................................... 28

6.10 – Management of the dimensions of the tanks ................................................................................29

6.11 –Modifying the programming during service, the flag 2CP .......................................................... 30

7 – What to do if … ...........................................................................................................................30

7.1 - ... Aqua Cubic Multiplex does not come on ?.................................................................................. 30

7.2 - ... the motors of the distributors do not stop ? ................................................................................ 30

7.3 - ... there is no current to the utilisers? .............................................................................................. 30

7.4 - ... Aqua Cubic Multiplex works in an irregular way?.................................................................... 31

7.5 – … one column is not working ? ....................................................................................................... 31

Appendix A ........................................................................................................................................32

Appendix B ........................................................................................................................................33

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 5/33

1 – INTRODUCTION

Aqua Cubic Multiplex is a controller dedicated to the realisation of water softening systems working on the

principle of the ionic exchange of the resins.

The systems can be produced according to the following operative modalities:

- one single column;- one duplex column;

- two alternated single columns;- two single columns in parallel;

three single columns;

Aqua Cubic Multiplex automatically calculates the volume of water which can be treated based on the

hardness of the water, on the volume of the tanks and on the exchange capacity of the resins used, values

which must be programmed by the operator when the appliance is installed.

It is also possible to programme a percentage of reserve of the total volume, which allows for the

regeneration of the resins to be started before they have completely run out.

Aqua Cubic Multiplex allows for columns with different dimensional characteristics to be controlled,

that is with different volume values, also allowing the differentiation of the regeneration cycle times.

The regeneration cycle is completely programmable: it can be started up by the control on the volume,

manually, or by an external signal, it is possible to cancel the whole cycle or to jump one or more phases.

The regeneration may be immediate or deferred to a programmed time.

Aqua Cubic Multiplex may be connected to a computer via RS232 using the cable cod. 881-1, so as to be

able to acquire and then analyse the progress of the work parameters

Aqua Cubic Multiplex is equipped with a buffer battery which allows for the work parameters to be

retained in the memory should the electricity current fail.

Aqua Cubic Multiplex is equipped with an EEPROM memory, on which the programmed data is

memorised, with the capacity to retain data for over 10 years.

Aqua Cubic Multiplex, like all the range of SIATA controllers, conforms to the EEC Directives and is

produced in the SIATA plant of Montespertoli which operates with the certified Quality System according to

the regulation

ISO 9001 / UNI EN ISO 9001.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 6/33

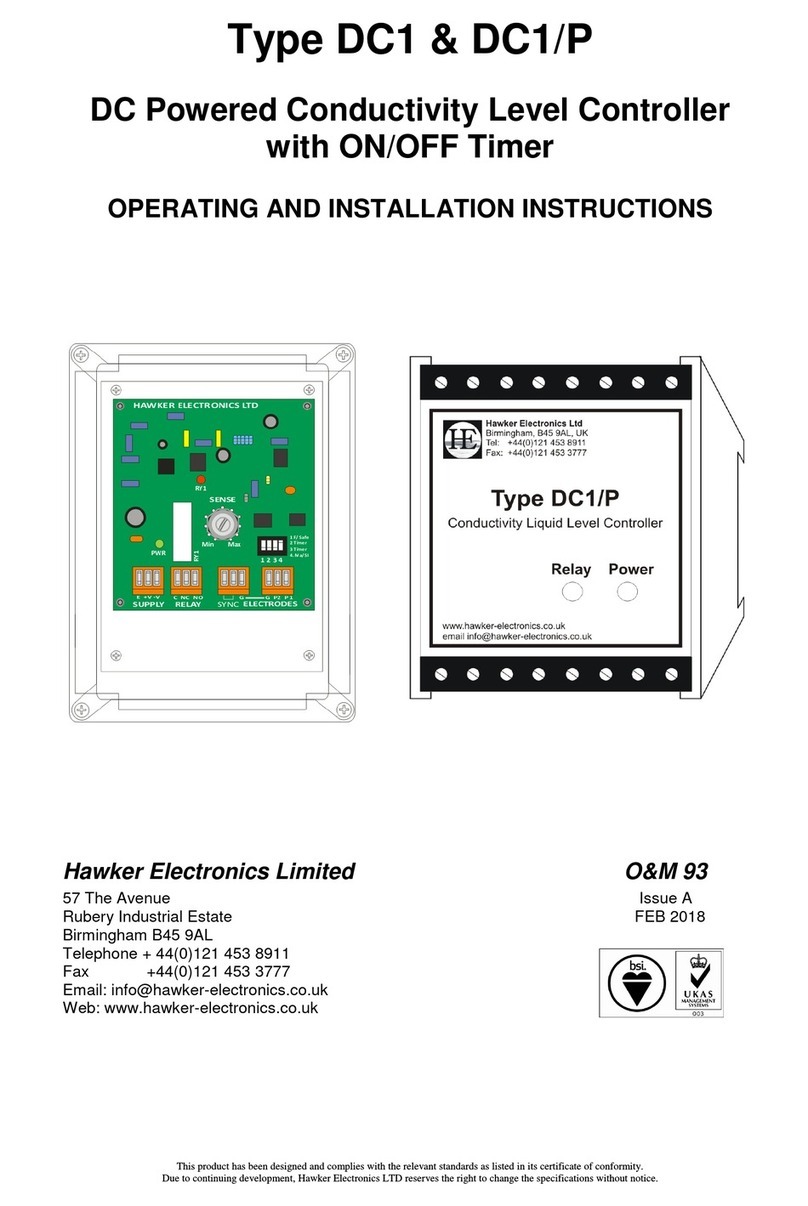

2 – TECHNICAL DATA

Supply voltage 230 Vac ±10%

Network frequency 50 Hz ±3%

Power absorbed 30 VA

Operative temperature 0° C – 55° C

Class of protection IP65

Protection from disturbances ICE 65 Trial class 4 ( 3000 V )

Reading scale 0 – 999,999 Litres

Container dimensions 240 mm x 185 mm x 115 mm

Total weight 1.5 Kg

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 7/33

3 – EXPLANATION OF THE LEDs AND OF THE KEYS

Tab. 1 – Functionality of the LEDs

Led Meaning

A SERVICE The column A is in service

B SERVICE The column B is in service

C SERVICE The column C is in service

REGENERATION Regeneration in progress

AThe display is visualising the data of the column A

BThe display is visualising the data of the column B

CThe display is visualising the data of the column C

ALARM Alarm

Tab. 2 – Functionality of the keys

0

Key in the number 0in the programming code.

Within a programming code annuls the value of the number being modified.

When the flag 1dP is programmed to 1, terminates any regeneration in progress.

RESET Allows for the programming to be exited from without memorising the last value keyed in.

PROGRAM Allows access to the programming functions.

1

Key in the number 1in the programming code.

When the flag 1dP is programmed to 1, starts up the regeneration of the column visualised by the

display.

During a stop phase of the regeneration cycle, annuls the residual time and accesses the next phase.

2 / +

Key in the number 2in the programming code.

During the programming increases the value on the display.

During the service, allows the column visualised by the display to be changed.

ENTER Confirms the programming code keyed in.

4 – STATES OF VISUALISATION OF THE DISPLAY

The display allows the visualisation of the data and of the operative states. When possible, the key 2/+ allows for the

passing from one column to the other. In this case, the LEDs A, Bor Cwill indicate to which column the data

visualised refers.

Tab. 3 – Visualisation of the display

Display Operative state / Data visualised

1 2 2.4 The column is in service. The display shows the available volume.

- - - - The column is in the stand-by phase after the regeneration.

1 C 2 0 The column is in regeneration.

0.0 0 0 The column has finished the volume programmed and is waiting to regenerate.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 8/33

5 – GENERAL

The installation of the controller must be carried out by qualified personnel; the installation procedures must be carried

out when the controller is disconnected from the electricity supply

5.1 – Packaging and storage

The packaging consists of a cardboard box with a label identifying the product, carrying the following information:

name of producer and PN producer AC-MULT2/05; the quick reference guide for the installation and programming

may be found inside.

No particular procedures are necessary for the removal of the controller from the packaging.

The controller must be stored in environments with the following characteristics:

• Temperature of between +0°C and +55°C;

• Relative humidity of between 30 % and 95 %.

5.2 – Installation

The appliance consists of a PVC box with a cover in plexi-glass which may be opened manually, giving access to the

keypad, and of a cover which may be removed by loosening two screws and which gives access to the external

connection terminal board.

The box is covered by a certificate with the IP65 grade of protection, Aqua Cubic Multiplex is therefore protected

against infiltration of dust and direct jets of water. This protection is valid when the cover is closed, and the wiring slots

are of the correct size for the cables used and are correctly assembled. If these conditions are not respected, the level of

protection falls to IP40, which gives no protection against infiltration of dust and water.

The back of the box is equipped with mechanical details which allow it to be wall-mounted.

5.3 – Electrical connections

The electrical connection of the controller must take place conforming to the conditions stated in the diagram CE0024

shown on the attached page.

The appliance is equipped with free contact exits with the following signals.

- Dosage pump

- A in service

- B in service

- C in service

- Alarm

Warning!!

Before carrying out any installation and/or maintenance operation, check that the controller is disconnected from the

electricity supply.

5.4 – Protection devices

The appliance is protected from current overloads by a 0.6A supply retardant fuse which is assembled on the front

panel. It is also protected against disturbances originating from the electricity supply by filters mounted inside the

controller.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 9/33

6 – INSTRUCTIONS FOR USE

6.1 – Turning on

The appliance is turned on via the main switch ON (I) - OFF (0) situated on the front panel. This switch acts on both

supply cables

The supply voltage must be 24 Vac - 50 Hz. (on demand 24 vac – 50 Hz. )

Check the supply voltage using the adhesive labels situated on the cover of the connections.

6.2 – Programming of the operative modalities

Before proceeding to the programming of Aqua Cubic Multiplex, it must be checked that the distributor cams are

positioned at the stroke end and that any unused limit switch entries on the terminal are closed with a connector

bridge. If this simple rule is not respected, Aqua Cubic Multiplex cannot enter into service and access to the keypad

will be limited after a few operations.

The programming will be carried out via the keypad on the front of the appliance.

Aqua Cubic Multiplex Plus has the following operative modalities:

Tab. 4 – Table of the operative modalities

Code Description Rotation times

P P P 0 One single column Regeneration in 4phases with rotation time of 50 seconds

P P P 1 Three single columns Regeneration in 4phases with rotation time of 50 seconds

P P P 2 Two alternated single columns Regeneration in 4phases with rotation time of 50 seconds

P P P 4 One duplex column Regeneration in 4phases with rotation time of 25 seconds

P P P A Two single columns in parallel Regeneration in 4phases with rotation time of 50 seconds

The selection takes place in accordance with the following sequence:

Tab. 5 – Selection of the operative modalities

Display Operative state / Data visualised

PROGRAM P 0 0 0 State of access to the selection of the operative modality

ENTER P P P x Visualisation of the current operative modality (x = 0, 1, 2, 4, A)

2 / + P P P * The key 2 / + modifies the operative modality as per tab. 4

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 10/33

6.2.1 – PPP0 – One single column

6.2.1.a – Operative characteristics.

This operative modality has been provided to resolve situations of emergency; Aqua Cubic Multiplex allows for the

use of a distributor connected to a valve to ensure the supply of treated water to the utiliser when breakdowns of any

degree of gravity do not allow the system to work fully and properly ( see par. 7.5 for details ).

The distributor must be connected to the terminals of the column A.

When the column is in service, the LED A Service will come on on the panel and the relative signal on the pins 43 – 44

of the terminal board will be active. The LED Awill be on, to confirm the fact that the display is visualising the

parameters of that column. As soon as the controller is in the position of waiting for the regeneration time, for example

because the volume has run out, the signal on the terminal board will go out, while the LED A Service will remain on

on the panel. As soon as the regeneration cycle starts, the signal on the terminal board will remain off, while on the

panel, the LED A Service will go out, and the LED Regeneration will come on.

The display will show the progression of the regeneration cycle.

The start of the regeneration cycle is controlled by the flags 0HP, 1HP, 2HP and 0dP.

To know how the controller reacts to the events, consult tab. 6. In the column Programming find the sequence of

values which corresponds to that programmed on the controller, and so, on the basis of the events, the manner in which

the controller will react may be seen.

Tab. 6 – Consequences of the events on the reaction of the controller based on the programming.

Events

Programming

0HP 1HP 2HP 0dP

The reg. time starts

with the finished days.

(1)

The volume reaches

the reserve.

The volume runs

out.

Remote start active

for 15 seconds.

0 0 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 0 0 0 The reg. starts. The reg. starts at the time. The reg. starts at the time. Imm. start. (2)

1 0 0 1 The reg. starts. The reg. starts at the time. The reg. starts at the time. Imm. start. (2)

1 0 1 0 The reg. starts. The reg. starts at the time. The reg. starts at the time. The reg. starts at the time.

1 0 1 1 The reg. starts. The reg. starts at the time. The reg. starts at the time. The reg. starts at the time.

1 1 0 0 The reg. starts. The reg. starts at the time. The reg. starts at the time. Imm. start. (2)

1 1 0 1 The reg. starts. The reg. starts at the time. The reg. starts at the time. Imm. start. (2)

1 1 1 0 The reg. starts. The reg. starts at the time. The reg. starts at the time. The reg. starts at the time.

1 1 1 1 The reg. starts. The reg. starts at the time. The reg. starts at the time. The reg. starts at the time.

N.B. :

(1) The expression “when the days have run out” is substituted with the expression “on the active days” when the flag

1HP is at 1. In fact, in these cases, the interval days between two regenerations are not programmed, but the active

days of the week on which the regeneration cycle is required.

(2) The start of the cycle is immediate if, at the moment of the activation of the remote Start signal, the controller is in

service. If, on the other hand, it is waiting for the regeneration time because the volume has run out, and the

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 11/33

controller is therefore not in service, the remote start signal is ignored and the regeneration will be carried out at the

programmed time.

(3) The expression “The reg. starts at the time” means that the cycle starts at the programmed time even if the

programmed interval days have not passed or if it is not an active day for the start of the regeneration cycle.

6.2.1.b – Programming of the flags

Tab. 7 shows the options available for the modality PPP0:

Tab. 7 – Selection of the operative modality “one single column, PPP0”

FLAG Display Operative state / Data visualised

PROGRAM P 0 0 0 State of access to the selection of the operative modality

ENTER

P P P x Visualisation of the current operative modality (x = 0, 1, 2, 4, A)

2 / + P P P 0 The key 2 / + modifies the operative modality as in tab. 4 : returns to 0

PROGRAM 0 H P 0 H P 0 Immediate regeneration by finished volume.

2 / + 0 H P 0 H P 1 Regeneration at the programmed time and deferred to the time by finished

volume.

PROGRAM 1 H P 1 H P 0 The interval days between two regenerations are programmed.

2 / + 1 H P 1 H P 1 The active days of the week are programmed.

PROGRAM 2 H P 2 H P 0 Immediate regeneration by Remote Start

2 / + 2 H P 2 H P 1 Regeneration deferred to the programmed time by Remote Start

PROGRAM 3 H P 3 H P 0 FLAG not used

PROGRAM 0 C P 0 C P 0 Modality of the litre counter divider (0 = free, see par. 6.6)

2 / + 0 C P 0 C P 1 Modality of the litre counter divider (1 = pre-programmed, see par. 6.6)

PROGRAM 1 C P 1 C P 0 FLAG not used

PROGRAM 2 C P 2 C P 0 The new programming is immediately operative.

2 / + 2 C P 2 C P 1 The new programming is operative after the next regeneration

PROGRAM 3 C P 3 C P 0 FLAG not used

PROGRAM 0 d P 0 d P 0 FLAG not used

PROGRAM 1 d P 1 d P 1 Enables the start and stop of the manual regeneration with the keys 1and 0

PROGRAM 2 d P 2 d P 0 FLAG not used

PROGRAM 3 d P 3 d P 0 FLAG not used

PROGRAM The rapid flashing of the display indicates that the values have been saved in

the eeprom.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 12/33

At the end of the programming the code 220 must always be keyed in (see par. 6.3) to initialise Aqua Cubic Multiplex

with the new parameters.

Note that the control on the reserve (flag 0dP) is automatically active and cannot be dis-activated.

6.2.1.c – List of codes to be programmed

For the programming and the meaning of the codes, see par. 6.3. In this modality, the programming of the following

codes is recommended:

Tab. 8 – Table of the codes recommended in the modality “one single column, PPP0”

Code Meaning

011 Programming of the value of the exchange capacity of the resins

012 Programming of the regenration time and the interval days between two regenerations

020 Programming of the time and day of the week

100 Programming of the volume of resin and of the percentage of reserve of the column A

110 Programming of the litre counter divider ( prescaler )

112 Programming of the regeneration cycle ( stop times )

010 Programming of the hardness value

220 Initialisation of the system

6.2.2 – PPP1 – Three single columns.

6.2.2.a – Operative characteristics.

This operative modality allows for the use of three distributors each of which is connected to a single SIATA valve.

The three columns alternate in service, so that while two are in service, the third will be first in regeneration and

then in stand-by.

When the controller is put into service, typically after having keyed in the 220, the column C is put into stand-by, while

the columns A and B are put into service. The signals to the pins 43 – 44 and 45 – 46 of the terminal board will be

active, respectively for the column A and the column B, while the pins 47 – 48 for the column C will be inactive. The

LEDs A Service and B Service on the panel will be on, while the LED C Service will be off.

The LED Awill be on to indicate that the display is visualising the volume of the column A.

With the key 2/+ it is possible to change the column visualised on the display. Each time the key is pressed, the LEDs

A, Bor Cwill come on when the data of the relative column is transferred to the display. If the column visualised is in

service it is possible to read the residual volume. If it is in regeneration it is possible to follow the progression. If it is in

stand-by, the display will show four lines.

When one of the columns in service goes into in regeneration by finished volume, the column in stand-by will go into

service in place of the column which has just run out. The LEDs on the panel will come on to indicate the new situation.

The LED Regeneration will be on for the whole duration of the regeneration cycle. The signals to the pins of the

terminal board mentioned above will also activate in accordance with the new situation.

This operative modality is not programmable. As seen in tab. 9, any programming of the flags always takes place in the

same way.

When one column finishes the available volume, the controller immediately enters into regeneration, and the column in

stand-by enters into service. If both of the columns in service have a residual volume of less than the calculated reserve,

the controller will start up a regeneration immediately for the column which in that moment has the lowest volume. The

control on the reserve cannot be disactivated. If this control is not required, the effects can be minimised by

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 13/33

programming the percentage of reserve at the minimum value of 10%.

Tab. 9 – Consequences of the events on the working of the controller on the basis of the programming.

Events

Programming

0HP 1HP 2HP 0dP

The reg. time is set

off with the finished

days.

The volume reaches

the reserve.

The volume runs

out.

Remote start active

for 15 seconds.

0 0 0 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 0 0 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 0 1 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 0 1 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 1 0 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 1 0 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 1 1 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

0 1 1 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 0 0 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 0 0 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 0 1 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 0 1 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 1 0 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 1 0 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 1 1 0

The reg. does not start. Immediate start. (1) Immediate start. Not available.

1 1 1 1 The reg. does not start. Immediate start. (1) Immediate start. Not available.

N.B. :

1) The start of the cycle is immediate only when both of the columns in service have a volume below the value of

reserve. The column which has the lowest volume out of the two starts in regeneration. If only one of the columns

reaches the value of reserve, the regeneration does not start, even at the programmed time.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 14/33

6.2.2.b – Programming of the flags

Tab. 10 shows the options available for the modality PPP1:

Tab. 10 – Selection of the operative modality “three alternated single columns, PPP1”

FLAG Display Operative state / Data visualised

PROGRAM P 0 0 0 State of access to the selection of the operative modality

ENTER P P P x Visualisation of the current operative modality (x = 0, 1, 2, 4, A)

2 / + P P P 1 The key 2 / + modifies the operative modality as per tab. 4 : returns to1

PROGRAM 0 H P 0 H P 0 FLAG not used

PROGRAM 1 H P 1 H P 0 FLAG not used

PROGRAM 2 H P 2 H P 0 FLAG not used

PROGRAM 3 H P 3 H P 0 FLAG not used

PROGRAM 0 C P 0 C P 0 Modality of the litre counter divider (0 =free, see par. 6.6)

2 / + 0 C P 0 C P 1 Modality of the litre counter divider (1 = pre-programmed, see par. 6.6)

PROGRAM 1 C P 1 C P 0 Same times of the regeneration cycle for the columns A/C and B

2 / + 1 C P 1 C P 1 Different times of the regeneration cycle for the columns A/C and B

PROGRAM 2 C P 2 C P 0 The new programming is immediately operative.

2 / + 2 C P 2 C P 1 The new programming is operative after the next regeneration

PROGRAM 3 C P 3 C P 0 FLAG not used

PROGRAM 0 d P 0 d P 0 FLAG not used

PROGRAM 1 d P 1 d P 0 Manual start and stop of the regeneration not active

2 / + 1 d P 1 d P 1 Enables the start and stop of the manual regeneration with the keys 1e 0

PROGRAM 2 d P 2 d P 0 FLAG not used

PROGRAM 3 d P 3 d P 0 FLAG not used

PROGRAM The rapid flashing of the display indicates that the values have been saved in the

eeprom

At the end of the programming the code 220 must always be keyed in (see par. 6.3) to initialise Aqua Cubic Multiplex

with the new parameters.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 15/33

6.2.2.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality, the programming of the following

codes is recommended:

Tab. 11 – Table of the codes recommended in the modality “three alternated single columns, PPP1”

Code Meaning

011 Programming of the value of the capacity of resins exchange

020 Programming of the time and of the day of the week (non influential)

100 Programming of the volume of resin and of the percentage of reserve of the column A

110 Programming of the litre counter divider (prescaler)

112 Programming of the regeneration cycle ( stop times ).

210 Transfer of the parameters programmed for the column A to the Band C

010 Programming of the hardness value

220 Initialisation of the system

N.B. :

If the three columns are of the same dimensions, it is supposed that they will alsobe regenerated with the same times of

the regeneration cycle. To this end, the flag 1CP must be programmed with the value 0. If the separate programming of

the cycle times of the column B is required, (the columns A and C use the same times, programmed with the code 112),

it is necessary to add to the list of tab. 11, the code 111, and the flag 1CP must be programmed with the value 1.

In the case in which columns of different dimensions are used, the recommended programming varies as follows:

Tab. 12 – Table of the codes recommended in the modality “three alternated single columns, PPP1” of different

dimensions

Code Meaning

011 Programming of the value of the capacity of resins exchange

020 Programming of the time and of the day of the week (non influential)

100 Programming of the volume of resin and of the percentage of reserve of the column A

101 Programming of the volume of resin and of the percentage of reserve of the column B

102 Programming of the volume of resin and of the percentage of reserve of the column C

110 Programming of the litre counter divider (prescaler)

111 Programming of the regeneration cycle ( stop times ) per the column B

112 Programming of the regeneration cycle ( stop times ) for the columns Aand C

010 Programming of the hardness value

220 Initialisation of the system

Remember that in order to use Aqua Cubic Multiplex as described in tab. 12, the flag 1CP must be programmed to 1.

6.2.3 – PPP2 – Two alternated single columns.

6.2.3.a – Operative characteristics.

This operative modality allows for the use of two distributors, each of which connected to a single SIATA valve.

The two columns alternate in service, and so while one is in service, the other will be first in regeneration and then

in stand-by.

As soon as it is put into service, typically after having keyed in the code 220, the column B is put into stand-by, while

the column A is put into service. The signal to the pins 43 – 44 of the terminal board will be active, while the signal to

the pins 45 – 46 for the column B will be inactive. The LED A Service on the panel will be on, while the LED B

Service will be off. The LED Awill be on to indicate that the display is visualising the volume of the column A.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 16/33

With the key 2/+ it is possible to change the column visualised on the display. Each time the key is pressed, the LEDs A

or Bwill come on when the data of the relative column is transferred to the display. Se the column visualised is in

service the residual volume can be read. If it is in regeneration, the progression can be followed. If it is in stand-by, the

display will show four lines.

When the column in service goes into regeneration by finished volume, the column in stand-by will go into service in

place of the column which has just run out. The LEDs on the panel will come on to indicate a new situation. The LED

Regeneration will be on for the whole duration of the regeneration cycle. The signals to the pins of the terminal board

shown above will also activate in line with the new situation.

This operative modality is not programmable. As may be seen in tab. 13, any programming of the flags always brings

on the same result.

When one column finishes the available volume, the controller immediately enters into regeneration, and the column in

stand-by enters into service. There is no control either on the reserve or on the remote start.

Tab. 13 – Consequences of the events on the working of the controller on the basis of the programming.

Events

Programming

0HP 1HP 2HP 0dP

The reg. time is set off

with the finished days.

The volume reaches

the reserve.

The volume runs

out.

Remote start active

for 15 seconds.

0 0 0 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 0 0 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 0 1 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 0 1 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 1 0 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 1 0 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 1 1 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

0 1 1 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 0 0 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 0 0 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 0 1 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 0 1 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 1 0 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 1 0 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 1 1 0

The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

1 1 1 1 The reg. does not start. The reg. does not start. Immediate start. The reg. does not start.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 17/33

6.2.3.b – Programming of the flags

Tab. 14 shows the options available for the modality PPP2:

Tab. 14 – Selection of the operative modality “two alternated single columns, PPP2”

FLAG Display Operative state / Data visualised

PROGRAM P 0 0 0 State of access to the selection of the operative modality

ENTER P P P x Visualisation of the current operative modality (x = 0, 1, 2, 4, A)

2 / + P P P 2 The key 2 / + modifies the operative modality as per tab. 4 : returns to2

PROGRAM 0 H P 0 H P 0 FLAG not used

PROGRAM 1 H P 1 H P 0 FLAG not used

PROGRAM 2 H P 2 H P 0 FLAG not used

PROGRAM 3 H P 3 H P 0 FLAG not used

PROGRAM 0 C P 0 C P 0 Modality of the litre counter divider (0 = free see par. 6.6)

2 / + 0 C P 0 C P 1 Modality of the litre counter divider (1 = pre-programmed see par. 6.6)

PROGRAM 1 C P 1 C P 0 Same times of the regeneration cycle for the columns Aand B

2 / + 1 C P 1 C P 1 Different times of the regeneration cycle for the columns Aand B

PROGRAM 2 C P 2 C P 0 The new programming is immediately operative.

2 / + 2 C P 2 C P 1 The new programming is operative after the next regeneration.

PROGRAM 3 C P 3 C P 0 FLAG not used

PROGRAM 0 d P 0 d P 0 FLAG not used

PROGRAM 1 d P 1 d P 1 Enables the start and stop of the manual regeneration with the keys 1and 0

PROGRAM 2 d P 2 d P 0 FLAG not used

PROGRAM 3 d P 3 d P 0 FLAG not used

PROGRAM The rapid flashing of the display indicates that the values have been saved in the

eeprom

At the end of the programming the code 220 must always be keyed in (see par. 6.3) to initialise Aqua Cubic Multiplex

with the new parameters.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 18/33

6.2.3.c – List of codes to be programmed

For the programming and the meaning of the codes see par. 6.3. In this modality, the programming of the following

codes is recommended:

Tab. 15 – Table of the codes recommended in the modality “two alternated single columns, PPP2”

Code Meaning

011 Programming of the value of the capacity of resins exchange

100 Programming of the volume of resin and of the percentage of reserve of the column A

110 Programming of the litre counter divider (prescaler)

112 Programming of the regeneration cycle ( stop times )

210 Transfer of the parameters programmed for the column A on the column B

010 Programming of the hardness value

220 Initialisation of the system

In the case of use of columns of different dimensions, the recommended programming varies as follows:

Tab. 16 – Table of the codes recommended in the modality “two alternated single columns, PPP2” different

columns

Code Meaning

011 Programming of the value of the capacity of resins exchange

100 Programming of the volume of resin and of the percentage of reserve of the column A

101 Programming of the volume of resin and of the percentage of reserve of the column B

110 Programming of the litre counter divider (prescaler)

111 Programming of the regeneration cycle ( stop times ) for the column B

112 Programming of the regeneration cycle ( stop times ) for the column A

010 Programming of the hardness value

220 Initialisation of the system

Remember that in order to use Aqua Cubic Multiplex as described in tab. 16, the flag 1CP must be programmed to 1.

6.2.4 – PPP4 – One duplex column.

6.2.4.a – Operative characteristics.

In this modality a single distributor connected to 2 SIATA valves is used. The distributor is connected to the

terminals of the column A.

This distributor has a special cam, modified so as to divide the 360º of rotation between the two valves; the first 180º

are dedicated to column A, the second to column B. Normally defined as column A is the valve connected to the pilots

1 and 2, those nearest to the distributor, and defined column B is the valve connected to the pilots 3 and 4 ( see also the

connections indicated in the attached page C).

Which of the two columns is active, and therefore which valve is in use, depends only on the position of the cam of the

distributor. The controller cannot know which column is in service. In fact, as will be shown, both the optical and

electrical signals will always communicate that column A is in service.

Suppose the following operations are to be carried out when the distributor has the cam in the stroke end position at the

beginning of the first 180º of rotation, that is so as to have the valve A in service. After having keyed in the code 220,

the controller will begin with the valve A in service. The signal to the pins 43 – 44 of the terminal board will be active.

The LED A Service on the panel will be on. The LED Awill be on to indicate that the display is visualising the volume

of the column A.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 19/33

The key 2/+, which normally allows for the column visualised on the display to be changed, cannot be used until a

regeneration starts. Normally the display shows the parameters of the column in service, indicating that they belong to

the column A. Having positioned the distributor so as to have the valve A in service, the parameters visualised are in

fact those of the column A. As soon as this valve enters into regeneration, regeneration, the signal to the pins 43 – 44

goes out and the rotation of the cam causes valve B to be put into service. The display visualises the progression of the

regeneration cycle.

Now pressing the key 2/+ it is possible to visualise the residual volume of the column as soon as it has entered into in

service, that is the volume of the valve B. Note that the LED Astill remains on.

As soon as the regeneration terminates, the LEDs on the panel will indicate again that the column A is in service and

that its parameters are being visualised. In reality, the display is showing the parameters of the valve B, those which,

during the regeneration cycle, it was possible to see only with the key 2/+. When the valve B has run out of volume and

starts the regeneration, the operations just described will be repeated and the parameters of valve A will be visualised

again.

To summarise:

1- the controller always indicates that the column A is in service;

2- the signal to the pins 43 – 44 of the terminal board goes off during the regeneration, so this signal cannot be used

for an electrical column exchange;

3- which valve is actually in service depends only on the position of the cam of the distributor;

4- during the regeneration, pressing the key 2/+ it is possible to visualise the volume of the column which has taken

over in service.

This operative modality is not programmable. As shown in tab. 17, any programming of the flags always brings on the

same result.

When one column finishes the available volume, the controller immediately enters into regeneration. The rotation of the

cam controls the exchange of the columns, so the stand-by valve enters into service.

Tab. 17 – Consequences of the events on the working of the controller ion the basis of the programming.

Events

Programming

0HP 1HP 2HP 0dP

The reg. time is set off

with the finished days.

The volume reaches

the reserve.

The volume runs

out.

Remote start active

for 15 seconds.

0 0 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 0 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

0 1 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 0 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 0 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 0 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 0 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 1 0 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 1 0 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 1 1 0

The reg. does not start. The reg. does not start. Immediate start. Immediate start.

1 1 1 1 The reg. does not start. The reg. does not start. Immediate start. Immediate start.

Aqua Cubic Multiplex - MAN0004 Rev. B 29.03.99 20/33

6.2.4.b – Programming of the flags

Tab. 18 shows the options available for the modality PPP4:

Tab. 18 – Selection of the operative modality “one duplex column, PPP4”

FLAG Display Operative state / Data visualised

PROGRAM P 0 0 0 State of access to the selection of the operative modality

ENTER P P P x Visualisation of the current operative modality (x = 0, 1, 2, 4, A)

2 / + P P P 4 The key 2 / + modifies the operative modality as per tab. 4 : returns to 4

PROGRAM 0 H P 0 H P 0 FLAG not used

PROGRAM 1 H P 1 H P 0 FLAG not used

PROGRAM 2 H P 2 H P 0 FLAG not used

PROGRAM 3 H P 3 H P 0 FLAG not used

PROGRAM 0 C P 0 C P 0 Modality of the litre counter divider (0 = free see par. 6.6)

2 / + 0 C P 0 C P 1 Modality of the litre counter divider (1 = pre-programmed see par. 6.6)

PROGRAM 1 C P 1 C P 0 FLAG not used

PROGRAM 2 C P 2 C P 0 The new programming is immediately operative.

2 / + 2 C P 2 C P 1 The new programming is operative after the next regeneration

PROGRAM 3 C P 3 C P 0 FLAG not used

PROGRAM 0 d P 0 d P 0 FLAG not used

PROGRAM 1 d P 1 d P 1 Enables the start and stop of the manual regeneration with the keys 1e 0

PROGRAM 2 d P 2 d P 0 FLAG not used

PROGRAM 3 d P 3 d P 0 FLAG not used

PROGRAM The rapid flashing of the display indicates that the values have been saved in the

eeprom

At the end of the programming the code 220 must always be keyed in (see par. 6.3) to initialise Aqua Cubic Multiplex

with the new parameters.

Table of contents

Other SIATA Controllers manuals