Hardi ISOBUS VT User manual

The Sprayer

Operator’s Manual

CONTROLLER

ISOBUS VT

Instruction book - SW 3.XX

67023603 - Version 1.10

US - 06.2015

CONTROLLER

ISOBUS VT

Instruction book - SW 3.XX

67023603 - Version 1.10

US - 06.2015

HARDI® reserves the right to make changes in design, material, or specification without notice thereof.

HARDI® and other product names are registered trademarks of HARDI® Inc. in the U.S. and in other countries.

Table of contents

TOC.1

1 - Welcome

Welcome letter ......................................................................................................................................1

2 - Safety notes

Operator safety .....................................................................................................................................1

Symbols ........................................................................................................................................................................................................................ 1

Precautions ................................................................................................................................................................................................................ 1

3 - Description

Introduction ..........................................................................................................................................1

About the ISOBUS VT system ......................................................................................................................................................................... 1

System description ................................................................................................................................2

Overall description ................................................................................................................................................................................................ 2

Terminals and boxes ..............................................................................................................................3

Types of terminals .................................................................................................................................................................................................. 3

ISOBUS Terminal layout ...................................................................................................................................................................................... 4

Soft keys menu tree .............................................................................................................................................................................................. 6

SetBox ............................................................................................................................................................................................................................ 7

HC 6300 Grip ............................................................................................................................................................................................................. 8

General keystrokes ................................................................................................................................................................................................ 8

Extended menu ................................................................................................................................................................................................... 10

Functions .............................................................................................................................................11

Auto functions general info .......................................................................................................................................................................... 11

End nozzles (Fence line) (optional) .......................................................................................................................................................... 11

DynamicFluid4 pressure regulation ........................................................................................................................................................ 12

SafeTrack (Trailed sprayers only) ................................................................................................................................................................ 14

HARDI® AutoSectionControl (optional) ................................................................................................................................................. 14

Menus ..................................................................................................................................................15

Full menu structure ........................................................................................................................................................................................... 15

4 - System setup

Tractor installation ................................................................................................................................1

Installation of control unit brackets ............................................................................................................................................................ 1

Printer ............................................................................................................................................................................................................................ 1

Speed transducer for sprayer ......................................................................................................................................................................... 2

How to set clock ..................................................................................................................................................................................................... 2

Initial settings ........................................................................................................................................3

System start-up ....................................................................................................................................................................................................... 3

Display readout ....................................................................................................................................................................................................... 3

ESC key for ISOBUS terminals ......................................................................................................................................................................... 3

Working in the field ...............................................................................................................................4

Set up before spray job ...................................................................................................................................................................................... 4

Volume rate ............................................................................................................................................................................................................... 5

Register readout and selection ..................................................................................................................................................................... 6

Tank contents ........................................................................................................................................................................................................... 6

TWIN Preset ................................................................................................................................................................................................................ 7

Spraying with DynamicFluid4 pressure regulation .......................................................................................................................... 7

Spraying with FlexCapacity pump .............................................................................................................................................................. 8

5 - Menu 1 Daily settings

Menu 1 Daily settings ............................................................................................................................1

Menu 1.1 Volume rate ......................................................................................................................................................................................... 1

Menu 1.2 Tank contents .................................................................................................................................................................................... 1

Menu 1.3 Select register .................................................................................................................................................................................... 1

Table of contents

TOC.2

6 - Menu 2 Setup

Menu 2 Setup .........................................................................................................................................1

General info ............................................................................................................................................................................................................... 1

Menu 2.1 Display readout ................................................................................................................................................................................. 1

Menu 2.2 Auto functions ................................................................................................................................................................................... 2

Menu 2.3 Variable Rate Application (VRA) / Remote / HARDI® AutoSectionControl ................................................... 3

Menu 2.4 Set clock ................................................................................................................................................................................................ 3

Menu 2.5 Alarms ..................................................................................................................................................................................................... 3

7 - Menu 3 Calibration

Menu 3 Calibration ................................................................................................................................1

Menu 3.1 Speed calibration ............................................................................................................................................................................. 1

Menu 3.2 Flow calibration ................................................................................................................................................................................ 3

Menu 3.3 Boom ....................................................................................................................................................................................................... 6

Menu 3.4 Regulation user setup ................................................................................................................................................................... 8

Menu 3.5 Tank gauge ....................................................................................................................................................................................... 11

Menu 3.6 Track ...................................................................................................................................................................................................... 14

8 - Menu 4 Toolbox

Menu 4 Toolbox .....................................................................................................................................1

Menu 4.1 Measure ................................................................................................................................................................................................. 1

Menu 4.2 Service intervals ................................................................................................................................................................................ 1

Menu 4.3 Service interval reset ...................................................................................................................................................................... 1

Menu 4.4 Reserved ................................................................................................................................................................................................ 1

Menu 4.5 Test ........................................................................................................................................................................................................... 2

Menu 4.6 Speed simulation ............................................................................................................................................................................. 2

Menu 4.7 Emergency ........................................................................................................................................................................................... 3

Menu 4.8 Computer CAN status ................................................................................................................................................................... 3

9 - Menu 5 Logbook

Menu 5 Logbook ....................................................................................................................................1

Menu 5.1 Print .......................................................................................................................................................................................................... 1

Menu 5.2 Data dump ........................................................................................................................................................................................... 2

10 - Maintenance

Off-season storage ................................................................................................................................1

Storage ......................................................................................................................................................................................................................... 1

11 - Fault finding

Operational problems ...........................................................................................................................1

Fault finding the system .................................................................................................................................................................................... 1

Checks for clogging .............................................................................................................................................................................................. 2

Checks for external leak ..................................................................................................................................................................................... 2

Location of components (trailed sprayers) ............................................................................................................................................ 3

Location of components (self-propelled sprayers) ........................................................................................................................... 4

Fault codes ................................................................................................................................................................................................................. 5

Emergency operation ..........................................................................................................................15

In an emergency situation ............................................................................................................................................................................ 15

Operation when a sensor fails ..................................................................................................................................................................... 15

12 - Testing and fine tuning

Testing and fine tuning .........................................................................................................................1

Fine tuning the flow constant - PPU .......................................................................................................................................................... 1

Pin & Wire connection ........................................................................................................................................................................................ 1

Testing flow transducer ..................................................................................................................................................................................... 2

Testing speed transducer ................................................................................................................................................................................. 2

Table of contents

TOC.3

13 - Technical specifications

Specifications ........................................................................................................................................1

Specifications ............................................................................................................................................................................................................ 1

Flow ranges for the flow transducers ........................................................................................................................................................ 1

Electrical connections ............................................................................................................................2

Types of plugs and fuses ................................................................................................................................................................................... 2

Materials and recycling .........................................................................................................................3

Disposal of electronics ........................................................................................................................................................................................ 3

Packaging information ....................................................................................................................................................................................... 3

Charts ....................................................................................................................................................4

Chart for recording values ................................................................................................................................................................................ 4

14 - Warranty

Warranty policy and conditions ............................................................................................................1

Table of contents

TOC.4

1.1

1 - Welcome

Welcome letter

Dear New HARDI® Owner,

Thank you for purchasing your new HARDI® product and welcome to the ever-increasing family of proud HARDI® owners.

HARDI® is the leading sprayer company in offering growers strong, reliable products made for the widest range of

applications worldwide. Quality, reliability, and resale value make the HARDI® product line the preferred product line of

customers both in North America as well as worldwide. Our guiding principle is to provide the highest level of customer

satisfaction and long term value in the marketplace today. We have developed a very high level of customer loyalty in the

marketplace which we are very proud of and strive every day to maintain and to continue to grow.

HARDI® is your specialist in spraying and we spend all of our time and keep all of our focus on spraying. We do not share our

resources between other types of products or compromise on anything in providing the best quality sprayers to the market

today. We can provide the latest in technology with our products if desired, or allow them to operate with the technology

that you already use on other products in most cases. You get to decide that, and what best suits your needs. We feel that

you, our customer, are the best suited to answer that question for your operation. Either way, you decide, and we will try and

help make it happen for you.

Our broad spectrum of product offerings, from the ruggedly simple models we build to our highly sophisticated models,

the built-in HARDI® strength and reliability ensures a low cost of ownership. HARDI® sprayers are all based on a functional

design concept of being as simple to operate as possible and to meet our customers’ requirements for all their application

needs.

Please take the time to thoroughly read the Operator’s Manual before using your equipment. You will find many helpful hints

as well as important safety and operation information.

Some of the features on your HARDI® sprayer were suggested by growers. There is no substitute for “on farm”experience

and we invite your comments and suggestions. If any portion of this instruction book remains unclear after reading it,

contact your HARDI® dealer or service personnel for further explanation before using the equipment.

For Product, Service or Warranty Information please contact your local HARDI® dealer.

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

HARDI® NORTH AMERICA INC.

Visit us online at: www.hardi-us.com

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1280

Sincerely,

Wayne Buchberger

President

1 - Welcome

1.2

2.1

2 - Safety notes

Operator safety

Symbols

These symbols are used throughout the book to designate where the reader needs to pay extra attention.

€This symbol means DANGER. Be very alert as your safety is involved!

±This symbol means WARNING. Be alert as your safety can be involved!

This symbol means ATTENTION. This guides to better, easier and safer operation of your sprayer!

÷This symbol means NOTE.

Precautions

Note the following recommended precautions and safe operating practices before using the sprayer.

General info

€Read and understand this instruction book before using the equipment. It is equally important that other operators

of this equipment read and understand this book.

€If any portion of this instruction book remains unclear after reading it, contact your HARDI® dealer for further

explanation before using the equipment.

€Keep children away from the equipment.

€Press the keys with the underside of your finger. Avoid using your fingernail.

€Local law may demand that the operator is certified to use spray equipment. Adhere to the law.

€Tractor driver’s seat is the intended working place during operation.

Service

€Test with clean water prior to filling with chemicals. Rinse and wash equipment after use and before servicing.

€Never service or repair the equipment while it is operating. Always replace all safety devices or shields immediately

after servicing.

€Turn electrical power off before connecting and disconnecting the display and transducers, servicing or using a

battery charger.

€If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

welding. Remove all flammable or explosive material from the area.

€Do not use a high pressure cleaner to clean the electronic components.

2 - Safety notes

2.2

3.1

3 - Description

Introduction

About the ISOBUS VT system

The ISOBUS VT is for use in agricultural and horticultural production. The components are developed to last many years

under agricultural conditions.

The system has a non-volatile memory without battery which simplifies storage. All parameters in the menus are saved in

the memory and are not lost when the power is disconnected.

The transducers utilized are chosen for long service life and good signal quality. The speed and flow transducers have a built-

in diode that will flash to indicate when it’s functioning, to aid servicing.

Optional transducers include pressure and revolutions readout. Other options include a 12 Volt printer.

Working pictures will be shown in different colors, depending on the function used.

Display readouts

Among many possible display readouts, are:

•Volume rate.

•Speed.

•Liquid rate per minute.

•Total covered area.

•Total volume sprayed.

•99 trip registers. It includes a total register that summarizes data from the 98 trip registers.

The system is also compatible with Variable Rate Application (VRA) and is prepared for communication with Precision

Farming tools (e.g. HARDI® AutoSectionControl). Data dump of registers and configuration to a personal computer

are possible.

Functions include

•Correct area with closure of up to 13 spray boom sections.

•Many alarm functions and possibility for audio/visual alarm etc.

•Many warnings depending on operation. Alarms and warnings is shown in the bottom left 1/4 corner of the display

on some VT screens. HC 9500 will show alarms in top of the screen.

Main components Location

ISOBUS terminal Tractor/Self-propelled

HC 6300 Grip Tractor/Self-propelled

HC 6400 SetBox/Spray Center Tractor/Self-propelled

HC 6100 JobCom Sprayer/Self-propelled

HC 6200 FluidBox/Outside Box Sprayer/Self-propelled

3 - Description

3.2

System description

Overall description

The precise wiring setup can vary, depending on the terminal mounted.

ISOBUS system (trailed)

ISOBUS system (self-propelled)

A. HC 9500 or VT Terminal.

B. SetBox and Grip.

C. GPS antenna (optional).

D. IBBC connector.

E. Vehicle bus.

F. ISOBUS.

G. FluidBox (i-sprayers only).

H. JobCom (Implement ECU).

I. Center section junction box.

J. Hydraulics block.

K. AutoHeight UC5.

L. ISOBUS bridge.

M. Cabin connector.

3 - Description

3.3

Terminals and boxes

Types of terminals

This software can run with two types of ISOBUS display terminals.

ISOBUS terminals with physical buttons

ISO terminals with physical function buttons, e.g. the Massey Ferguson

terminal shown.

•Conventional or touch screen and physical buttons.

•Function buttons are graphical but are operated by physical

buttons on the terminal.

•The software runs as a Virtual Terminal (VT) into the terminal

software.

ISOBUS terminals with touchscreen interface

HARDI® HC 9500 or similar ISO terminals with touchscreen interface. The

HC 9500 is shown.

•Touchscreen and no buttons (except ON/OFF).

•Function buttons are graphical and operated by pressing the

touch screen.

•The software runs as a Virtual Terminal (VT) into the terminal

software.

3 - Description

3.4

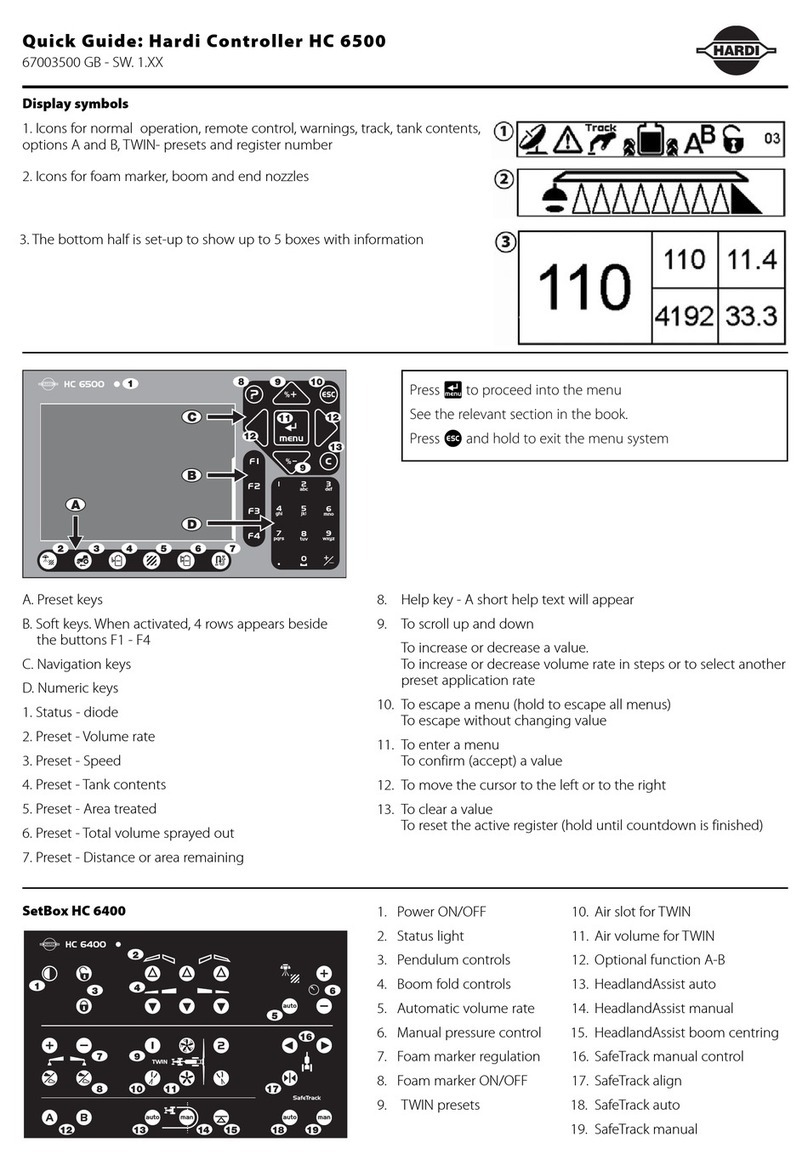

ISOBUS Terminal layout

The ISOBUS terminal layout is described as follows:

ISOBUS virtual terminal buttons

1. Scroll up, increase a value or volume rate.

2. Enter menu.

3. Scroll down, decrease a value or volume rate.

4. Preset keys.

5. Soft menus.

6. Escape a menu.

7. Scroll up.

8. Enter menu or confirm a value.

9. Scroll down.

3 - Description

3.5

Display symbols

These symbols are common on VT (Virtual Terminal) displays.

1. The 1st Line is for status symbols, register number and alarm

number. All status symbols will be displayed here.

ATTENTION! If an error occurs, alarm/warning error number will

be shown instead of register number. The alarm/warning

number can be recognized by the exclamation sign in front of the

number.

2. The 2nd Line is for boom status, foam marker and end nozzle

indications.

3. ISOBUS: The bottom half has 6 boxes with selectable information.

÷NOTE! See “Menu 2.1 Display readout” on page 6.1 for setup of

the display readouts in the bottom half of the terminal display.

1st line status icons

All “OK” Information Warning Stop (critical) Over or under

application

Volume rate

Automatic

Variable rate (GPS)

active

Volume rate Manual Pendulum Locked Pendulum

Unlocked

Track Crab left Track Crab right Track Lock Track Automatic Track Manual

Options A on Options B on Options both on Options both off

TWIN Preset 1 TWIN Preset 2 TWIN Manual

Auto mode

Nozzle size

calculated

Auto mode

No flow to sections

Auto mode

Nozzle size not

calculated

Manual mode

Nozzle size

calculated

Manual mode

No flow to sections

Manual mode

Nozzle size not

calculated

Increment steps

mode

Nozzle size

calculated

Increment steps

mode

No flow to sections

Increment steps

mode

Nozzle size not

calculated

3 - Description

3.6

A. Preset keys

Vital information while spraying is quick and easy

to access.

Pressing the button will enter a submenu with the

preset keys.

B. Soft keys

Soft keys control optional features. Press the soft

key button to activate a submenu with further

features.

ATTENTION! The number of levels in the soft

key menu system depends on the number

of functions - see also “Soft keys menu tree”

below.

C. Navigation keys

The navigation keys are initially used for set up in the menu system by coding in values. The navigation keys can change the

volume rate in a set percentage or fixed volume rate. Other keys appear as needed on the ISOBUS Terminal.

D. Numeric keys

The keys will be the standard numeric keypad for the specific ISOBUS terminal.

Soft keys menu tree

ISOBUS Description

This key appears whenever necessary at respective menus, etc.

See “ESC key for ISOBUS terminals” on page 6.1 for setup of this

button.

Used to escape back to previous screen.

This key appears whenever necessary at respective menus, etc. Used to scroll up.

This key appears whenever necessary at respective menus, etc. Used to enter a menu or confirm a value.

This key appears whenever necessary at respective menus, etc. Used to scroll down.

This is normally a key in the standard numeric keypad of the specific

terminal.

Used to clear a value or register.

LEVEL 1 LEVEL 2 LEVEL 3 LEVEL 4

ICON FUNCTION ICON FUNCTION ICON FUNCTION

F1 EndNozzles F1 Left ON Work screen

F2 Left OFF

F3 Right OFF Work screen

F4 Right OFF

3 - Description

3.7

SetBox

The SetBox controls secondary functions. The keys are grouped into control areas to simplify operator understanding.

÷NOTE! Self-propelled sprayers do not have a SetBox as the controls are built-in to the cabin.

1. Power ON/OFF.

2. Pendulum unlock.

3. Pendulum lock.

4. Inner wing fold.

5. Inner wing unfold.

6. 1st outer wing fold.

7. 1st outer wing unfold.

8. 2nd outer wing fold.

9. 2nd outer wing unfold.

10. Automatic volume rate selector.

11. Manual pressure control.

12. Foam marker regulation.

13. Foam marker Left/Right selector.

14. DynamicCenter adjustment (increments).

15. DynamicCenter outer positions 1 or 5.

16. Optional function A-B.

17. HeadlandAssist automatic.

18. HeadlandAssist boom align.

19. SafeTrack manual control (if installed).

20. SafeTrack align selector (if installed).

21. SafeTrack automatic selector (if installed).

ATTENTION! Button 1 has different function on ISOBUS sprayers as this turns the JobCom ON/OFF.

ATTENTION! Buttons 17 and 18 can have different functions if the sprayer is equipped with AutoHeight.

ATTENTION! The Grip cannot be switched ON/OFF separately. It is automatically switched ON when tractor power is

turned ON (ISOBUS).

3 - Description

3.8

HC 6300 Grip

The Grip is an ergonomic remote unit that can be easily mounted inside

the tractor cabin. All common functions required during normal

spraying can be operated with the Grip. Also the Grip controls some

optional functions.

ATTENTION! The Grip cannot be switched ON/OFF separately. It is

automatically switched ON when tractor power is turned ON

(ISOBUS).

A. Status LED.

B. Boom section controls (up to 13).

C. Main ON/OFF.

D. Tilt.

E. Boom height.

F. Boom slant.

G. Not used.

H. TWIN presets.

General keystrokes

The first steps to choose a menu are shown below. See also “Full menu structure” on page 3.15.

Menu selection

1. Press {Menu} Virtual Terminal button to proceed into the menu.

2. Navigate to desired submenu using arrows.

3. In the menu, the current selection is marked with a colored bar.

4. Move the menu colored bar up and down by using the {up} and

{down} arrows.

÷NOTE! A maroon colored bar indicates current setting.

5. Confirm selection by pressing the enter arrow.

ATTENTION! Press {ESC} to leave the menu without changing values.

÷NOTE! There is help text for each menu in the bottom of the display. The displayed help text corresponds to the

location of the colored bar on the Virtual Terminal.

Table of contents

Other Hardi Controllers manuals

Hardi

Hardi HC 9600 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC 5500 SPRAY BOX III User manual

Hardi

Hardi HC 8500 User manual

Hardi

Hardi HC 6500 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC 6500 User manual

Hardi

Hardi HC5500 User manual

Popular Controllers manuals by other brands

Power Electronics

Power Electronics VS65 Series Hardware and installation manual

Bürkert

Bürkert TopControl ON/OFF operating instructions

Cisco

Cisco Catalyst C9800-L Hardware installation guide

ASG

ASG ASG-SD2500 user guide

AGS

AGS Merlin 1000S Installation, operation and maintenance guide

Emerson

Emerson AMPGARD RVSS Instruction booklet