TECH ST-77 Assembly instructions

ST – 77

Manual Guide

ST-77 – Manual Guide

TECH

Declaration of compatibility number 3/2004

We, TECH company, ul St Batorego 14, 34-120 Andrychów, declare with

the full responsibilty, that thermoregulator ST-77 230V, 50Hz produced

by our company complies with the demands of the Decree of the Ministry

of Economy, Employment and Social Politics (Dz U 03 49 414) from 12th

March 2003, implementing decisions of Low Voltage Directiv

73/23/EWG, and the Decree of the Ministry of Infrastructure (Dz U

03 90 848) from 2nd February 2003 impplementing decisions of EMC

Directiv 89/336/EWG

Harmonised standards PN-EN 60730-2-1:2002 were used to evaluate

compatibility

For the first time, the product was marked CE on 4th May 2004

Co-owners:

Paweł Jura, Janusz Master

Andrychów, 4th May 2004

- 2 -

TECH

CAUTION!

LIVE ELECTRIC DEVICE!

Before doing anything demanding current

supply (e g connection of wires,

installation of the device, etc ) one must

make sure that the regulator is not live!

The device should be intstalled by a person

with adequate electrical training and

certificates

Before starting the programmer one

should measure the effectiveness of

neutralization of electric engines, boiler, as

well as measure insulation of electric

wiring

- 3 -

ST-77 – Manual Guide

I. Description

Temperature regulator ST-77 is to be used with the Central Heating

Boilers It steers the pump of water circulation, the pump of Consumed

Hot Water (C H W ), the fan and the fuel feeder

●if the temperature of the boiler is lower than the Set Temperature, the

regulator is in a cycle of ork in which the fan works all the time; fuel

feeder working time is set up by the user (both the time of work and

the time of break have to be set up)

●if the themperatre of the boiler is equal or higher than the Set

Temperature, the regulator is in the cycle of support

- 4 -

Button MINUS

Button that allows

for escaping from the

menu and cancelling

the set up

Button that allows

for entering menu

and confirming the

set up

Button PLUS

TECH

II. Functions of the regulator

This chapter describes the functions of the regulator, the way of

changing the set up, and the way of using the menu

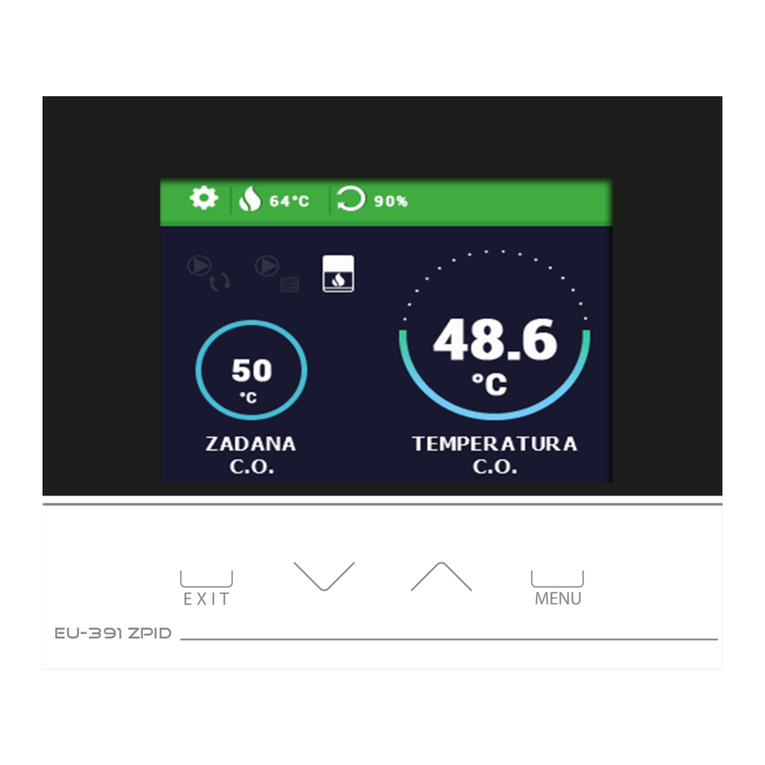

II.a) Main page

During the normal work of the regulator, the LCD projector shows

the main page, which gives the following information:

●The temperature of the boiler (CH)

●The set temperature

This screen enables quick change of the Set temperature by using

buttons PLUS and MINUS Pressing button MENU takes user to the first

level of the menu The projector shows first two lines of the menu One

can move in ech of the menus by using buttons PLUS and MINUS

Pressing button MENU takes the user to the further menu or starts the

chosen option ESCAPE takes the user back to the previous menu In the

case of projecting the main page, pressing (and holding) the button

ESCAPE will show the screen informing of turning the pump of consumed

hot water on or off

II.b) Manual work

- 5 -

62oc 72oc

CH SetTemp

Manual Work

WorkingTimeoffee

62oc 72oc

CH SetTemp

Feeder

Fan

ST-77 – Manual Guide

For the user’s comfort, the regulator was equipped with the Manual

Work function This function allows for turning each element of the

system on and off regardless of the other elements

Pressing button MENU starts the fuel feeder The feeder works until

button MENU is pressed again

Pressing MENU turns the fan on/off

Pressing button MENU turns the water pump on/off

Pressing button MENU turns the CHW pump (boiler pump) on/off

Pressing button MENU turns alarm on/off (see also the chapter

Alarm)

- 6 -

Feeder

Fan

Feeder

Fan

Fan

Pump

CHW Pump

Alarm

CH Pump

CHW Pump

TECH

II.c) Working time

This option allows for setting up the working time of the

fuel feeder Working time set up depends on the type used fuel as well as

on the type of the boiler

II.d) Break Time

Button Feeder Break Time is for setting break in the feeder working

time The break has to be adequate to the type of fuel used in the boiler

Wrong set up of both the feeder working time as well as the feeder break

time may cause faults in the work of the boiler, i e coal may not get

burnt in full or the boiler may not reach the set temperature Choosing

the right times allows the boiler to work well

II.e) Temperature of turning CH and CHW pumps on.

- 7 -

62oc 72oc

CH Set Temp

12 min 3 sek

Feeder BreakTime

Feeder Work Time

Feeder BreakTime

62oc 72oc

CH Set Temp

62oc 72oc

CH Set Temp

Feeder Work Time

Feeder BreakTime

min 3 sek

Feeder Work Time

ST-77 – Manual Guide

This function allows to set up the temperature of turning CH and

CHW Pumps on (it’s the temperature measured in the boiler) Below the

set temperature both pumps don’t work, above the set temperature both

pumps are turned on, but they work depending on the settings, i e they

are turned on alternately (see function priority pump or constant CH

pump)

II.f) CHW Hysteresis

This function allows for setting up the hysteresis of the set

temperature in the boiler It is a difference between the set temperature

(so the temperature the user wants to have in the boiler) and the

temperature that is in the boiler at a certain time (e g if the set

temperature equals 55 C and hysteresis equals 5 C: after reaching the

set temperature, i e 55 C, the CHW pump turns itself off and the CH

pump turns itself on; the CHW pump will turn itself on again after the

temperature drops to 50 C)

II.g) Hysteresis

- 8 -

Feeder BreakTime

CH and CHW Pump

35 oc

CH and CHW Pump

62oc 72oc

CH Set Temp

62oc 72oc

CH . Set Temp

CH and CHW Pump

CHW Hysteresis

1 oc

CHW Hysteresis

TECH

This function allows for setting up hysteresis of the set temperature

It is the difference between the output temperature in the support cycle,

and the temperature needed for return to the cycle of work (e g when

set temperature equals 60 C, and hysteresis equals 3 C, the boiler will

enter the cycle of support after reaching temperature of 60 C, whereas it

will return to the cycle of work when the temparture drops to 57 C)

II.h) an Speed

This function steers the speed of work of the fan It can be regulated

between speed 1 nad speed 6 (it can be said that these are the fan’s

gears) The higher the gear the faster the fan works Gear 1 is fan’s

minimum speed and gear 6 is fan’s maximum speed

Changes between gears can be introduced by pressing buttons PLUS or

MINUS The fan always starts working with the maximum speed –

thanks to this set up it is possible to turn the fan on even when the

engine is dusted

II.i) Activation of CHW Pump – Boiler’s priority

Activation of CHW pump (by pressing button ON), will make

regulator work in the process called Boiler’s priority In this process CHW

pump (boiler’s pump) is on until it reaches the set temperature, then it is

automatically turned off and the CH pump is activated

- 9 -

3

Fan Speed

Hysteresis

Fan Speed

62oc 72oc

CH Set Temp

CHW Hysteresis

Hysteresis

2oC

Hysteresis

ST-77 – Manual Guide

To change the set temperature of CHW pump, press button Escape-

wyjscie (hold it for a few seconds) and the screen will project boiler’s set

temperature and boilers actual temperature

To change the temperature range use buttons PLUS or MINUS

After a few seconds the projector goes back to its initial stage After

reaching the boiler’s set temperature, CHW pump is turned off and the

CH pump is turned on

In this process, the work of the fan and the feeder is limited to the

temperature of 62 degrees in the boiler It prevents the boiler from over-

heating This state of the boiler will be supported until it reaches the the

set temperature If the set temperature is reached, CHW pump is turned

off and the CH pump is turned on

CH pump continues working until the temperature in the boiler drops

below the set temperature Then CH pump is turned off and the CHW

pump is turned on

The process of ‘boiler’s priority’ makes the boiler heat the consumed hot

water first and only afterwards heat the water in radiators

Caution! Non-return valves should be installed on the CHW and CH

pumps’ circulations The valve installed on the CHW pump prevents from

taking the hot water out of the boiler The valve installed on CH pump

does not let the hot water that heats the boiler be used in the house

II.j) Room regulator

- 10 -

62oc 72oc

CH Set Temp

CHW Pump

CHW Pump

62oc 72oc

CH Set Temp

Fan Speed

CHW Pump

off

on

TECH

Room regulator can be adjusted to the regulator ST-77 Then it has

a higher priority The feeder and the fan work until the temperature set

on the room regulator is reached However, the work of the boiler is

limited by the temperature set on the regulator installed on the boiler

II.k) Alarm

To set up the activation time for the alarm of temperature use

buttons PLUS/MINUS To save the set time press button MENU This

function is activated only in the cycle of ork (i e when the temparuter

of the boiler is lower than the set temperature If the temperature of the

boiler does not increase in the time set by the user, alarm is activated:

the feeder and the fan are automatically turned off, (water pump is

turned on/off independenty), and the sound signalling is turned on The

screen projects an adequate message (see chapter Safety Protection)

II.l) unction of the constant CH pump

Activating this function of the regulator starts parallel work of the

pumps above the set temperature (see sub-chapter: Temperature of

turning CH and CHW pumps on): CH pump works all the time and the

CHW pump is turned off after reaching the set on the boiler temperature

Caution! It is important to install a three-way valve or another mixing

valve that would keep different temperature in the boiler from the one in

the house

- 11 -

off

on

1 gdz 1 min

ALARM

62oc 72oc

CH Set Temp

Room Regulator

ALARM

ST-77 – Manual Guide

II.m) Summer function

After activating this function the CH pump is turned off and the CHW

pump is turned on above the set temperature (see sub-chapter:

Temperature of turning CH and CHW pumps on) It is turned off after

reaching the temperature set on the boiler CHW pump is turned on again

after the temperature on the boiler drops 10 degrees

II.n) Burning

- 12 -

on

off

62oc 72oc

CH Set Temp

alarm

Constant CH Pump

yes

no

62oc 72oc

CH Set Temp

Constant CH Pump

Summer Function

Burning Break

Produce. Settings

62oc 72oc

CH Set Temp

TECH

This function allows for regulating the work of the boiler during the

support cycle It prevents the boiler from burning out when the

temperature of the boiler is above the set temperature.

In this function the break time of the feeder and the fan need to be set

up After the set time the feeder and the fan are turned on for the time

set by the producer of the boiler The time of work of the fan and the

feeder can be changed in the service functions The time of break of

burning should be set up depending on the type of the fuel and the boiler

Caution! Wrong set up of the described functions may cause

constant increase in the temperature! The time of break of

burning shouldn’t be too short.

II.o) Producer’s settings

The regualtor is preliminarily configurated for work However, it

should be adjusted to the individual needs of the user It is possible to

return to the Producer’s settings at any time

III. Safety Protection

In order to provide the maximum of safe and faultless work, the

regulator is equipped in a variety of safety protections Alarm activates

sound signalling and the screen projects an adequate message The

regulator will start working again after pressing button MENU.

- 13 -

62oc 72oc

CH . Set Temp

no

yes

Feeder and Fan

Produce Settings

ST-77 – Manual Guide

III.a) Temperature Alarm

This protection activates only in the cycle of ork (i e when the

temperature of the boiler is lower than the Set Temperature) If the

temperature does not increase in the time set by the user (see sub-

chapter: Alarm) , alarm is activated: the feeder and the fan are

automatically turned off, (water pump is turned on/off independenty),

and the sound signalling is turned on The screen projects an adequate

message:

The regulator expects the button MENU to be pressed, after which

the alarm is turned off The regulator returns to the previously set

process of work

III.b) Thermal Protections

It is an additional bimetallic mini-sensor (installed next to the

boiler’s sensor) which cuts off the feeder and fan’s exits in the case of

reaching and exceeding the temperature of 90 degrees It prevents water

which is in the system from boiling in case of the failure in the work of

the regulator

III.c) Automatic Sensor Control

Alarm is activated in the case of failure in the work of the sensors of

CH or CHW temperature or in the work of worm Adequate message

about the failure is also projected on the screen, e g :

The feeder nad the fan are turned off The pump is turned on

independently of the actual temperature The regulator i waiting for the

button MENU to be pressed after which alarm is turned off and the

regulator starts working again

- 14 -

A L A R M

NOINCREASE INTEMP

A L A R M

SENSOR FAILURE

TECH

III.d) Protection against boiling water in the boiler

This protection prevents high temperature to appear in the

boiler (only during using the function: boiler’s priority) When the

set on the boiler tempertaure equals 55 degrees Celsius and the actual

temperature in the boiler equals 62 C, the feeder and the fan are turned

off When the temperature increases to 80 C, CH pump is turned on

When the temperature still continues to increase, when it reaches 85 C

alarm is turned on Described situation may appear when boiler is

damaged or faulty, the sensor is installed in the wrong way, or the pump

has a fault However, if the temperature decreases, when it drops to 60 C

the regulator will turn the feeder and the fan on and it will work until

reaching the set on the boiler temperature

III.e) Temperature Safety Protections

The regulator is equipped in an additional protection in the case of

faulty bimetallic sensor: alarm is turned on and an adequate message is

projected on the screen after the tempertaure of 95 degrees is exceeded:

III.f) uel eeder Protection

The worm in the fuel feeder is equipped in an additional sensor

measuring temperature Alarm is turned on when the temperature

increasea significantly (above 65 C): the feeder is turned on for 10

minutes in order to move the fuel to the combustion chamber The sensor

in the worm prevents the fuel from burning in the basket

III.g) use

The regulator is equipped in tubular fuse-element WT 6 3A, that

protects the system

- 15 -

A LA R M

BasketSen Failure

A L A R M

TOO HIGH TEMP

ST-77 – Manual Guide

IV. Maintenance

It is important that the technical condition of the cabling is checked

before and during the heating period Additional actions that need to be

taken in the same time are: check the fastening of the regulator, clean it

from dust and other contamination; measure the effectiveness of the

engines earthing (pump, CHW pump, fan and feeder)

L.p. Specification Units

1 Current Supply V 230V/50Hz +/-10%

2 Power Consumption W 4

3 Ambinet Temperature OC0±40

4 Load of the Circulating Pump Exit A 1

5 Range of Temperature Measuring OC0±90

6 Measuring Error OC 1

7 Range of Set Temperatures OC0±85

8 Temperature Resistance of the Sensor OC- 25 to 100

V. Repairs

All faults should be reported to:

TECH S C

34-120 Andrychów ul St Batorego 14

tel 33 8705105 , 33 8759380

- 16 -

TECH

VI. Installation

Caution! Installation should be performed by a person with

adequate training and certificates The device MUST NOT BE LIVE at the

time of installation (one MUST make sure that the plug is

DISCONNECTED from the power network)

CAUTION! Wrong installation of the cabling may damage

the regulator.

The regulator cannot work in the closed system of the central

heating Safety valves, pressure valves and surge tank that protect the

boiler from boiling of water in the central heating system must be

installed

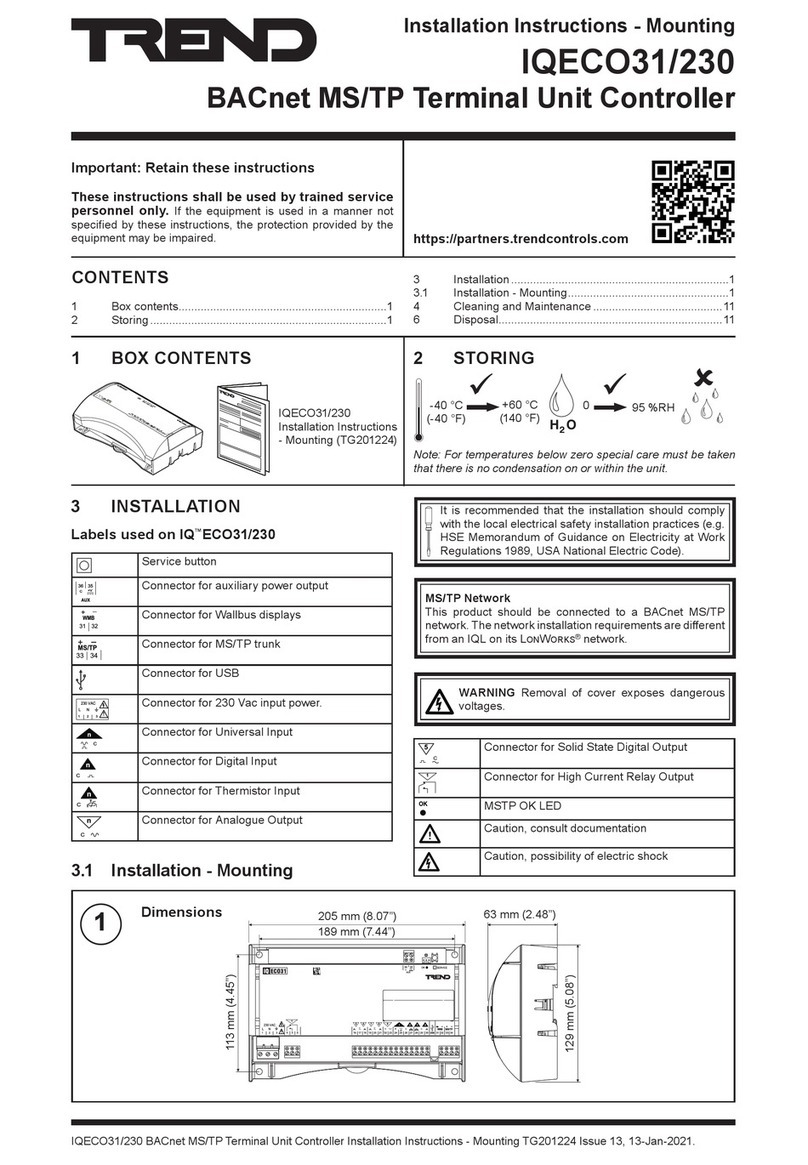

VI.a) Diagram of the regulator’s cabling installation

Additional attention has to be paid during installation of the regulator’s

cabling It is very important to install the earthing wiring in the right

way

- 17 -

PE

N

L

FUSE 6 3A

~

Transmiter

230V AC

Fan

~

Transmiter

230V AC

CH Pump

~

Transmiter

230V AC

Feeder

~

Transmiter

230V AC

CHW Pump

Room

regulator

Thermical

Fuse

Boiler s

Sensor

Worm s

Sensor

Boiler s

Sensor

Feeder

Fan

CH

Pump

CHW

Pump

Network

L L L L

N N N N NL

1 2 3 4 5 6

7 8 9 10 11 12

Reed Relay

Spis treści

I Description 4

II Functions of the regulator 5

II a) Main page 5

II b) Manual work 5

II c) Working time 7

II d) Break Time 7

II e) Temperature of turning CH and CHW pumps on 7

II f) CHW Hysteresis 8

II g) Hysteresis 8

II h) Fan Speed 9

II i) Activation of CHW Pump – Boiler’s priority 9

II j) Room regulator 10

II k) Alarm 11

II l) Function of the constant CH pump 11

II m) Summer function 12

II n) Burning 12

II o) Producer’s settings 13

III Safety Protection 13

III a) Temperature Alarm 14

III b) Thermal Protections 14

III c) Automatic Sensor Control 14

III d) Protection against boiling water in the boiler 15

III e) Temperature Safety Protections 15

III f) Fuel Feeder Protection 15

III g) Fuse 15

IV Maintenance 16

V Repairs 16

VI Installation 17

VI a) Diagram of the regulator’s cabling installation 17

GWARANCJA

TECH company gaurantees correct functioning of the product

for the period of 30 months from the date of purchase The

company obliges itself to repair any faults that are producer’s fault,

free of charge In this case the device has to be delivered to the

place of purchase It is the user’s responsiblity to cover the costs of

such delivery

This guarantee does not include faults that occurred due to the

wrong use of the product, or those that are the user’s fault;

mechanical faults or those that appeared after atmospherical

discharge, overvoltage or shorting

Without the attached receipt of purchase, date of purchase, date of

delivery or signatures, this guarantee is not valid

This guarantee is the only document that gives the user rights to

repairs free of charge

The producer does not issue duplicates of this guarantee in case of

its loosing or damaging

Delivery Date Seller’s Stamp Date of Purchase

Notes:

Table of contents

Other TECH Controllers manuals

Popular Controllers manuals by other brands

Watts

Watts valpes VRX Series Installation and operation manual

Gebruder Heyl Analysentechnik

Gebruder Heyl Analysentechnik Testomat 808 quick start guide

Pego

Pego 200NDINFSC User and maintenance manual

Lennox

Lennox PRODIGY M2 Installation & setup guide

MKS

MKS MC20A manual

TREND

TREND IQECO31/230 installation instructions