Sic Marking ec7 User manual

User Guide

ec7 – e7p62 – e7p122

SIC MARKING

13 route de Limonest

ZAC de la Braille

69380 LISSIEU – France

Telephone: (+33) 04.72.54.80.00

Fax: (+33) 04.78.47.39.40

E-Mail: [email protected]

http://www.sic-marking.com

NOTE7V1EC7P62P122US-R01.doc 1/46

CONTENTS

EQUIPMENT SUPPLIED FOR THE STANDARD SYSTEM ..........................................................................7

UNPACKING ......................................................................................................................................7

INSTALLATION ..................................................................................................................................7

a) Fixing.......................................................................................................................................7

b) Power supply ...........................................................................................................................7

II - USE ...............................................................................................................................................8

SAFETY .............................................................................................................................................8

HOW TO MARK ..................................................................................................................................8

a) Positioning and securing of the part to be marked..................................................................8

b) Regulating the stylet / part distance .......................................................................................9

c) Starting / stopping marking .....................................................................................................9

INTRODUCTION TO THE SOFTWARE..................................................................................................10

III - STARTING UP ........................................................................................................................12

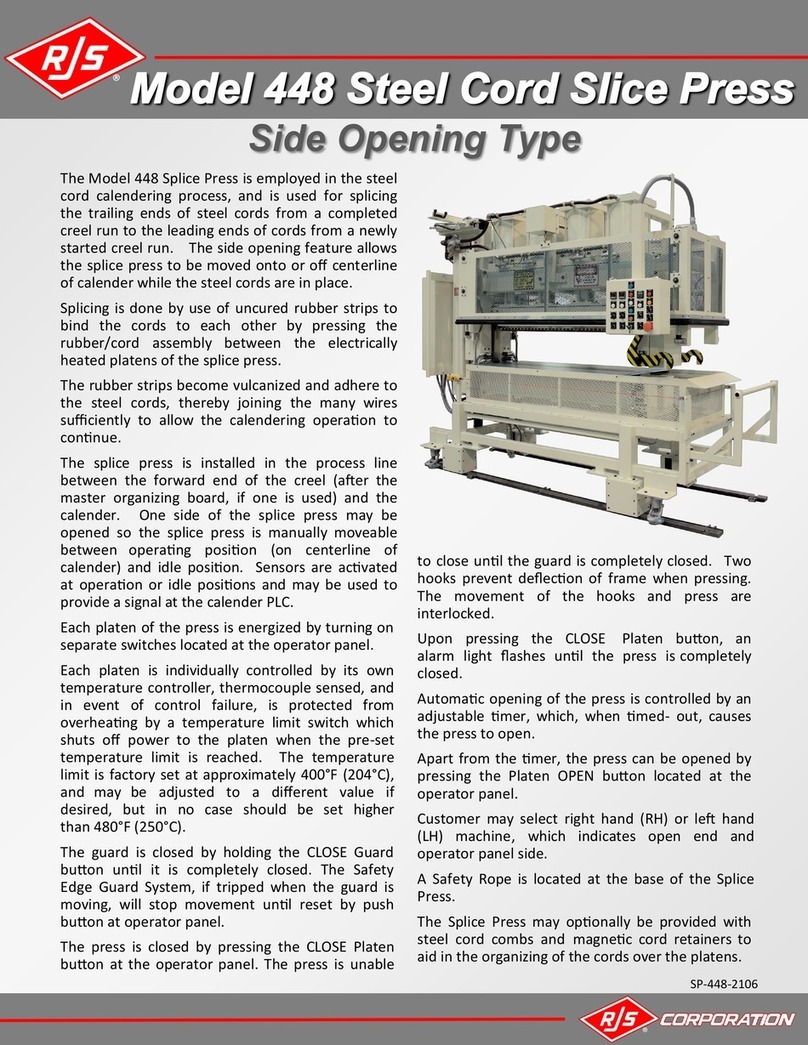

THE OPENING SCREEN .....................................................................................................................12

MARKING MODE......................................................................................................................12

a) Description of the screen........................................................................................................12

b) Tab functions .........................................................................................................................12

INTRODUCTION........................................................................................................................13

c) Description of the screen .......................................................................................................13

FIRST MARKING FILE .......................................................................................................................13

d) Printing..................................................................................................................................13

e) Marking..................................................................................................................................14

SETTINGS IN WRITE MODE. .............................................................................................................14

IV - FILE MANAGEMENT ...........................................................................................................17

INTRODUCTION........................................................................................................................17

LOADING A FILE INTO MEMORY.......................................................................................................17

DELETING FILES ..............................................................................................................................17

V - ADVANCED FUNCTIONS ......................................................................................................18

USING THE ADJUSTMENT FUNCTION ........................................................................................18

USING THE GRAPHIC VIEW.......................................................................................................18

USING THE VARIABLE FIELDS ..........................................................................................................20

a) The time variables and special characters ............................................................................20

b) Increments..............................................................................................................................21

ENTRY OF A LOGO:..........................................................................................................................22

VI - CONFIGURATION .................................................................................................................23

CONFIGURING THE MACHINE...................................................................................................23

CONTROL HANDBOX ACCESSORY (4 300 379).................................................................................24

VII - MAINTENANCE....................................................................................................................25

INTRODUCTION ...............................................................................................................................25

AFTER SALES SERVICE....................................................................................................................25

NOTE7V1EC7P62P122US-R01.doc 3/46

PREVENTATIVE MAINTENANCE ........................................................................................................25

1ST LEVEL MALIGNANCE ..................................................................................................................26

.........................................................................................................................................27

VIII - ANNEXES..............................................................................................................................28

1 - PERCUTEURS GAMME E7 ............................................................................................................28

a) hammer mechanism ec7.........................................................................................................28

b) hammer mechanism ep7 ........................................................................................................30

2 - COLUMN MOUNTED MARKING MACHINE EC7..............................................................................32

3 - MARKING GUN E7P62 ................................................................................................................39

4 - MARKING GUN E7P122 ..............................................................................................................43

5 - E7 MONITOR..............................................................................................................................46

c) Electrical diagram for e7 monitor .........................................................................................46

NOTE7V1EC7P62P122US-R01.doc 4/46

INTRODUCTION

Thank you for choosing an SIC MARKING machine.

SIC MARKING systems help improve the traceability of your products as

required by industrial standards.

We would like to extend a warm welcome you to as one of the users of our

systems.

This guide contains installation instructions for our micro percussion series and

also instructions for use. We strongly advise that you read these instructions

carefully before starting to install the system.

Our technical advice team remains at your disposal for further information.

NOTE7V1EC7P62P122US-R01.doc 5/46

EQUIPMENT AND INSTALLATION

Equipment supplied for the standard system

The standard system is made up of -

• marking mechanism with integrated electronic controls

• power lead

• maintenance kit

Unpacking

Unless delivered by us, the marking equipment is delivered in its own packaging. This packaging

should be kept carefully in case the equipment needs to be returned under guarantee.

Carefully unpack the pre-packed sub-units

Installation

a) Fixing

o install the equipment on a rigid, stable surface

b) Power supply

o before connecting the marking machine to the power supply (230V or 115V) check

that it has been set to the right voltage; check the voltage marked on the fuse drawer

o if the voltage selected is not the right one -

remove the fuse drawer from the base of the power unit

switch over the power switch

change the fuses (2 AT at 230V and 4 AT at 115V)

put the unit together again

o Switch on the marking equipment using the On/Off (0/I)switch at the back of the unit.

o the SIC screen will appear after a few moments, the software will load and the

main menu window will appear. The monitor is now ready.

ALTHOUGH THE EQUIPMENT IS PROTECTED IN LINE

WITH CURRENT STANDARDS

THE ELECTRONICS MAY BE SENSITIVE TO EXTERNAL

INTERFERENCE

IT SHOULD BE INSTALLED USING A STANDARD CABLE

WARNING

AND PROTECTED FROM POSSIBLE RADIATION

NOTE7V1EC7P62P122US-R01.doc 7/46

II - USE

Safety

When used intensively the temperature of the hammer unit may

reach 100 °C

the wearing of goggles is recommended

the wearing of helmet mounted ear defenders os also recommended

sound level of the machine when marking:

76 dB* on a steel block at an average impact and speed

(* Warning, this is not an upper limit the noise will depend on the

ob

j

ect to be marked

)

When using the marking system never hammer into an empty space

the tip may shatter

How to mark

a) Positioning and securing of the part to be marked

Although during marking the part will not be subject to much force it will be necessary to

immobilize it in order to achieve the best quality marking.

Depending on the nature of the part and the working conditions, this may vary from simple

manual holding in place against a right angle (angle bar) to mechanical, magnetic or

pneumatic securing.

If a marking gun is used, place the anti-skid universal support against the surface to be

marked and hold the gun manually in position during marking.

The holding system should position the part in such a way that the plane in which the stylet

operates should be parallel with the surface to be marked.

For portable machines, if the marking is always on the same type of part, we would advise

that a guide plate be machined so as to be able to guarantee the marking position.

NOTE7V1EC7P62P122US-R01.doc 8/46

b) Regulating the stylet / part distance

The quality of the marking depends in large measure on the part to be marked (materials,

state of the surface, hardness etc.).

A smooth, flat surface will be much easier to mark than a granulated irregular surface.

Usually it will be necessary to adapt the force used in the marking to the height of the

characters. The smaller the letters the less impact there will need to be to make them

legible. It is also possible to select more or less close marking with the help of the software

matrix.

Good quality marking can be obtained by adjusting the impact of the marking and the

stylet / part distance. If using a marking gun the stylet / part distance can regulated by

adjusting the position of the supporting surface

As a guide below are the recommended distances between the stylet and the part taking

into account the marking impact chosen.

Impact 1 2 3 4 5 6 7 8 9

Minimum distance 0.5 0.5 0.5 1 1 2 3 5 6

Maximum distance 1 2 3 5 6 7 9 9 9

Maximum distance stylet / part 9 mm

It would be wise therefore, to undertake preliminary tests on any new parts.

c) Starting / stopping marking

o set the monitor to marking (for more information see the software manual)

o put the part to be marked into position

o start the marking by pressing on the 'start' button or on the 'on/off' button on the handle

of the gun (portable machine)

o to stop the marking, press on the 'stop' button or for more than two seconds on the

'on/off' button of the gun.

NOTE7V1EC7P62P122US-R01.doc 9/46

Introduction to the software

- Special keys

The F1 to F9 ( …) keys are generally keyboard shortcuts.

The key cancels data input in progress or returns you to the previous window

The key enables you to validate data entry or move on to on to the next field.

The key enables you to return to the previous field, to validate the data in the

present field and to return to the previous field

The and keys enable you to scroll through a list

Combining the + keys enables you to go to the end of the data field

Combining the + keys enables you to return to the start of the data field

In write mode the keys enable you move from one line to another.

- The data fields

In the active field (here zone X) the field is in reverse- video and a cursor is blinking at the

insertion point.

- The fields list

S

p

ee

d

NOTE7V1EC7P62P122US-R01.doc 10/46

The fields followed by arrows: (as for the Speed field) are list type fields:

- the and arrows enable you to scroll through this list

- the key enables you to show the contents of the list:

- another key starts a search from the first letter of the list

- Data entry using insert mode

By pressing on the key the cursor moves from being a hyphen to a

square this means that you have moved form insert mode to over-write

mode.

Those fields that are longer than the screen display are displayed as follows:

NOTE7V1EC7P62P122US-R01.doc 11/46

III - STARTING UP

The opening screen

V

1-0-0

(2004-01-26)

V1-0-0 : Programme version number,

(2004 –01-26) : programme creation date (Year, Month, Day)

After initialisation the monitor moves into marking mode.

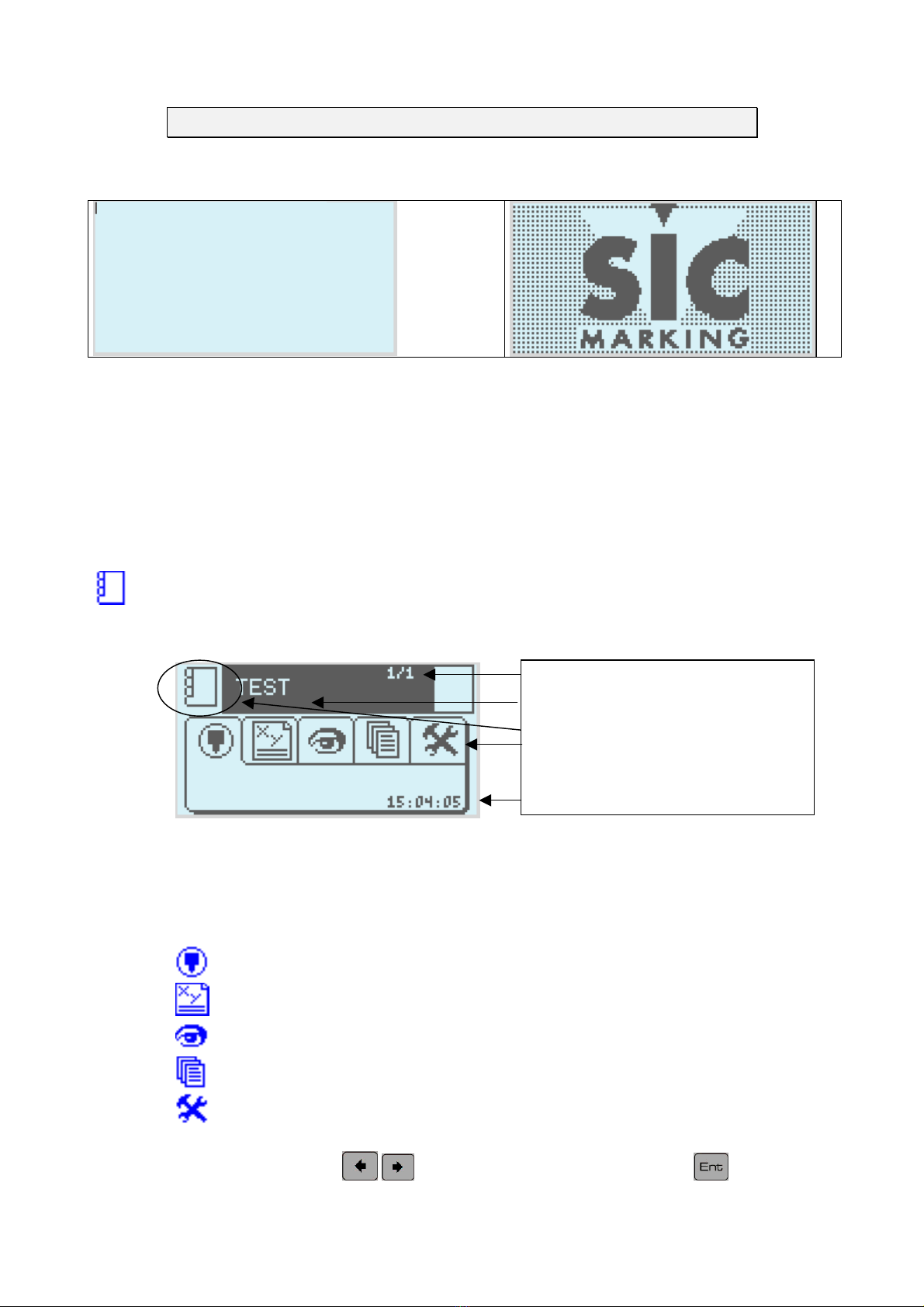

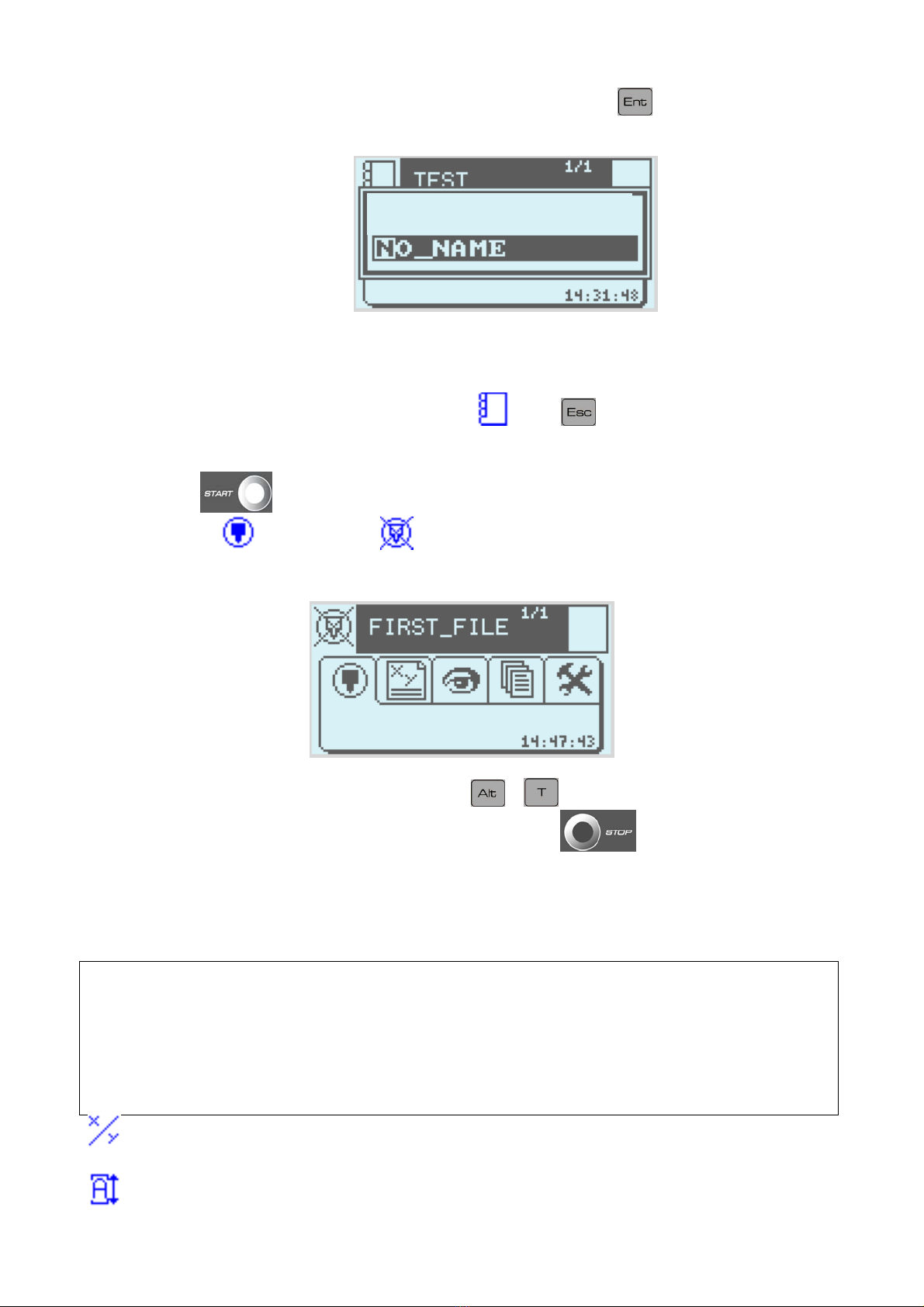

Marking Mode

a) Description of the screen

N

umber of lines in the file

N

ame of the active file

Mode in use indicator

Selector tab

Time

b) Tab functions

The main screen is the software's point of entry.

Marking mode.

Write mode of the marking file.

Graphic representation of the marking file

File management.

Configuring the machine.

Tab selection: use the keys to select a tab then press on the key to see the

menu.

NOTE7V1EC7P62P122US-R01.doc 12/46

Introduction

c) Description of the screen

From marking mode open the tab to go into write mode.

This mode enables you to create a marking file

Write icon

Toolbar

Configuration values

First marking file

d) Printing

As an example we will create a new file

Press the key to create a new file

The monitor screen should be as follows

The X and Y fields represent the marking coordinates

(Y is aligned on the base of the characters)

Let us create a line where the word TEST will be engraved

where X=5 and Y=5 and size is 3 by 3 mm

Press then 5 5

Then press then 3 3

Finally select then [T] [E] [S] [T]

Finally, save the file

NOTE7V1EC7P62P122US-R01.doc 13/46

Name it, for instance, FIRST FILE then validate it using .

Save as

e) Marking

To leave write mode and enter marking mode , press .

- One press on will start the marking

- Opening the tab then clicking on allows you can simulate the marking cycle (moves the

marking head but there is no power to the stylet)

At the end of the marking cycle (or the simulation) + will give you the marking time.

It is possible to interrupt the marking underway by pressing on .

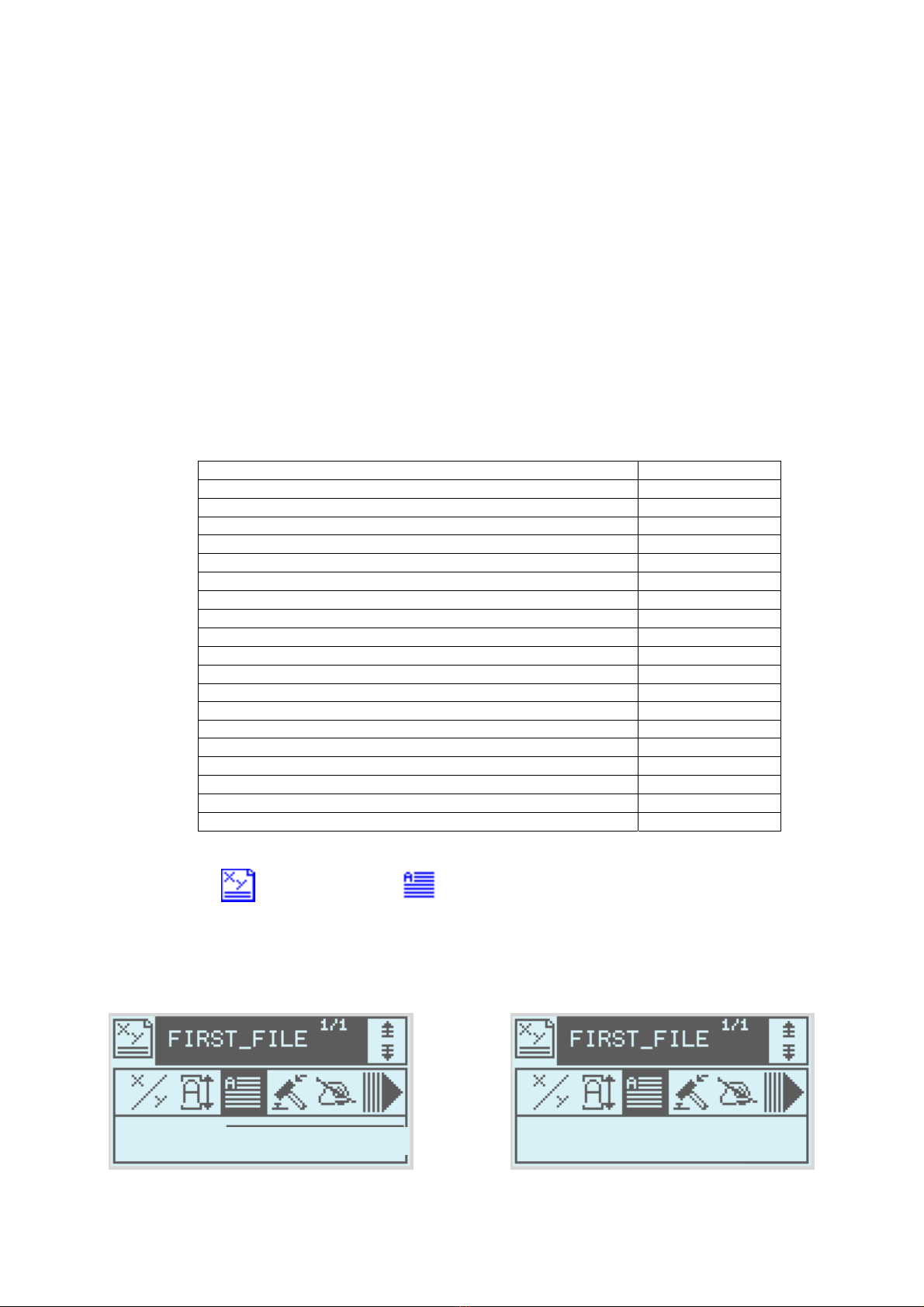

Settings in write mode.

Function keys in write mode

F2………..Delete line in progress.

F3………..Load a file.

F5………..Insert Line.

F7………..Graphic View.

F8………..Adjustment.

F9……….New marking file.

The X and Y fields represent the marking coordinates (Y is aligned on the base of the

characters)

The Land Hfields represent the width and height of the characters.

NOTE7V1EC7P62P122US-R01.doc 14/46

Text to be marked.

The Depth field represents the force of the impact: Impact 1is weak, Impact 9is strong

Impact 0does not mark

The Quality field represents point size Smp = character on a 5x7 grid

Dbl = character on a 9x13 grid

0.58 = 0.58 mm between each point

Font style of character OCR, OCRA, ARIAL, COURIER

The Speed field allows you to regulate the speed of movement of the slotted table during

marking

1= Slow speed, 2= intermediate speed, 3 = fast speed

Angled marking

Radial marking

The X and Y fields represent the centre of the circle (and not the co-ordinates of the first letter)

The angle represents the starting angle of the trace

Adjustment mode

Some examples

•Straight marking

ANGLE RADIUS

original position

Y

X

•angled marking

ANGLE RADIUS

X

Y

ANGL

original position

NOTE7V1EC7P62P122US-R01.doc 15/46

•Circular marking

ANGLE RADIUS

X

Y

ANGL

RADIUS

original position

NOTE7V1EC7P62P122US-R01.doc 16/46

IV - FILE MANAGEMENT

Introduction

Open the file management tab .

The monitor screen should be as follows

Search area

File list

Memory in use

FIRST

_

FILE

2%

Loading a file into memory

select a file using the , , and arrows.

You can search for a file by starting to type in its name in the search area (the key removes

what you have typed)

Deleting files

Selection of files is the same as for opening files

Once selected the file can be deleted using the key

Delete

FIRST_FILE

Yes(y) No(n)

to confirm deletion press (y)es

NOTE7V1EC7P62P122US-R01.doc 17/46

V - ADVANCED FUNCTIONS

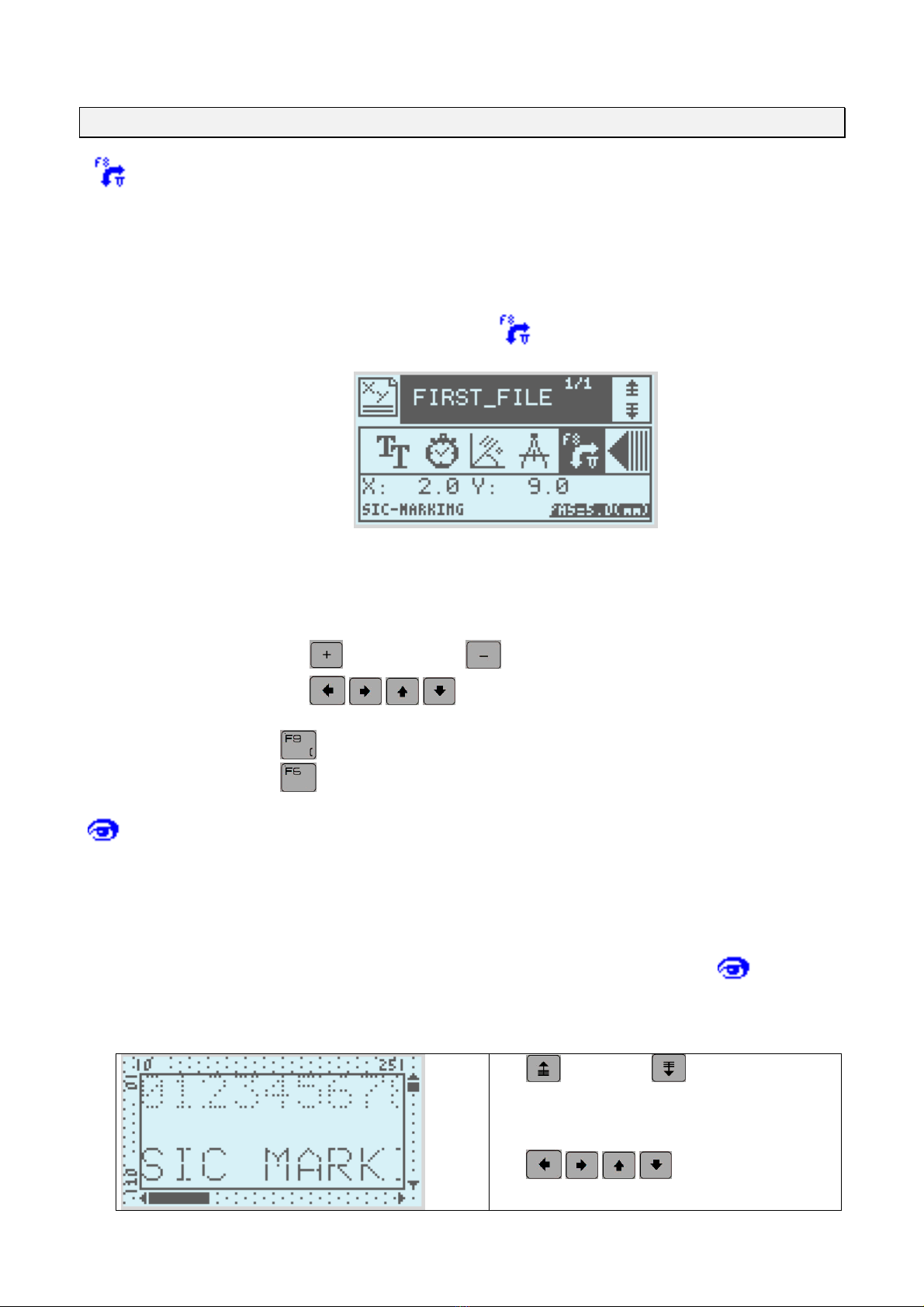

Using the adjustment function

To help the operator in adjusting the marking files, the ADJUSTMENT function allows

you to position the marking head with the marking co-ordinates.

This function is available from write mode or by using F8

The screen is then as follows

Setting the X, Y co-ordinates by adjusting the marking head

use the (+) and arrows (-) keys to set the adjustment.

use the keys to move the stylet one step in the

corresponding direction

the key allows you to simulate marking.

the keys allows you to draw the marking outline.

Using the graphic view

The graphic view function enables the operator to pre-view the marking on the

machine's screen.

This function can be accessed from write mode, from F7 or form the tab from

marking mode.

The screen is then as follows

the and arrows allow you to

regulate the zoom.

the keys allow you to

move the window

NOTE7V1EC7P62P122US-R01.doc 18/46

NOTE7V1EC7P62P122US-R01.doc 19/46

Using the variable fields

When one part of the text to be marked regularly needs modifications, such as increments

using a counter or date stamping, it is advisable to use the variable functions rather than

completely re-enter the data every time (and thereby increase the possibility of errors at each

change)

There are two function types; time variables and increments.

The increments are attached to a single file

The time variables are common to all files.

a) The time variables and special characters

•introduction

The time variables are: code

The current year; 3 formats are available

4 numbers eg. 2004 #Y4

2 figures eg 04 #Y2

1 figure eg 4#Y1

The current month; 1 format is available

2 figures eg 12 for December #M

The week in progress , One format available #W

The current day; 3 formats are available #D3

A part of the year (from 1 to 366) #D2

The day of the month using 2 figures (from 1 to 31) #D1

The day of the week (0=Sunday, 6=Saturday)

Time 2 formats are available #h

The hours using 2 figures #m

Minutes using 2 figures

Configuration of times

From write mode select the text icon

Instead of entering text from the keyboard press Alt-H

Then select the variable timing format from the list.

After validation

Text : #Y4

#

Y4

V

AR. H.

NOTE7V1EC7P62P122US-R01.doc 20/46

This manual suits for next models

2

Table of contents

Other Sic Marking Industrial Equipment manuals