SICK APS User manual

O P E R A T I N G I N S T R U C T I O N S

APS

Driver assistance system

2

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

Described product

Product name: Aircraft Protection System (APS)

Document identification

Title: Aircraft Protection System (APS) operating instructions

Part number: 8018378-1AH8

Status: 2021-01

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be trademarks and are

only used here for identification purposes.

Original documents

The German issue 8018377 of this document is an original document of

SICK AG.

SICK AG does not assume liability for the correctness of any unauthorized

translation.

In case of doubt, contact SICK AG or your local agency.

Legal notes

Subject to change without notice

© SICK AG. All rights reserved

ABOUT THIS DOCUMENTATION 1

3

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Contents

1About this documentation ..........................................................................................6

1.1 Purpose of this document................................................................................6

1.2 Target group ....................................................................................................6

1.3 Information depth............................................................................................6

1.4 Abbreviations used ..........................................................................................7

1.5 Symbols used ..................................................................................................7

2On safety......................................................................................................................8

2.1 Qualified safety personnel ...............................................................................8

2.2 Intended use....................................................................................................8

2.3 General safety notes and protective measures ...............................................9

2.3.1 Safety notes and symbols .................................................................9

2.3.2 General safety notes .......................................................................10

2.3.3 Potential hazardous points .............................................................11

2.4 Protection of the environment .......................................................................13

2.4.1 Power consumption.........................................................................13

2.4.2 Disposal after final decommissioning .............................................13

3Product description...................................................................................................14

3.1 Scope of delivery............................................................................................14

3.2 System components ......................................................................................15

3.3 System functionality ......................................................................................17

3.4 Project planning.............................................................................................20

3.5 Status indicators............................................................................................21

4Mounting....................................................................................................................23

4.1 Function test before mounting ......................................................................23

4.2 Mounting the 2D LiDAR sensor......................................................................23

4.3 Mounting the bracket for the operator display ..............................................25

4.4 Mounting the buzzer......................................................................................26

4.5 Mounting the Ethernet switch........................................................................26

5Electrical installation ................................................................................................27

5.1 Wiring diagram...............................................................................................27

5.2 Connecting the 2D LiDAR sensor...................................................................28

5.3 Connecting the Ethernet switch.....................................................................30

5.4 Connecting the operator display ....................................................................30

5.4.1 Plugging the connecting cables into the operator display...............31

5.4.2 Mounting the operator display on the bracket ................................32

5.4.3 Connecting the operator display to the voltage supply ...................33

5.4.4 Connecting the operator display to the Ethernet switch .................33

5.5 Connecting the buzzer to the display.............................................................34

5.6 Connecting the display to digital signaling devices (optional) .......................35

6Commissioning..........................................................................................................36

6.1 System start-up..............................................................................................36

6.2 The operator display in configuration mode ..................................................37

6.3 Configuring the system settings.....................................................................38

6.3.1 System configuration without signaling the direction of travel........38

6.3.2 System configuration with signaling of the direction of travel.........39

6.3.3 Activating digital input signals for waiting position and speed........40

1ABOUT THIS DOCUMENTATION

4

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

6.4 Configuring the 2D LiDAR sensor .................................................................. 41

6.4.1 Starting sensor setup ..................................................................... 41

6.4.2 Specifying the mounting position of the 2D LiDAR sensor ............. 41

6.4.3 Aligning the 2D LiDAR sensor in the yaw axis................................. 42

6.4.4 Aligning the 2D LiDAR sensor in the pitch and roll axes ................. 44

6.4.5 Restrict angle range ....................................................................... 47

6.4.6 Completing the configuration of the 2D LiDAR sensor ................... 48

6.5 Configuring the warning strategy................................................................... 48

6.5.1 Configuring the danger zone........................................................... 48

6.5.2 Configuring the warning zone ......................................................... 49

6.6 Switch to the operating mode ....................................................................... 50

6.6.1 Quit configuration mode ................................................................. 50

6.6.2 Operating mode for person carrying out commissioning ................ 50

6.6.3 Enable operating mode for tractor drivers...................................... 51

7Operation................................................................................................................... 52

7.1 Start the tractor............................................................................................. 52

7.2 The operator display in the operating mode for tractor drivers..................... 53

7.3 Accepting the nose wheel landing gear......................................................... 53

7.3.1 Determination of the aircraft type .................................................. 53

7.3.2 Confirm aircraft type ....................................................................... 54

7.3.3 Disabling of the acoustic warning in the waiting position

(optional) ........................................................................................ 55

7.4 Towing the aircraft ........................................................................................ 56

7.4.1 Customizing the screen display ...................................................... 56

7.4.2 Visualization of the towing process in the monitored area ............. 57

7.4.3 Warning concept for obstacles within the danger zone.................. 58

7.4.4 Collision warning for obstacles within the warning zone ................ 59

7.4.5 React to collision awareness .......................................................... 59

7.4.6 Towing at high speed (optional)...................................................... 60

7.5 Releasing the nose wheel landing gear again............................................... 61

8Maintenance............................................................................................................. 62

8.1 Overview of maintenance tasks .................................................................... 62

8.2 Maintenance during operation...................................................................... 62

8.2.1 Cleaning the 2D LiDAR sensor........................................................ 62

8.2.2 Visual inspection of the cables ....................................................... 63

8.3 Replacing components.................................................................................. 64

8.3.1 Replacing the 2D LiDAR sensor...................................................... 64

8.3.2 Replacing the operator display ....................................................... 66

8.3.3 Replacing the Ethernet switch ........................................................ 66

8.4 Tasks in the web interface ............................................................................ 67

8.4.1 Calling up the web interface ........................................................... 67

8.4.2 Enable configuration mode on the display ..................................... 68

8.4.3 Activating operating mode for tractor drivers via the web

interface ......................................................................................... 69

8.4.4 Updating aircraft database............................................................. 69

ABOUT THIS DOCUMENTATION 1

5

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

9Fault diagnosis ..........................................................................................................71

9.1 Response to errors ........................................................................................71

9.2 Fault indicators of the LMS511 .....................................................................71

9.3 Typical fault situations during commissioning ...............................................72

9.3.1 Configuration incomplete or incorrect.............................................72

9.3.2 2D LiDAR sensor not available........................................................72

9.4 Typical fault situations during operation........................................................74

9.4.1 Aircraft type not detected................................................................74

9.4.2 Aircraft type lost during the towing process ....................................75

9.4.3 Contamination on the viewing window of the 2D LiDAR

sensor .............................................................................................77

9.4.4 2D LiDAR sensor not available........................................................78

9.4.5 Display of the direction of travel suddenly switches .......................79

9.4.6 No image on display........................................................................80

9.5 SICK support..................................................................................................81

10 Annex .........................................................................................................................82

10.1 Technical data ...............................................................................................82

10.2 Dimensional drawings ...................................................................................83

10.2.1 Dimensional drawing for the LMS511 2D LiDAR sensor.................83

10.2.2 Display dimensional drawing...........................................................84

10.2.3 Ethernet switch dimensional drawing .............................................85

10.2.4 Dimensional drawing of the buzzer .................................................85

10.3 Using a connection unit (optional) .................................................................86

10.4 Buzzer tone selection ....................................................................................87

10.5 Overview of operating processes ...................................................................88

1ABOUT THIS DOCUMENTATION

6

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

1About this documentation

Please read this chapter carefully before you begin working with this documentation and

the APS driver assistance system.

1.1 Purpose of this document

These operating instructions are designed to give technical personnel instructions on

the safe mounting, configuration, electrical installation, commissioning, operation and

maintenance of the APS Aircraft Protection System.

These operating instructions do not provide information on operating the vehicle into

which the APS is or will be integrated. For information about this, refer to the vehicle’s

operating instructions.

1.2 Target group

These operating instructions are intended for people who install, connect, commission,

operate, and maintain the APS.

Activities

Target group

Mounting, electrical

installation, maintenance,

and replacement of system

components

Qualified personnel, such as service technicians

or industrial electricians

Commissioning and

configuration

Qualified personnel, such as technicians or

engineers

Operating the system

Personnel qualified in running and operating

the system (tractor drivers)

Tab. 1: Target group

1.3 Information depth

These operating instructions contain information about the APS driver assistance system

on the following topics:

•Product description

•Mounting

•Electrical installation

•Commissioning and configuration

•Operation

•Maintenance and repair

•Fault diagnosis and troubleshooting

•Technical data and dimensional drawings

When planning and using the APS driver assistance system, technical skills are required

that are not covered by this document.

The official and legal regulations for operating the APS must always be complied with.

Further information on laser measurement technology can be obtained from the

department for automatic detection and position determination at SICK AG or is available

online at www.sick.com.

ABOUT THIS DOCUMENTATION 1

7

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

1.4 Abbreviations used

Aircraft Protection System = driver assistance system for aircraft tractors

Laser measurement sensor = laser scanner from SICK AG

1.5 Symbols used

Recommendations are intended to help you make a decision regarding the use of a

particular function or technical feature.

Notes provide information about the features of a device, application tips, or other useful

information.

Instructions that must be carried out in the described order are referred to as step-by-step

instructions and are indicated by numbered lists. Carefully read and follow the

instructions for action.

Instructions requiring specific action are indicated by an arrow. Carefully read and follow

the instructions for action.

LED symbols describe the status of a diagnostics LED. Examples:

The LED is illuminated continuously.

The LED is flashing.

The LED is off.

Display symbols show the status of the 7-segment display:

Constant display of characters, e.g., U

Flashing display of characters, e.g., 8

Alternating display of characters, e.g., L and 2

APS

LMS

Recommendation

Note

1. / 2. ...

,

,

2ON SAFETY

8

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

2On safety

This chapter provides information that concerns your own safety as well as the safety of

the plant operator.

Please read this chapter carefully before working with the APS.

2.1 Qualified safety personnel

APS must be installed, commissioned, and maintained only by adequately qualified

personnel.

A person is considered qualified safety personnel if he/she

•Has sufficient skills in the field of the respective equipment based on his/her technical

training and experience and

•Has been instructed by the manufacturer on system operation and all applicable safety

guidelines and

•Is familiar with all relevant country-specific occupational safety regulations, work safety

regulations, guidelines, and generally accepted technical rules and standards (e.g.,

DIN standards, VDE regulations, country-specific rules) to such an extent that he/she is

able to evaluate the safe condition of the power-driven machinery and he/she

•Has access to and has read the operating instructions.

2.2 Intended use

APS is a driver assistance system for aircraft tractors without tow bars at airports. The

system gives the driver visual and acoustic warnings of possible obstacles during the

towing process. The towing processes Towing/maneuvering, Push-back and Enter/exit

hanger are supported.

A 2D LiDAR sensor mounted on the rear of the tractor detects the aircraft type to be

monitored as the nose landing gear is engaged. APS uses this to determine the size and

geometry of the towing corridor, thereby supporting a three-stage monitoring and warning

concept for the wing and rear hazardous points.

The towing corridor is continuously monitored during the towing process. The monitored

area includes everything that is within the field of view of the 2D LiDAR sensor and can be

shown on the display.

The towing corridor is also the danger zone in which visual, and optionally also acoustic

warnings of possible obstacles are issued. A warning zone enclosing the aircraft contour

allows visual and acoustic warning of imminent collisions.

APS detects only objects which are visible in the measurement plane of the 2D LiDAR

sensor. The 2D LiDAR sensor must therefore have an unobstructed view of the area to

be monitored.

Using APS means that hazardous situations, such as parked vehicles, ground equipment,

staircases, landing gear blocks, insufficiently opened hanger doors or incorrectly

positioned aircraft, are detected in a timely manner and that accidents during the towing

process are avoided.

Note

ON SAFETY 2

9

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

•APS is a driver assistance system. This means that at all times the driver bears the full

responsibility for safe operation, in particular for people who are in the danger zone of

the vehicle.

•APS is not a safety device for human protection and therefore does not comply with

any safety standards. For safety applications, please contact SICK AG.

In the event of any other usage or of modification to the system –including in the context

of mounting and installation –any claims against SICK AG under the warranty will be

rendered void.

2.3 General safety notes and protective measures

2.3.1 Safety notes and symbols

The following safety and hazard notes are used for your own safety, for the safety of third

parties, and for the safety of the machine. You should therefore observe them at all times.

DANGER

Denotes an immediate hazard that may result in severe to fatal injuries.

The pictogram shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from electrical current).

WARNING

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The pictogram shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of damage to the eye by laser radiation).

WARNING

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

NOTE

Denotes a potential risk of damage or functional impairment of the device or the devices

connected to it.

This symbol refers to supplementary technical documentation.

Notes

2ON SAFETY

10

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

2.3.2 General safety notes

APS has been designed in a way that allows for safe operation. However, a certain level

of risk will always remain.

Awareness of potential sources of danger in the system will help you to work in a safer

manner and thus prevent accidents.

To avoid risks, please also observe the special warnings in each of the individual

chapters.

WARNING

Safety notes

Observe the following to ensure the safe use of the system as intended.

•The notes in these operating instructions must be complied with.

•All official and statutory regulations governing the operation of the system must be

complied with.

•The national and international legal specifications apply to the installation and use of

the system, to its commissioning, and to recurring technical inspections, in particular:

–The accident prevention regulations and work safety regulations

–Any other relevant safety regulations

•The checks must be carried out by qualified safety personnel or specially qualified and

authorized personnel, and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

•These operating instructions must be made available to the operator of the system.

The system operator must be instructed by qualified safety personnel and read the

operating instructions.

•The driver must follow relevant instructions and conduct inspections in order to ensure

that the screen of the 2D LiDAR sensor is clean and undamaged.

•The 2D LiDAR sensor must have a free field of view. The sensor head must not be

covered by other objects, for example.

•SICK AG recommends carrying out a system check before commissioning the system.

WARNING

Risk resulting from improper operation

Improper installation and commissioning, damaged components, and unsuitable ambient

conditions such as excessively cold or warm temperatures and high levels of dust, fog

or spray, may cause faults and faulty alarms and may result in a complete system crash.

ON SAFETY 2

11

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

WARNING

System does not comply with safety standards

APS is not suitable for the protection of persons according to the applicable safety

standards for machines. The system therefore does not comply with safety standards.

APS is a driver assistance system. It provides the driver with visual and acoustic warnings

about objects outside of the tractor. At all times the driver bears the full responsibility for

safe operation, in particular for people who are in the danger zone of the tractor.

WARNING

Operation site

The system is intended exclusively for use in industrial environments.

2.3.3 Potential hazardous points

Laser protection

WARNING

Damage to the eye by laser radiation

The LMS511 2D LiDAR sensor used by APS conforms to laser class 1 (eye-safe) as per

EN 60 825-1 (see laser warning label on the device for publication date). This ensures

compliance with 21 CFR 1040.10 except for conformance with Laser Notice No. 50 of

July 26, 2001.

The laser operates at a wavelength of γ= 905 nm (invisible infrared light). The laser beam

is not visible to the human eye.

The radiation emitted in normal operation is harmless to human skin and eyes.

Improper use (e.g., opening the housing and stopping the motor) can result in dangerous

exposure to radiation.

▸Never open the housing of the 2D LiDAR sensor. Opening the housing does not

interrupt the operation of the laser beam.

▸Laser safety regulations as per IEC 60 825Q1 (latest version).

•No maintenance is required to ensure compliance with laser class 1.

•The laser output aperture is the front screen on the LMS511 2D LiDAR sensor.

•The laser warning is located on the right-hand side of the 2D LiDAR sensor.

WARNING

Important

2ON SAFETY

12

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

Electrical current

DANGER

Risk of injury and damage caused by electrical current

Improper handling of live devices may lead to severe personal injury or death by electric

shock!

▸Electrical installation and maintenance work must only be carried out by personnel

authorized to do so.

▸Be sure to disconnect the voltage supply before attaching or detaching any electrical

connections.

▸Select and implement wire cross-sections and their correct fuse protection in

accordance with the applicable standards.

▸Do not touch live parts.

▸In the event of danger, immediately disconnect the system from the voltage supply.

▸Always use original fuses with the specified current rating.

▸Report any damaged cables to the maintenance team without delay.

▸Comply with standard safety requirements when working on electrical plants.

Commissioning/operation/maintenance

WARNING

Risk resulting from incorrect commissioning and configuration!

Do not commission without testing by qualified personnel!

Before you operate the system or a device for the first time, you must have it checked and

approved by qualified safety personnel.

NOTE

Claims under the warranty rendered void

If the device is opened, any warranty claims against SICK AG will be void.

▸Do not open the device housing. The devices are sealed.

WARNING

Risk resulting from faults

Cease operation if the cause of the malfunction has not been clearly identified!

A defect in the system may result in fatal accidents or damage to the system.

▸Take the APS out of operation if an error cannot be clearly identified and safely

remedied.

ON SAFETY 2

13

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

2.4 Protection of the environment

The system has been designed to minimize its impact on the environment. It consumes

very little energy.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information on disposal.

2.4.1 Power consumption

Including its components, the system typically consumes 27 W.

The peak power consumption when starting up or in the event of integrated sensor

heating is 82 W.

2.4.2 Disposal after final decommissioning

▸Dispose of unusable or irreparable devices in an environmentally safe manner in

accordance with the relevant national waste disposal regulations.

▸Dispose of all electronic assemblies as hazardous waste. The electronic assemblies

can be easily removed.

SICK AG does not take back devices that are unusable or irreparable.

Note

3PRODUCT DESCRIPTION

14

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

3Product description

This chapter provides information on the special properties of the APS driver assistance

system. It describes the design and operating principle of the system.

Always read this chapter before mounting, installing, or commissioning the system.

3.1 Scope of delivery

APS consists of an LMS511 2D LiDAR sensor, an interactive operator display, an Ethernet

switch, mounting kits and connecting cables as well as a buzzer. A connection unit can

optionally be used.

Fig. 1: Scope of delivery for the APS

Thorough check for completeness

▸It is recommended that you carefully check for and report transport damage of any kind

as soon as possible after receiving the system.

▸Also verify that the delivery includes all components listed on the delivery note.

Note

Important note

PRODUCT DESCRIPTION 3

15

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Quantity

Part no.

Description

1069176

APS

1

1109177

LMS511S07 2D LiDAR sensor

1

2078363

Operator display

1

6051544

Ethernet switch

1

6043994

Buzzer

1

2015623

Mounting kit 1 for mounting the LMS511

1

2015624

Mounting kit 2 for adjusting the LMS511 on

mounting kit 1

1

5326406

Mounting system with swivel connector for mounting the operator

display, incl. adapter for operator display with screws

1

6048243

Ethernet cable for connection of the LMS511 to the Ethernet switch,

10 m, 2 M12 male connectors, straight

1

6048251

Ethernet cable for connection of the operator display to the Ethernet

switch, 5 m, M12 male connector, straight, M12 male connector,

angled

1

6036160

Cable for supplying voltage to the Ethernet switch, 10 m, M12 female

connector, 5-pin, open end

1

6042564

Cable for supplying voltage to the LMS511 (electronics and heater),

20 m, M12 female connector, 5-pin, open end

1

2058813

Cable for connecting the display to the voltage supply, Ethernet switch,

buzzer, and digital signaling devices.

Tab. 2: Scope of delivery for the APS

You can optionally use a connection unit if there are not enough terminals for connecting

the devices to the voltage supply of the tractor.

1

2070552

Connection unit for power (sensors, display, buzzer, Ethernet switch)

3.2 System components

LMS511 2D LiDAR sensor

The 2D LiDAR sensor mounted on the rear of the tractor constantly monitors the entire

surroundings behind the tractor during the towing process, in a radius of up to 80 m

around the sensor.

The 2D LiDAR sensor scans its surroundings with a laser beam on a single plane and

using the optical time-of-flight method. The maximum aperture angle is 190°. If the

emitted laser beam is reflected by an object, the distance to the object is calculated.

The laser beam is emitted through the front screen. The scan plane position is indicated

by a housing marking next to the front screen.

Fig. 2: Laser output aperture of the LMS511

The 2D LiDAR sensor features an automatic contamination detection for the front screen

as well as interior heating. The contamination notification is output on the operator

display.

Optional

3PRODUCT DESCRIPTION

16

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

The operator display

The interactive operator display is the central component of the system. During the towing

process, it visualizes the outline of the aircraft/tractor combination and the aircraft’s

towing corridor to the driver. Obstacles in the monitored area are identified according to

the danger and warning level and can thus be localized quickly.

The display has a touch screen, which allows the user to make entries during initial

commissioning and subsequent operation.

The operator display is attached to a mounting kit with a swivel connector in the tractor

cab, within the driver’s field of view.

Fig. 3: Operator display with mounting kit

No.

Meaning

1

Touchscreen

2

Mounting kit with swivel connector

Ethernet switch

An Ethernet switch connects the 2D LiDAR sensor with the operator display.

Buzzer

A buzzer supports the visual warning about an obstacle on the display with an acoustic

warning.

PRODUCT DESCRIPTION 3

17

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

3.3 System functionality

APS is a driver assistance system for aircraft tractors without tow bars at airfields.

It supports the following processes:

Identification of the aircraft type

After the nose wheel has been engaged by the tractor, the system determines

the trackwidth of the main landing gear (track) and the distance to the nose wheel

(wheelbase) based on the values measured by the 2D LiDAR sensor.

Fig. 4: Typical installation position of the LMS511 and definition of track and wheelbase

APS compares the measured values with those in the aircraft database saved in the

system. Matching aircraft types are suggested. The tractor driver selects the correct

aircraft and confirms the selection.

On the display, the driver can now see an outline display of the aircraft/tractor

combination and the towing corridor.

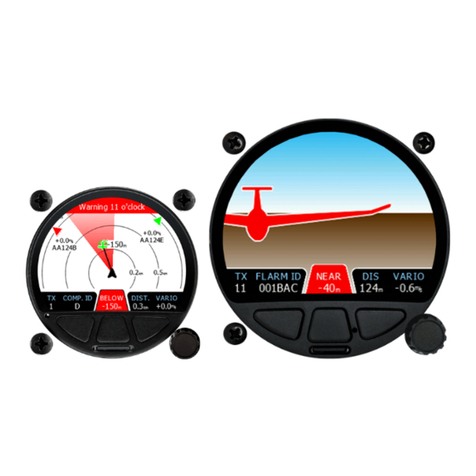

Fig. 5: Representation of the aircraft/tractor combination and towing corridor on the display

Measurement points of the main landing gear and low-hanging engines as well as

measurement points of objects located below the aircraft are masked out by the system.

They are not visible on the display.

Note

3PRODUCT DESCRIPTION

18

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

Monitoring and warning concept

During the towing process, the 2D LiDAR sensor constantly monitors the surroundings of

the aircraft. The APS driver assistance system supports a three-stage warning concept

based on a monitored area, a danger zone, and a warning zone.

•The monitored area includes everything that is within the field of view of the 2D LiDAR

sensor and can be represented on the display. In it, the outline of the aircraft/tractor

combination and the towing corridor are continuously displayed during the towing

process. The size and geometry of the towing corridor are predefined when the aircraft

type is selected. The towing corridor is the gray outlined area that moves with the

aircraft.

The contour of objects detected outside the towing corridor is visible on the display.

Since they do not pose a threat, they are not visually highlighted further. There is also

no acoustic warning.

Fig. 6: Representation of the towing process in the monitored area of the display

•The towing corridor also marks the danger zone, i.e. the area where collisions can

occur. The danger zone automatically adjusts to the towing corridor of the aircraft.

If objects are detected within the danger zone (but still at a large distance to the

aircraft), a visual warning of the obstacle is given. In this case, the object closest to

the aircraft outline is highlighted as a flashing object point with a red circle.

In addition to the visual warning, an acoustic warning can be given via the buzzer

installed in the tractor cab. To limit the warning signals to truly collision-relevant

obstacles, it is possible however to switch off the acoustic warning for the danger

zone when commissioning the system.

Fig. 7: Visualization of obstacles in the danger zone

PRODUCT DESCRIPTION 3

19

8018378-1AH8/2021-01 SICK

Subject to change without notice

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

•The warning zone defines an area around the aircraft. It is defined by a specific

distance around the aircraft contour, depending on the type of aircraft. A distance of

1 to 3 meters can be defined.

Fig. 8: Warning zone

Since a collision is now imminent in the warning area due to the proximity of the object

to the aircraft, the warning concept makes a visual and acoustic warning mandatory.

The object closest to the aircraft outline is highlighted as a fixed object point with a

red circle. In addition to the visual warning, the driver is alerted to the imminent risk of

collision by a warning tone with a short frequency.

Fig. 9: Visual and acoustic warning of obstacles in the warning zone

The 2D LiDAR sensor must always identify the engaged aircraft type during the towing

process. In order to do this, the wheelbase of the main landing gear and the distance to

the nose wheel are constantly measured and monitored.

Situational muting of the acoustic warning (optional)

To suppress acoustic warnings, the warning tone can be muted via digital input signals

according to the situation. This applies

•to the preparation time of the engaged aircraft at the terminal before push-back.

•to towing operations at high speed.

Note

3PRODUCT DESCRIPTION

20

8018378--1AH8/2021-01|SICK

O R I G I N A L O P E R A T I N G I N S T R U C T I O N S | APS

Subject to change without notice

3.4 Project planning

Reliable and problem-free use of APS depends on a number of different factors.

Aircraft tractor requirement

APS has been designed exclusively for aircraft tractors without tow bars. In this tractor

type, the nose wheel landing gear of the aircraft is grasped and lifted.

Requirements on the objects to be protected

APS protects aircraft with the following features:

Dimension

Meaning

Min.

Max.

Track

Trackwidth = distance between the wheels of the

main landing gear

4.5 m

15 m

Wheelbase

Wheelbase = distance from the nose wheel to the

main landing gear

10 m

32 m

Fuselage height

Distance from the ground to the body of the aircraft

> 80 cm

Tab. 3: Requirements on the objects to be protected

Requirements on the detection of obstacles

APS provides warnings of all obstacles under the aircraft at the mounted height (scan

plane) of the 2D LiDAR sensor.

Objects which protrude into the field of view above the mounted height (scan plane) of the

2D LiDAR sensor cannot be detected by the 2D LiDAR sensor due to its mounting position.

Table of contents