7

8 007 487/10-10-99 Technical Description • LGT © SICK AG • Safety Systems • Germany • All rights reserved

5 Installation and Commissioning

5 Installation and Commissioning

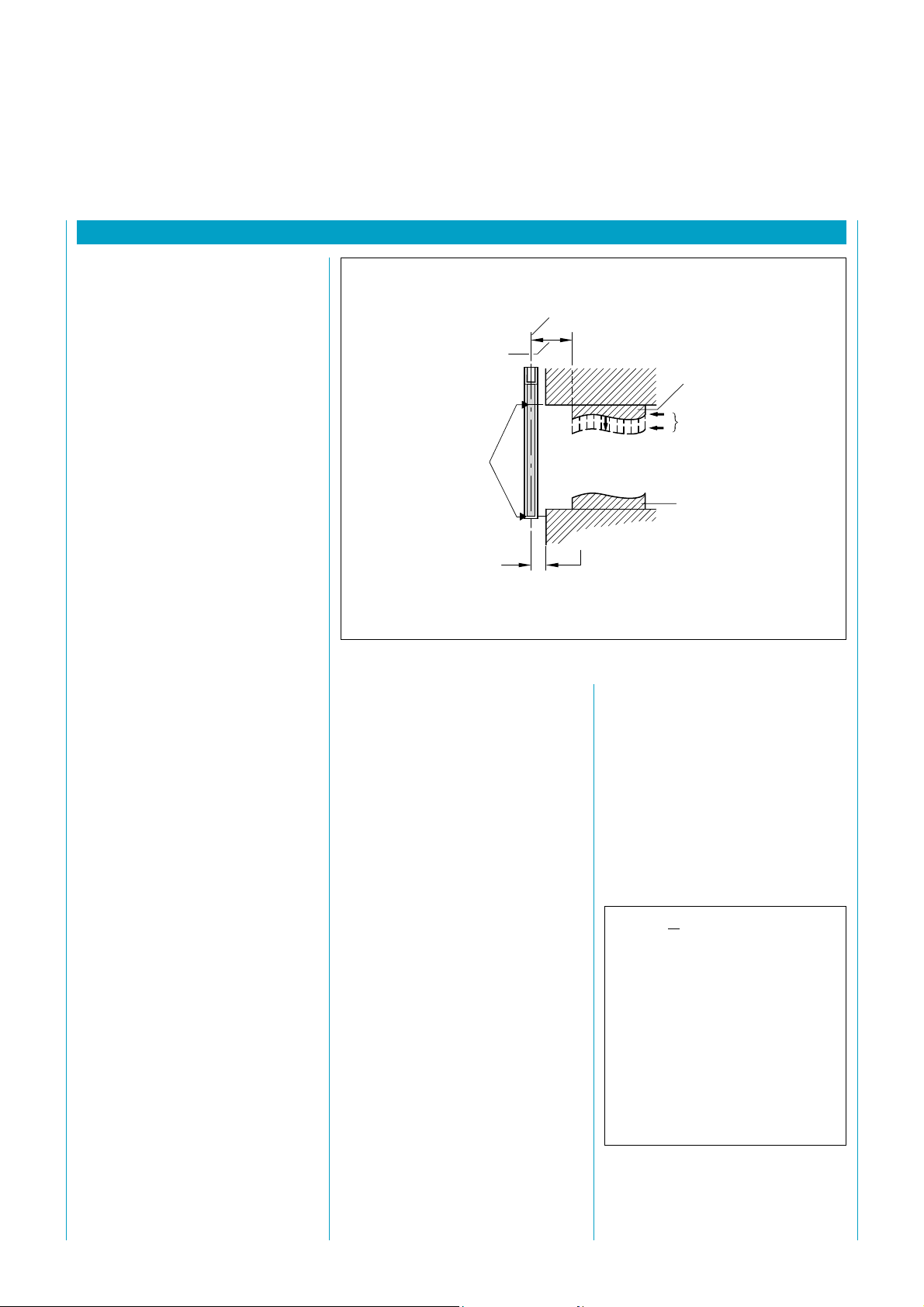

Fig. 7. Determining the coasting time and the safety clearance

For S < 500 mm

S = 2000 .....T + 8 (d - 14)

greater (S = > 500 mm)

S = 1600 .....T + 8 (d - 14)

S Safety distance

T Total response time in s

(stopping time of the machine

+ response time LGT)

d Resolution

The LGT must be commissioned in

accordance with the following steps

1 Clarify and carry out mechanical

mounting

2 Connect the sender and re-

ceiver strips to the control unit

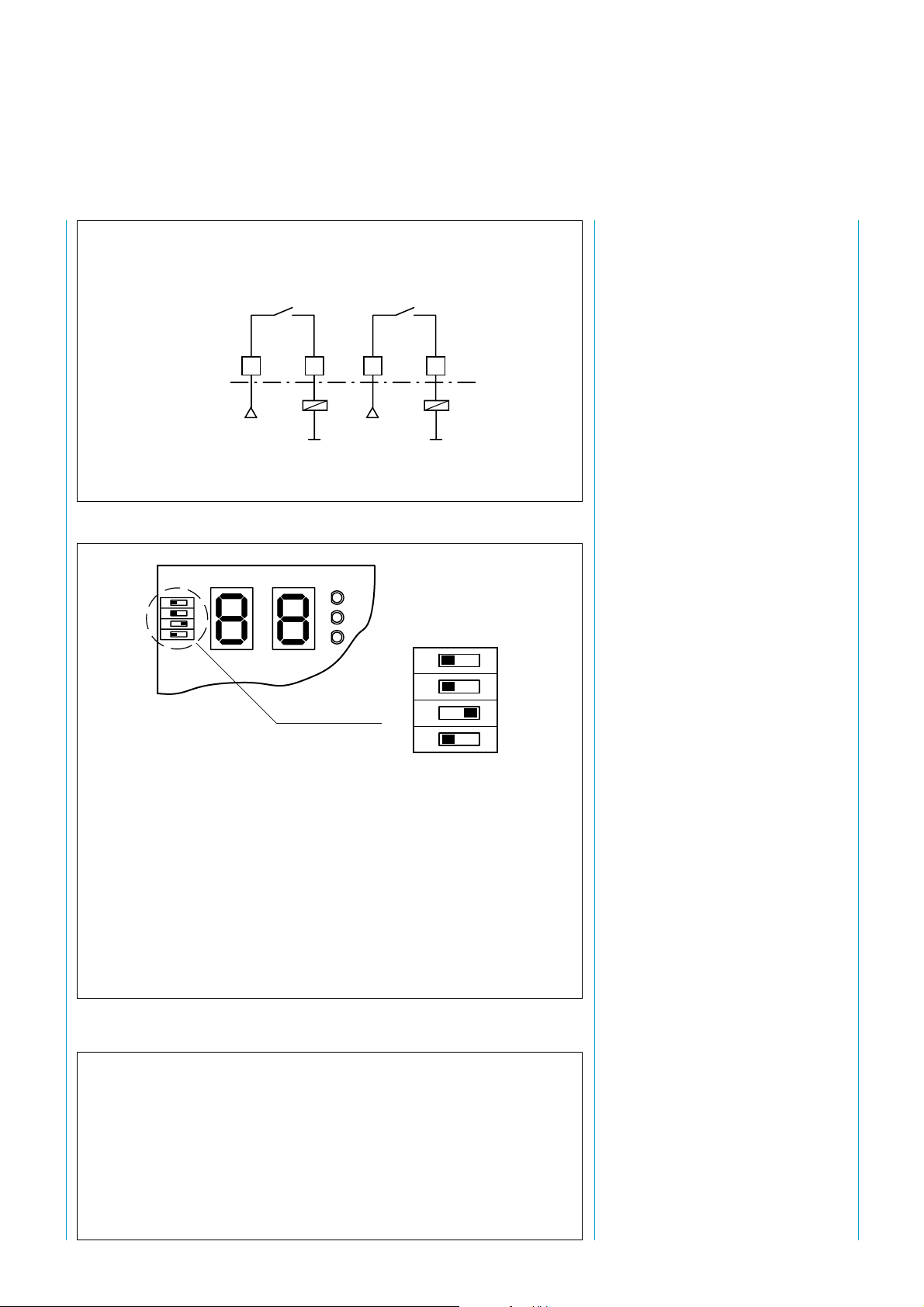

3 Set the DIP switches "With ...”

or "Without restart interlock"

(preset at factory), fig. 15

4 Connect the "machine control"

input (jumper or terminal)

5 Set the DIP switch: either 1 or

2 LGT connected to control

unit (fig. 15)

6 Connect or jumper the contac-

tor monitor

7 Perform blanking in accordance

with Section 5.3.8 if required

8 Set the sender power in ac-

cordance with 5.3.7

9 Insert the output elements in

the switch-off control line of the

machine

The individual measures for this

purpose are described in the fol-

lowing chapters.

5.1General

The LGT can be operated in any

position as long as the specified

safety distances and sufficient pro-

tective height are provided

(see 11 selection table).

Before the unit is installed, check

the components to ensure that

they are complete:

The LGT Light Grid comprises 5

individual parts. These must always

be available before starting the in-

stallation:

1 control unit LGTN

1 sender strip LGTS

1 receiver strip LGTE

2 connecting leads (preassembled)

Test rod (30 mm) as accessory

available.

Two sensor pairs (sender and re-

ceiver) can be connected to each

control unit.

5.1.1 Safety Distance from

Hazardous Point

The protective device requires a

certain minimum distance to the

hazardous point to ensure that the

point can only be reached once the

machine or system has come to a

standstill (Fig. 7). The safety dis-

tance (as per EN 775, 999 and

294) depends on the

‡stopping time of the machine,

‡response time of the protective

device,

‡resolution of the light grid

and the reach speed.

The stopping time is a measured

value of the machine. The reach

speed is equal to

at (short distances) up to 500 mm

safety distance 2 m/s

greater than this 1.6 m/s

The safety distance S is calculated

using the formula:

Mean protection field depth

S = Safety clearance Boundary of hazardous site

Protection field boundary

Upper edge of tool

Coasting time of machine

Lower edge of tool

This value must be strictly observed

in order to prevent access behind

the protection field.

≤ 75 mm