Shredder MA- ML-MP

- 5 -

1. INTRODUCTION

This manual is an integral part of the product and must be kept in an ap-

propriate manner, allowing easy consultation by the operator at any time. It

is advisable to make a copy of this manual.

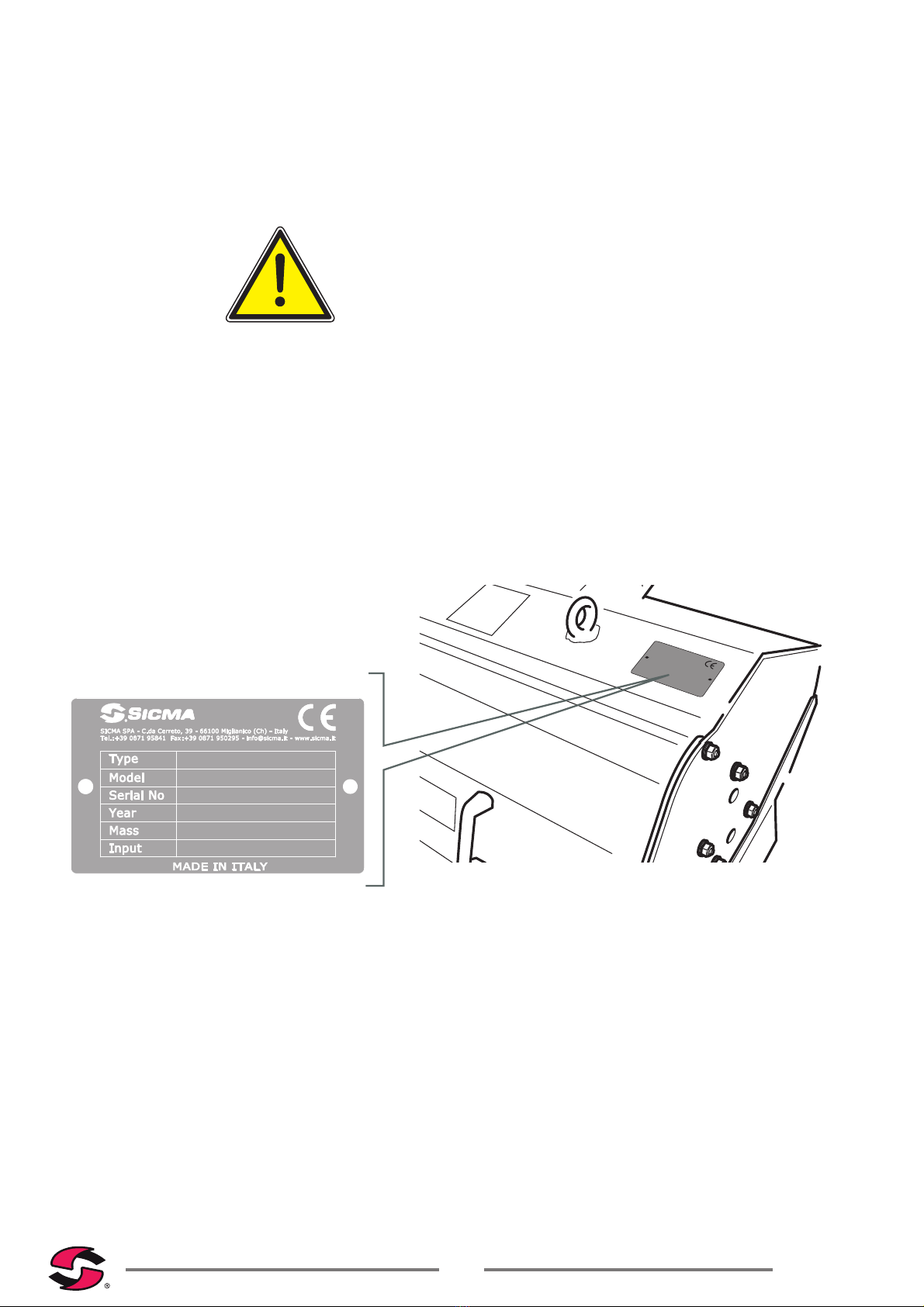

This manual is accompanied by the "DECLARATION OF CONFORMITY"

that certi!es compliance with the regulations in force and that must be pre-

sented to parties that expressly request it.

In addition, this declaration shows the "SERIAL NUMBER" of the machine.

Upon delivery check correspondence of the serial number of the machine.

Where there correspondence of the numbers is incorrect, immediately con-

tact the retailer to check the details.

"Sicma" thanks you for having chosen this excellent product.

During operation you will have the opportunity to appreciate the quality of

use and durability of your machine.

In order to maximise the qualities of this machine, it is advisable to spend a

little of your valuable time reading this manual. Superior knowledge of the

machine will pay dividends in terms of duration, safety and quality in the

productive use.

In case of uncertainty, please contact the authorised retailer that will advise

you, offering the appropriate support in the shortest time possible.

Your "SHREDDER" was designed exclusively

for agriculture use. Any other use of the ma-

chine is to be considered abusive and is whol-

ly at the risk of the user. In such case the legal

warranty ceases.

Appropriate use also involves compliance with

the instructions of service and maintenance

prescribed by the manufacturer.

Only authorised persons that are informed

about the possible risks must use, repair and

maintain the machine.

The relevant instructions for the prevention of

accidents must be observed as well as all the

other general technical provisions, the High-

way Code and regulations relating to health

and safety.

Never make any changes to the machine un-

der your own initiative. Where this is the case,

no liability can be held for any damage caused

to persons or property. In this case the legal

warranty also ceases with immediate effect .

"Sicma" reserves the right to suspend at any time the production of certain

models, to vary the characteristics and the design without being committed

in any shape or form to provide notice thereof and is not obliged to apply

these changes to models that have already been produced.