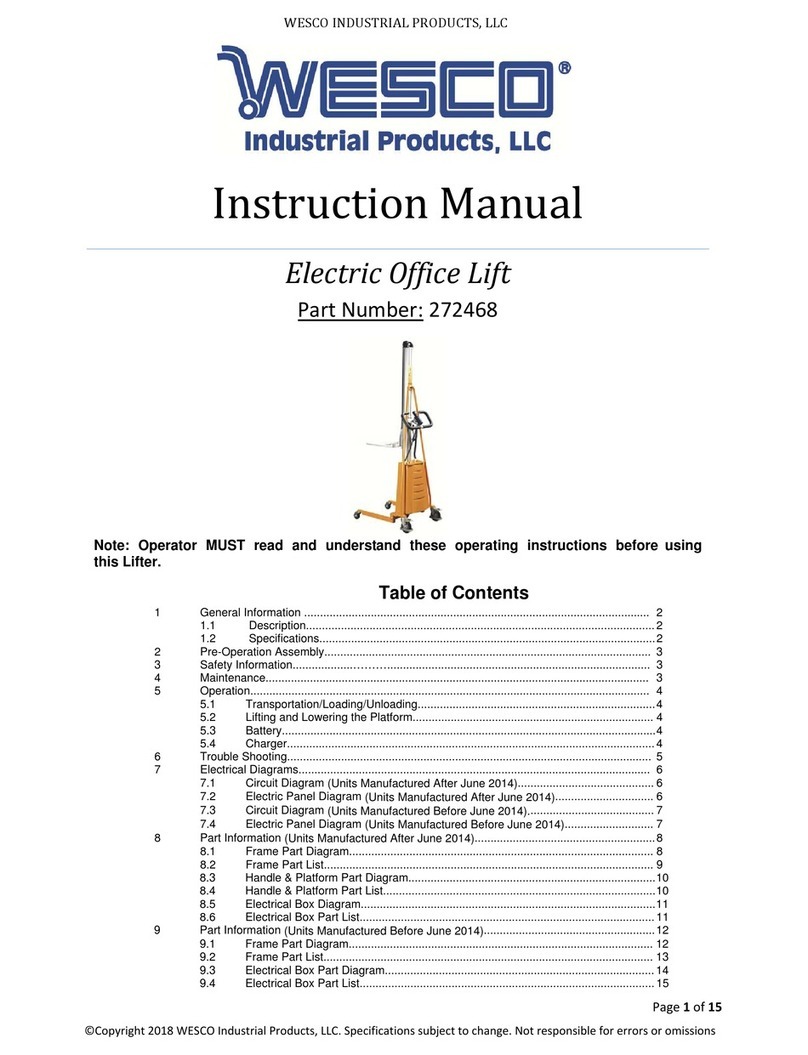

TABLE OF CONTENTS

Section Page Section Page

1 DESCRIPTION............................................................1-1

1-1. INTRODUCTION..............................................1-1

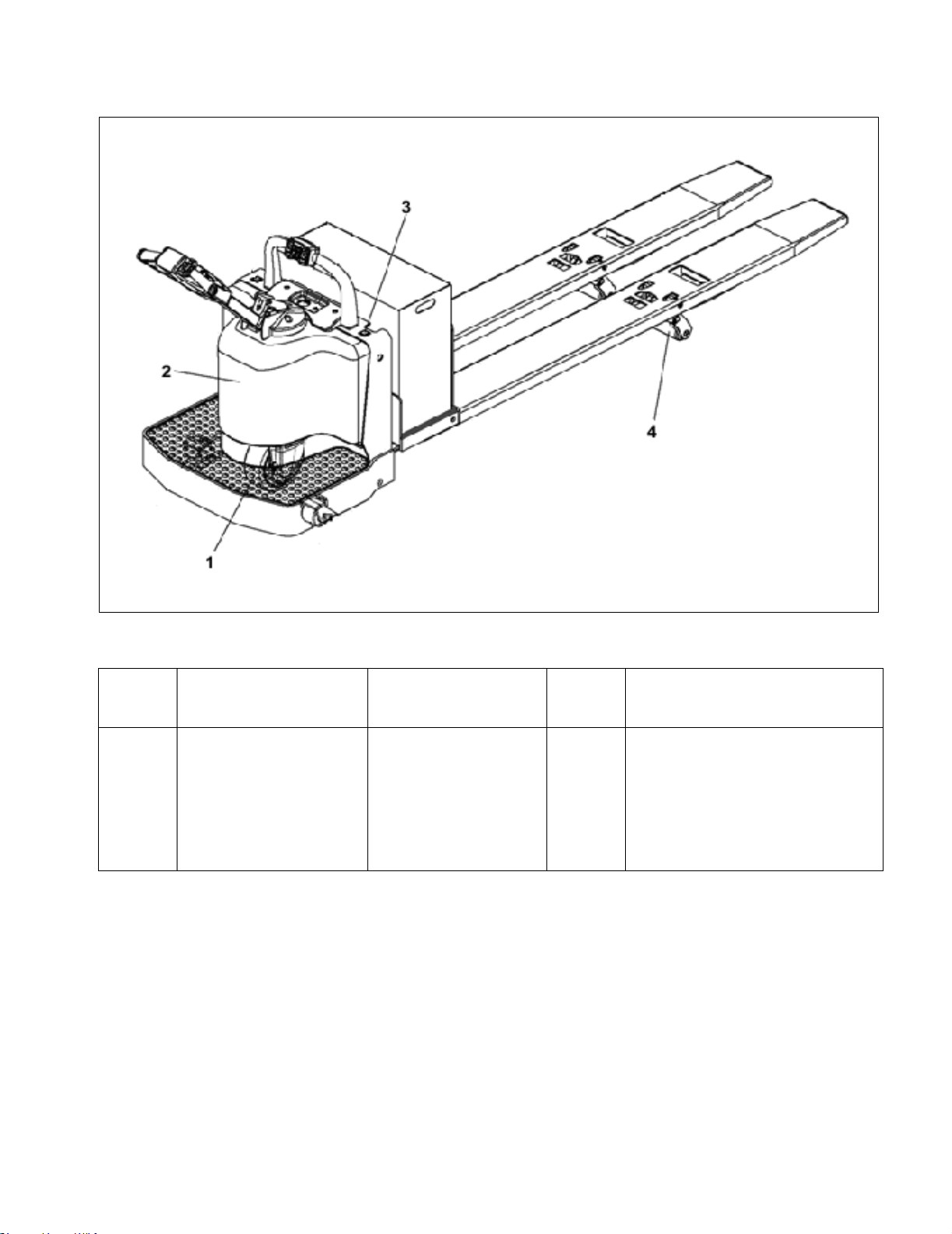

1-2. GENERAL DESCRIPTION...............................1-1

1-3. SAFETY FEATURES. ......................................1-2

2 OPERATION ...............................................................2-1

2-1. GENERAL. .......................................................2-1

2-2. OPERATING PRECAUTIONS. ........................2-1

2-3. BEFORE OPERATION.....................................2-1

2-4. TRAVEL. ..........................................................2-4

2-4.1. BRAKE.............................................................2-4

2-4.2. TRAVEL ...........................................................2-4

2-4.3. BELLY-BUTTON SWITCH...............................2-4

2-5. STEERING ARM GAS SPRING.......................2-5

2-6. LIFT AND LOWER CONTROLS. .....................2-5

2-7. LOADING AND UNLOADING. .........................2-5

2-8. PARKING. ........................................................2-5

3 PLANNED MAINTENANCE ........................................3-1

3-1. GENERAL. .......................................................3-1

3-2. MONTHLY AND QUARTERLY CHECKS........3-1

3-3. BATTERY CARE.............................................3-1

3-3.1. GENERAL ........................................................3-1

3-3.2. SAFETY RULES ..............................................3-2

3-3.3. BATTERY CARE AND CHARGING.................3-2

3-3.4. BATTERY CLEANING......................................3-2

3-3.5. MAINTENANCE FREE BATTERIES................3-3

3-4. CHARGING BATTERIES.................................3-3

3-5. LUBRICATION. ................................................3-4

4 TROUBLESHOOTING ................................................4-1

4-1. GENERAL ........................................................4-1

4-2. CONTROLLER TROUBLESHOOTING............4-4

4-2.1. ZAPI CAN CONSOLE KIT................................4-4

4-2.2. DIAGNOSTIC HISTORY..................................4-6

4-2.3. ADJUISTMENT. ...............................................4-6

5 STEERING ARM, CONTROL HEAD AND

COMPARTMENT ........................................................5-1

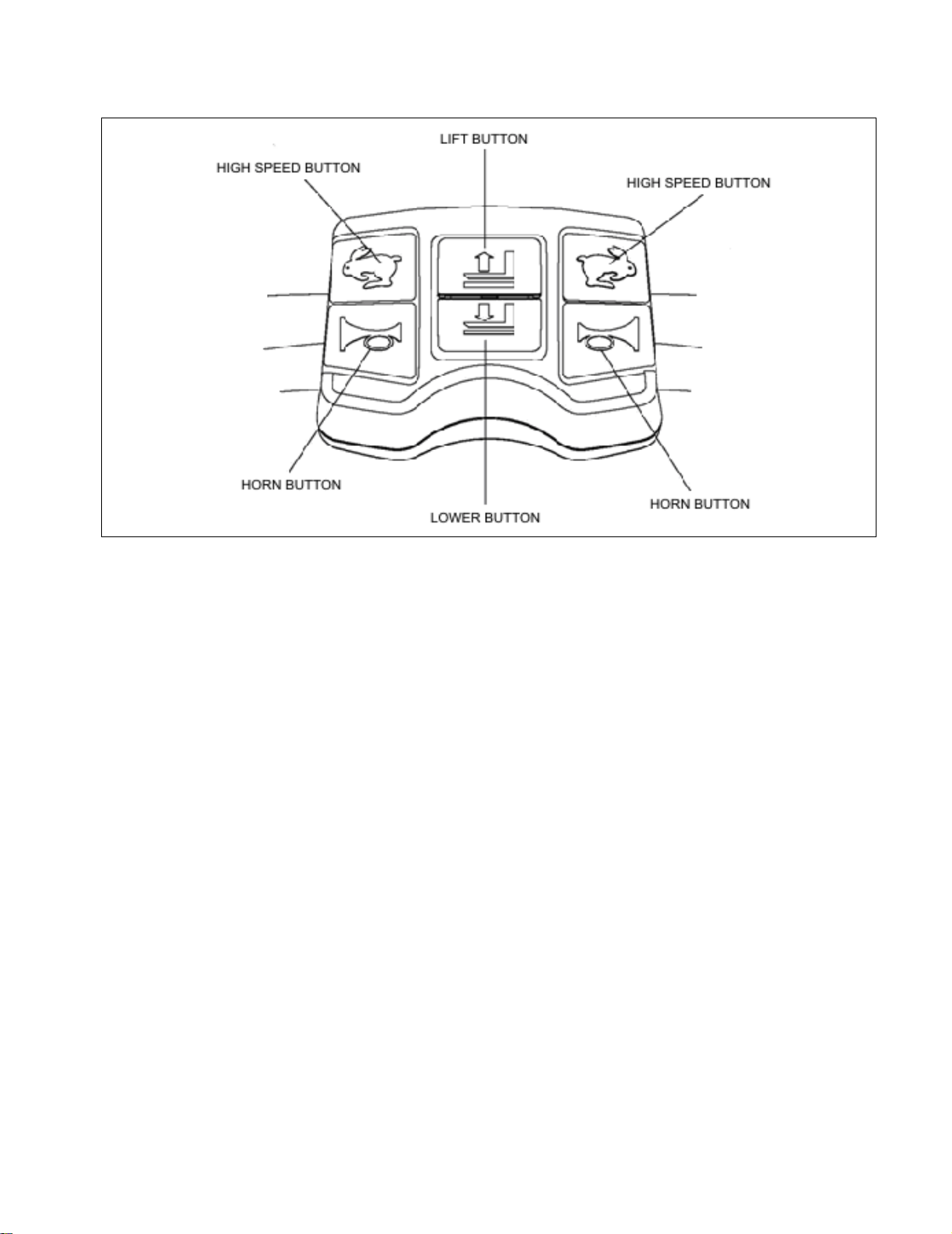

5-1. CONTROL HEAD.............................................5-1

5-1.1. COVER REMOVAL..........................................5-1

5-1.2. COVER INSTALLATION..................................5-2

5-1.3. CONTROL HEAD REMOVAL ..........................5-3

5-1.4. CONTROL HEAD INSTALLATION ..................5-3

5-1.5. BELLY-BUTTON SWITCH REPLACEMENT...5-3

5-1.6. HORN, LIFT AND LOWER SWITCH

REPLACEMENT...............................................5-3

5-1.7. SPEED POTENTIOMETER REPLACEMENT. 5-3

5-2. STEERING ARM..............................................5-3

5-2.1. RETURN SPRING REPLACEMENT................5-3

5-2.2. STEERING ARM REMOVAL............................5-4

5-2.3. STEERING ARM INSTALLATION....................5-4

5-3. COMPARTMENT COVERS.............................5-4

5-3.1. REMOVAL........................................................5-4

5-3.2. INSTALLATION................................................5-4

6 BRAKE SERVICING................................................... 6-1

6-1. BRAKE............................................................. 6-1

6-1.1. AIR GAP ADJUSTMENT................................. 6-1

6-1.2. STOPPING DISTANCE ADJUSTMENT.......... 6-2

6-1.3. BRAKE ASSEMBLY REPLACEMENT ............ 6-2

7 TRANSMISSION, DRIVE WHEEL, LOAD WHEEL.... 7-1

7-1. DRIVE WHEEL................................................ 7-1

7-2. TRANSMISSION. ............................................ 7-1

7-3. LOAD WHEEL. ................................................ 7-3

7-3.1. REMOVAL ....................................................... 7-3

7-3.2. REPAIR ........................................................... 7-3

7-3.3. LOAD WHEEL INSTALLATION....................... 7-3

7-4. CASTERS........................................................ 7-3

8 ELEVATION SYSTEM SERVICING........................... 8-1

8-1. LIFT LINKAGE................................................. 8-1

8-1.1. REMOVAL ....................................................... 8-1

8-1.2. REPAIR ........................................................... 8-1

8-1.3. INSTALLATION ............................................... 8-1

9 HYDRAULIC SYSTEM SERVICING........................... 9-1

9-1. LINES AND FITTINGS .................................... 9-1

9-2. HYDRAULIC PUMP, MOTOR, AND

RESERVOIR ASSY......................................... 9-1

9-2.1. REMOVAL ....................................................... 9-1

9-2.2. DISASSEMBLY AND REASSEMBLY ............. 9-3

9-2.3. INSTALLATION ............................................... 9-3

9-2.4. LIFT CYLINDER .............................................. 9-3

10 ELECTRICAL COMPONENTS................................. 10-1

10-1. ELECTRICAL CONTROL PANEL ................. 10-1

10-1.1.MAINTENANCE............................................. 10-1

10-1.2.CLEANING .................................................... 10-1

10-1.3.PANEL REMOVAL. ....................................... 10-1

10-1.4.PANEL DISASSEMBLY................................. 10-1

10-1.5.PANEL INSTALLATION. ............................... 10-1

10-2. HORN REPLACEMENT ................................ 10-4

10-3. PUMP MOTOR.............................................. 10-5

10-4. DRIVE MOTOR. ............................................ 10-5

10-4.1.MOTOR REMOVAL....................................... 10-5

10-4.2.MOTOR INSTALLATION............................... 10-5

10-5. LIFT LIMIT SWITCH...................................... 10-5

10-5.1.REPLACEMENT............................................ 10-5

10-5.2.ADJUSTMENT............................................... 10-5

10-6. DEADMAN SWITCH...................................... 10-6

10-6.1.REPLACEMENT............................................ 10-6

11 OPTIONAL EQUIPMENT ......................................... 11-1

11-1. LOAD BACKREST......................................... 11-1

12 ILLUSTRATED PARTS BREAKDOWN.................... 12-1