TERRY Melody 2 hydraulic MK2 User manual

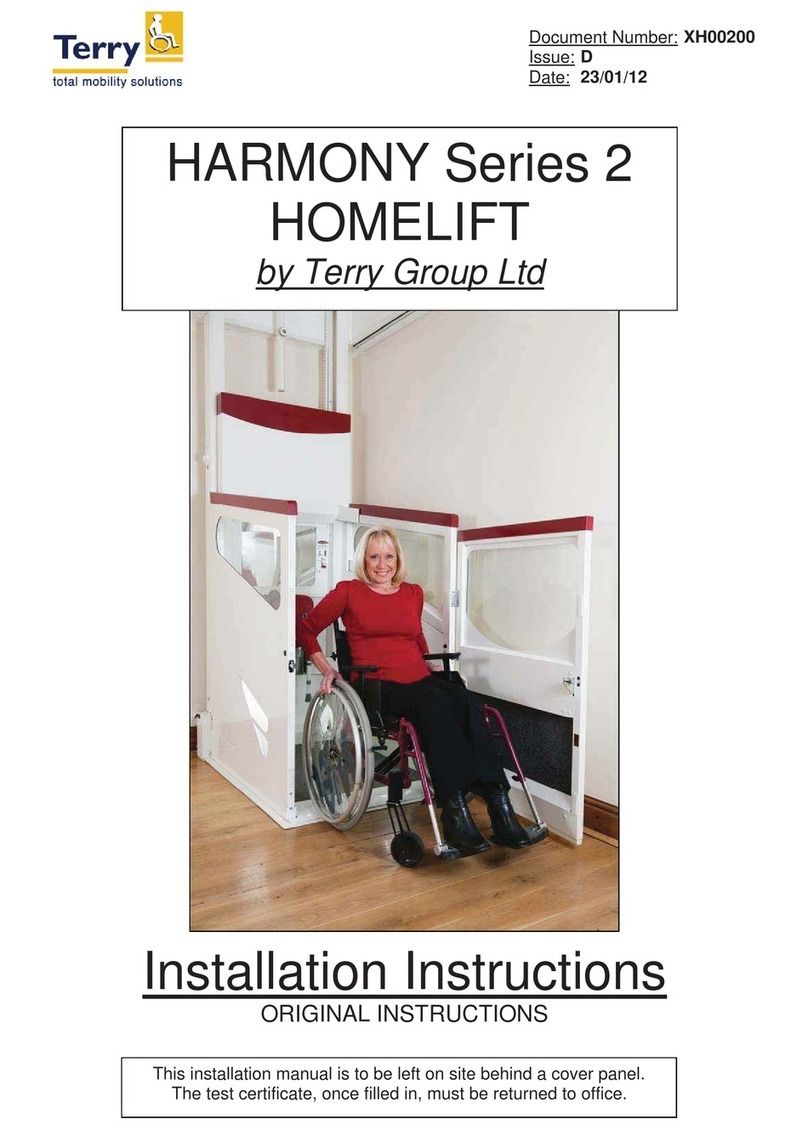

Installation Manual

Melody 2 MKII Platform Lift

Ref. ED20400f Date: 03/04/2012

Original instructions

2

Melody 2 hydraulic MK2 Installation Manual - Issue f

Contents

Safe Working 3

Weights of Main Parts /Assemblies 3

Health & Safety Compliance 3

Fitting safety scotch 4

Power Pack Isolate Switch 5

Powerpack / Circuit Box and Cable Runs 6

Installing Melody 2 Hydraulic Lift 7

Wiring 26

Diagnostic Flow Charts 29

Wiring Diagrams 34

To conduct an insulation resistance test on the safety circuit 41

Installation Test Certificate for Melody 2 Hyd Lift. 43

Trade Customer Feedback Questionnaire 47

Declaration of Conformity 49

Melody 2 Hyd. lift service points 51

Melody 2 Hyd. Lift Master Definition of Basic Safety Items 53

Melody 2 hyd 900 x 1400 Platform Details 55

Melody 2 hyd 1100 x 1400 Platform Details 56

Lift Disassembly/Safe Disposal of Hazardous Materials 57

Bulletins 58

Melody 2 Plinth - No Pins (XB00160B) 59

3

Melody 2 Hydraulic MK2 Installation Manual - Issue f

Safe Working

Ref. ED20101c

When working in the area below the platform ensure the lift is isolated. To

prevent downward movement of the platform refer to isolate switch (page 4) and

insert safety chock (page 3) and ensure the hydraulic shut-off valve in the power

pack is closed.

If any work is undertaken on the drive system ensure the platform is at its lowest

position.

Make sure you are familiar with the correct lifting techniques.

Do not jerk and shove - twisting your body may cause injury.

Lift in easy stages - floor to knee level, then from knee to carrying position.

Reverse this sequence when setting the load down.

Hold weights close to your body and lift with your legs keeping your back

straight.

Organise work to minimise the amount of lifting necessary.

Use mechanical means or other aids when necessary.

Do not lift parts that are excessively heavy by yourself. Seek assistance. Work

together but make sure that only one person gives clear, unhurried instructions.

Use protection for hands and feet and additional protective clothing where

necessary.

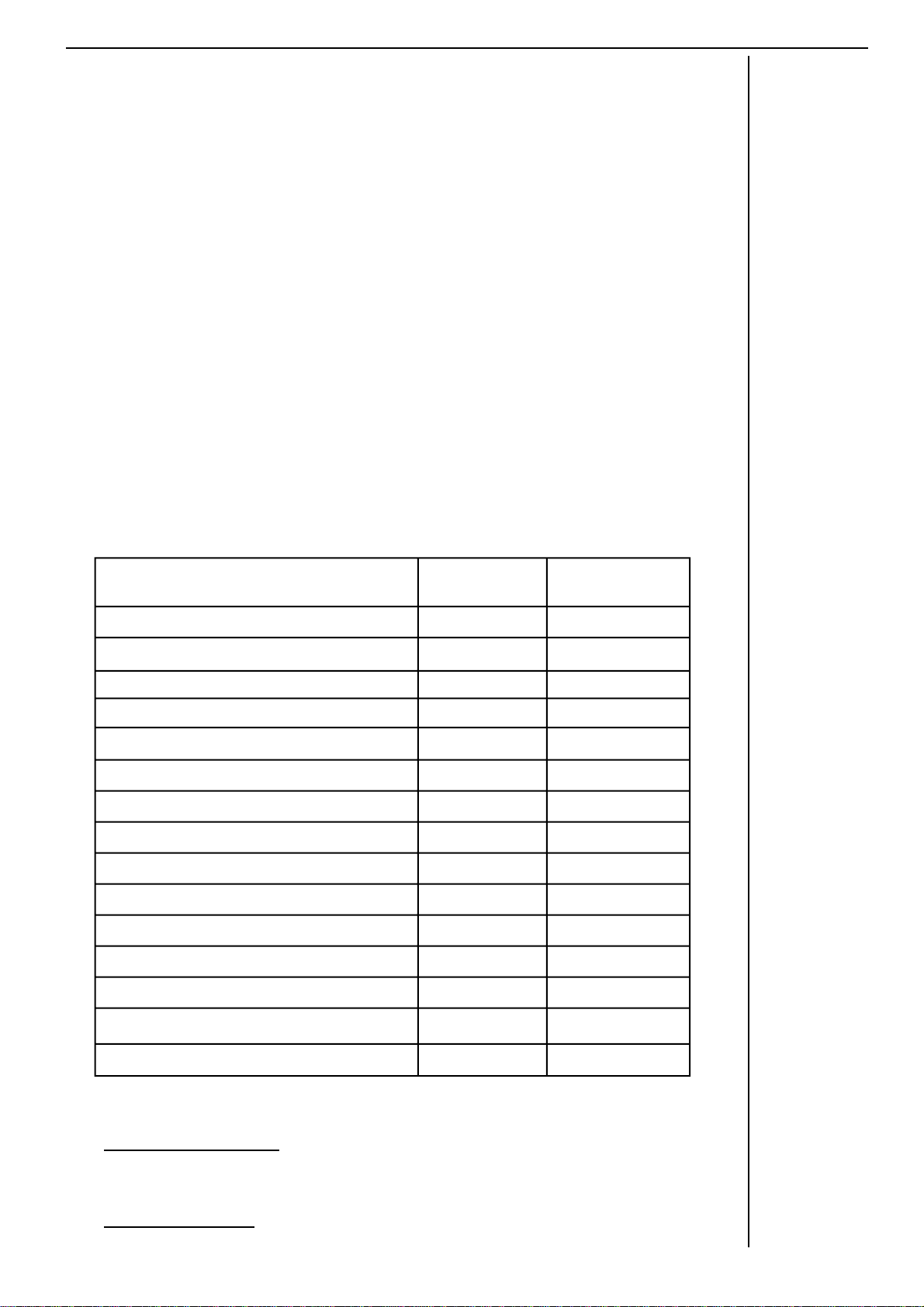

Weights of Main Parts / Assemblies

Part / Assembly Weight (Kg)

2m Lift Weight (Kg)

3m Lift

Power Pack 40 40

Upper Level Gate 33 33

Baseplate 11 11

Hydraulic Cylinder 30 40

Upper Guides 20 (each) 30 (each)

Lower Guides 11 (each) 25 (each)

Main Uprights 36 (each) 36 (each)

Chain Drive Assembly 22 23

Upper Level Plinth 24 24

Platform Floor 61 61

Platform Checker Plate Deck 13 13

Platform Handrail / Gate Assembly 36 36

Platform Handrail Assembly 21 21

Back Pillars 10 (each) 13 (each)

Platform Checker Plate 13 13

Health & Safety Compliance

COSHH Regulations - Terry Group Limited hereby certifies that COSHH

Data Sheets for all hazardous substances used in the manufacture,

installation and use of this equipment are available at www.terrylifts.co.uk

CDM Regulations - Terry Group Limited hereby certifies that the dismantling

and disposal of this equipment can be achieved by reversing the installation

procedure.

NOTES

4

Melody 2 Hydraulic MK2 Installation Manual - Issue f

NOTES

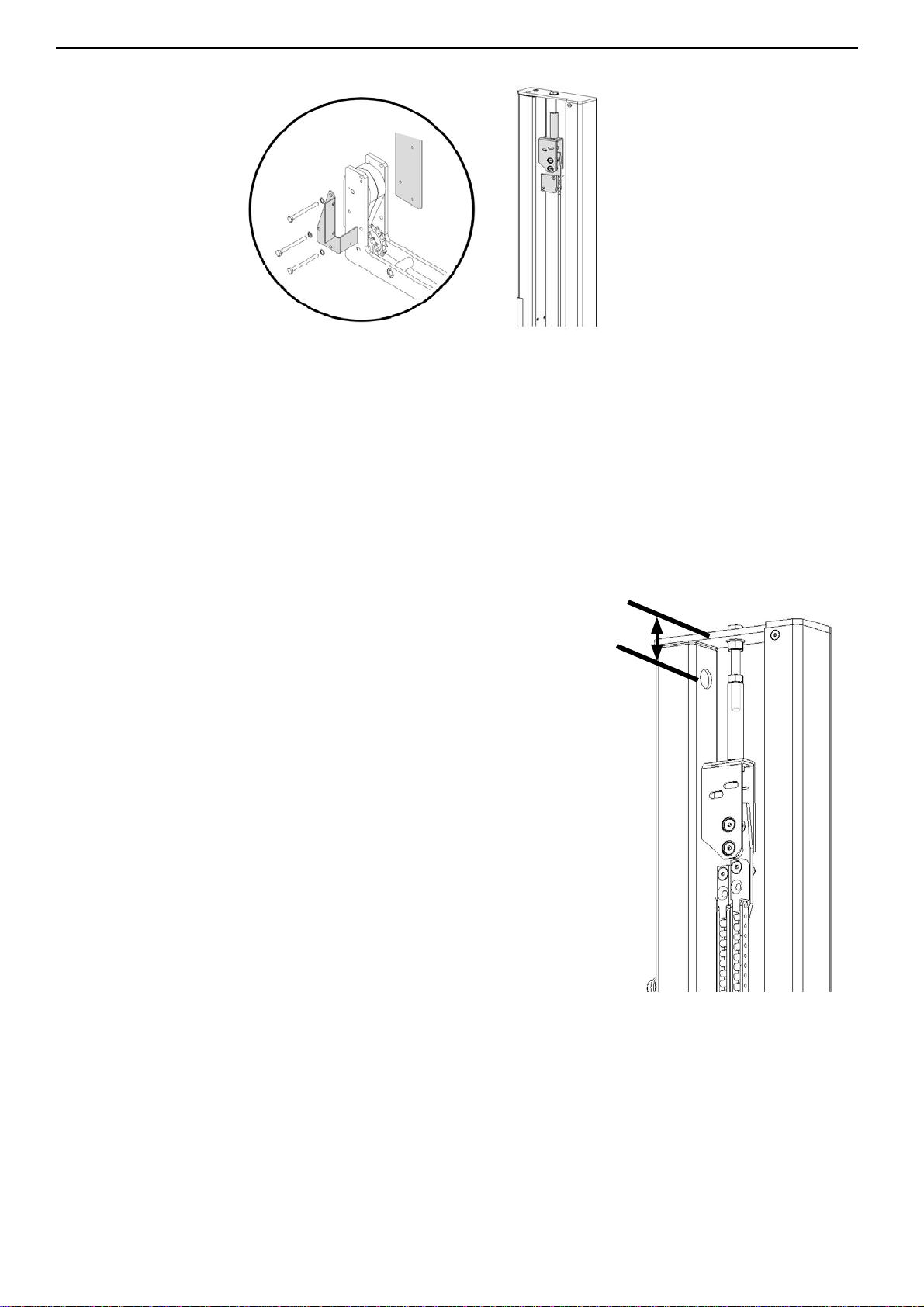

Working under the Lift – ALWAYS FIT THE SAFETY SCOTCH

IMPORTANT

Before any work is carried out underneath

the lift, the safety scotch must be fitted to the

LH Gate Post as indicated below.

The safety scotch can be found within the

powerpack and after use must be put back

there, so it remains with the lift.

1.

Raise the lift above

the safety scotch hole

in the LH Gate Post

2.

Remove

the blanking

cap

3.

Insert the scotch into

the guide and hook into

the hole in the LH Gate

Post

4.

Remember to remove the scotch

before operating the lift normally and

replace the CP154 blanking plug, using

the spare provided if necessary.

Fitting safety scotch

5

Melody 2 Hydraulic MK2 Installation Manual - Issue f

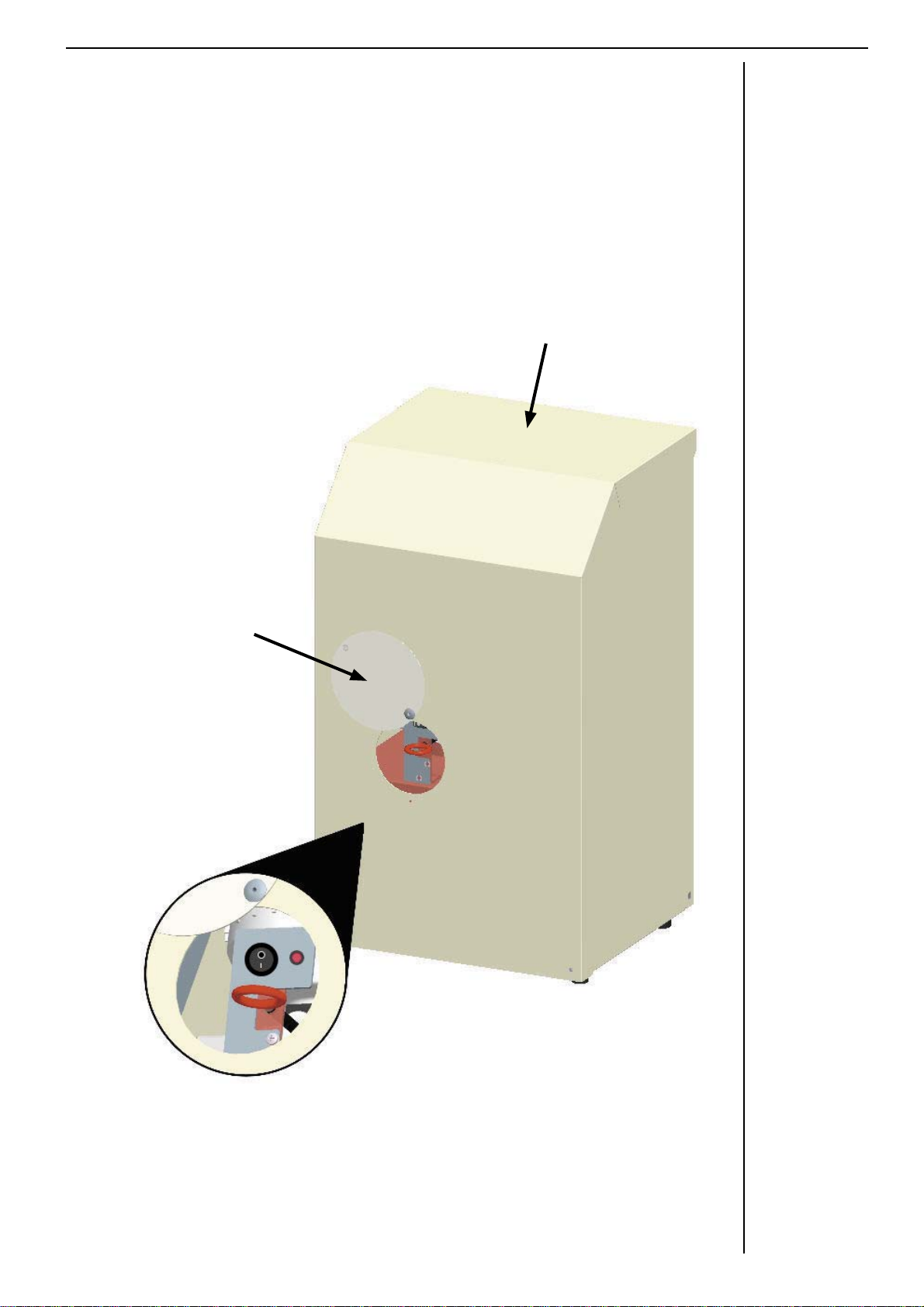

Power Pack Isolate Switch

In order to safely work on the lift and to perform a manual lowering operation,

a Lift Isolate switch has been provided. This switch isolates the 12V power to

the lifts carriage and disables the use of the call stations, re-levelling system

and gates when turned off. The switch contains a red indicator which will only

be illuminated when in the on position.

Detailed

View

of Switch Panel

and Emergency Release Handle

Powerpack

Assembly

Emergency

Access

Panel

6

Melody 2 Hydraulic MK2 Installation Manual - Issue f

Powerpack / Circuit Box and Cable Runs

Ref. ED20102c

Fit the hydraulic powerpack in a suitable location using 2 x 10mm Rawl bolts.

Fit the electrical control box as close to the powerpack as possible. Use the

mounting brackets supplied.

Fit the Earth bonding cables to the base plate and each guide.

Run the hydraulic hose in a suitable conduit from the ram to the powerpack. The

hose elbow goes on to the ram.

DANGER!. DO NOT turn power on from 13Aspur until lift is wired fully, and all

Control Mechanism Switches are adjusted.

Terminate the following cables into the control box and pump as follows. See

wiring diagram in Melody 2Hyd Installation Manual (PG25).

1. 1 x 7 core or 4 core from the upper call station.

2. 1 x 7 core or 4 core from the lower call station.

3. 1 x 7 core from the upper gate lock.

4. 2 x 7 core trailing cables from the RH guide.

5. 1 x 3 core from the mains spur.

6. 1 x 2 core from the pump solenoid.

7. 1 x 3 core from the pump mains up.

Wiring to be carried out by a competent person.

House the wiring in suitable conduit and terminate correctly where entering the

boxes.

NOTES

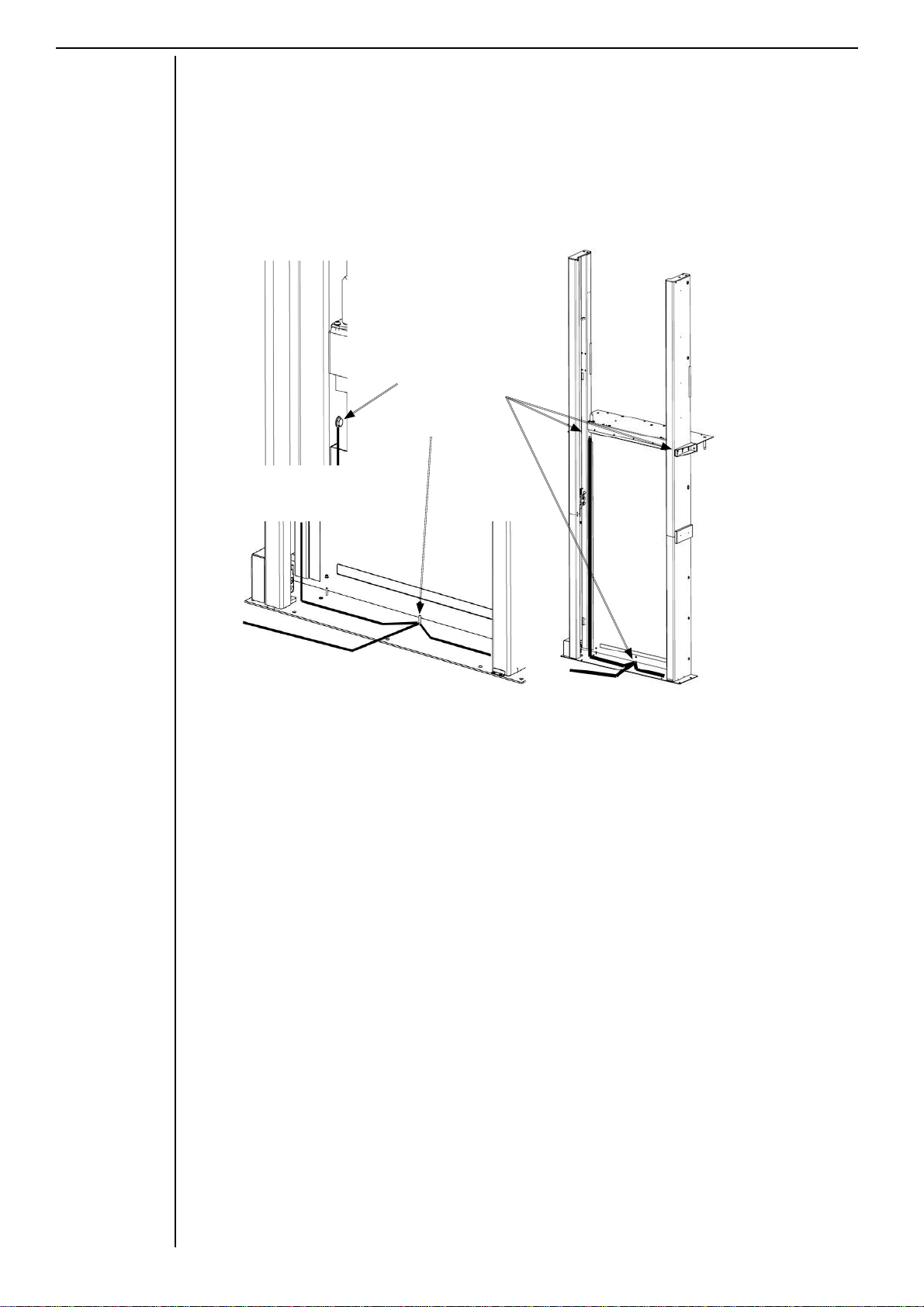

Earth Bond cable is

fastened to the guides

above cable slot using

a CB003 bolt & CW003

washer on both sides

and to the base place

on central m stud.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

7

NOTES

Installing Melody 2 Hydraulic Lift

Ref. ED20129e 23/08/2011

Specialist tools required

22mm SDS drill bit

Chain splitter

Pin punch

Metal cutting circular saw

Arrival on site

Lifting Height Application

750mm - 950mm Public and Domestic Access

951mm – 2000mm Public and Domestic Access

2001mm – 3000mm. Domestic Access only

Ensure the site is to the correct specification:

Lifting face vertical

Height not exceeding the type of lift ordered

Upper level plinth 1500mm x 1500mm x 200mm deep

Lower landing base level

Ducts , power supply on a dedicated supply and RCD protected as

specified on drawing

Ensure the site is safe to start work and also safe for the public.

Carry out any risk assessments if required.

Speak with end User to ensure they are aware of power pack positions and

call stations.

If the lift is to be sited between walls check the distance between them is at

least 1400mm and the walls are square to the lifting face.

Installation Procedure

1. Unpacking

Unload the lift carefully storing all unpacked parts safely out of harms way

and without any risk of falling.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

8

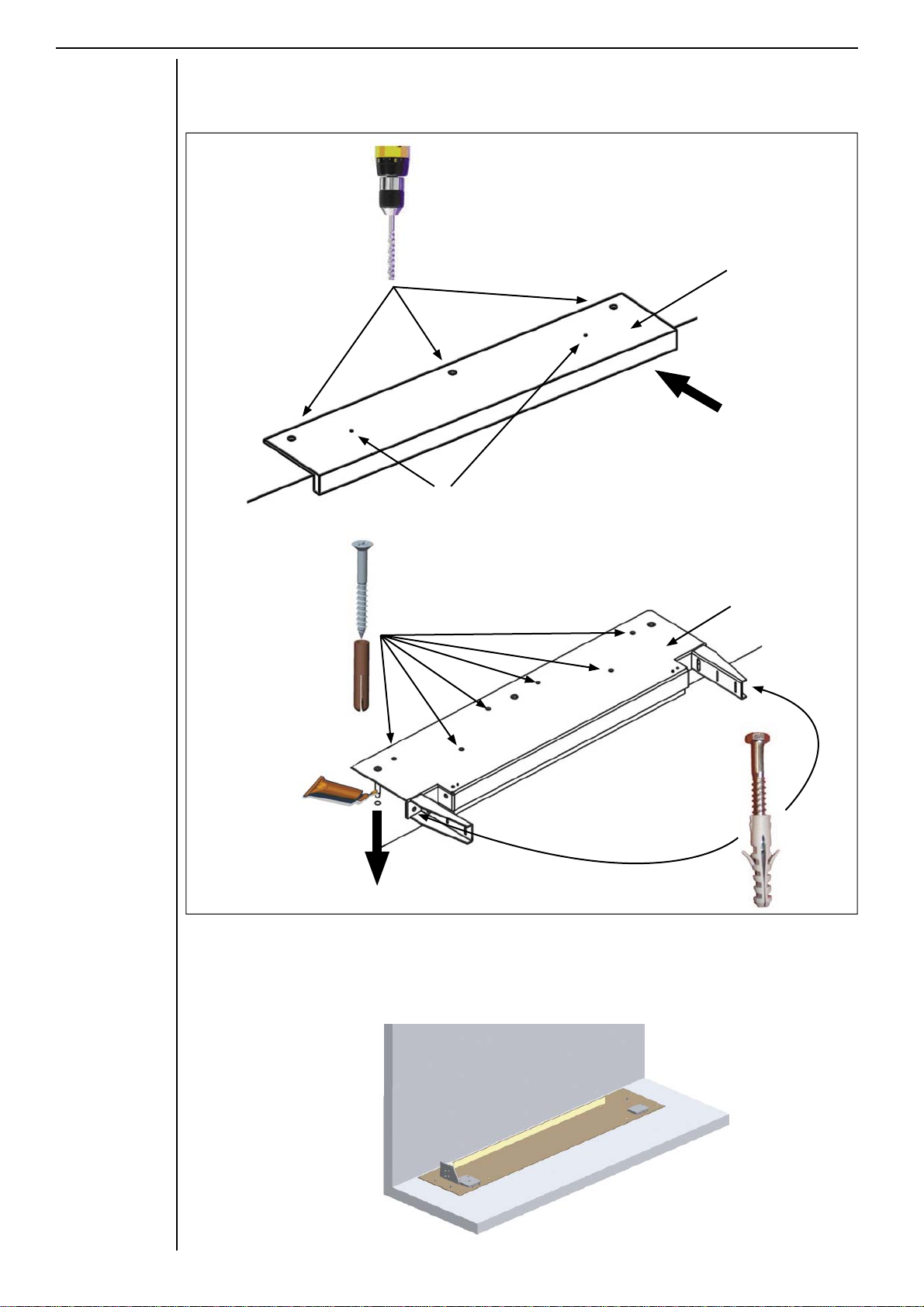

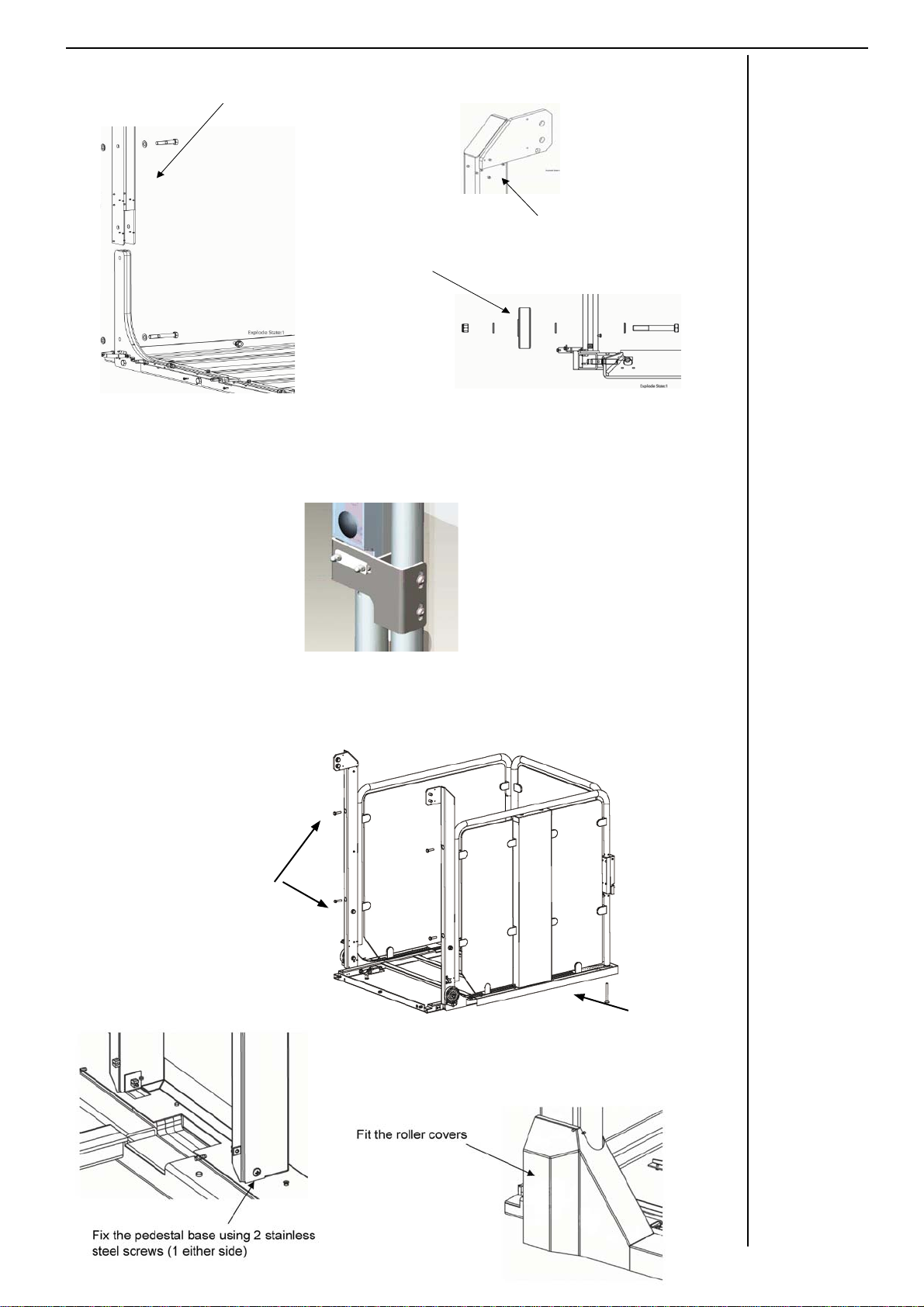

NOTES 2. Upper Level Plinth

Follow the diagram below to fix the upper level plinth.

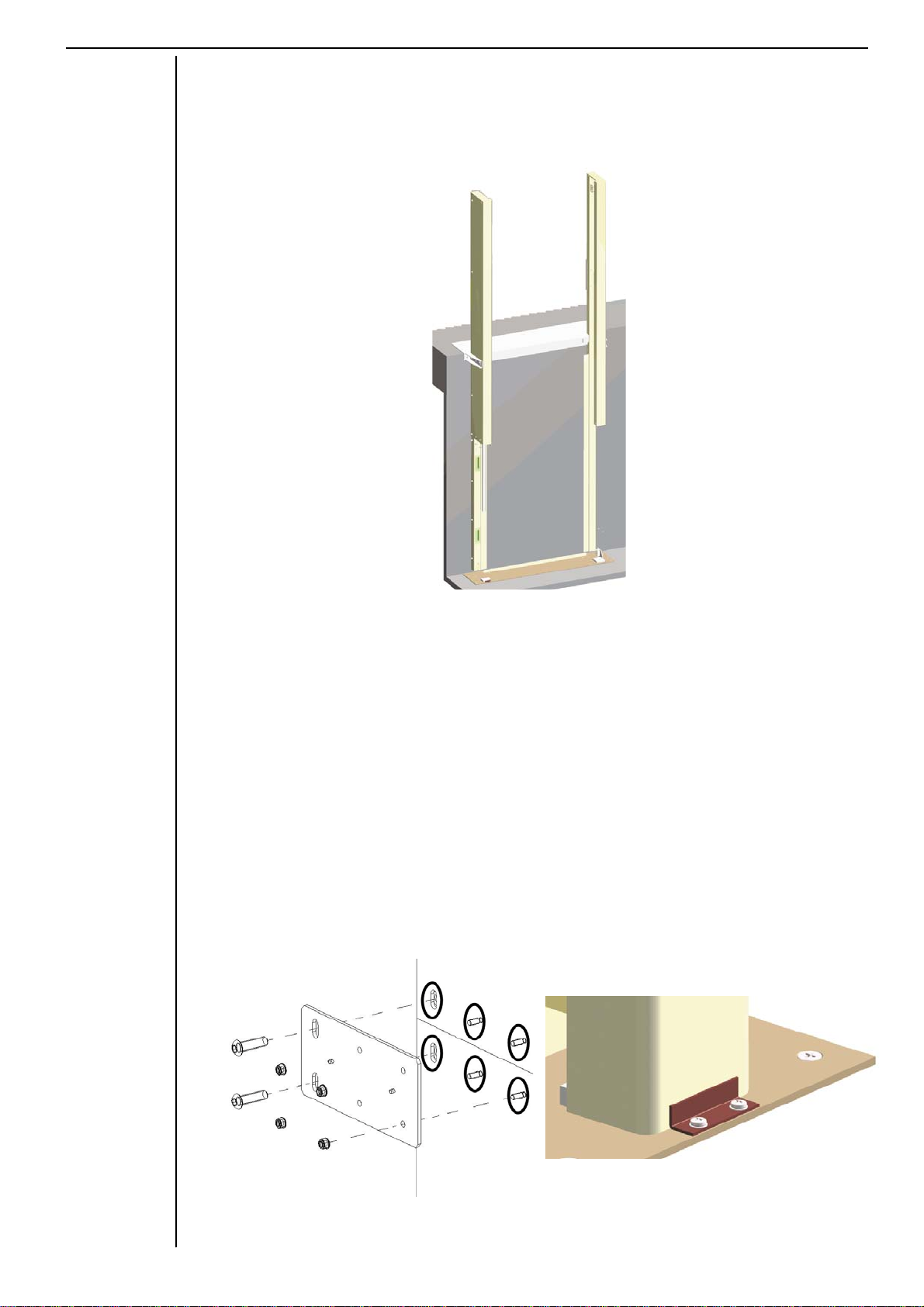

3. Base Plate (initial)

Supatrol the underside base plate and position it at the lower level. If

necessary pack the base plate so as to make level in both directions and

also level the surrounding area that the lifs car will land on. Do not fix

down yet.

322mm Diameter holes Jig

2.

Drill through two small fixing

holes and use screws and

plugs to secure jig in position

1.

Ensure the jig is pushed

hard against the lifting face

4.

Inject chemical fixing

into each spigot hole

then lower the plinth

into position

5.

x6 into plinth top

CF154 (screw)

CF120 (plug)

Upper Level

Plinth Fabrication

6.

x2 into lifting face

CF207 & CW066

CF206 (plug)

Melody 2 Hydraulic MK2 Installation Manual - Issue f

9

NOTES

4. Cutting of the Main Uprights and Lower Guides

Use a jigsaw or metal cutting saw to cut uprights and guides. Ensure burs are

removed and treat cuts before fitting as follows: Seal all exposed edges using

a touch-up can. Seal further with Supatrol once the paint has dried.

RH Main Upright: (60 x 60 Box Section)

Cut the upright using the following formula:

Measure from the baseplate top surface to the upper

level plinth top surface (Distance X).

For a 2m lift:

2000 – Distance X = calculated length (amount to cut

off).

For a 3m lift:

3000 – Distance X = calculated length (amount to cut

off).

Now cut the calculated length off the bottom of the

lower guides and main uprights OR In the case of a

3m lift, cut the calculated amount off the bottom of the

lower extension box section.

LH Main Upright: (60 x 60 Box Section)

Cut the calculated length PLUS 260mm off the LH Main Upright. This will

place the cut at 300mm above the base plate, which is the point where the

lower gate enable switch must roll off to enable the car gate.

Continued Over:

Melody 2 Hydraulic MK2 Installation Manual - Issue f

Guides

Cut the calculated length off the lower LH and RH Guides.

Take the off- cut from the lower left hand guide and copy the outline of

the ram cut-out onto to remaining guide. Either use a jigsaw or metal

cutting saw to create the guide cut-out. Seal all exposed edges using a

touch-up can. Seal further with Supatrol once the paint has dried.

10

NOTES

5. Upper Left Hand Guide Box Section

Attach the upper left hand guide and top cap to the left hand upright. If the

lift is a 3m model, an upper extension box section needs to be fixed onto

the top end of each upright. This is secured with M8 bolts inside and M8

countersunk bolts from above. Use M6 countersunk bolts in the sides.

A new square shaped washer is needed to locate the guide fixing bolt

centrally in the slot in the guide bracket when the guides are being attached.

Place washer into the bracket with the hole and slot aligned, the washer

can go in either way up with the flat side against the inside face of the guide

bracket.

f guide adjustment is required move this washer and replace with the M10

washer provided.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

11

Apply chemical fixing to areas

highlighted by black rings

Fish plate diagram Guide Fixing Bracket

Offer the left hand upper guide/upright assembly to the upper level plinth and

secure using an M12x110mm bolt. Once fitted, ensure a 40mm gap exists

between the base plate and the bottom of the upright. This is to allow the

trailing cables to exit the upright.

6. Upper Right Hand Guide

Attach the right hand upper guide/upright assembly to the upper level

plinth in the same way.

7. Lower Right Hand Guide

Fix the guide in place using M10 screws into the uprights. Fit the fish plate

by appling chemical fixing to the area around the fixing holes in the guides

before screwing the fish plate in to place. Fit the guide joining tab. Ensure

the bottom end of the guide is positioned correctly and secure using a

small guide fixing bracket.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

12

8. Ram

Carry the ram from the van (2 people) and locate between the pins

on the left side of the base plate. Ensure the head of the ram and the

bleed points are facing the correct way.

9. Lower Left Hand Guide

Fix the guide in place using M10 screws into the uprights. Fit the fish

plate by applying chemical fixing to the area around the fixing holes

in the guides before screwing the fish plate in to place. Fit the guide

joining tab. Ensure the bottom end of the guide is positioned correctly

and secure using a small guide fixing bracket.

Fit the ram catch tank.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

13

NOTES

Important! Ensure both guides are in good contact with the base plate and

that the baseplate is level in both directions.

Ensure the right hand guide is perfectly vertical in both directions by

moving the baseplate accordingly. Secure the right side of the baseplate

with two stainless steel screws and rawl plugs. Fit the remaining baseplate

screws.

Tighten all guide mounting screws and ensure structure is secure.

10.Upper Level Gate

Fit the lower hinge boss as detailed below.

Lubricate the pivot boss before the gate is fitted over it.

Fit the upper level gate, ensuring the glass is on the carriage side, flush

with the lifting face.

Secure top hinge bracket securely and align gate beak to gate lock.

If required, the gate can be re-handed on site by following these steps.

CRITICAL: THE FLUSH SIDE OF THE GATE MUST BE FACING THE

PLATFORM / LIFTING FACE

Lay the upper level gate down

on cardboard or similar protection

to ensure that it does not get

damaged and consider which side

becomes the hinged side and ensuring

the glass is on the carriage side.

Fit the lower hinge boss to the upper

level plinth.

Push the black nylon insert into

the top of the gate frame and then

fit the top gate bracket.

Fit the black 25mm cap in the

opposite end of the frame.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

14

NOTES Remove the gate beak bracket

assembly and move the correct

set of inserts to ensure the bracket

aligns with the gate.

Drop the gate over the gate pivoit pin

(Lubricating the pin first).

Ensure the glass is on the carriage side.

Fit the 2 black bushes in clips into

the unused inserts.

11.Upper Call Station

he upper call station is pre-fitted to the main upright.

n additional call station (free standing post, flush or surface mounted)

can

be fitted if specified.

12. Lower Call Station

Fit the lower call station in a suitable position 1000mm off the floor and run

the cable back to the control box position.

13. Energy Chain Roller Assembly

Fit the energy chain roller guide assembly into the right hand guide with

the energy chain attached and pass the two trailing cables behind the

lower gate enable switch. Locate the end of the energy chain channel into

the socket on the right hand side.

Remove the 2 x M12 bolts and keep safe.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

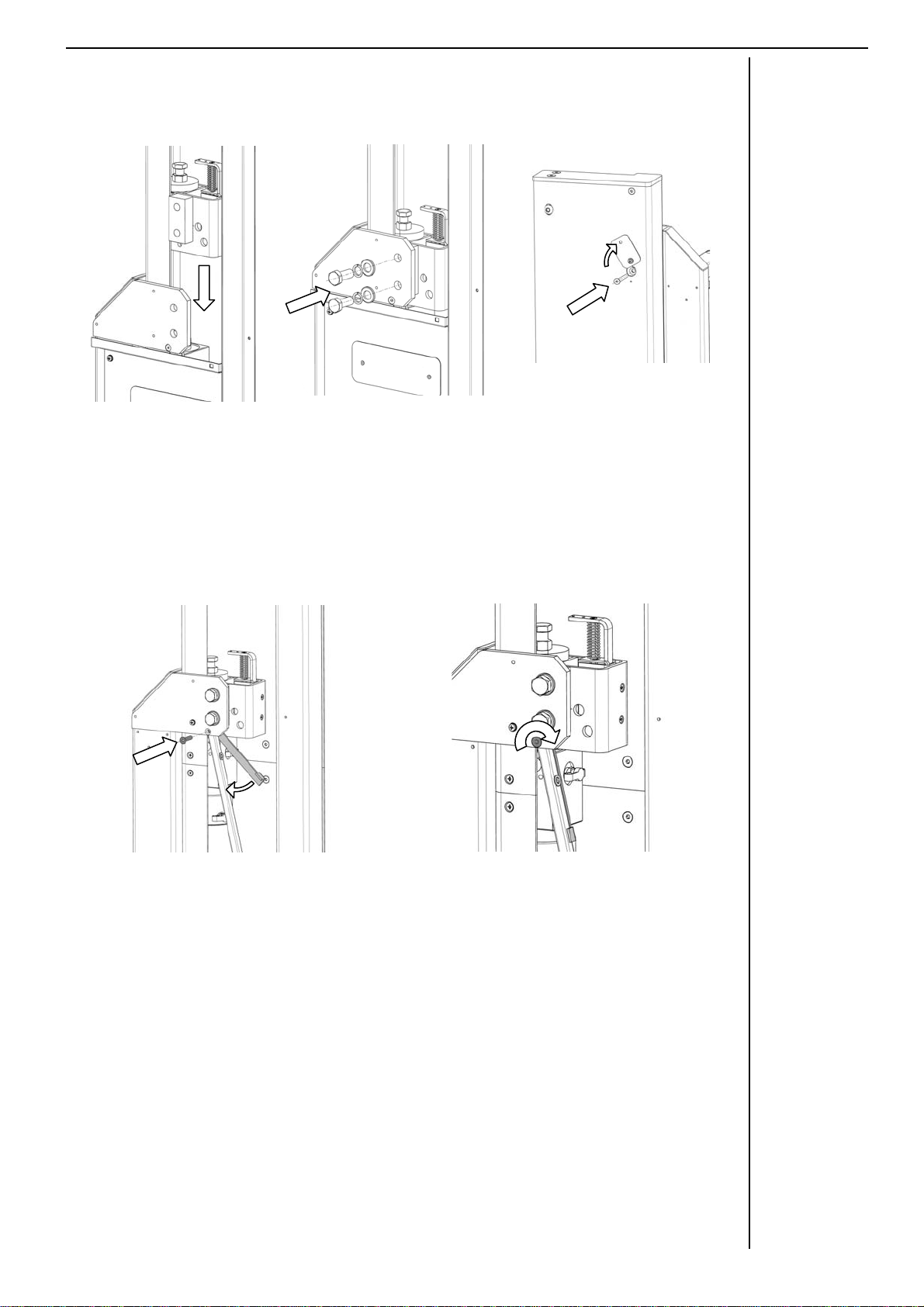

The method for fixing the new ‘ram-to-carriage bracket’ into position is very similar to the

previous method;

The method by which the anti-creep support bracket now fixes to the carriage up-right has

also slightly altered;

Adjustments to the safe switch can be made by using the access holes to the rear of the new

ram bracket.

Fit the bracket into the

guide then slide downwards

onto the top of the ram.

Fix into position using the

usual M12 x 30

bolts/washers

(2 x ‘CB263/CW187/CW018’).

Take the lift to its upmost

position and undo one of

the screws in the upper

gate blanking plate. Turning

this out of the way, secure

the ram head into position

using a M6 x 60 CSK bolt

(CB097, as pictured).

After fitting the ‘ram to carriage

bracket’ as above, place the

anti-creep support bracket

behind the carriage up-right and

fix into position using the clamp

plate and M6 x 30 CSK screw

(LT04917 and CB066).

a)

Screw into position whilst

holding the clamp plate. As it

begins to tighten, release the

clamp plate and tighten fully.

The clamp plate is shaped so

that it should be hard up against

the anti-creep support bracket.

b)

c)

b)

a)

15

NOTES

14. Ram Head Assembly

15. Chain Drive Assembly

Fasten the Anti-Creep Bracket Assembly (LT04427) to the chain drive

assembly using the M6 x 70 Hex. Bolts (CB179) and M6 Shake-proof

Washers (CW017) provided with the Anti-Creep Assembly.

Be sure to fasten through the left hand inner

cover mounting bracket (LT04553)

Melody 2 Hydraulic MK2 Installation Manual - Issue f

16

Lay out the chain drive assembly ensuring that no dirt or grit gets in the links, and attach

the Anti Creep unit as detailed above. The chains now need to be cut to length.

On the chain equaliser assembly, remove the chain from the swivelling chain brackets -

see B.

Attatch the chain equaliser assembly to the top right hand guide as normal, ensuring the

minimum engagement of the top adjustment bolt. - see A.

Fit the chain assembly, feeding it into the right hand guide. Sit this assembly on a suitable

packer on the baseplate (around 250mm high). Fit four M8 x 30mm countersunk allen

bolts to secure the chain brackets to the baseplate.

IMPORTANT:

The top bolt (M12x100 set screw, 12.9 grade) must

be engaged by a minimum of 30mm, when the lift is in

operation

This means that a absolute maximum distance of 64mm is

allowed between the underside of the top plate and the top

of the tapped boss of the chain hanger. (See diagram)

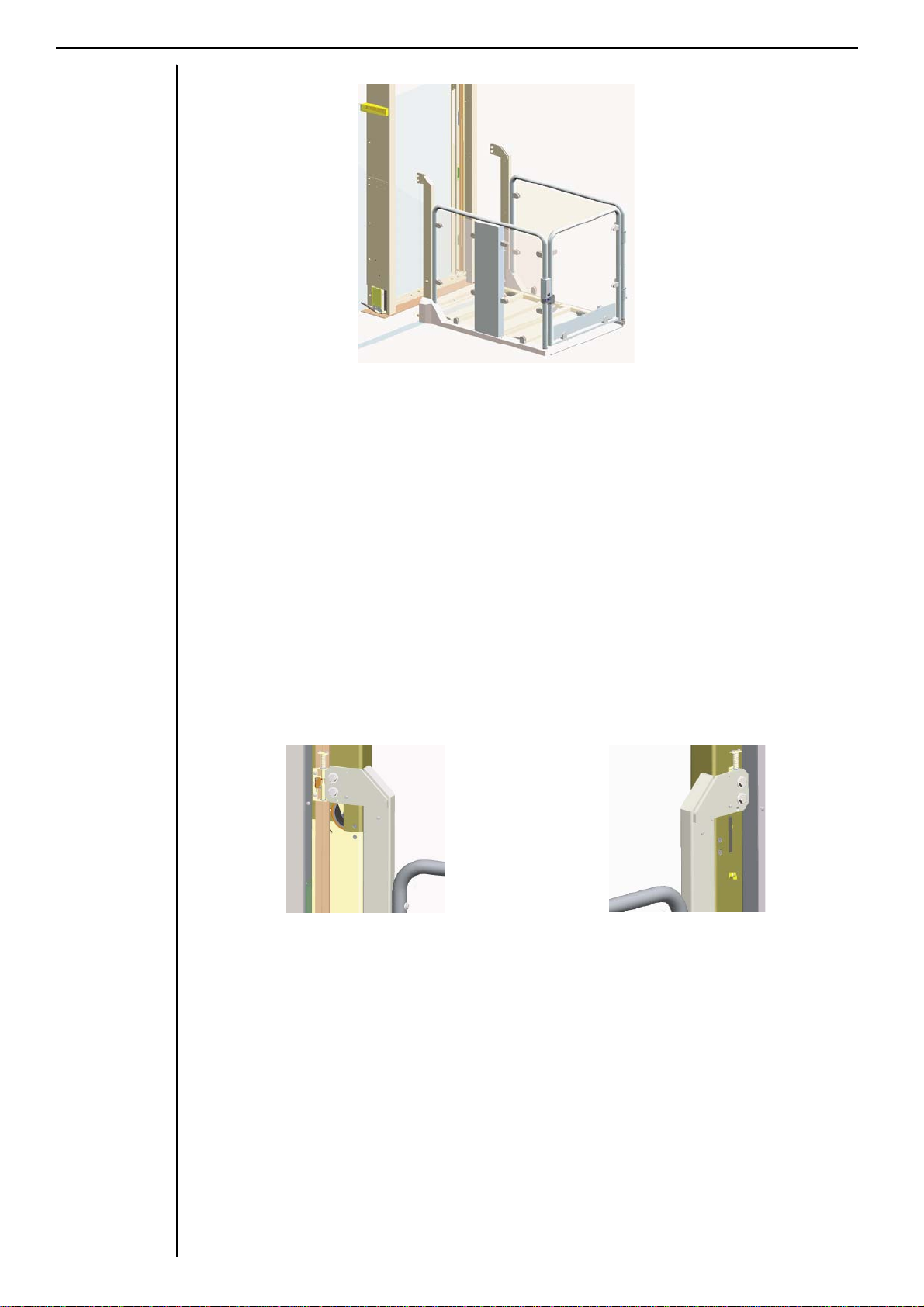

16. Carriage Assembly

The following diagrams and notes describe in detail assembly of the flat-packed carriage.

Follow them carefully and ensure all bolts and screws are correctly tightened.

Fit the side trim covers with glass clamps pre-attached.

Remove the bottom glass clamp on the gate hinge side handrail and slide handrail

through gate hinge tubes. Replace glass clamp afterwards. Then fix whole assembly to

carriage.

Fit the handrail assemblies using the fixings provided.

Once the Platform is attached to the chain

drive assembly, pull each chain through the

appropriate chain equaliser attachment

block (top right hand guide) to establish

where each chain needs to be cut (see B).

Cut the chains and re-attach to the swivelling

blocks.

Adjust the top bolt to level the platform as normal

MAX 64mm

B

A

Melody 2 Hydraulic MK2 Installation Manual - Issue f

1

clowns feet

Fix the backpillar and roller

Orientation of the roller

(thick side of hub faces

outwards)

Top plate of

backpillar on

inside of carriage

17

NOTES

2 x CB303

2 x CZ107 Each side

}

2 x CB243

Ensure very

tight!

NOTE: Box spanner

supplied in fixing kit

The beak bracket on the carriage is now a floating beak

There is no need to adjust the lock beak when the gate is fitted.

Attach the handrails and gate as standard and the self adjusting

beak will slide to the correct position when closing the gate.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

18

17. Attaching the Carriage to the Chain Drive Assembly

Remove the 3 x M12 bolts from the front of the chain assembly and keep

safe.

Position the carriage so its base butts up to the bottom of the chain drive

assembly. Loosely fit the 3 x M12 bolts with washers through the car into

the chain drive assembly.

Fit 2 x M12 bolts through the right hand carriage backpillar into the roller

assembly in the right hand guide.

Fit the 2 x M12 bolts through the left hand carriage backpillar into the ram

head assembly.

Tighten all 7 M12 bolts fully now.

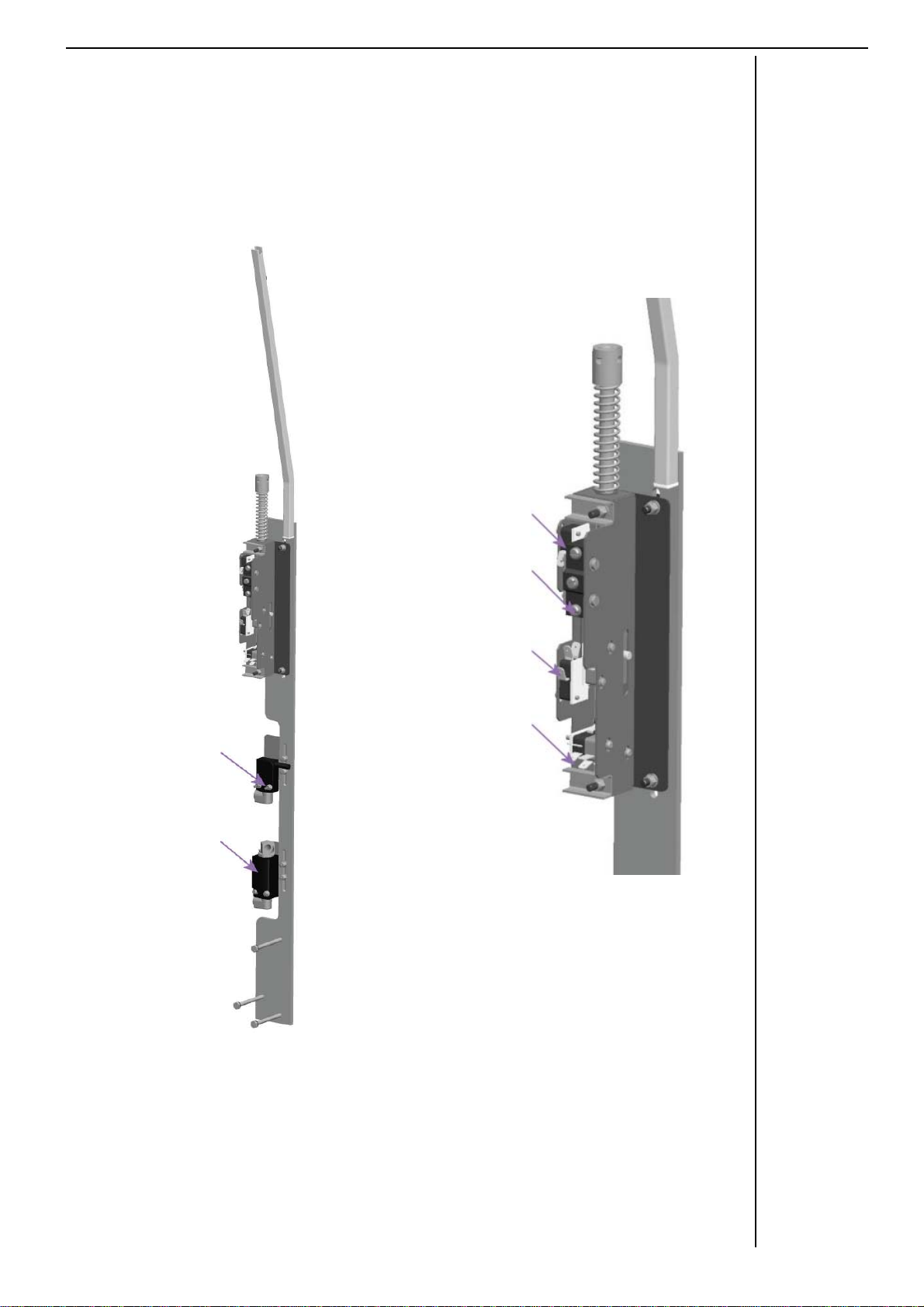

18. Limit Switch Control Mechanism Assembly and Strengthening Brace

The Control Mechanism consists of a number of switches that are individually

adjustable to ensure that the lifts stops at the correct level, the gates only open

when the lift arrives at the associated level, and that the lift will re-level at the

upper level if the hydraulic fluid in the ram were to expand or contract.

Melody 2 Hydraulic MK2 Installation Manual - Issue f

19

NOTES

Complete Control

Mechanism

Assembly

7) Lower Door

Enable and

Underpan Safe

Edge Override

Switch

6) Zone and

Upper Gate

Enable Switch

Control

Mechanism

Switch

Assembly

Control

Mechanism

Switch Assembly

Plunger

1) Creep Switch

2) Latch Switch

3) Top Limit

Switch

4) Dump Switch

5) Final

Limit

Switches

Switch Functions

1 Re-levels in the UP direction

2 Cancels the Creep/Dump Signals

3 Stop Lift if Creep System Disabled

4 Re-levels in the Down direction

5 Blows the Main 5A Fuse to stop lift travel

6 Enables the Levelling system and Upper

Level Gate

7 Enables Lower Level Gate and ram

resynchronisation timer.

The below diagrams show the location of each switch within the control

mechanism

Melody 2 Hydraulic MK2 Installation Manual - Issue f

In accordance with step 26. “Completion

Tasks” of the installation manual, adjust

the Anti Creep unit and the Gate

Activation Switches into their optimal

position using locators on the left hand

gate post.

The Anti Creep unit is pre set; adjust its

position so that the plunger just makes

contact with the anti creep lug on the left

hand gate post when the lift carriage is in

the upper level position and the platform is

flush with the upper landing.

Adjust the Gate Activation Switches

to achieve full engagement at the upper

and lower levels. The Lower switch will

drop off the end of the gate post (as

modified on site) to activate. The upper

will activate in the slot provided

Secure the anti-creep support bracket in place using the M6 x 30 CSK Screw

(CB066) + M6 Washer (CW005) & M6 Nyloc (CN002)

20

NOTES

Secure top of

brace with single

countersunk

M6 screw and

combie nut

Table of contents

Other TERRY Lifting System manuals

Popular Lifting System manuals by other brands

SAMES KREMLIN

SAMES KREMLIN 102 415 0001 manual

PFlow Industries

PFlow Industries Cartveyor CV Series owner's manual

morse

morse 400AM-60 Operator's manual

EAE

EAE EE-6214EKZ Installation, operation, and parts manual

Basta Boatlifts

Basta Boatlifts Over-Center 2k40 manual

ABS

ABS Sanimat 1501S Installation and operating instructions