DEALER INFORMATION

Name:

Contact:

Telephone:

2.3 MANUFACTURER’S NOTE

The dock equipment has been carefully inspected and tested at

the manufacturer’s plant prior to shipment, but should be checked

upon receipt for transport damage. Any observed transport

damage is to be listed on the signed copy of the freight document.

Notify the freight forwarder of any damage WITHIN 48 HOURS.

2.2 EXCLUSION OF LIABILITY

The manufacturer assumes no liability for damage or injury to

persons or property which occur as a result of defects or faults in

or incorrect use of the Loading Dock Equipment. The manufacturer

also assumes no liability for lost profits, operating downtimes, or

similar indirect losses incurred by the purchaser. Injury to third

parties, irrespective of its nature, is not subject to compensation.

The manufacturer reserves the right to make changes at any time

to the modules, components, and accessories, concurrent with

its continuing product improvements and development program.

Specifications, operating instructions, and illustrations included in

this manual are subject to change without notice. Please contact

manufacturer for the latest information.

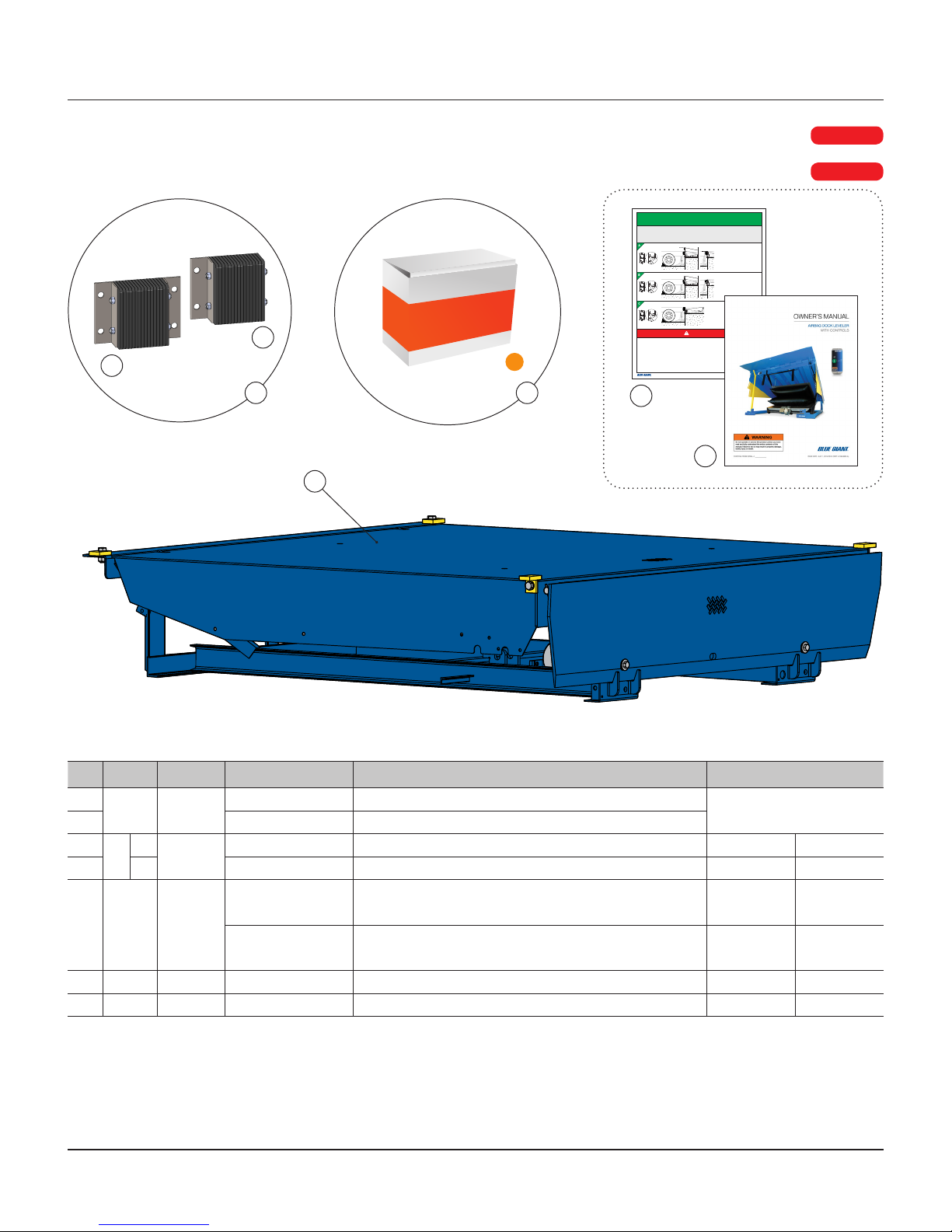

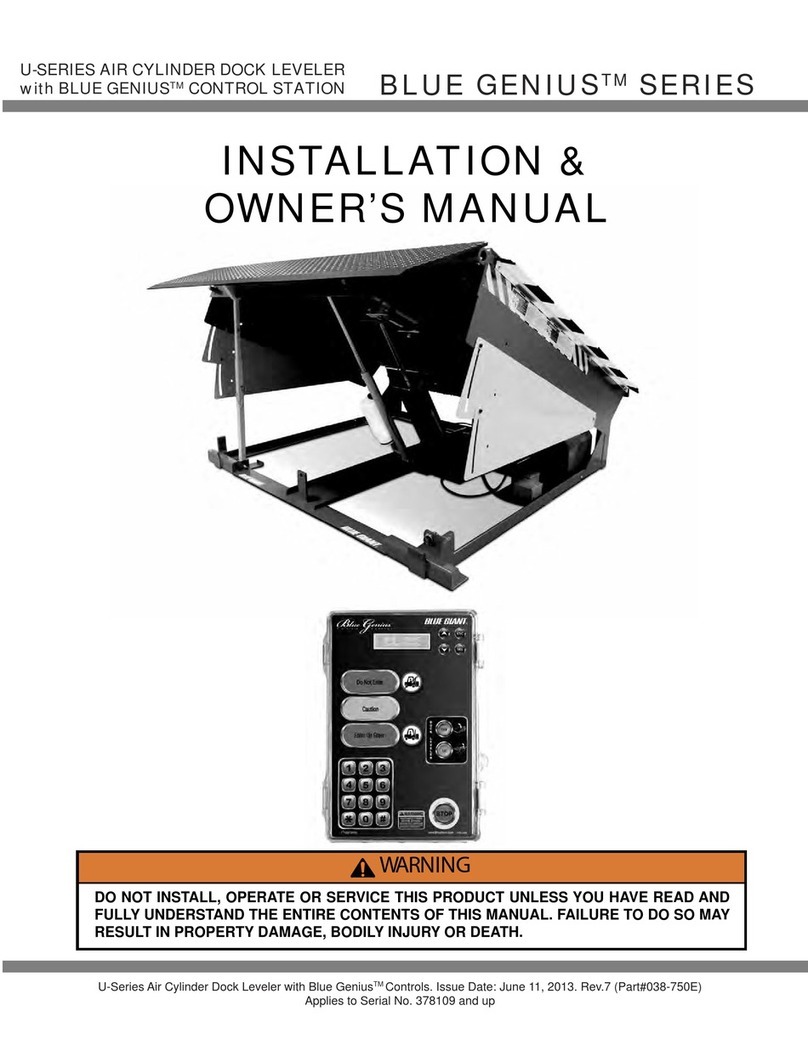

BLUE GIANT SERIES DOCK LEVELER—INSTALLATION & TECHNICAL MANUAL

5AUGUST 31, 2018 REV.1 (PART # 038-1073EI)

2.0 INTRODUCTION

The following is a quick reference to important procedures that

must be followed while installing the Loading Dock Equipment. It is

not intended to cover, or suggest that it does cover, all procedures

necessary to ensure safe installation and operation. All person-

nel who install and / or use this dock equipment should be aware

of and abide by all workplace safety regulations applicable to the

installation and operation of the Loading Dock. These laws and

regulations include but are not limited to:

• The Occupational Safety and Health Act

• Canada Occupational Health and Safety Regulations

• Occupational Safety and Health Acts for Individual States

(USA)

For additional information on these regulations as well as industry

standards that may apply to this product, please contact:

American National Standards Institute (ANSI)

1899 L Street, Washington, DC 20036

Telephone: 1.202.293.8020

www.ansi.org

Also a member of:

Loading Dock Equipment Manufacturers

A Division of Material Handling Industry

8720 Red Oak Blvd, Suite 201, Charlotte, NC, 28217-3992

Telephone: 704.676.1190

www.mhi.org/lodem

2.1 WARRANTY INFORMATION

Thank you for purchasing Blue Giant products. We appreciate

your business, and are confident that our product will serve

you for many years to come. In the event that you experience a

problem with our product, our Warranty Center is here to support

the Blue Giant Product(s) that you have purchased.

To validate warranty on recently purchased equipment,

please complete and submit your information with our

online Warranty Registration at www.bluegiant.com.

For more information about Blue Giant Warranty Support, please

contact your local Blue Giant Equipment dealer, representative or

authorized partner near you. You may also visit www.bluegiant.com

or phone 1.905.457.3900.

NOTE: Failure to validate warranty at the time of receipt can

seriously affect the outcome of any claim.

NOTE: Improper installation of equipment may void any

applicable warranties.

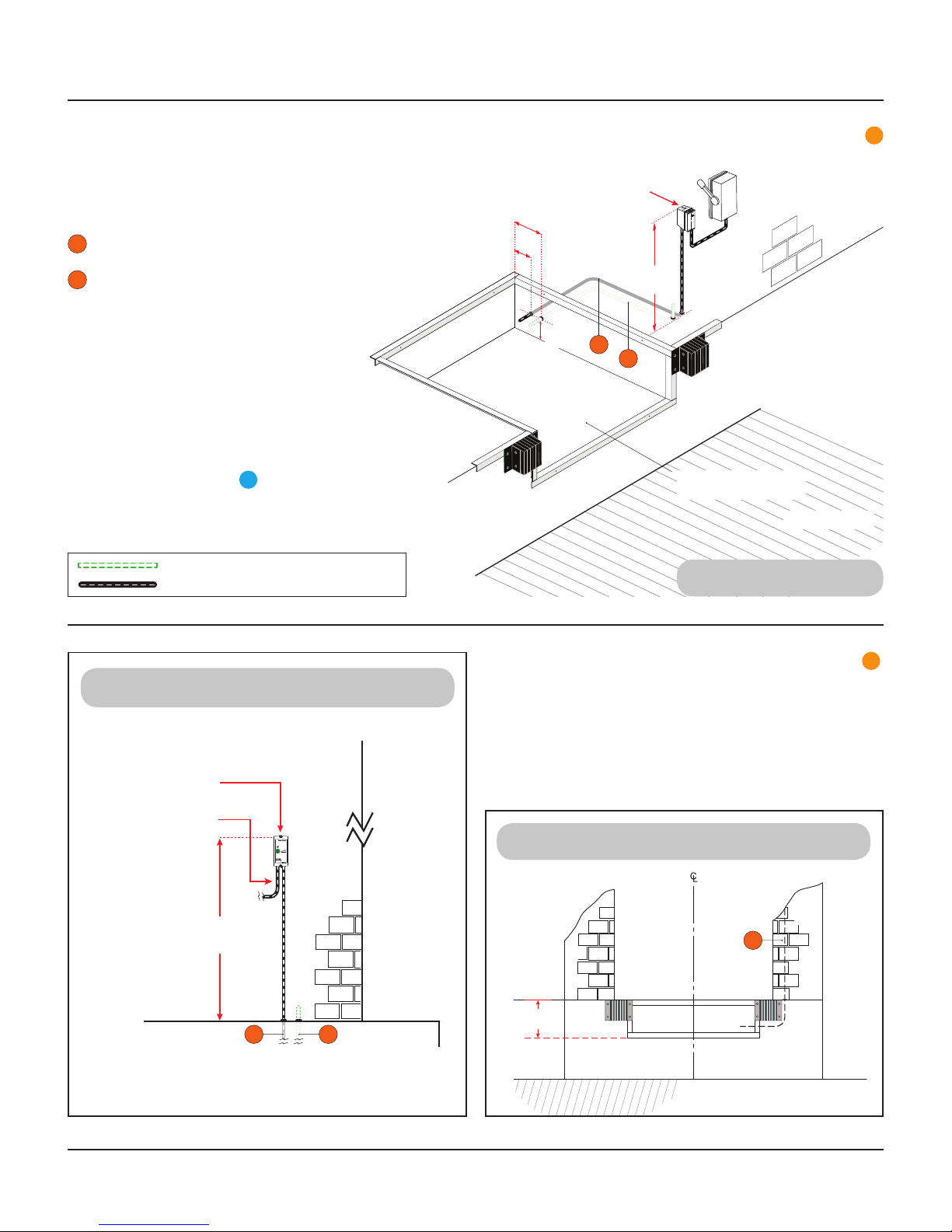

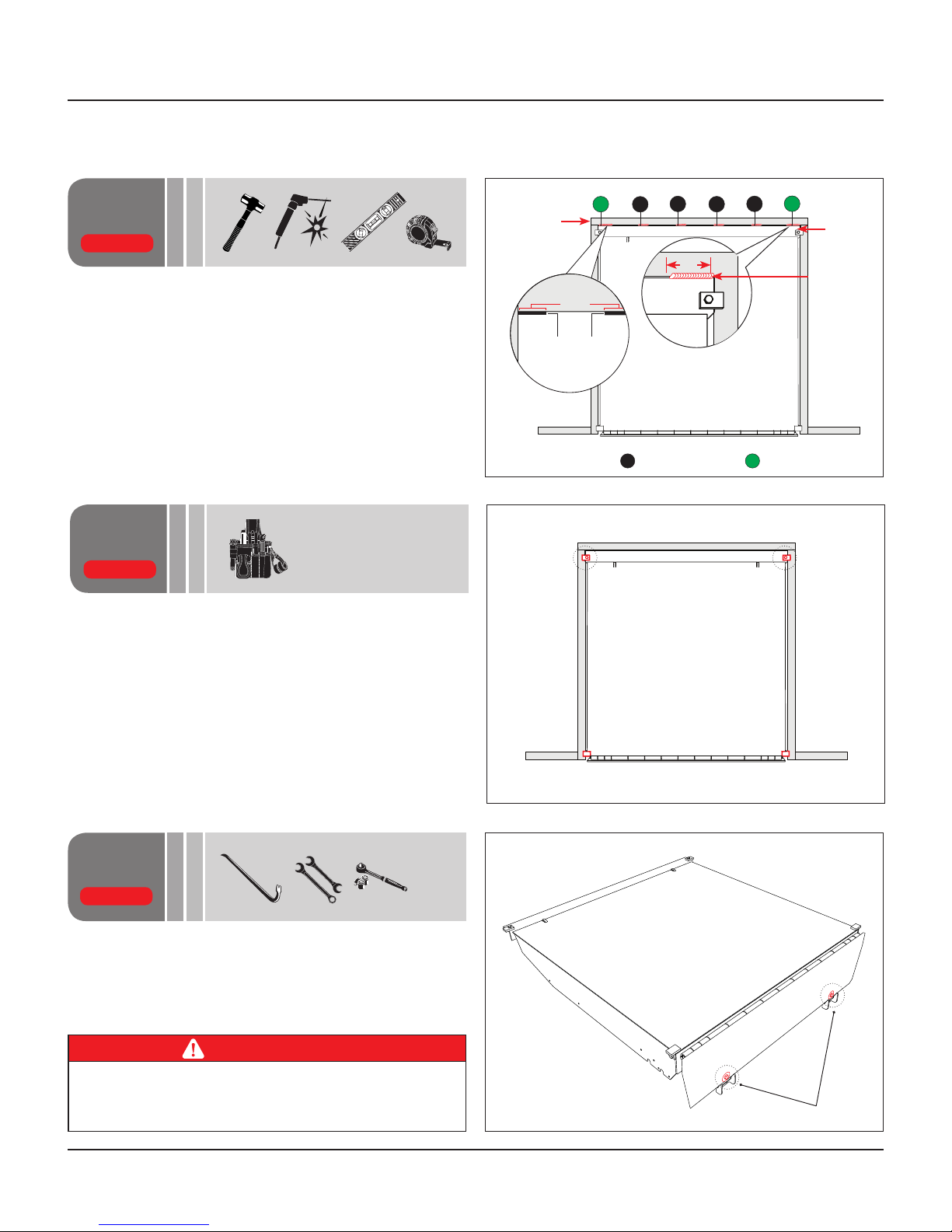

2.4 INSTALLER’S GUIDELINES

Please read all instructions carefully before installing this

Blue Giant dock product. It is the installer’s responsibility to

comply with the following:

• The installation of Blue Giant dock products should comply with

all applicable local or national building codes and regulations,

including any that may supersede this manual.

• Site surveys and other applicable install-related documentation

must be properly and accurately completed prior to installation.

Failure to comply with this requirement may result in an

improper install and possible voiding of the warranty.

• Only Blue Giant-supplied or approved parts must be used. Any

unauthorized parts substitution may void the warranty.

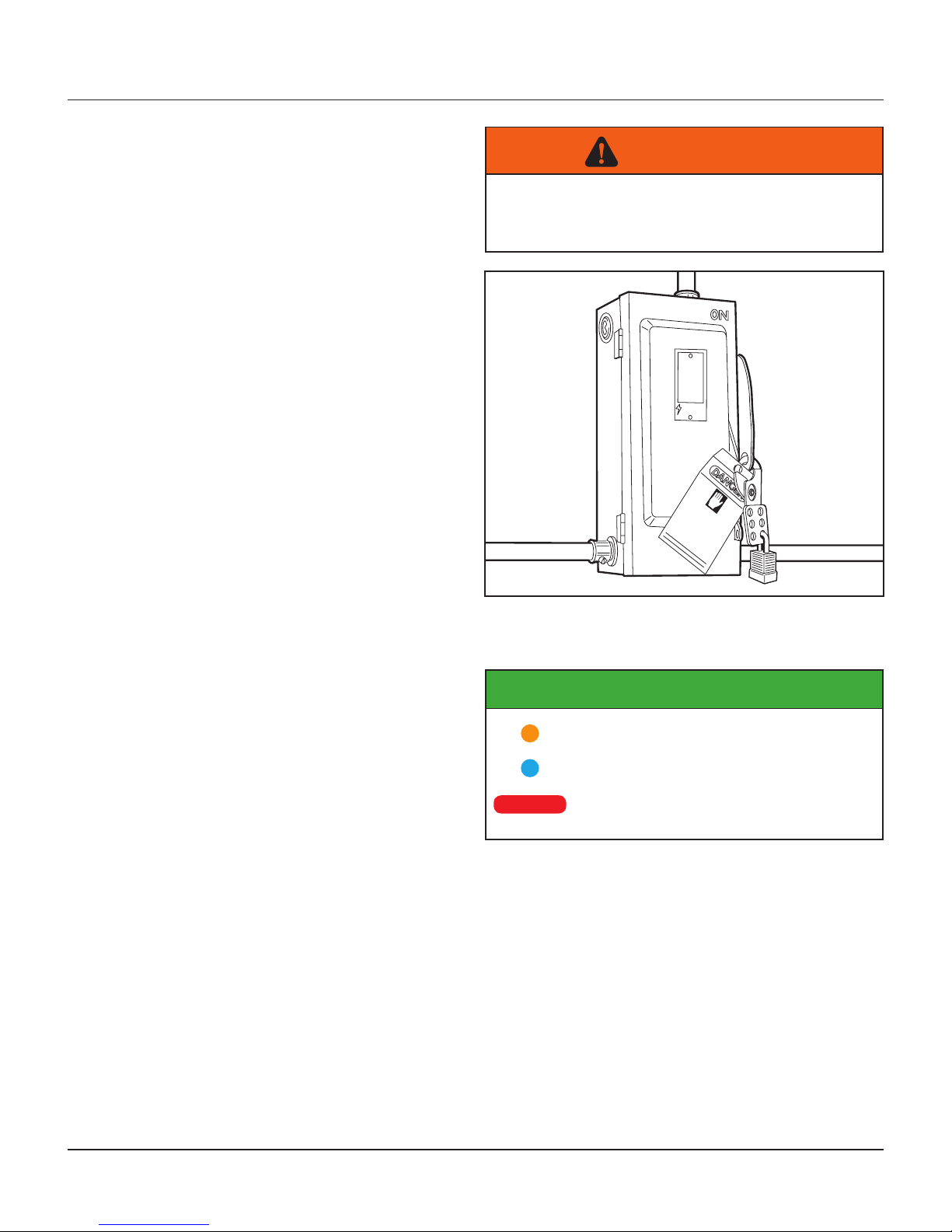

Always lockout and tagout any power source before performing

any electrical work, in accordance with OSHA regulations and

approved electrical codes. The installer is responsible for reading,

understanding, and complying with all personal protective

equipment (PPE) policies in effect.