SICO 3 Series User manual

SERIES 3RAMP

OWNER’S MANUAL

® SICO is a registered trademark of SICO Incorporated Part No. 117675 Rev. E

BEFORE YOU BEGIN . . .

Read and understand these instructions before

beginning a ramp setup.

Use caution and care for your back when lifting,

pushing, pulling, folding or unfolding your SICO®

ramp system. Never lift more than you are able to

safely handle.

SICO’s®ramp system is designed to comply with

ADA requirements, including a maximum slope

not exceeding 1” [25 mm] of elevation change

per foot [30.5 cm] of horizontal distance traveled.

The ramp system can be connected to any SICO®

portable stage.

TOOLS REQUIRED:

• T-Handle 8 mm [5/16”] hex wrench – provided.

• 8 mm or 5/16” socket or box end or open end

wrench.

• 17 mm socket or box end or open end wrench.

• 5 mm hex driver.

• Optional: Drill with 8 mm (5/16”) socket and hex

driver.

• T-Handle: 3 mm provided with turnaround kit.

If you have any problems or questions during setup,

contact SICO® Customer Care at 1-800-424-0796.

PAGE 2

INTRODUCTION

WEDGE SECTION

BRIDGE SECTION

FOLDING LEG SECTION

UPPER CLAMP

ASSEMBLY

RAMP CADDY

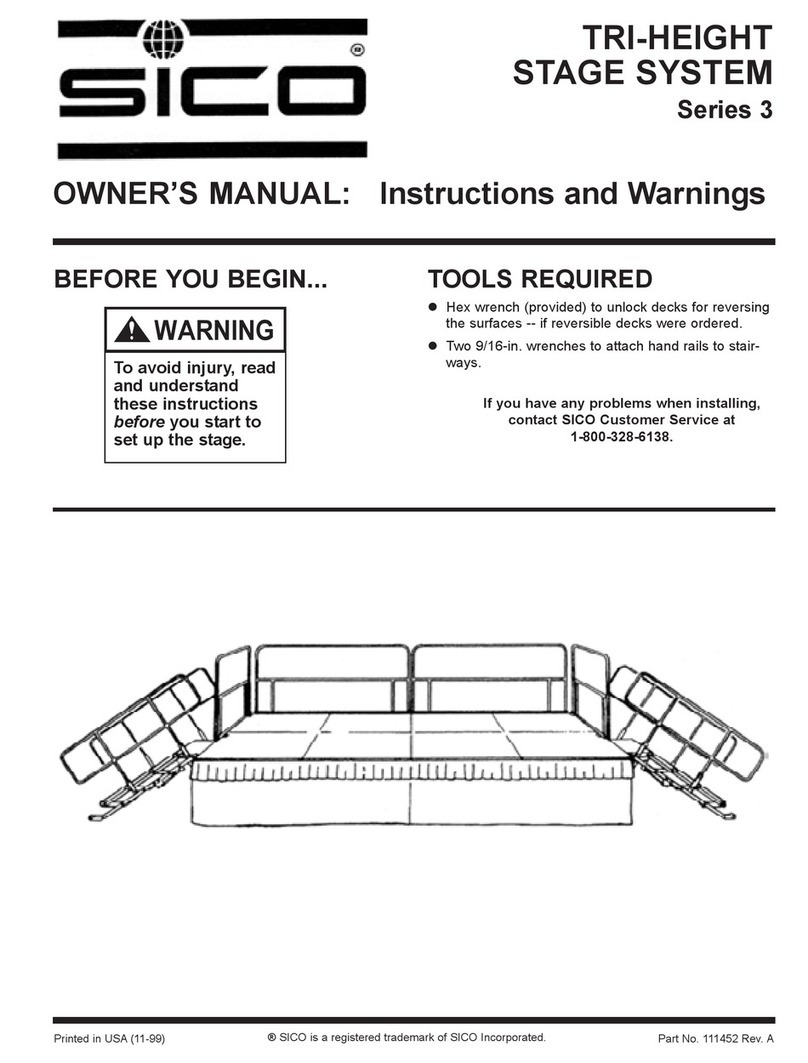

INTRODUCTION:

SICO’s®ramp system is a modular system that is

designed to connect to any SICO®portable stage.

Modules are available with either 6” [15.2 cm] or 8”

[20.3 cm] height increments up to 72” [183 cm] high

to match the height or the range of heights of your

SICO®portable stage. The ramp system includes

the ramp surface, handrails and all hardware that is

required.

A typical ramp system consists of:

• A 0”-6” [0-15.2 cm] or a 0”-8” [0-20.3 cm] wedge

section;

• A 72-3/8” [184cm] or 96-3/8” [245 cm] bridge

section;

• One or more 72-3/8” [184 cm] or 96-3/8” [245 cm]

folding leg sections;

• Right hand and left hand handrails for each ramp

section;

• An upper clamp for connecting the top ramp

section to the stage or ramp landing;

• Optional caddy for storing the ramp system and

for transporting the ramp system between the

storage location and the stage location.

ADA requires that ramp runs be no more than 30 feet

[9.14m] long, so ramps higher than 30” [76cm] will

require one or more ramp landings or turnarounds.

Space considerations may require turnarounds on

lower ramp systems. Each landing or turnaround

requires additional guardrails, an upper and a lower

clamp assembly and may require enter and exit

handles, and a handrail U-turn.

A typical ramp turnaround, where direction of travel

changes by 180 degrees, consists of two 3’x8’ [0.9m

x 2.4m] folding leg platforms, but could be a single

6’x8’ [1.8m x 2.4m] SICO® 1800 Series or Tri-Height

portable stage. A typical ramp landing, where direc-

tion of travel does not change, could consist of any

4’x8’ [1.2m x 2.4m] SICO®portable stage. If a ramp

landing is at the same height as the main stage and

is different from the main stage, a landing to stage

connector will be required. Note that a 60” [152 cm]

turning circle is required when there is a change in

the direction of travel.

PAGE 3

HANDLING YOUR SICO®RAMP

WHEN HANDLING YOUR RAMP, REMEMBER

TO:

1. Use two people to safely move and handle the ramp

sections.

2. To prevent injury, be careful to not drop ramp

sections. Damage to the ramp may also occur.

3. When setting up a ramp systems, always start at

the top end and work section by section toward the

bottom wedge section.

4. When taking a ramp system down, start at the

bottom (i.e., wedge) section.

5. Do not attempt to move ramp sections after they

are connected to the stage or other ramp sections.

PAGE 4

INSTALLATION OVERVIEW

Detailed instructions begin on the next page.

1. Plan the layout of the portable stages and the ramp

system.

2. Set up the stage system. See the instructions

supplied with the stage.

3. If there is a top landing, set up the top landing and

install the landing to stage connector, if required.

4. Attach the upper clamp assembly to the landing or

stage.

5. Connect the tallest ramp section to the upper clamp

assembly. Note the legs of the folding leg ramp

sections are toward the bottom of the ramp section.

Connect additional ramp sections as required by the

ramp layout.

6. If a ramp landing or turnaround is included in the

layout, set up the landing or turnaround, attach a

lower clamp assembly to the landing or turnaround

and connect the landing or platform to the bottom

end of the ramp section.

7. Repeat steps 4 through 6 as required for the ramp

layout.

8. When only the bridge section and wedge section

are left to install, position the wedge section and

then connect the bridge section between the wedge

section and the lowest folding leg section.

9. Install handrails and guardrails.

PAGE 5

PLAN THE RAMP LAYOUT

3. Ramp with Two Turnarounds

2. Ramp with Turnarounds

Guardrail or Stage to stage connector, if required

Guardrail or Stage to stage connector, if required

Guardrail

Guardrail

Folding Leg

Section

Folding Leg

Section

Folding Leg

Section Folding Leg

Section Folding Leg

Section

Folding Leg

Section

Folding Leg

Section

Folding Leg

Section

Folding Leg

Section

Folding Leg

Section

Bridge

Section

Bridge

Section

Turnaround

Section

Turnaround

Section

Turnaround

Section

Turnaround

Section

Turnaround

Section

Turnaround

Section

Wedge

Section

Wedge

Section

Handrail or

Guardrail

Handrail or

Guardrail

Handrail

Handrail

1. Straight Ramp System

Guardrail or Stage to stage connector, if required

Guardrail

Exit handle

Landing

or

Stage

Folding Leg

Section Bridge

Section Wedge

Section

Enter Handle

Handrail or

Guardrail HandrailUpper clamp assembly

Landing

or

Stage

Landing

or

Stage

Handrail or

Guardrail

Upper clamp

assembly

Upper clamp

assembly

Lower clamp

assembly

Guardrail

Guardrail

Enter Handle Upper clamp assembly

Upper clamp assembly

Lower clamp

assembly

Handrail or

Guardrail

Enter Handle

The exibility designed

into your SICO®ramp

system makes it possible

to set the ramp system

up in many different con-

gurations, particularly

the longer ramp systems.

If you need assistance

with designing a ramp

conguration for your site,

please contact your SICO®

sales representative or

SICO’s®Customer Care

Department (see contact

information on last page).

A few examples are

illustrated here.

1. Straight ramp system

that connects to a ramp

landing or directly to a

stage section without any

changes in the direction

of travel. This option is

limited to a maximum

ramp height of 30" [76 cm]

per ADA requirements.

(See layout 1)

2. A ramp with a turn-

around. The upper end

of the uppermost ran run

may connect to a SICO®

ramp landing or a SICO®

portable stage unit. (See

layout 2)

3. Ramp systems

more than 60" [152cm]

high must have at least

two landings or turn-

arounds. (See layout 3)

Note that turns in the

opposite direction to what

is shown can be set up

with the same equipment.

PAGE 6

TOP LANDING INSTRUCTIONS

1. If the ramp will connect directly to the

stage without a separate landing, skip

this section and proceed to attaching the

upper clamp assembly.

2. If the top landing is the same type of

stage as the main stage units, set up the

landing unit and connect it to the main

stage units with the stage unit to unit

connectors; skip the rest of this section

and proceed to attaching the upper

clamp assembly.

3. If the top landing is a different type of

stage than the main stage units, a

landing to stage connector is required.

The width of this connector must match

the width of the landing edge that

connects to the main stage units.

4. Place the connector rmly against the

stage edge at the desired location.

Using the provided T-handle hex

wrench, tighten the socket head cap

screws for the two clamps directed

toward the main stage unit. Firm

pressure is needed to ensure the

connector is solidly attached to the

stage. Do not over tighten to prevent

damage to the stage.

5. Position the landing rmly against the

connector and tighten the screws for the

two clamps directed toward the landing.

LANDING TO STAGE CONNECTOR

LANDING & STAGE CONNECTED

LANDING TO STAGE CONNECTOR

ATTACHED TO STAGE

PAGE 7

UPPER CLAMP ASSEMBLY INSTRUCTIONS

INSTALLED UPPER CLAMP ASSEMBLY

INSTALLED UPPER CLAMP ASSEMBLY

The upper clamp assembly provides a

secure attachment of the upper end of the

highest ramp section.

To attach the upper clamp assembly:

1. Place the upper clamp assembly

against the edge of the stage or ramp

landing with the top tubular member

rmly against the stage or landing.

2. Using the provided T-handle hex

wrench, tighten the two socket head

cap screws on the top of the clamp

assembly. Firm pressure is needed to

ensure the clamp is solidly attached.

Do not over tighten to prevent damage

to the stage or landing.

3. Disengage the two hitch pins from the

holes in the clamp assembly.

PAGE 8

ATTACH THE FIRST RAMP SECTION

Note: Use the optional SICO®caddies to

save time and effort.

1. Move the loaded ramp caddy to near

where the ramp section will be set up.

Lock the caddy casters to keep the

caddy from moving while unloading the

ramp sections.

2. Ramps with three or more sections will

have at least one section with folding

legs. The ramp section with the

longest legs is the rst section to install.

3. With the ramp section on the caddy,

release the leg brace locking pins by

rotating the two yellow handles until the

handles are perpendicular to the legs.

See Figure 1.

4. Partially extend the legs as shown in

Figure 2.

5. Rotate the yellow handles to their

original position.

6. Swing the legs fully out until both

locking pins engage in the leg braces.

7. While holding the ramp section in

place, lift the lock on the caddy to

release the deck.

See Figure 3.

8. Rotate the deck until one of the legs

contacts the oor.

9. With one person at each end of the

ramp section, pivot the ramp off the

caddy so that is rests on its legs and

the upper attachment brackets.

See Figure 4.

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

PAGE 9

ATTACH THE FIRST RAMP SECTION (CONTINUED)

10. With a person on each side of the ramp, lift the

upper end of the ramp (i.e., the end without the

legs) so that it is slightly higher than the stage

or landing to which it will connect.

11. Pull the ramp section toward the upper clamp

until the ramp section brackets are against the

at plates of the upper clamp assembly.

12. Lower the ramp onto the support plate.

13. Secure the ramp in place using the hitch pins

that are part of the upper clamp assembly.

14. If the ramp is on an uneven oor, adjust the

glides to level the ramp as needed.

ATTACHING THE NEXT RAMP SECTION

1. If the next section is a ramp section with folding

legs (i.e., not a landing or turnaround or the bridge

ramp section or wedge ramp section), connect

the second ramp section to the bottom end of the

rst ramp section the same way the rst ramp

section was attached to the upper clamp.

2. Repeat this process until the next piece of the

ramp system is either the bridge section or a

landing or a turnaround.

3. If the next section of the ramp system is the bridge

section, skip the next section on turnarounds and

landings.

RAMP CONNECTED TO UPPER CLAMP ASSEMBLY

SECURE RAMP IN PLACE USING HITCH PINS

PAGE 10

TURNAROUNDS AND LANDINGS

Landings and turnarounds are ADA requirements

for longer ramps systems. They are also used to

change the direction of travel as required to t

within the building’s dimensions; see the section

on planning the ramp layout.

1. Set up the stage unit(s) that will function as

the landing or turnaround at the desired

height. Refer to the operating manual

provided with that product for additional

information regarding that product. If two 3'

x 8' [0.91 x 2.44m] folding leg units serve as

the turnaround, connect them to each other

with the rotolocks.

2. Attach the lower clamp assembly to the edge

of the landing or turnaround where the upper

ramps sections will connect; the clamp

attaches the same way the upper clamp was

installed.

3. Attach an upper clamp assembly to the

edge of the landing or turnaround in the

location where the lower ramp sections will

connect to the landing or turnaround.

4. Move the landing or turnaround so the lower

clamp assembly is adjacent to the bottom

edge of the ramp section that has already

been set up.

5. If necessary, adjust the glides in the landing

or turnaround and the ramp section until the

heights match.

LOWER CLAMP ASSEMBLY ATTACHED TO RAMP

LANDING

RAMP LANDING CONNECTED TO RAMP WITH

LOWER CLAMP ASSEMBLY

RAMP LANDING

PAGE 11

TURNAROUNDS AND LANDINGS - continued

UPPER CLAMP ASSEMBLY INSTALLED ON RAMP

LANDING 6. Lift the landing or turnaround slightly as you slide

it toward the bottom edge of the ramp section

and engage the lower clamp assembly onto the

bottom end of the ramp section.

7. Attach the next ramp section to the landing or

turnaround in the same manner as the earlier

ramp sections were installed.

8. Install additional ramp sections as required until

another landing or turnaround is reached or until

the next section is the bridge section. If the next

part of the ramp system is a landing or turn

around, repeat the steps in this section. If the

next section is the bridge section, proceed to the

next section.

PAGE 12

BRIDGE & WEDGE SECTION INSTALLATION

The bottom two sections of the ramp are the

bridge section and the wedge section.

1. Tilt the bridge section off the ramp caddy so

the bridge section is resting on all four

connector brackets that are mounted near

the four corners. See Figure 1.

2. Lift one edge of the bridge section and insert

the two brackets into the brackets on the

bottom edge of the lowest folding leg ramp

section or the upper clamp of a landing or

turnaround. See Figure 2.

3. Place the wedge ramp section adjacent to the

bottom edge of the bridge ramp section.

Remove the hitch pins from the holes in the

wedge section connector brackets.

See Figure 3.

4. With one person on each side, lift the low

end of the bridge section while pulling the

wedge section toward the bridge section until

the bridge section brackets contact the

vertical plates of the wedge section and the

lower the bridge section brackets into the

wedge section brackets. See Figure 4.

5. Secure all four corners of the bridge section

by installing the hitch pins. See Figure 5.

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

PAGE 13

The connector at the upper end of the wedge ramp

section is designed to connect to the lower end of

the bridge ramp section. When the wedge ramp

section connects to a stage or landing or turnaround,

two special connectors (part number 118309B) are

required to connect the wedge ramp section to an

upper clamp assembly.

1. Pin the square tube end of both of the special

connectors to the wedge ramp section assembly

using the hitch pins.

2. Push the wedge ramp section with the special

connectors attached against the upper clamp

assembly.

3. Secure the special connectors now attached

to the wedge ramp section to the upper clamp

assembly with the hitch pins.

SPECIAL CONNECTORS

SPECIAL CONNECTOR ATTACHED TO WEDGE

RAMP SECTION

WHEN THE WEDGE RAMP SECTION CONNECTS TO A

LANDING OR TURNAROUND OR STAGE

PAGE 14

ATTACHING GUARDRAILS

ALWAYS install guardrails and connect

handrails of adjacent guardrails to provide

a continuous handrail and to prevent ramp

sections from separating from each other.

Failure to do so may result in serious injury

or death.

WARNING

IMPORTANT: Guardrails and handrails are

critical safety features of any ramp and

stage. Handrails on the SICO Series 2

ramps also serve to lock the ramp sections

together, essentially created one integral

ramp system.

Ramp handrails/guardrails come in right

hand and left hand versions. When installed

correctly on the ramp, the posts will be

vertical.

1. Lay out the handrails and guardrails

next to where they will be installed.

2. It is typically easiest to start from the top

of the ramp and work your way down,

usually with the Inside rails rst.

WARNING

Use only metric 10mm bolts to connect the

guardrails to the decks. 3/8”-16 bolts will

engage the threads of the metric nut but

may strip out under load resulting in injury

or death.

Contact SICO®Customer Care for

replacement parts if the provided bolts

are lost or damaged.

PAGE 15

ATTACHING GUARDRAILS

3. Place the rst handrail on the ramp surface

with the handrail toward the center of the

ramp section. Note that the posts should be

vertical; if they are not, use that guardrail on

the opposite side of the ramp.

4. Align the holes in the guardrail mounting

plates with the holes in the top of the ramp.

5. Attach the guardrail to the ramp using two

at washers and two M10-1.5 x 110mm

[4.33”] socket head screws; there are M10-1.5

nuts on the underside of the ramp deck.

6. Using the 8mm [5/16”] T-handle hex wrench

provided, tighten the two screws enough to

keep the handrail standing vertically. It will

be easier to connect other handrails and/or

guardrails if the screws are not tight. They

will be tightened later.

7. If there is another ramp section before

coming to a landing or the wedge section,

install a 5” [13cm] long straight locating sleeve

in the bottom end of the handrail tube. Insert

half of the locating sleeve into the handrail

tube, and install a self-tapping screw to

secure the sleeve to the handrail. A drill with

an 8 mm (5/16") hex driver recommended.

The locating sleeve normally does not need to

be disassembled when the ramp is taken

down.

8. Place the handrail for the next section of ramp

on the ramp surface. Align the upper end of

the handrail with the locating sleeve and push

the handrail so the handrail engages the

locating sleeve. Then, align the holes in

the guardrail mounting plates with the holes in

the deck, install two at washers and two

M10-2x110mm screws and tighten just

enough so the guardrail stands reasonably

straight.

HANDRAIL WITH LOCATING SLEEVE INSTALLED

PAGE 16

ATTACHING GUARDRAILS - continued

9. Repeat steps 7 & 8 until you get either to a landing

or the wedge section.

10. Repeat steps 3 through 9 for the opposite side

of the ramp and for the other runs of ramp until

you get to the wedge (bottom) ramp section.

11. If the wedge ramp section is not connected to

the bridge section, skip this step. Otherwise,

install locating sleeves into the bottom end left

hand and right hand handrails that are mounted

on the bridge section as directed in step 7 above.

12. Position one of the bottom ramp guardrails on

the ramp and engage the upper end of its handrail

with the locating sleeve.

13. Attach the upper end of the guardrail to the

ramp wedge section with a at washer and an

M10-1.5x60mm [2.36”] socket head screw.

14. Insert a 10mm carriage bolt (see picture) into the

slot at the bottom edge of the ramp with the

thread end facing up. Set the guardrail mounting

plate hole over the carriage bolt and install a at

washer and 10mm nut. It may be necessary to

lift up slightly on the guardrail for the slot at the

bottom edge of the wedge ramp section to

capture the square neck of the carriage bolt

during the initial tightening.

15. Repeat steps 12 through 14 for the other bottom

guardrail.

16. If the ramp system has a turnaround with a 180

degree direction change, install a handrail U-turn

piece between the two adjacent handrails.

Attached an angled sleeve to the bottom end of

the handrail with a self-drilling screw, making

certain that the end of the angled sleeve is

horizontal. Attach an angled sleeve to the upper

handrail, again making certain that the end of the

angled sleeve is horizontal. Install the ends of the

U-turn over the two angled sleeve. Secure by

tightening the two setscrews using the 3 mm

T-handle hex wrench.

INSTALLED WEDGE RAMP SECTION GUARDRAIL

PAGE 17

ATTACHING GUARDRAILS - continued

17. If the ramp system has landings or turnarounds with

guardrails with integral handrails, insert an angled

locating sleeve into the end of the handrail of the

ramp guardrail, and attach it with a self-drilling

screw. Engage the handrail of the landing guard

rail with the angled locating sleeve. Attach the land

ing guardrail to the landing with two at washers

and two M10-1.5x60mm [2.36”] screws and tighten

just enough so the guardrail stands reasonably

straight.

18. Repeat step 17 for the other landing and turnaround

guardrails with integral handrails.

19. Tighten all of the guardrail mounting screws. All

of the guardrails with integral handrails should now

be securely fastened.

20. Install the other landing guardrails per the

instructions included with them. All edges of the

ramp and the landings should now have guardrails

installed and securely fastened.

21. Install enter handles on the two ramp guardrails

installed on the wedge (bottom) ramp section.

Enter handles have the locating sleeve angled

upwards. Insert the locating sleeve into the end of

the handrail. Secure the bottom end to the guard

rail post with an M10x1.5x60mm [2.33”] hex head

screw, leaving it a bit loose for now. Secure the top

end to the handrail with a self-drilling screw. Then

tighten the hex head screw.

22. Install another enter handle on the other bottom

guardrail.

23. If required, install enter handles on the bottom

ends of ramp guardrails that terminate at a landing

or turnaround.

24. Install exit handles at the top end of ramp guard

rails. These are similar to the enter handles except

the locating sleeve is angled down.

PAGE 18

DISSASSEMBLING THE RAMP

Disassembly of the ramp is basically the

reverse of the assembly procedure, starting

with the guardrails at the bottom end of the

ramp. Enter and exit handles do not need to

be removed. The carriage bolts at the bottom

end of the bottom guardrails just have to be

loosened and can stay with the guardrails.

The locating sleeves between guardrails do

not need to be removed. Loosen the two

setscrews on the handrail U-turn and remove

the U-turn. As each handrail and guardrail is

removed, be sure to install the attachment

hardware to the ramp or platform so that it is

available the next time the ramp is set up.

Put the handrails and guardrails on the

optional caddy.

After the guardrails are removed and stored,

start disassembly of the ramp from the bottom

wedge section. As each ramp and landing

section is disconnected from the rest of the

ramp system, install it onto the optional caddy.

PAGE 19

Notes:

PAGE 20

Notes:

Please have the serial number of the

product when contacting customer service.

To receive assistance for:

- Selecting replacement parts / decals

- Repairing the product

- Adjusting and operating the product

- Obtaining on-line assistance

TELEPHONE: 1-800-424-0796

FAX: (952) 829-5141

WEB SITE: WWW.SICOINC.COM

SICO AMERICA INC.

7525 Cahill Road

Minneapolis, MN 55439 USA

Other manuals for 3 Series

1

Table of contents

Languages:

Other SICO Lifting System manuals