Sicon EVMS Series User manual

1

Electric Vehicle Charging Station

EVMS-150

2021 V1.0

USER MANUAL

2

Content

PART 1 Safety Instruction ..................................................................................................................3

1.1 General Instruction .............................................................................................................3

PART 2 EVMS-150 Charger Installation............................................................................................5

2.1 transport .............................................................................................................................5

2.2 Charger Receiving Inspection...........................................................................................5

2.3 Charger Storage...................................................................................................................6

2.4 Installation environment.....................................................................................................6

2.5 Unboxing .............................................................................................................................7

2.6 Position................................................................................................................................8

PART 3 Introduction and installation of charge ............................................................................10

3.1 Product Overview..............................................................................................................10

3.2 Feature ..............................................................................................................................10

3.3 Outline Dimension ............................................................................................................11

3.4 Appearance .......................................................................................................................12

3.5 Charger dust screen and air inlet and outlet.....................................................................14

3.6 Charger diagram................................................................................................................17

3.7 Input Connection Terminals ..............................................................................................18

3.8 Install and remove the main power module.....................................................................19

3.9 After the initial setup boot................................................................................................20

3.10 Charging status indicator.................................................................................................20

3.11 Emergency stop button...................................................................................................20

3.12 Charger connector bin.....................................................................................................21

3.13 RFID Card reader .............................................................................................................21

3.14 Charging strategy ............................................................................................................21

3.15 Charger parameters. .......................................................................................................22

PART 4 Product Overview ..............................................................................................................23

4.1 Module Introduction .........................................................................................................23

4.2 Appearance .......................................................................................................................23

4.3 Feature ..............................................................................................................................25

4.4 Module diagram................................................................................................................25

4.5 Specification ......................................................................................................................26

PART 6 Charging Operation............................................................................................................27

6.1Charging Flow Chart...........................................................................................................27

6.2 Charging process ...............................................................................................................28

PART 7 Enter the administrator interface .....................................................................................29

7.1 How to enter the administrator interface.........................................................................29

7.2 Each unit described ...........................................................................................................30

PART 8 Troubleshooting.................................................................................................................31

3

PART 1 Safety Instruction

1.1 General Instruction

Operating at AC mains high voltage, the charger is composed of high current/voltage withstanding

components. Proper installation of the charger to be grounded to defense electric shock and

foreign objects. Installation service should be performed by qualified technician or authorized

service partner of the manufacturer.

WARNING!

Operations inside the charger should be performed by qualified

technician or authorized service partner of the manufacturer.

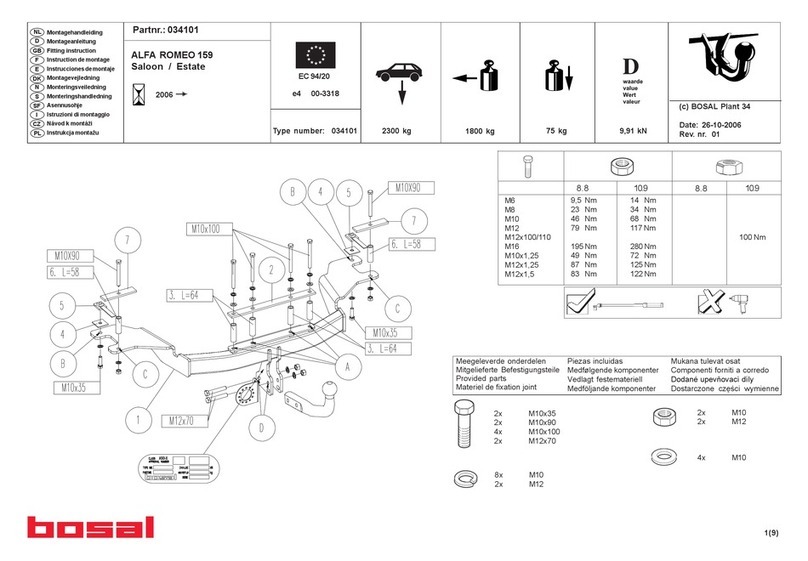

1.1.1Symbols introduction

WARNING!

Warning

Refer to the manual for more information.

Danger

There is risk of electric shock, the charger has high voltage.

NOTE!

Note

Read this information to avoid damage to the charger.

1.1.2 Grounding symbol

Protective grounding wire

Grounding terminals must be connected before making other

connections to the charger.

1.1.3 Safety notes

1) Please carefully follow the safety instructions to keep the electric car out of danger;

2) Before charging, check the charger touch screen and indicator light. If there’s fault, the fault

must be solved before using the charger to charge.

3)Before the charger starts charging, make sure that the Electric car is in power off state;

4) Completely follow the text prompts to conduct charging process.

4

5) It is prohibited to unplug the charging connector during charging process to prevent Any

kind of unwanted accident and ensure safety;

6) The entire charging process is completely automatic, EVMS-150 will shut down by itself

while it finishes charging the car. The charging process don’t need any human intervention but we

recommend regular inspection to check if there’s any abnormal situation,

7) When not in use, try to avoid direct exposure of the tip of Charging connector, and plug it

back into the socket to prevent damage. Check the charging cable or charging tip if the shell is

damaged, exposed cables and other problems, please stop using until fixing it t;

5

PART 2 EVMS-150 Charger Installation

2.1 transport

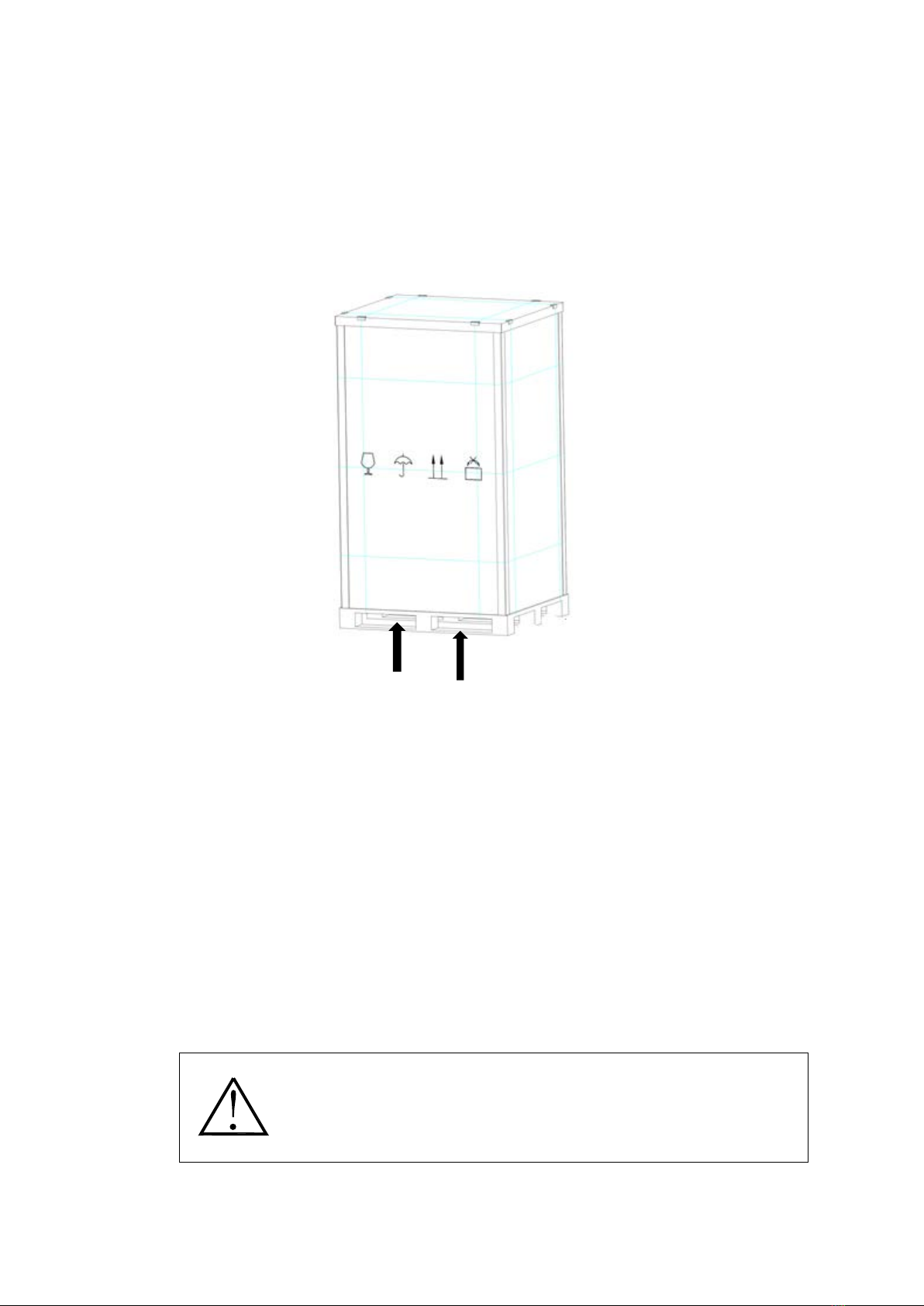

Note: The center of gravity of the equipment is not in the center. When using a forklift to

unload and transport, please fork in the direction as shown in the figure to prevent the

equipment from tipping over.

sketch map

Transport, road transport choice, should choose a better road traffic, to prevent

excessive turbulence can also choose rail transport and water transport.

2.2 Charger Receiving Inspection

When receiving the charger, please carefully check the box and the charger whether there are

any signs of physical damage. The logo on the box should be complete. If there is a rupture or

suspected rupture, please inform:

* Carrier

* Manufacturer

NOTE!

Visible Transport Damage must inform the carrier immediately upon

receipt of the goods!

Other transport damage must also be declared immediately and the

6

carrier must be notified within seven days of receiving the equipment.

The packaging material should be kept for later inspection.

2.3 Charger Storage

If the charger is not to be installed immediately it must be stored in stable position, and in a certain

temperature and humidity environment, the environmental conditions are as follows:

Temperature : -25°C to 60°C

Relative humidity: ≤95%, non-condensing

The recommended storage temperature is between: 10°C to 30°C.

2.4 Installation environment

To ensure the safe and healthy use of the charger, the location should be appropriate. Not only to

maintain a clean working environment, avoiding moisture, flammable gases, flammable liquids or

corrosive substances; users can place them at designated locations by means of manpower or

equipment, but be careful to maintain the spacing around the charger, to facilitate air circulation

and heat dissipation.

The following points should be noted:

A minimum of one meter of space must be left in front of and behind the machine to ensure

adequate space for operation and maintenance.

The input cable for the AC enters from the bottom of the charger.

Input and output wiring check

To ensure the safety of personnel during the installation of the charger, it is important to ensure

that all connections are made in the following conditions:

●Keep EVMS-150 installation area clean and dust free

● All power cables are Proper length and diameter

●Startup and operational checks are performed by authorized service personnel.

●Confirm the input and output voltage and frequency of the charger

●Ground connection in accordance with IEC standards or local regulations.

7

Installation environment

●Sufficient ventilation distance should be maintained on all sides of the charger case

●Away from heat and corrosive substances, avoid direct sunlight

●Maintaining normal operating temperature and altitude; Working temperature: -20 ℃~ 60 ℃

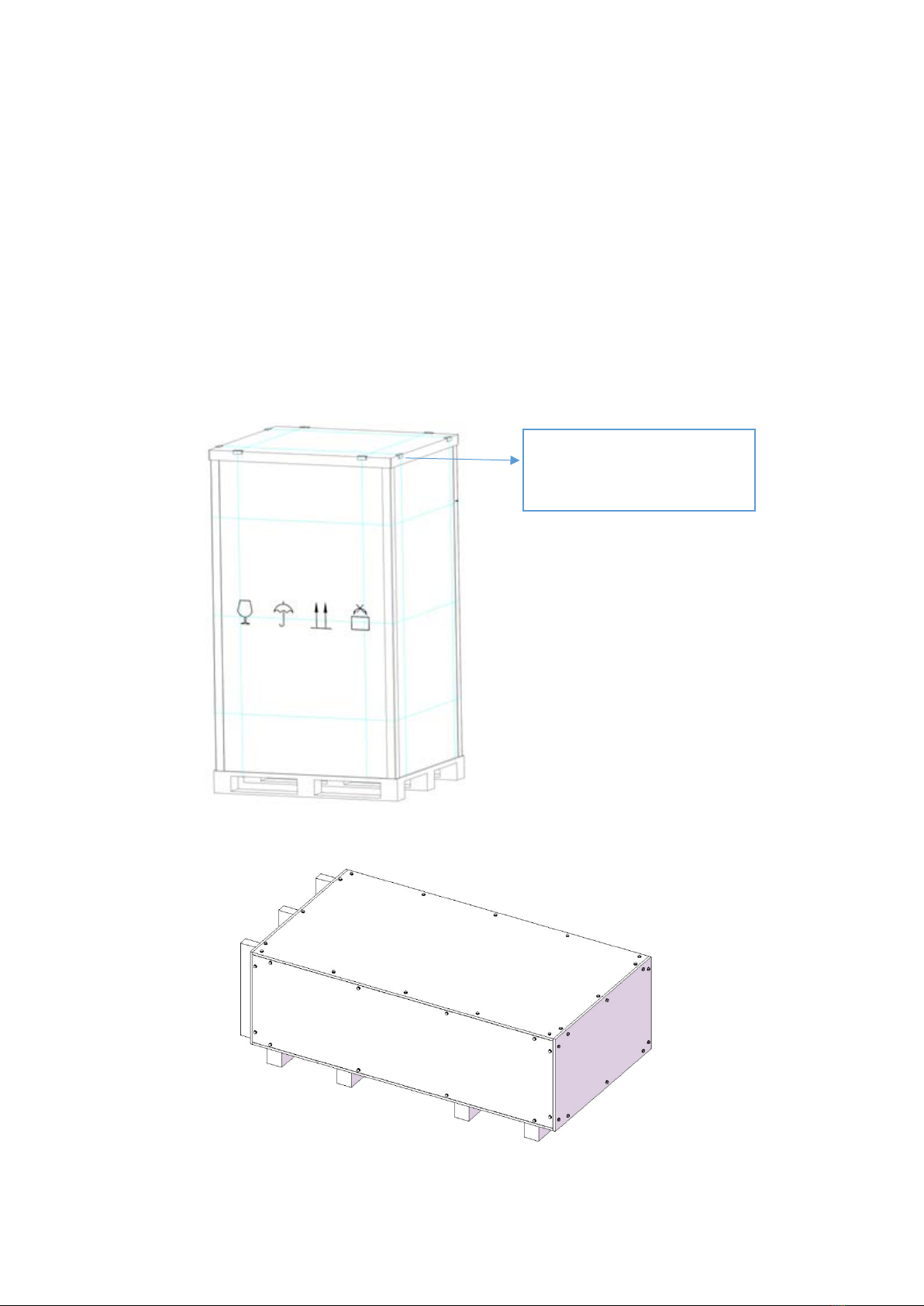

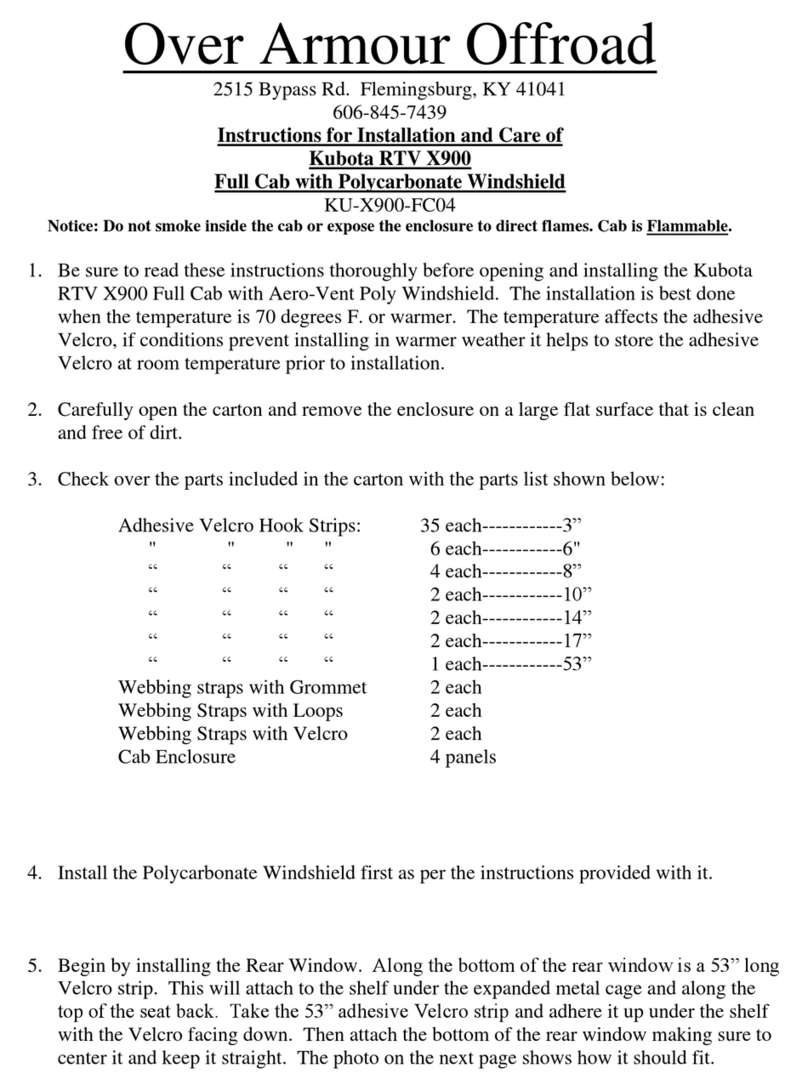

2.5 Unboxing

Vertical steel edge wooden packaging

Horizontal detachable packaging

Disassembly and assembly are carried out in the horizontal state:

Use a flat-blade

screwdriver to open it to

remove the wooden box

8

Use the open spanner SJGJ-17-19 to disassemble and assemble the bolts and washers in

the blue frame line as shown in the figure, each with 40 pcs.

Save the bolt, washer, and the honeycomb inner corner removed, according to the

position of the mounting place when unpacking the package again.

2.6 Position

In order to ensure smooth and reliable charger, the charger must be vertical basic construction

charger mounted on cement concrete cement based on custom and mounted above the base

level of the ground is not less than 220mm,.

Drilling template according to claim 6 Drill hole depth of 12mm in diameter 100mm in a cement

base, and then through the wall portion of the expansion bolt is inserted in a hole drilled;

Charging the cement foundation piles and reliable ground connection, the ground resistance

must ≤4Ω.

Before installing the charger, it should be checked as follows: the

device is damaged, if damaged, the shipper immediately; product

label check, confirm the correctness of the device. The equipment

label is affixed to the equipment, and the model, capacity and main

parameters are indicated on the label.

9

Front

Remove the anti-vibration components at the bottom of the cabinet, and then use a crane

(recommended) or a forklift to move the cabinet to the installation location on the concrete

foundation.

NOTE!

1. The lifting equipment used to carry the charger must have sufficient lifting

capacity.

2. When removing the loaded pallet, ensure that there is sufficient manpower

and lifting equipment.

3. The charger has a high center of gravity, so be careful to tip over.

Base anchoring hole diagram

10

PART 3 Introduction and installation of charge

3.1 Product Overview

EVMS series Electric Vehicle charger station is an intelligent integrated DC charging station system

promoted meet market demands. It adopts modular concept and cutting-edge electronic circuit

technology, integrating power conversion, charge control, management, query, display and

background communication in one cabinet. By communication with the BMS of electric vehicles,

to achieve intelligent control of the entire charging process. It is composed of Human-machine

Interaction Unit, Control Unit, Charging Module unit, Measurement Unit and Protection Unit. The

design conforms to EN61851, EN62196, DIN70121, CHAdeMO1.2 and other standards.

3.2 Feature

The charger supports CCS2 connectors could be used simutaneously.

Built-in power meter with charging power metering function.

Configured with DPM1000/30 charging modules.

Support RFID Card charging(Mobile app optional) , support reservation function.

widescreen TFT touch screen with good human-machine interface, which can display QR code,

status information, metering information, alarm, charging records, etc.

LED indicators of power, charging status and fault.

Self-identifying electric vehicle BMS protocol function, mufti-models compatible charging;

Emergency stop button can cut off the charger output in urgent situations.

protection, AC input over voltage protection, AC input under voltage protection, short circuit

retraction protection, DC output over voltage protection, DC output under voltage protection,

battery anti-reverse protection, current anti-reverse and other protection functions;

Charging process protection function, when it occurs BMS communication failure,

disconnection, battery temperature, voltage exceeds the allowable limit, etc. During charging

process, the charge will immediately stop charging;

11

It has function of communicating with the monitoring system of the station, and can upload the

charging information through Ethernet or 3G, 4G wireless network to realize remote monitoring.

Built-in DSP in the charging module realizes intelligent management and digital control functions;

Built-in active power factor correction module in the charging module, input THDi ≤ 3%; power

factor 0.99.

The charging module adopts ZVZCS and LLC resonant soft switching technology, the efficiency up

to 95%.

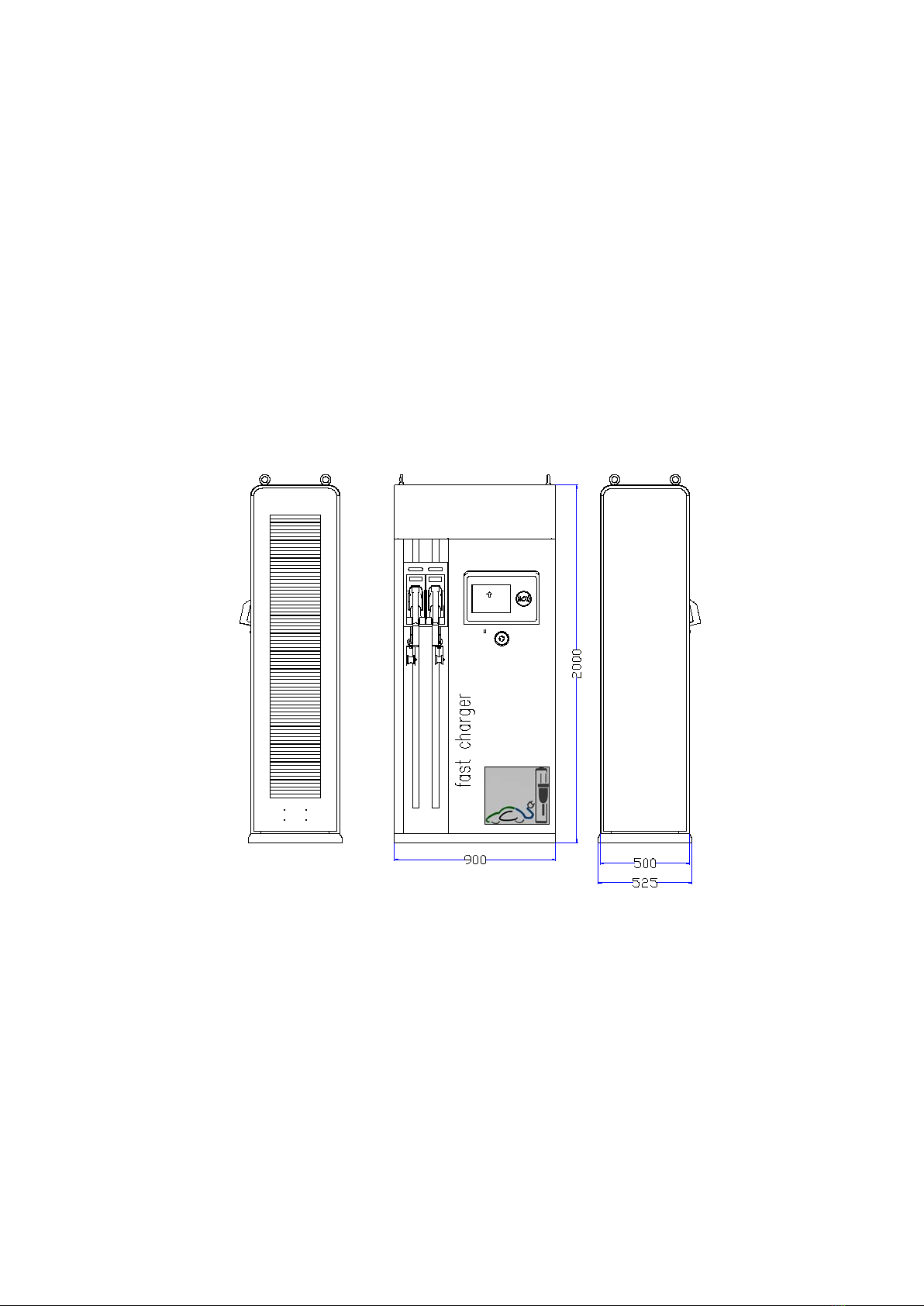

3.3 Outline Dimension

12

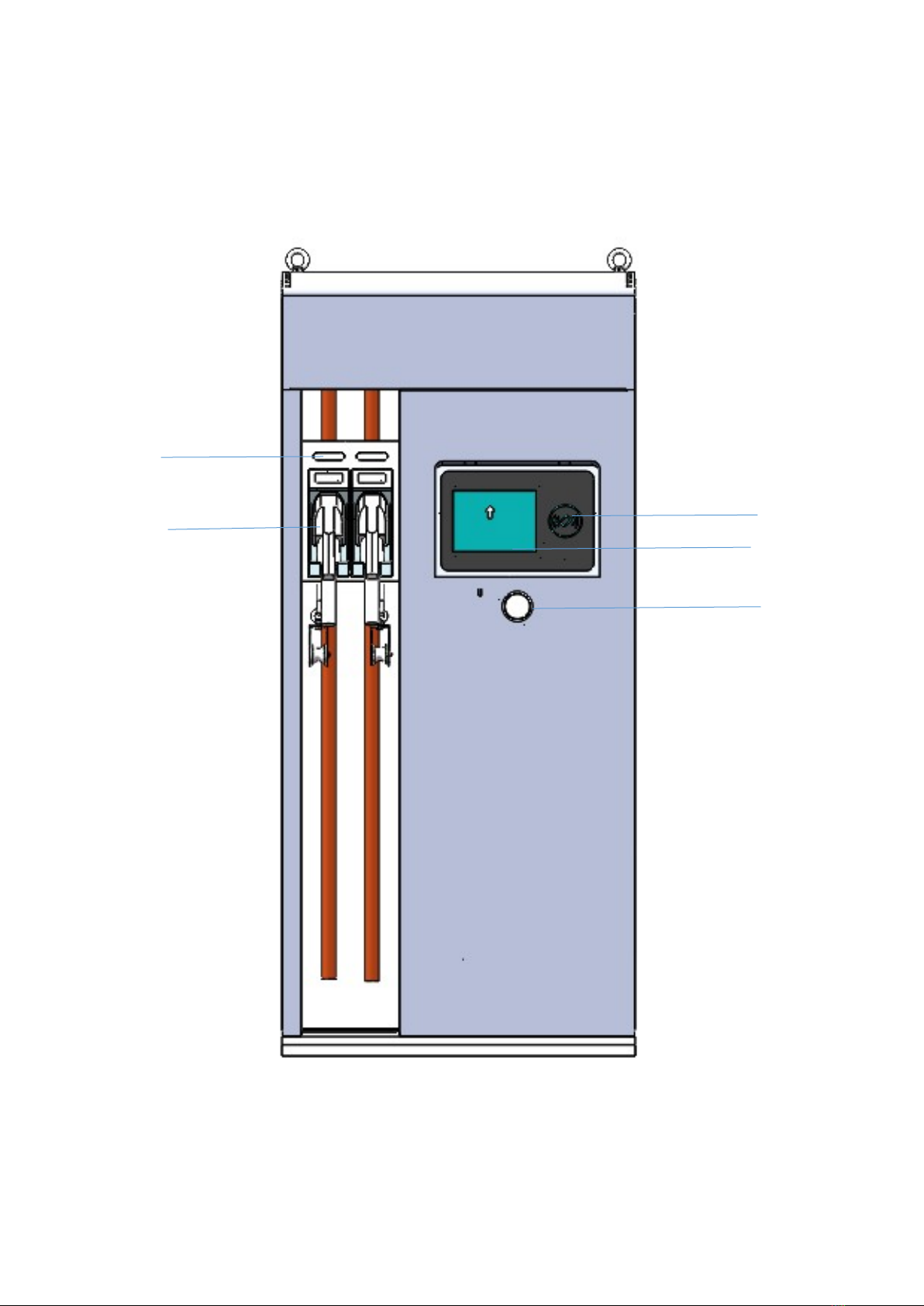

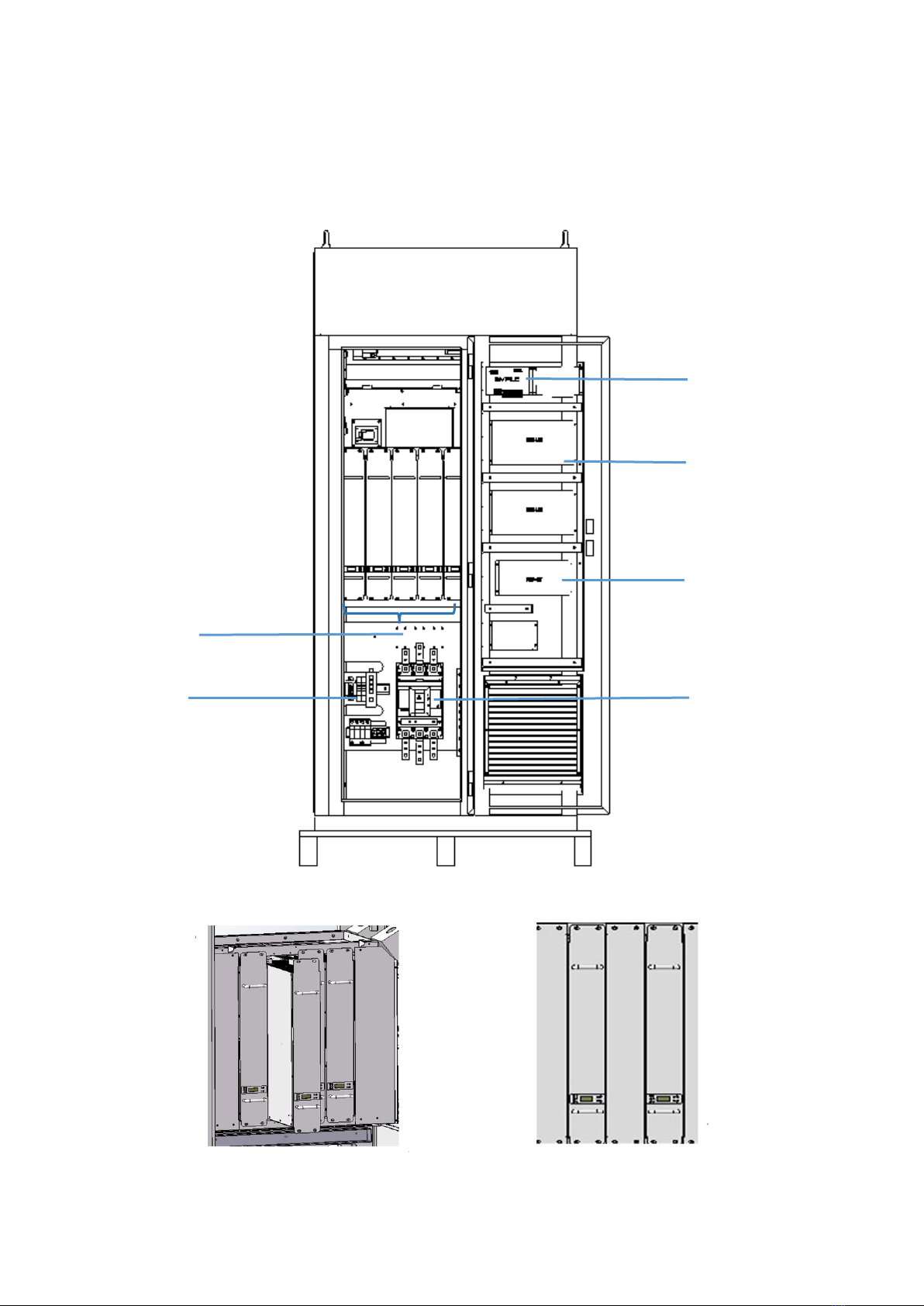

3.4 Appearance

Front View

1

23

5

4

13

Internal view

1 Charging status LED 2 charging connector

3 RFID Reader 4 Monitor display

5 Emergency stop button 6 Charging module

7 Industrial Switch 8 leakage protector

9 SPD 10 EVPLC

10

6

11

12

7

8

14

9

13

14

11 EVMS-MCM 12 EVMS-MCM2

13 EVMS-CSU 14 AC input switch

3.5 Charger dust screen and air inlet and outlet

Note: Effective ventilation of equipment In order to prevent dust and

obstruct the harmful substances such as PM2.5, the equipment is dust-proofed

by adopting international advanced honeycomb textile technology on the side

Air outlet

Air inlet

15

Note: Please open front door to replace the air filter on the side of

the device. There’s butterfly nut at the side of device (no need of any

tools), just to pull out the air filter for flushing or fan dust

Vibration-proof

Use a screwdriver to remove 4 screws and open

the side door. Please note that when

disassembling, it is recommended that both the

inside and outside doors fall down. It is

recommended that two people operate and

dump carefully

air filte

16

To remove the shockproof components at the bottom of the cabinet, you need to open the rear door, left door, and

all of them. Use a wrench to remove the bolts at the bottom of the cabinet and remove the wooden base. The

installation of the DC charger adopts the method of lower cable entry, the pile body is aligned with the hole,

placed on the cement base, fixed with 6 M12*60 anchor bolts, tightened and locked;

17

3.6 Charger diagram

18

3.7 Input Connection Terminals

Note: For safety, AC input wiring is recommended to use 150 mm2 cable! The wiring is directly connected to the

upper port of the terminal, from left to right: A, B, C. Neutral and Grounding are on the right side of the

circuit breaker.Circuit breaker has type A RCD function,RCD rated residual operating current is 30 mA.

A, B, C, Neutral, Grounding input

terminal wiring

19

3.8 Install and remove the main power module

Charging

module

EVMS-MCM

EVMS-CSU

EV-PLC

Switch start state After wiring, start

the main input switch

20

The installation steps of the main power module are as follows:

1. Insert the AC input and DC output of the cabinet into the corresponding module position;

2. Fix the module to the cabinet through the fixing holes on the upper and lower front panel of

the module;

NOTE!

After the module is installed in the system, please set the address of the

module as "- -01", "- -02", "- -03" and so on in order from left to right.

3.9 After the initial setup boot

Before the system boot, check whether the module is installed, whether the AC input wiring is

correct, after all the preparations are completed, turn on all the switches, a module address bits

are set in accordance with 5.2 after power, and the background set in accordance with 8.1.

3.10 Charging status indicator

With luminous and indicating function, the charger is convenient for customers to conduct

charging operations at night. Three-color indicator: red, yellow, green.

1) Red light indicates fault and alarm status; it will not light on when charger work normally.

2) Yellow light indicates the load is charging.

3)Green light indicates that the battery is fully charged; the charger is in standby mode.

3.11 Emergency stop button

There’s emergency stop button above card billing area. When the charger fails, user can press

the emergency stop button, which make the charger output disconnected, meanwhile the

indicator light keeps to be red. After corresponding troubleshooting, the emergency stop button

will restore by rotated to the right.

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

Kuda-Phonebase

Kuda-Phonebase 291750 Installation instruction

Over Armour Offroad

Over Armour Offroad KU-X900-FC04 Instructions for Installation and Care

bosal

bosal 027201 FITTING INSTRUCTION

Hook

Hook 420516 manual

Connects2

Connects2 CAM-MB2-AD instruction manual

Royal Rascals

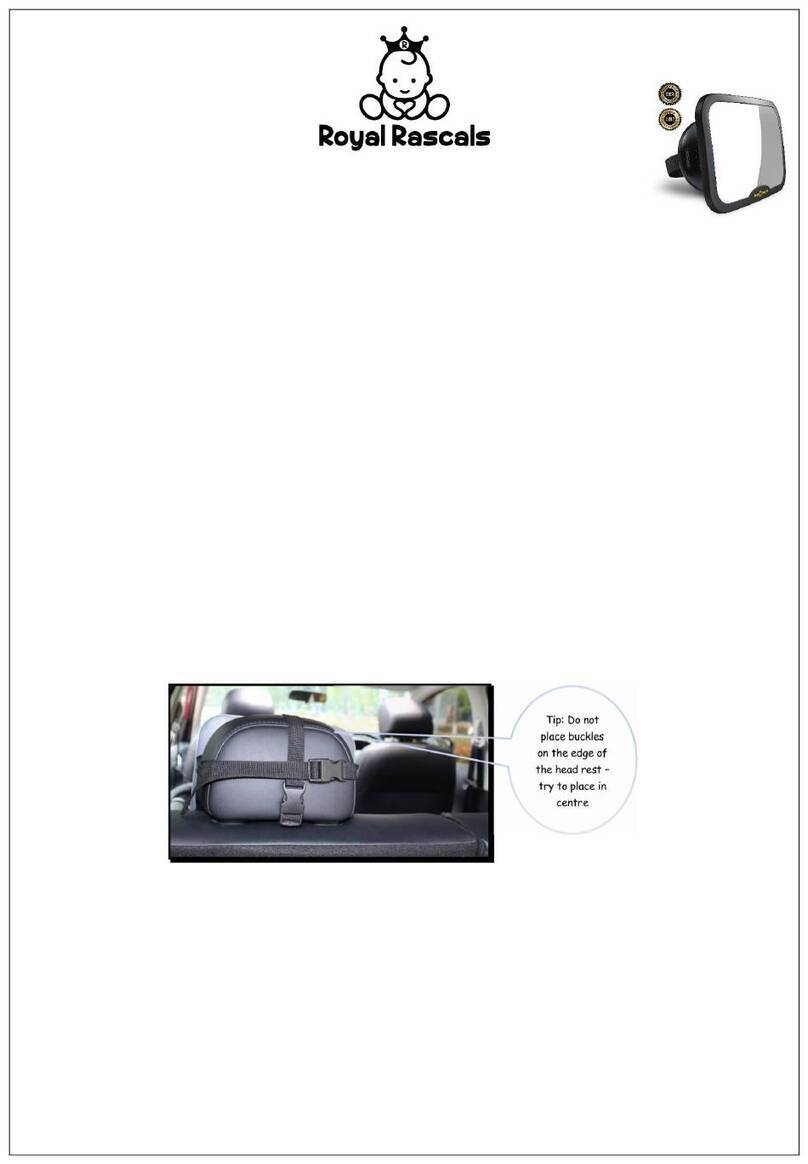

Royal Rascals XLR-5 Installation instructions and tips