Sicor EDL-01 User manual

Via Pisacane, 23/A EN 397

20016 PERO MI EN 166

Tel. 02 3539041 - Fax 02 3539060 EN 170

e-mail : info@sicor-sureco.it EN 50365

UK

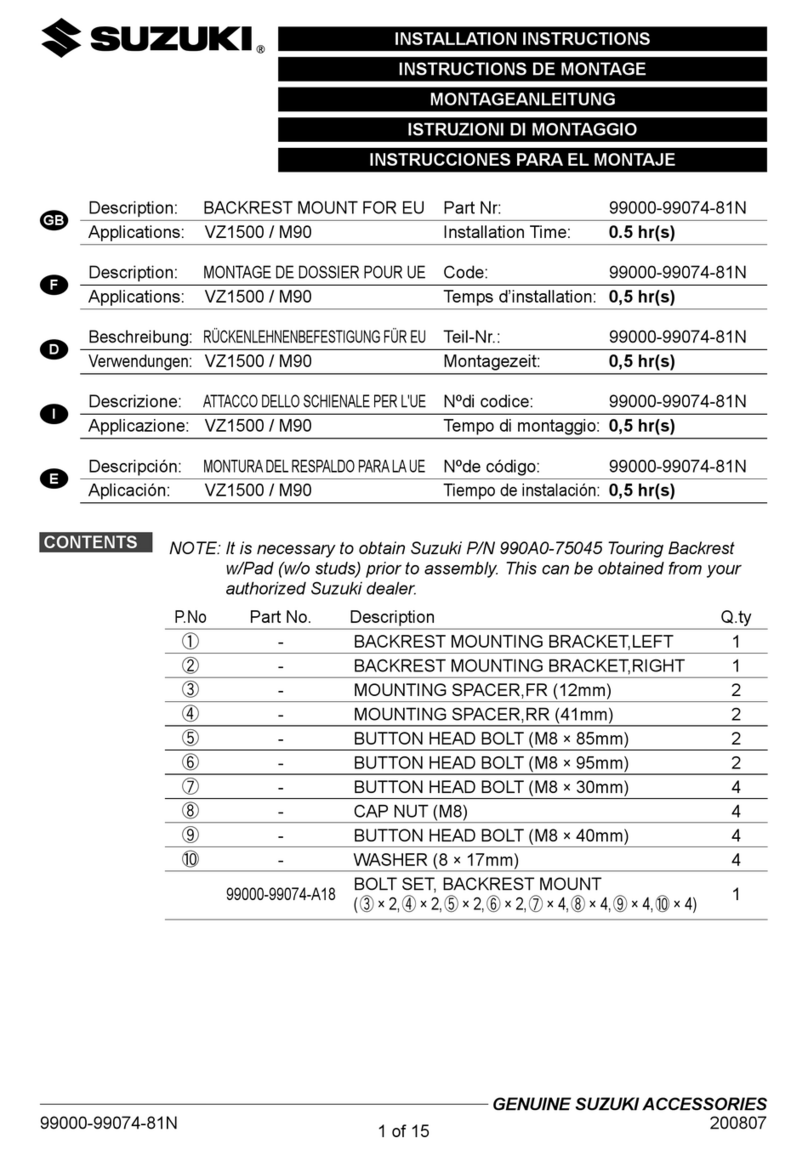

INDUSTRIAL HELMET EDL-01

INSTRUCTION MANUAL

This manual must be read carefully both by the individuals

who wear the helmet and by those responsible for its

maintenance. Keep this manual, because it represents,

together with the purchase invoice, the guarantee for the

helmet.

These are the instructions for the use and maintenance of the

EDL-01 helmet. It is our hope that the product will meet your

needs and prove to be of use for many years.

A great deal of attention has been paid to the text

and illustrations in this user’s manual. Nevertheless, the

publisher cannot be held liable for any errors or for their

consequences. Suggestions regarding the product and its

manual can be presented to our company, which shall take

them into account, should they result in concrete

improvements.

SICOR S.p.A. reserves the right to modify, even without

advance notification, both the product and its accessories, as

well as their technical characteristics.

The companies, brands and products mentioned all represent

registered or pending trademarks or titles

FEATURES

The performance characteristics for which the helmet has

been designed are guaranteed only if it used correctly and if

maintenance is performed as described in the instructions.

Should this not be the case, then the protective

features cannot be guaranteed.

The guarantees provided by SICOR with regard to this product

shall be null and void should the warnings, precautions and

instructions contained in the present manual not be followed.

After reading the manual, should you still have any doubts

regarding the level of protection offered by the helmet, the

conditions for its use or the maintenance procedures, feel free

to contact us at the numbers indicated.

WARNINGS

Failure to respect the warnings listed below could have grave,

and even life-threatening, consequences. This helmet is

designed to provide protection from impact, from

penetration from above, from crushing, from tension and from

exposure to flames, within the limits contemplated under the

EN 397 Norms.

It is meant to reduce the effects of unforeseen events, but it

cannot protect the head from all eventualities.

To ensure maximum protection, the helmet:

MUST be properly placed on the head, and the

webbing must be adjusted to ensure that the helmet

fits snugly, through with a certain degree of comfort.

To ensure maximum stability of the helmet, always

attach and adjust the chin-strap correctly; this will help

reduce shifting of the helmet resulting from certain

environmental conditions.

Do not place any outside objects between the padding

and the parts of the helmet beneath it, given that such

objects, in the event of an impact, can

transmit significant force to the head, with serious,

potentially life-threatening consequences.

NEVER USE this helmet for driving or for ports

activities.

Inspect the helmet before and after each use,

employing the inspection procedures described in this

manual and immediately replacing any worn

or damaged parts exclusively with spare parts

supplied by SICOR S.p.A. .

NEVER alter or modify the helmet.

NEVER attach accessories and/or decals or labels

within 25 mm of the edge of the head-piece. Any

modifications or any utilisation of accessories

other than those supplied by SICOR S.p.A. may

reduce the levels of protection or the dielectric

properties.

NEVER use paints, solvents or detergents made from

hydrocarbons on this helmet. Such substances can

damage the materials in a manner not visible to

the eye, reducing their protective action.

Scratched or damaged visor should be replaced.

PRECAUTIONS

This helmet MUST be kept in a clean, dry, dark spot, not

near source of heat and at constant temperature of between

+10° and + 40 °.

. The helmet should be washed with lukewarm water and

neutral soap

. NEVER keep the helmet inside the vehicle when not being

used. Not only will it be exposed to sunlight (UV rays and

heat), but, if not adequately set in place, it could also be

thrown about inside the vehicle in the event of a sudden

stop. SHOCKS

After a strong shock this helmet has to be used anymore.

Internal invisible breakings could cause resistance reductions

in the following impacts. In case of doubt do not hesitate to

contact Sicor S.p.A. .

CHEMICAL AGENTS

All chemical products, corrosive substances and solvents

could, in certain concentrations, prove dangerous for this

product. If it is possible or necessary for your helmet to come

into contact with such substances, consult Sicor, indicating the

name or the compound, and you will be given an appropriate

response following careful study of the specific case.

DISINFECTING PROCEDURE

Should it be necessary to disinfect the helmet, use only

products compatible with the following materials:

-Polypropylene (shell and front-shell)

-Polycarbonate (visor)

-Polyamide 6 – ABS (internal harness)

Immerse the helmet in a solution containing lukewarm water

and disinfectant liquid or powder (medical chirurgical product

certified , Eg . Amuchina) following the warnings given by

producer regarding time and dosage.

DECLARATION OF CONFORMITY

The company: SICOR S.p.A.

Via C. Pisacane no. 23/A – 20016 Pero (MI) – Italy

DECLARES

that the DPI III cat. described below:

A) Protective helmet: model EDL 01

B) Visor for helmet EDL-01

comply with the provisions of Directive 89/686/EEC, to EN

397:2013 Norm , to UNI EN 166:2004 Norm, to CEI EN

50365:2004 Norm and are identical to the DPI covered in EC

certification statements:

A) No. DPI/0497/213, issued on 23 th December 1998and

up- to-date on July 04, 2013.

B) No. AC 99006 issued on 31st March 1999 and following

annual confirmations.

ISSUED BY:

A) C.S.I. S.p.A. Laboratory ; Viale Lombardia n 20 – 20021

BOLLATE (MI). Owner of the identification N. 0497;

B) CERTOTTICA S.C.A.R.L. Laboratory – Villanova Industrial

Zone LONGARONE (BL), owner of the identification

number 0530. SICOR S.p.A.

The legal representative

LIFE EXPECTANCY

The helmets model EDL 01 if stored properly has a life

expectancy of 8 years.

In case of normal use have a life expectancy of 5 years.

The helmets model EDL 01 have an excellent resistance to

aging, the life expectancy of use depends on stress sustained

during the whole life of the helmet. In order to extend as much

as possible the life expectancy of use must comply the

requirements of use and maintenance described in this

manual.

DISPOSAL

CER Number = 20 01 39 plastic material.

CER Category: urban solid waste and similar refuse from

commercial , industrial , and institutional activities (including

materials for recycling).

ACCESSORIES and SPARE PARTS

Accessories

Codes Description

5490105779 Frontal lamp

5220216589 Bag for helmet

Spare parts

Codes Description

5230007900 Spare part visor

5220260000 Chin strap

5220210200 Harners

MAINTENANCE

Follow the procedures to clean the helmet:

1) dismantle the helmet

2) clean all the pieces inside and outside using only neutral

soap and lukewarm water , with the exception of the

following pieces:

Shell: wash with cold water and neutral soap.

Do not use solvents, let dry at room temperature.

Visor: wash with lukewarm water and dry with a soft

cloth to avoid scratches on the surface.

Before assembling the helmet make sure that all the pieces

are dry.

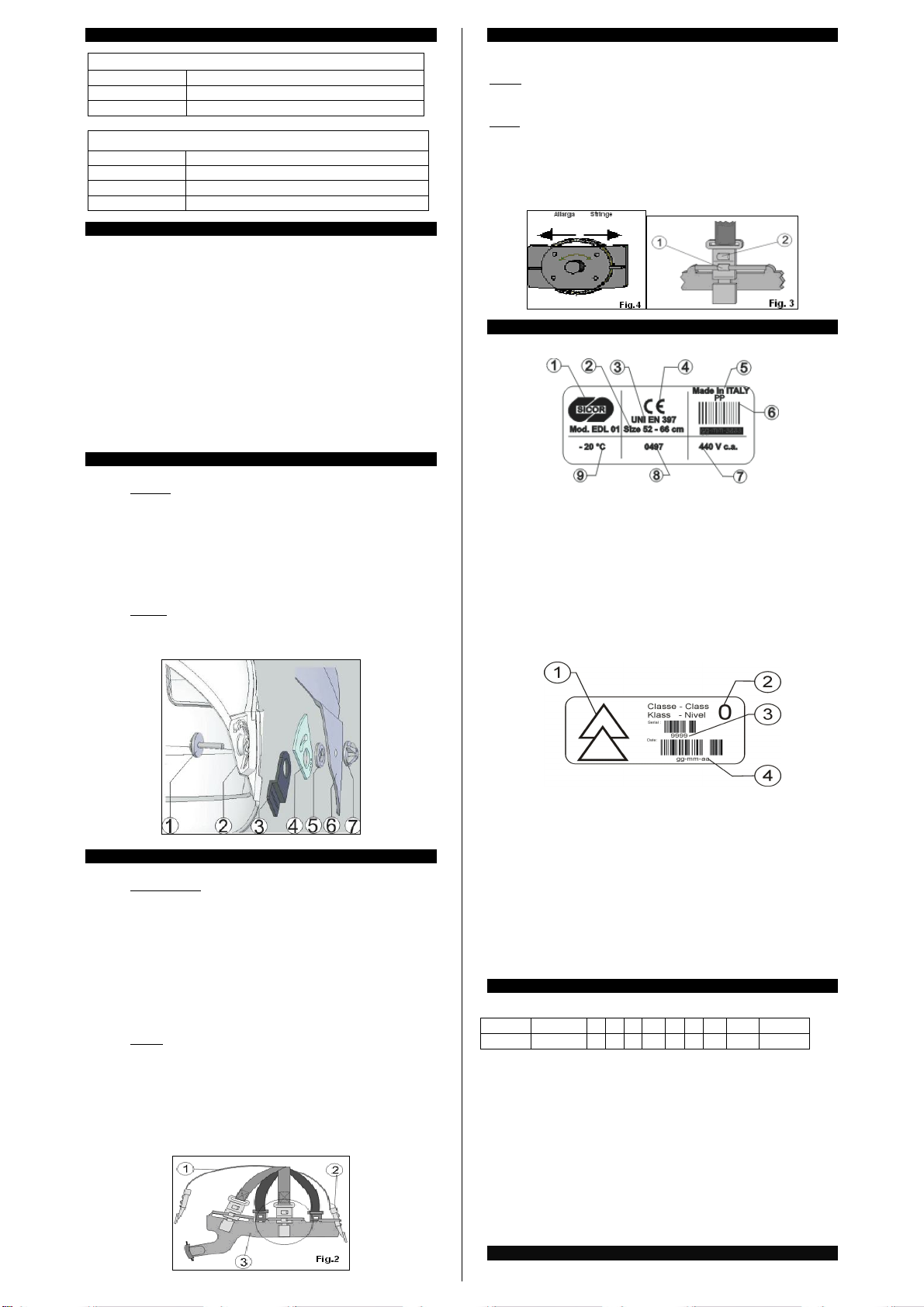

DISASSEMBLY

For the outside proceed as follows:

1) Unscrew the lateral screws (figure 1, point 1 and 7 ).

2) Remove the front-plate (figure 1, point 6 ), having care

to remove the central part from its support.

3) Remove the washers (figure 1, point 5).

4) Remove the visor (figure 1, point 4).

5) Remove the retention system (figure 1, point 3).

For the inside:

1) Extract the clips of the harness from the connection

system placed in the shell.

2) Extract the clips from the size adjustment system.

Fig. 1

MOUNTING

For the external side proceed as follows:

1) Position the system of the retaining system (fig. 1 point

3) in the special housing found in the headpiece .

2) Insert the visor (fig.1 point 4).

3) Insert the washer that block the visor (fig. 1 point 5).

4) Position the front plate (fig. 1 point 6).

5) Lightly tighten the screw M/F (fig. 1 point 1 and 7).

6) Repeat the operation on the opposite part.

7) Firmly tighten the two screws.

For the inside:

1) Insert the clips in the adjustment system, as shown in

picture 3, being careful to place the longest one on the

front side.

2) Insert the entire harness in the helmet and place the

clips in the special housings found on the head –

piece , beginning from the front and gradually moving

to the right and to the left finishing in the rear. (Fig.2)

ADJUSTMENT

There are two types of adjustment.

width:

by using the specially designed ratchet system could be

possible to adjust the size. from 52 to 64 (picture 4).

hight:

when installing the webbing, the wearer can decide how the

helmet have to fit on the head. The height can be adjust by

moving the clips from the insertion (n.1) to the point (n.2) of

the picture 3.

For intermediate adjustments , use only a portion of the clip.

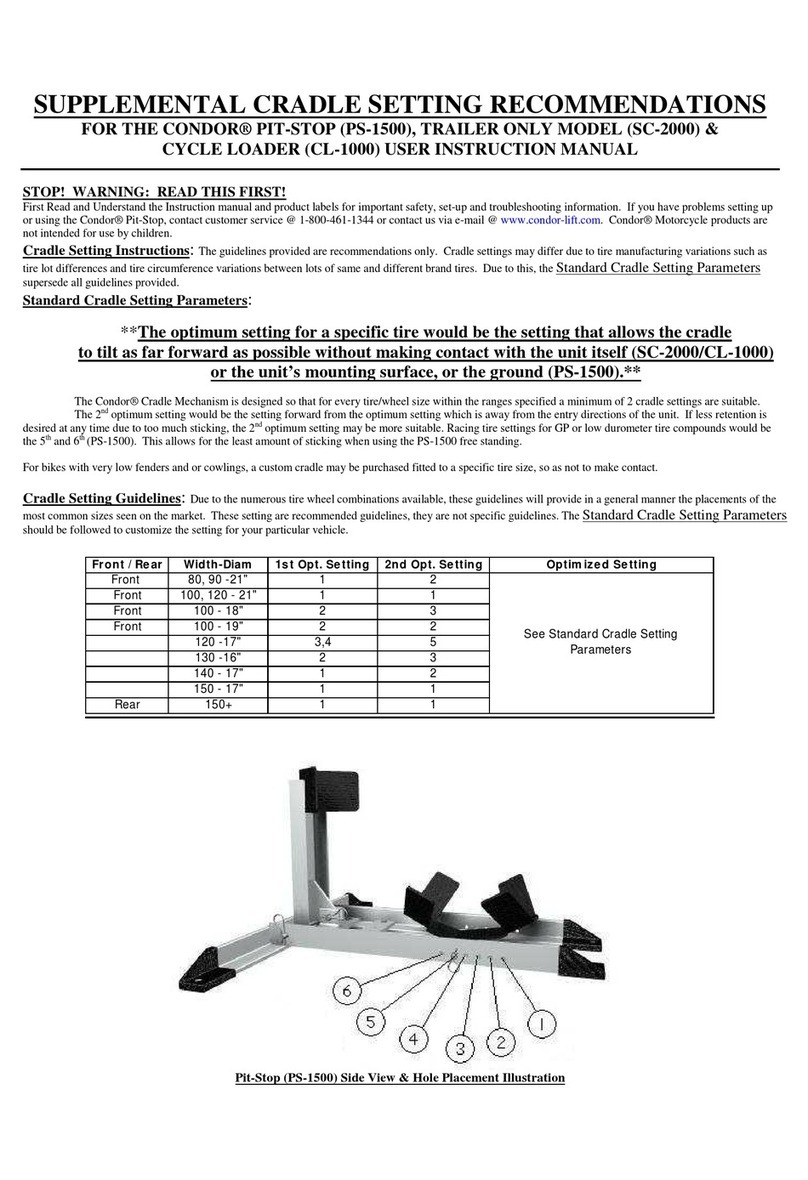

HELMET LABEL

Marking CE UNI EN 397

1) Name of the manufacturer and helmet model

2) Sizes covered by the webbing

3) Norm of reference

4) Marking CE,

5)Country of origin and material used for the shell

6) Lot of production

7) Optional trial ; tested for electrical insulation

8) Number of the notified laboratory that checks the

production

9) Optional trial; tested at low temperatures

Marking CEI EN 50365

1 - “Double triangle” Symbol CEI EN 50365:2004 Norm

2 - Class

3 - Daily production progressive number.

4 - Production date

The insulating helmet EDL 01 with a built-in face shield it is

classified in class " 0 " for the employ on installation with a

nominal tension till at 1000V c.a and 1500 V c.c.

The helmet insulating electrical can not be employed alone. It

is necessary to use other protection insulating devices, in

relation with the risks connected to the work.

VISOR LABEL

1 2 3

4

5

6 7

8

9 10 11

2.1.2 SICOR 2

B

3

8 9

K

N

CE 0497

1) Scale n°

2) Constructor identification

3) Optics class

4) Resistance at particles at high speed – impact

Medium energy

5) Protection against droplets and splashes liquids

6) Electric arc protection from short circuit

7) Molten metal resistance

8) Resistance against fine dust particles

9) Resistance at particles at high speed – impact

10) CE mark

11) Identification notified organisation

EDITION 10/2013

Other Sicor Motorcycle Accessories manuals

Popular Motorcycle Accessories manuals by other brands

Chicago Electric

Chicago Electric 91212 Set up and operating instructions

Wunderlich

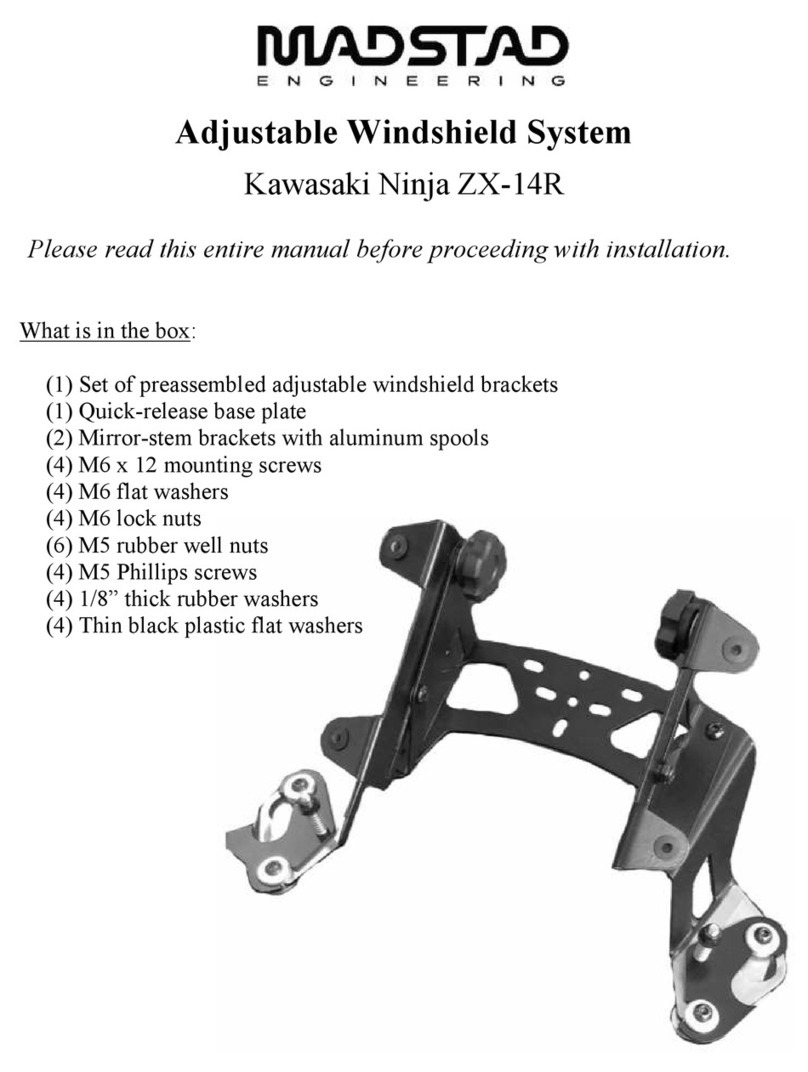

Wunderlich 35520-101 Mounting instructions

Condor

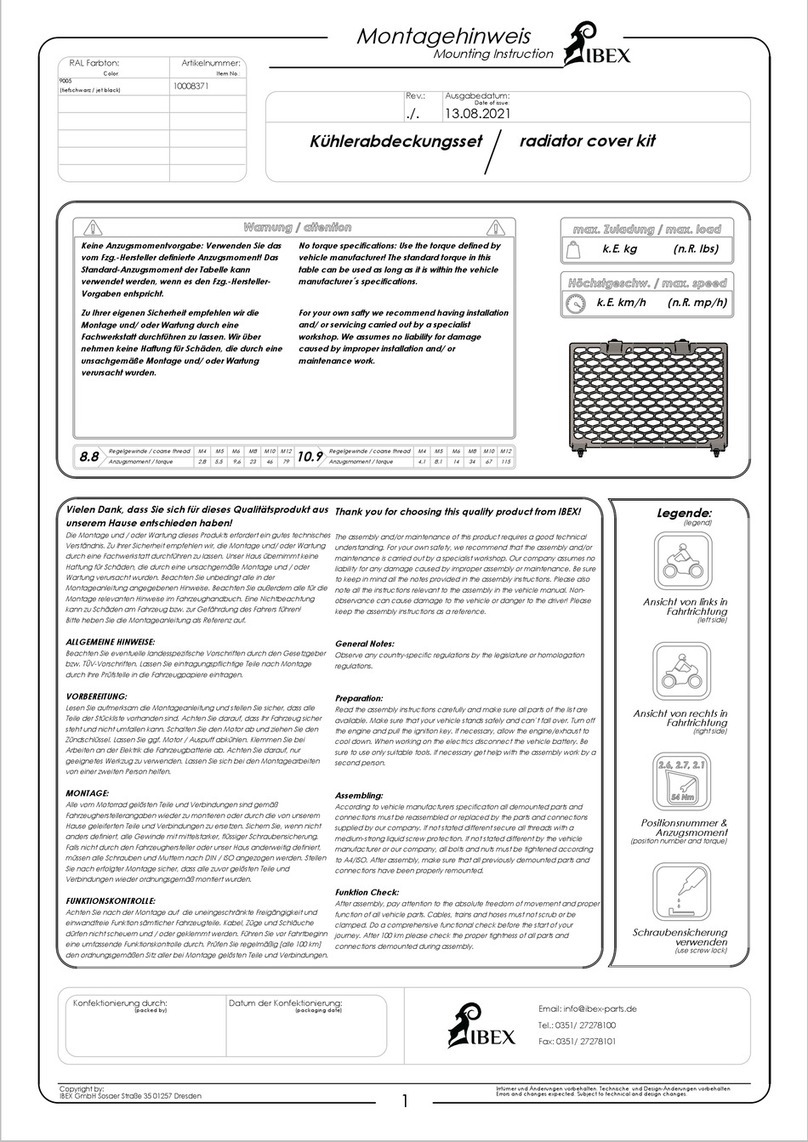

Condor SC-2000 User instruction manual

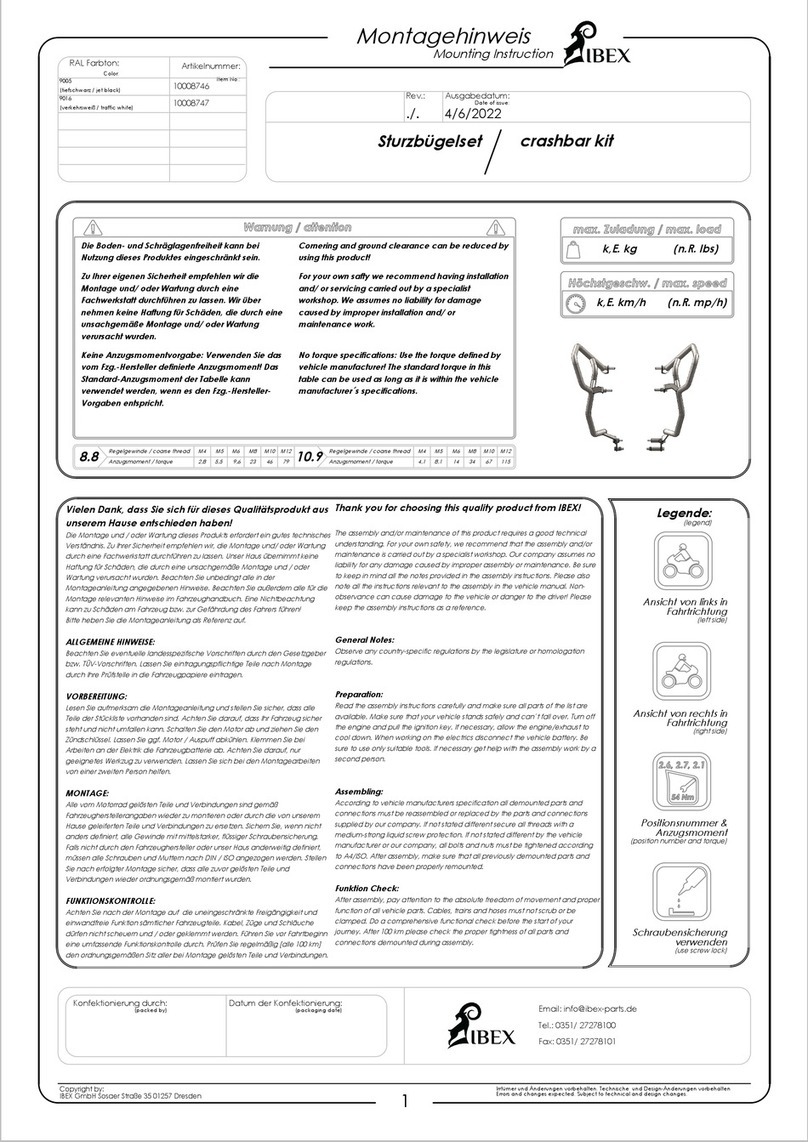

IBEX

IBEX 10008371 Mounting instruction

hepco & becker

hepco & becker LOCK IT 5067609 00 01 quick start guide

Kuryakyn

Kuryakyn 4261 quick guide