7

SE 40/125S2 ignition protected thruster assembly 5456-2 - 2018

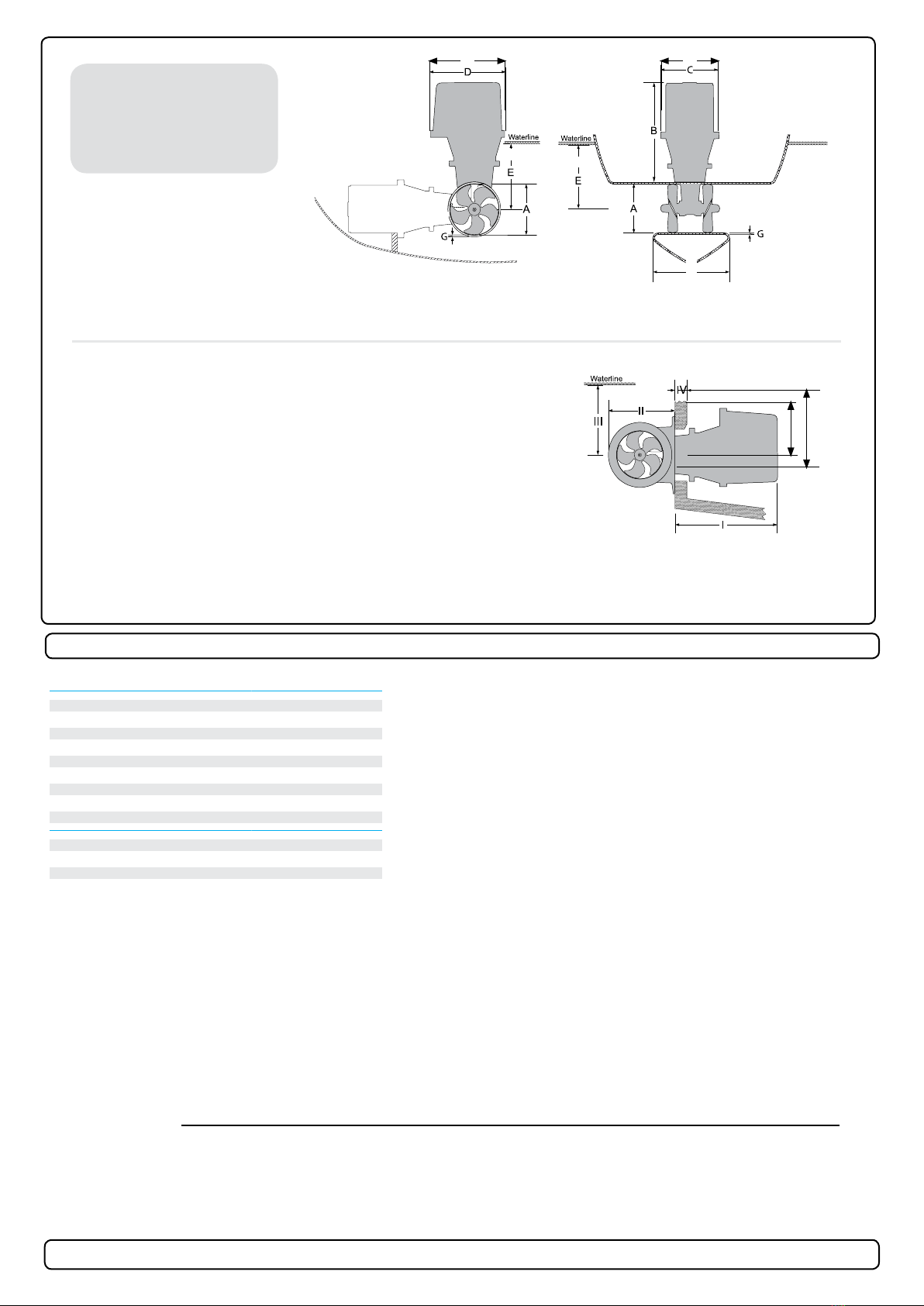

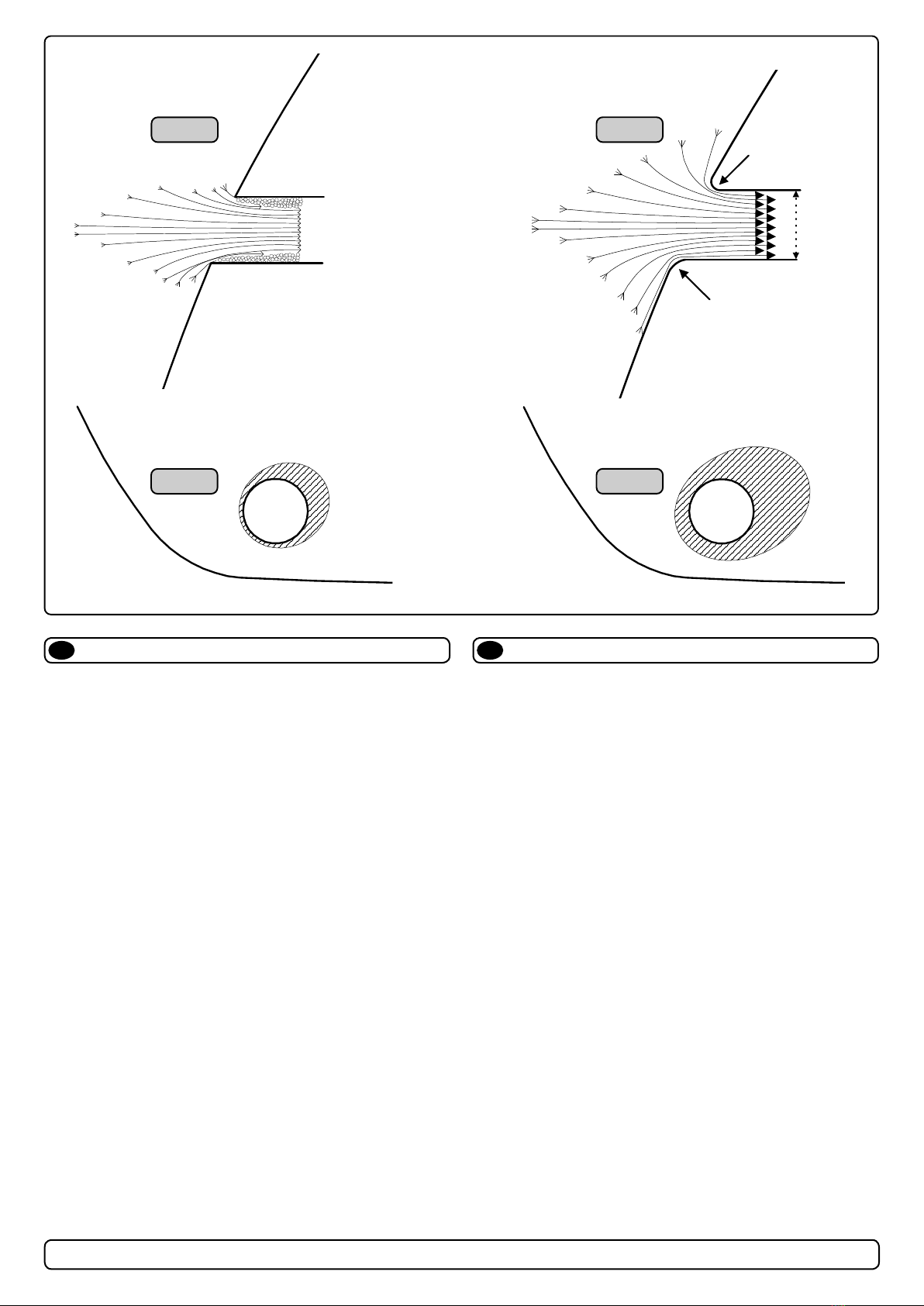

A possible problem in sailboats or fast powerboats, is that they

get a drag from the back face of the tunnel, as this becomes a

“ at” area facing the water ow (Fig. 1).

This can also create problems with the thruster spinning (passive)

and making noise while sailing or driving the boat with water be-

ing pushed through the tunnel at high speed.

This can be solved in two di erent ways, depending on what is

possible or more easy to do.

1. The best solution which normally reduces the drag most, is to

make a recess in the hull at the back of the tunnel.

Thereby the back face is gone and about all the drag (Fig. 2).

The depth and shape of this recess will depend on the boat.

Basically you should not see the back face of the tunnel when

standing directly in front of the tunnel at the angle of the boats

centreline.

The angle up or down backwards of the insert in the hull, de-

pends on the hullshape, but normally it is angled slightly down

because of the water ow on this area of the hull.

2. The drag will also be reduced a lot, especially in fast power

boats, by making a de ector / spoiler in front of the tunnel.

This will push the water ow out from the hull so that most of it

passes by the back face of the tunnel (Fig. 3).

The shape and size of this de ector will depend on the hull

shape. Basically you should not see the back face of the tunnel

when standing directly in front of the tunnel at the angle of the

boats centreline.

The easiest way of making this is to let a part of the tunnel

stick out in the lower forward area of the hole, and use this as

a support to mould a soft curve / spoiler shape.

Remember to still round the tunnel ends as much as possible to

get optimum thruster performance and minimum noise.

More information on how to practially do this on pages 6.

Prevent drag from tunnel

EN Motstand forårsaket av tunnel

NO

Et mulig problem for seilbåter eller meget hurtiggående båter er

motstand i tunnelen. Aktre ende på tunnelen vil være en liten lod-

drett ate mot vannstrømmen som skaper uønsket motstand.

Denne aten kan også forårsake problemer med at vann føres

inn i tunnelen under seilas, eller kjøring i høy fart og får da propel-

len til å rotere, dette skaper uønsket støy.

Det er to mulige løsninger på problemet, avhengig av hva som er

enklest å få til på båten.

1. Den løsningen som vanligvis reduserer motstanden mest er å

lage en fordypning i skroget i aktre ende av tunnelåpningen.

Den loddrette aten vil da forsvinne og dermed motstanden.

Hovedregelen å følge er at bakkanten av tunnelen ikke skal

synes når man står rett foran båten og titter akterover langs

båten senterlinje. Dybden, utformingen og vinkling av fordyp-

ningen avhenger av båttypen, og hvordan vannet følger skro-

get, men de este båter vil være tjent med en fordypning som

vinkler lett nedover (Fig. 2).

2. Motstanden vil også reduseres av en spoiler i forkant av

tunnelen. Spoileren fører det meste av vannstrømmen rundt

og forbi tunnelen. Størrelsen og utformingen på spoileren

avhenger av båten. Hovedregelen er at bakkanten av tunnelen

ikke skal synes når man står rett foran båten og titter akterover

langs båten senterlinje. Den enkleste måten å lage spoileren

på er å la tunnelen stikke ut i forkant av tunnelen, og forme

spoileren opp mot den (Fig. 3).

Det er alltid viktig å avrunde tunnelåpningene mest mulig for å

motvirke støy og for å få mest mulig eff ekt av thrusteren.

Mer informasjon om dette på side 10.

12

SP 75 Ti / SP 95 Ti / SP 125 Ti

2.5.1- 2007

Formgebung der Tunnelenden

☺☺☺☺☺

�����

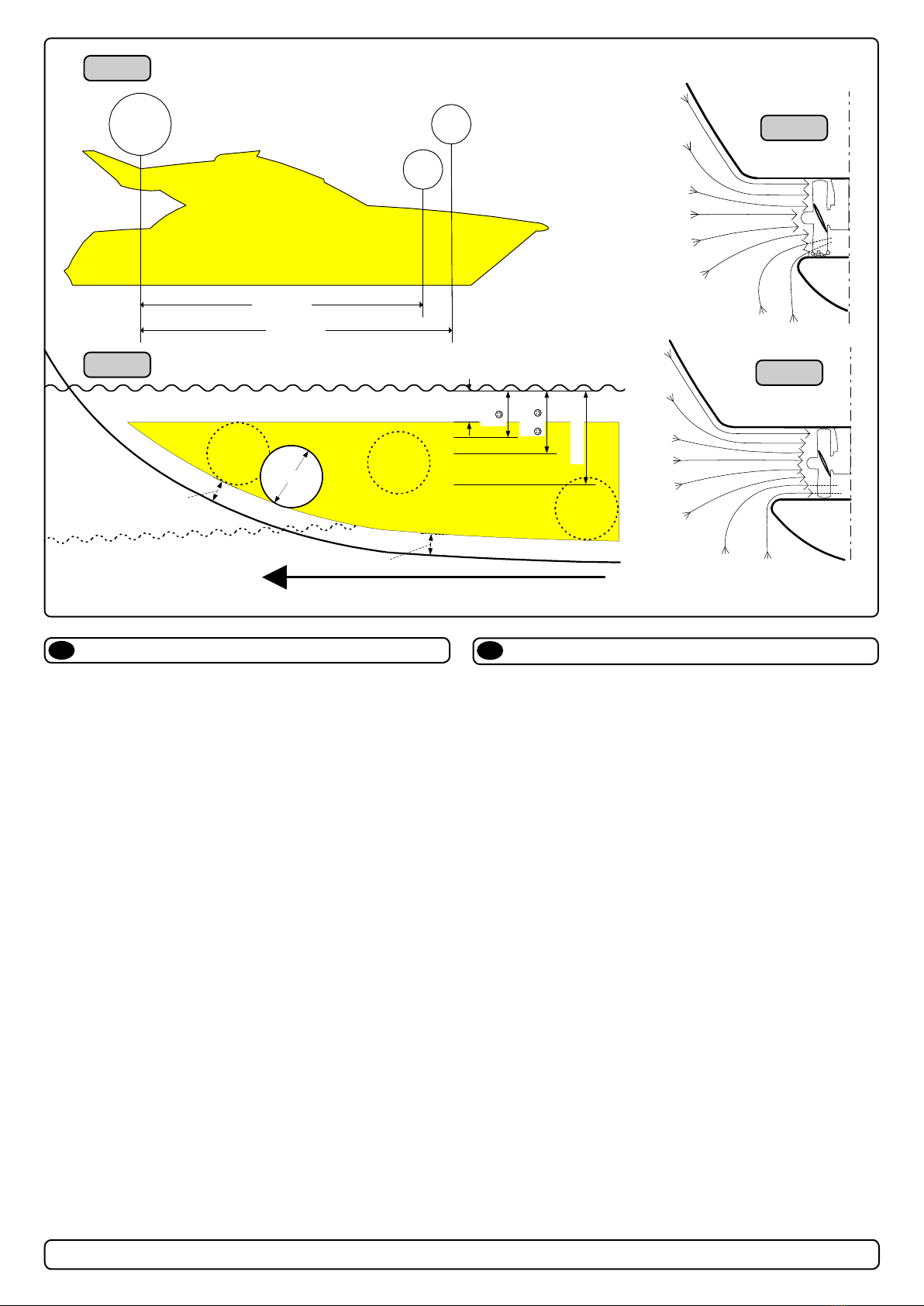

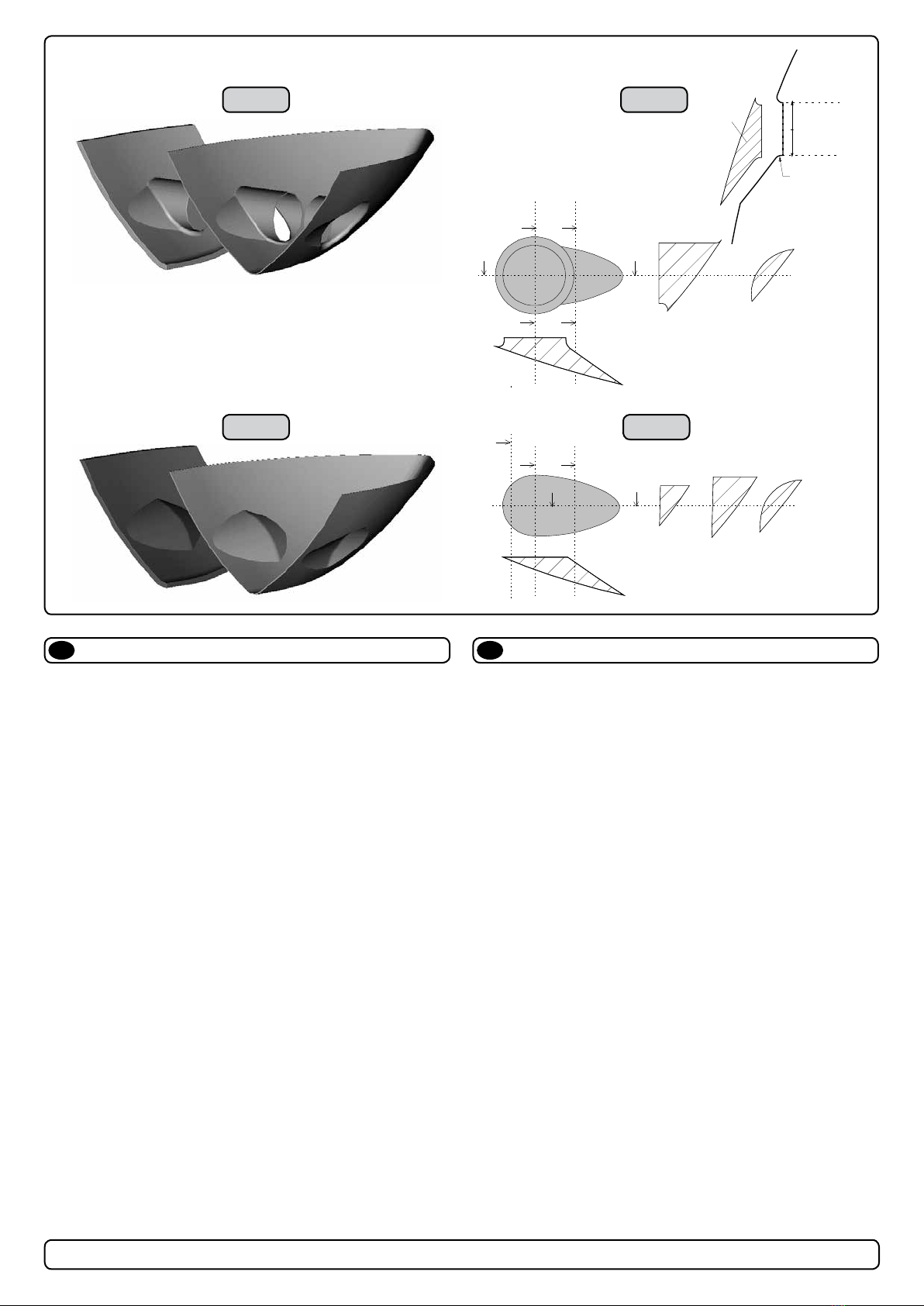

Abgerundete Tunnelenden erhöhen die Schubkraft und

reduzieren das Geräuschniveau.

Der Bereich Tunnelende / Außenseite des Rumpfes ist soweit

möglich abzurunden. Der optimale Wert für den Radius dieser

Rundung beträgt 10% des Tunneldurchmessers.

Vorteile gegenüber einer scharfen Tunnel / Rumpfverbindung sind:

1. Abgerundete Tunnelenden verhindern Turbulenzen / Kavitation,

wie sie an scharfenkantigen Tunnelenden auftreten. Damit

werden zwei negative Auswirkungen auf Schubkraft und

Geräuschentwicklung vermieden (Fig. 1 & 2).

- Turbulenz / Kavitation blockieren den äußeren Tunnelbereich.

Dadurch werden effektiver Tunneldurchmesser und Schub-

kraft reduziert.

- Die Turbulenz / Kavitation trifft auf den Propeller und reduziert

dessen Effektivität und führt zu zusätzl. Geräuschentwicklung.

2. Abrundungen ermöglichen, daß Wasser entlang der Rumpf-

außenseite angesaugt werden kann. Dadurch entsteht ein

Vakuum ("zusätzliche" Schubkraft"), das das Schiff seitwärts

bewegt (Fig. 3 & 4). Bei scharfkantigen Enden kann kein

Wasser entlang der Rumpfaußenseite angesaugt werden,

wodurch das benötigte Vakuum nicht zustande kommt.

Diese Schubkraft kann bei optimaler Installation bis zu 30-40%

der absoluten Schubkraft betragen.

NB ! Sidepower Propeller sind so ausgelegt, daß sie nicht

kavitieren, sodaß die Geräuschentwicklung aufgrund von

Kavitation durch die Tunnelinstallation bedingt ist.

NB ! Ist eine optimale Abrundung nicht möglich, so sind die

Tunnelenden soweit möglich abzurunden. Angeschrägte

Tunnel / Rumpfverbindungen sind zu einem gewissen Grad

ebenfalls mit ähnlich positiven Auswirkungen wie eine

Abrundung verbunden (siehe Seite 20, Fig. 1b & 1d).

Tunnel ends

Fig. 2

Fig. 4

Fig. 1

Fig. 3

R = 0,1 x D (10%)

R = 0,1 x D (10%)

D

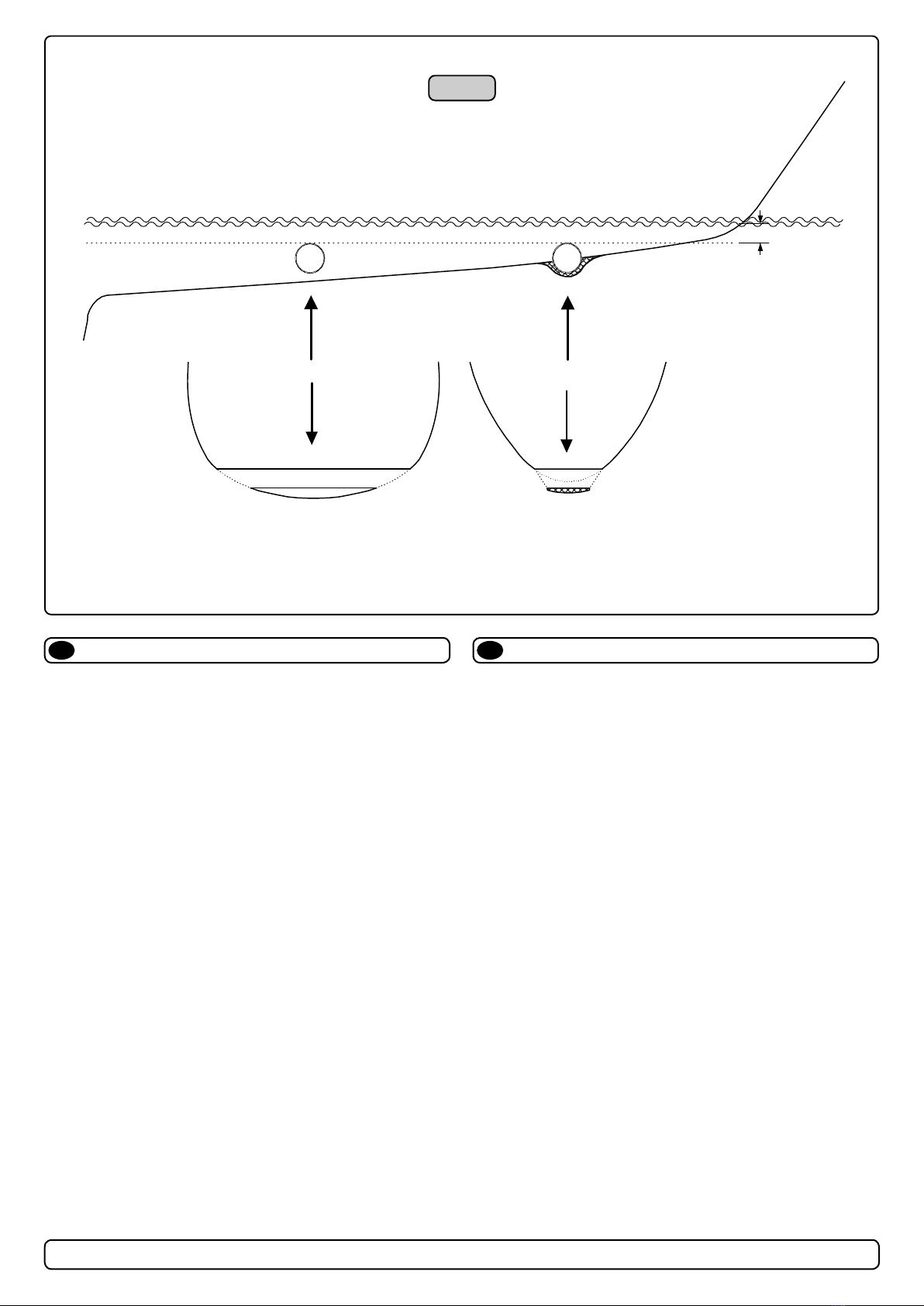

Rounded tunnel ends will maximize thrust and minimize

noise.

We recommend rounding the tunnel connection to the hull-side as

much as possible.

The optimum rounding has a radius of 10% of the tunnels diameter.

Important advantages over sharp tunnel to hull connections are:

1. The rounded tunnel end will prevent creation of turbulence

cavitation that will come from a sharp tunnel end when water

passes by fast, thereby preventing a double negative impact on

the thrust and noise level (Fig. 1 & 2).

- The turbulence / cavitation blocks the outer area of the tunnel

and thereby reduces the effective tunnel diameter and thrust.

- The turbulence / cavitation hits the propeller and thereby reduce

the propellers performance and creates noise.

2. The curved tunnel end makes the thruster take water also from

along the hull-side, creating a vacuum that will suck the boat

sideways and thereby give additional thrust (Fig. 3 & 4).

With a sharp tunnel end, the thruster will be unable to take water

from along the hull-side, and you will not get the desired vacuum

and additional thrust. This “free” additional thrust can in optimal

installations be as much as 30 - 40% of the total thrust.

NB! A Sidepower thruster propeller does not cavitate at working

speed so that all cavitation and cavitation noise in the tunnel will

be caused by the tunnel installation.

NB! Even if it is not possible to make the perfect rounding, it is very

important to round the tunnel end as much as possible. A

angled tunnel to hull connection will also do much of the same

job as a rounded connection (see page 20, Fig. 1b & 1d).