PSS®and Bodyguard®are registered trademarks of Dräger 3358298 (A3-D-P) 1 / 3

3358298

© Dräger Safety UK Limited

Edition 07 – August 2019 (Edition 01 – December 2009)

Subject to alteration

Draeger Safety UK Limited

Ullswater Close Tel +44 1670 352 891

Blyth, NE24 4RG Fax +44 1670 356 266

United Kingdom www.draeger.com

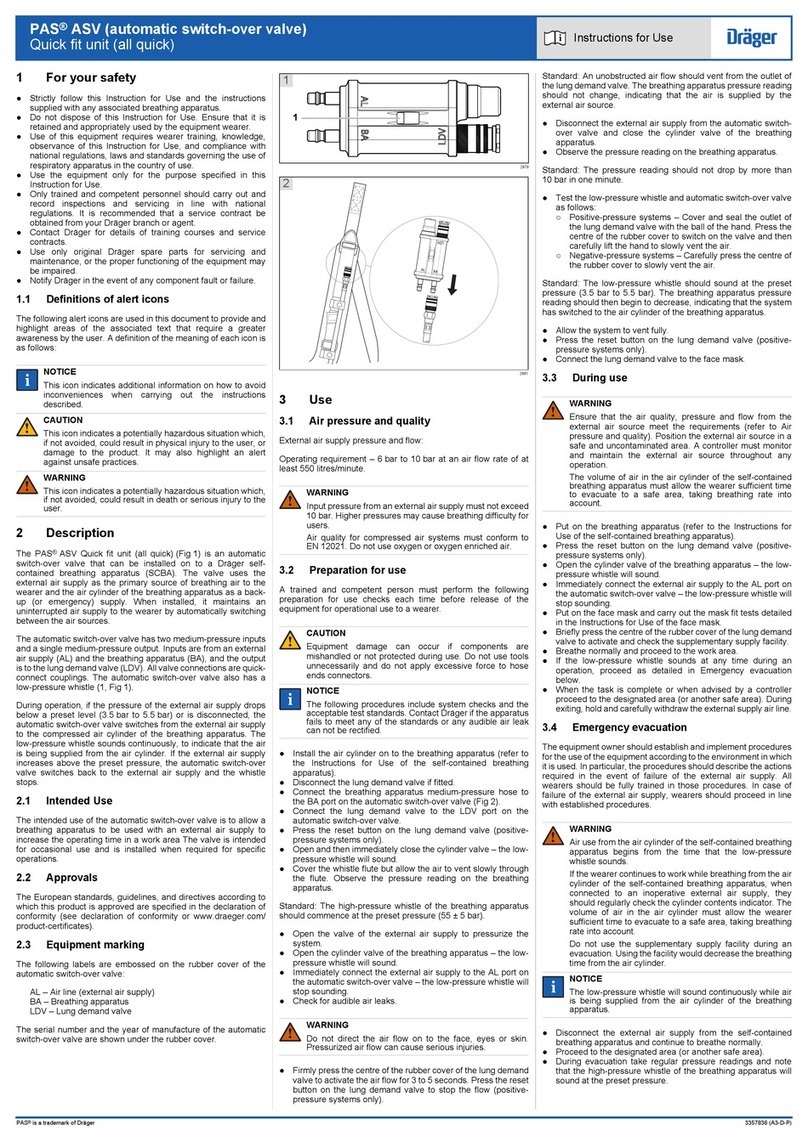

PSS®5000 Series

Self-contained breathing apparatus Instructions for use

1 For your safety

1.1 General safety statements

●Before using this product, carefully read the Instructions for Use.

●Strictly follow the Instructions for Use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the Intended Use section of this document.

●Do not dispose of the Instructions for Use. Ensure that they are

retained and appropriately used by the product user.

●Only fully trained and competent users are permitted to use this

product.

●Comply with all local and national rules and regulations associated

with this product.

●Only trained and competent personnel are permitted to inspect, repair

and service the product. Dräger recommends a Dräger service

contract for all maintenance activities and that all repairs are carried

out by Dräger.

●Properly trained service personnel must inspect and service this

product as detailed in the Maintenance section of this document.

●Use only genuine Dräger spare parts and accessories, or the proper

functioning of the product may be impaired.

●Do not use a faulty or incomplete product, and do not modify the

product.

●Notify Dräger in the event of any component fault or failure.

●The air supply shall meet the requirements for breathing air according to

EN12021.

1.2 Definitions of alert icons

Alert icons are used in this document to provide and highlight text that

requires a greater awareness by the user. A definition of the meaning of

each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in physical injury or damage to the product or

environment. It may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

2 Description

2.1 Product overview

The Dräger PSS®5000 Series is a self contained breathing apparatus

(SCBA) that uses an open-circuit breathing system. The series is

compatible with a wide range of compressed-air cylinders, face masks and

lung demand valves (e.g. FPS 7000 and Panorama Nova face masks, PSS

Series lung demand valves, and steel or composite cylinders).

The apparatus can also be fitted with a multi-function electronic monitoring

system (e.g. Bodyguard®7000). Refer to the relevant Instructions for Use

for the description, operation and testing of electronic systems.

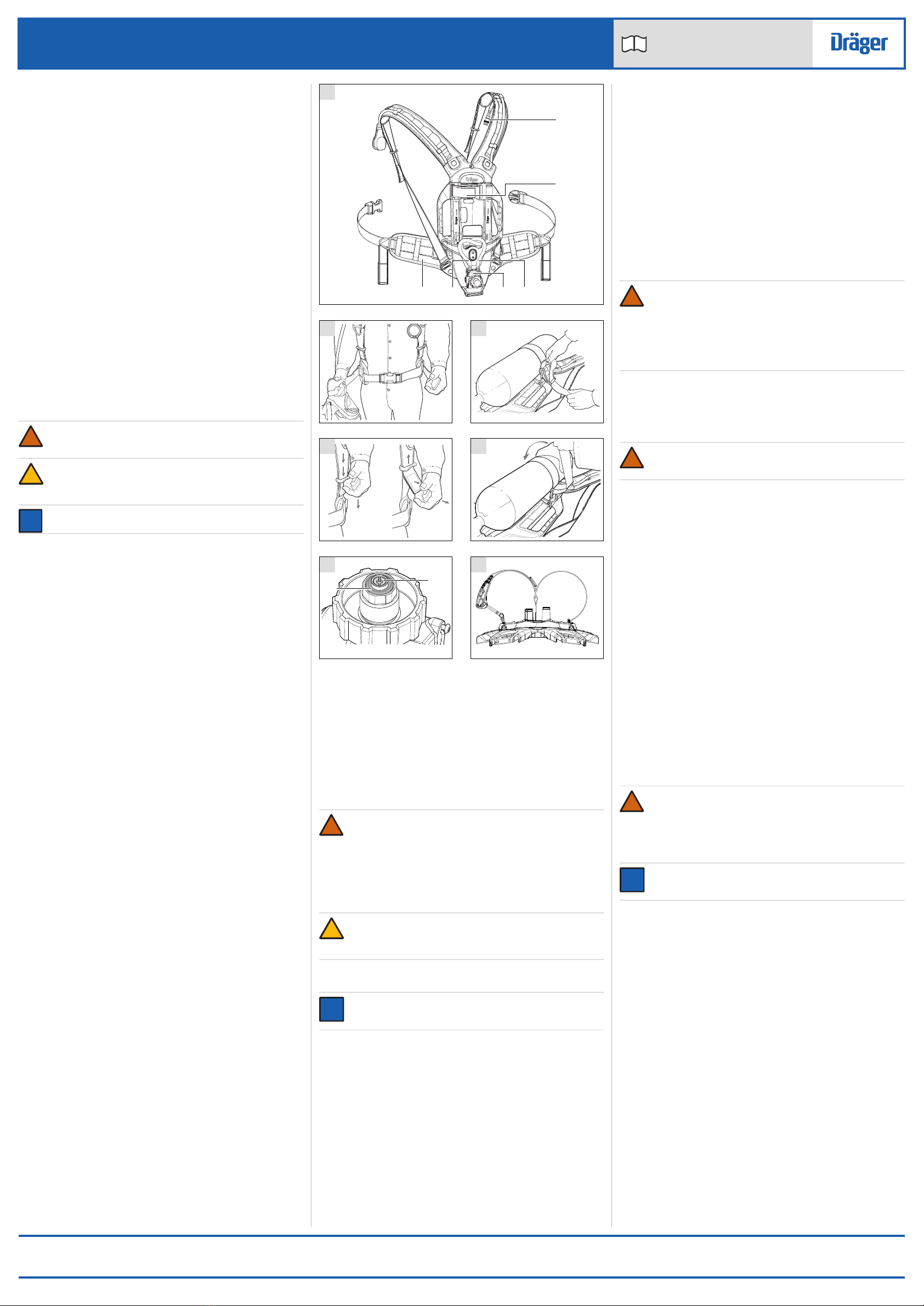

2.2 Feature description

The carrying system has a carbon-composite backplate, with adjustable

shoulder straps and waist belt connected using quick release connectors.

A waist pad (Fig 1, Item 6) connected at a flexible joint compensates for

the twisting and bending of the user. Cylinder mounting systems include a

single cylinder strap (2) or a universal cylinder strap for use with twin

cylinders.

The apparatus uses the Dräger high-performance pressure reducer (4)

that reduces cylinder pressure and supplies breathing air through a

medium-pressure hose (5) and coupling (1) to the attached lung demand

valve. A dual-pressure hose (3) supplies air to the whistle when it is

activated, and has an internal capillary tube that supplies high-pressure air

from the cylinder to the gauge. Air hoses and modular components of the

monitoring system are integrated into the backplate to prevent snagging

and enhance component protection.

Compressed air cylinders, lung demand valves and face masks

The Dräger PSS 5000 Series is compatible with steel or composite

material cylinders of 4 to 9 litre capacities, and 200 or 300 bar pressure.

Full descriptions and user instructions are contained in separate

instructions supplied with the cylinder, mask or lung demand valve.

2.3 Intended use

The Dräger PSS 5000 Series breathing apparatus, when fitted with a

cylinder, lung demand valve and face mask, is intended for use by

emergency services and in industrial applications where a high level of

respiratory protection is required. The assembled breathing apparatus

provides the wearer with respiratory protection for working in contaminated

or oxygen-deficient conditions, and is suitable for fire fighting.

The cylinder, lung demand valve, face mask and other accessories used

with this product must be certified Dräger components, assembled in an

approved configuration. Contact Dräger for further information.

Use in potentially explosive atmospheres

The PSS 5000 Series is type tested as suitable for use in potentially

explosive atmospheres. Electronic sub-assemblies are ATEX certified.

All combinations are suitable for use in hazardous areas up to and

including zone 0 and zone 20.

2.4 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

declaration of conformity or www.draeger.com/product-certificates).

!

!

2.5 Explanation of marking and symbols

Refer to the relevant authority for explanation of approval body symbols

and marking on the equipment. Examples of other marking on component

parts of the breathing apparatus are:

BRAC-1359 – Dräger serial number

08/09 – Month and year of manufacture

3356812 or R21034 – Dräger part number

SF – Standard force coupling

LF – Low force coupling

3 Use

WARNING

Only trained and competent personnel may prepare and use

breathing apparatus. Ensure that any accessories, ancillary

equipment and other protective clothing items do not interfere with

the apparatus and do not create a safety hazard.

The effective working duration of the apparatus is dependent on

the initial air supply available and the breathing rate of the wearer.

Fill all air cylinders to their full rated pressure prior to use, and do

not commence any operation using a cylinder that is less than

90 percent full (or greater when national regulations dictate).

CAUTION

Do not apply excessive force or use tools to open or close a

cylinder valve, and do not drop or throw down the breathing

apparatus.

3.1 Preparation for use

NOTICE

The face of the pressure gauge may be fitted with a thin flexible

protective covering. Remove this covering before first use.

1. Carry out a visual inspection of the apparatus (see Section 3.5.1).

2. Fit the air cylinder (see Section 3.5.2).

3. For breathing apparatus with a medium-pressure coupling for the lung

demand valve, disconnect and then reconnect the male coupling. To

connect, press the male coupling into the female coupling until an

audible click is heard. If there is any difficulty disconnecting or

connecting, see the troubleshooting information in Section 4.

4. Press the reset button when using a positive-pressure lung demand

valve (see the Instructions for Use supplied with the lung demand

valve).

5. Carry out a full functional test of the apparatus (see Section 3.5.3).

6. Connect the lung demand valve to the face mask and check the

security of attachment by gently attempting to pull the coupling apart.

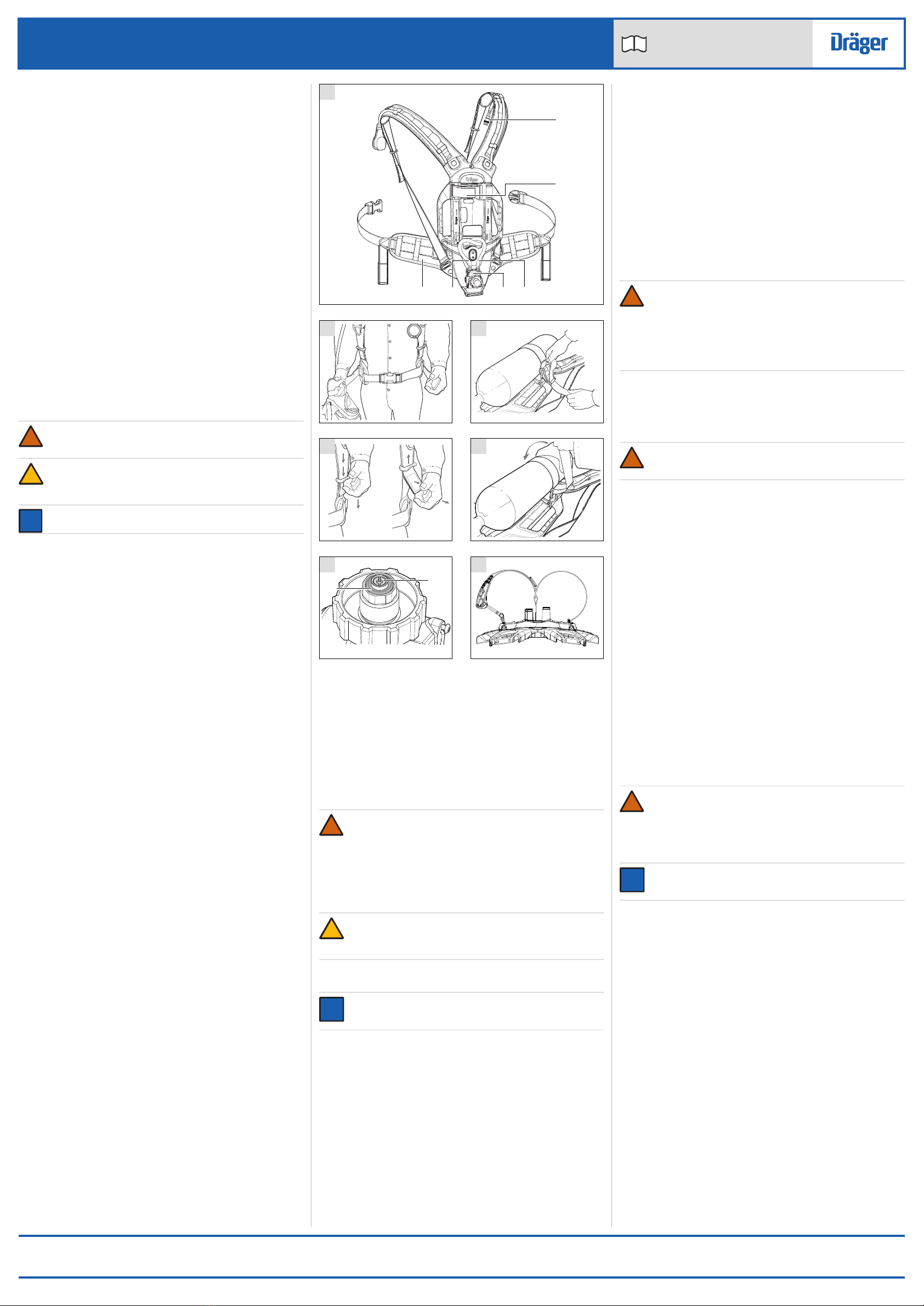

3.2 Putting on the breathing apparatus

1. Fully loosen the shoulder straps and waist belt and put on the breathing

apparatus.

!

2. Check that the shoulder pads are not twisted and take the weight of the

system on the shoulders by pulling the shoulder straps. Do not fully

tighten at this stage.

3. Close the waist belt buckle and pull the ends of the waist belt forward

until the strap padding fits securely and comfortably over the hips

(Fig 2). Tuck the belt ends behind the waist pad.

4. Pull the shoulder straps until the breathing apparatus rests securely

and comfortably on the hips. Do not over tighten. Pull the strap

retainers down to secure the strap ends (Fig 3).

5. Fully loosen the head straps of the face mask and place the neck strap

over the back of the neck.

6. Press the reset button when using a positive-pressure lung demand

valve.

7. Open the cylinder valve slowly, but fully, to pressurize the system (if

two cylinders are fitted, fully open both cylinder valves).

8. Put on the face mask and check for tight fit (see the Instructions for Use

supplied with the mask).

3.3 During use

WARNING

Fully open all cylinder valves and ensure that they remain open

during use.

Users should be in a safe area before the whistle warning

commences. Evacuate to a safe area immediately if warnings

commence during an operation.

Using the supplementary air supply will use air from the cylinder

and rapidly reduce the working duration of the apparatus.

●Regularly check the remaining cylinder pressure on the gauge.

●If supplementary air is required, briefly press the rubber cover at the front

of the lung demand valve to deliver extra air into the face mask..

3.4 After use

WARNING

Do not remove the breathing apparatus until in a safe breathing

environment.

1. Loosen the face mask straps. As the seal to the face is broken, press

the reset button when using a positive-pressure lung demand valve.

Remove the face mask.

2. Close the cylinder valve or valves.

3. Press the rubber cover at the front of the lung demand valve to vent

the system fully. Press the reset button when using a positive-pressure

lung demand valve.

4. Release the waist belt buckle.

5. Lift the shoulder strap ends to release the strap retainers (Fig 3) and

then lift the shoulder strap buckles to loosen the straps.

6. Remove the breathing apparatus and face mask.

7. Remove the air cylinder (see Section 3.5.2) if required.

8. Carry out the after use tasks in the maintenance table (see Section 5).

9. Pass the breathing apparatus to the service department with details of

any faults or damage that occurred during use.

3.5 Common user tasks

3.5.1 Visual inspection

A visual inspection must check the full breathing apparatus including all

component parts and accessories. Check that the equipment is clean and

undamaged, paying particular attention to pneumatic components, hoses

and connectors. Typical signs of damage that may affect the operation of

the breathing apparatus include impact, abrasion, cutting, corrosion and

discolouration. Report damage to service personnel and do not use the

apparatus until faults are rectified.

3.5.2 Air cylinder fitting and removing

WARNING

High-pressure air release may cause injury to the user or other

personnel near the breathing apparatus. Close the cylinder valve and

fully vent the system before attempting to disconnect an air cylinder.

Impact damage to the cylinder valve or reducer connector may

prevent valve connection or cause an air leak. Handle the air

cylinder and breathing apparatus with care.

NOTICE

For other cylinder connector types, refer to the Instructions for Use

supplied for the connector.

Fitting a single cylinder with a threaded connector

1. Check the threads of the cylinder valve port and the pressure reducer.

Ensure that the O-ring seal (Fig 4, Item 1) and the sintered filter (2) in

the reducer are clean and undamaged.

2. Lay the backplate horizontal, with the reducer uppermost, and fully

extend the cylinder strap.

3. Insert the cylinder through the loop of the strap, and align the valve with

the reducer.

4. Lift the cylinder and backplate into the vertical position (supported on

the end of the cylinder opposite the valve).

5. Tighten the hand wheel of the reducer, using only the thumb and index

finger, until a definite metal-to-metal contact is felt. Do not use tools or

over tighten.

6. Place the unit back into the horizontal position.

7. Take up the slack in the cylinder strap (Fig 5).

8. Pull the strap over the cylinder to operate the cam lock (Fig 6) and

secure using the hook-and-loop fastening.

Removing a single cylinder with a threaded connector

1. Close the cylinder valve and fully vent the system.

2. Lay the backplate horizontal, with the cylinder uppermost.

3. Remove the free end of the cylinder strap from the hook-and-loop

fastening.

4. Lift the strap against the cam lock to release the buckle tension and

loosen the strap.

5. Disconnect the cylinder valve from the pressure reducer.

6. Lift the cylinder away from the reducer and remove the cylinder.

!

!

!