Side TMS 5001 User manual

TMS 5001

INSTRUCTIONS MANUAL

OPERATION MANUAL

INDEX

1.

INTRODUCTION

2.

GENERAL FACTS

3.

TECHNICAL DATA

3.1.

BLOW MOULDING MACHINE SPECIFICATIONS

3.2.

GENERAL INSTALLATION GUIDELINES

3.3.

SAFETY

3.4.

SAFETY DEVICES

4.

CUSTOMER PREMISES INSTALLATION INSTRUCTIONS

4.1.

UNLOADING THE MACHINE

4.2.

PLACING THE FEET ON THE MACHINE

4.3.

PLACING THE LEAD IN CONVEYOR

4.4.

PLACING THE PREFORM ELEVATOR

4.5.

PLACING THE DISCHARGE HOPPER

5.

OPERATION STAGES

5.1.

STRETCHING-BLOWING

5.2.

IMPERVIOUS CYLINDER

5.3.

PRESS

5.4.

MOULD

5.5.

BOTTLE MOULD BOTTOM PIECE

5.6.

OVEN STRETCHING

5.7.

OVEN

5.8.

PREFORM CARRIER

5.9.

DELIVERY

5.10.

PRESS FEED CONVEYOR

5.11.

LOADING AND NAILING

5.12.

NOZZLE COOLING

5.13.

HOPPER AND FEEDER

5.14.

CONVEYOR BRAKE

6.

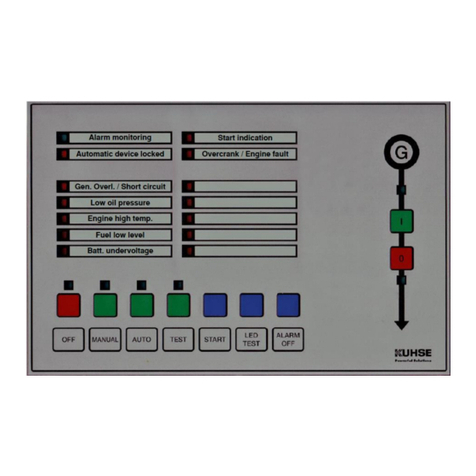

SCREEN

6.1.

EXTERNAL SWITCHES

6.2.

MANOEUVRES

6.3.

SCREENS

6.4.

ALARMS (MALFUNCTION – CAUSE – SOLUTION)

7.

FORMAT CHANGE

7.1.

PREVIOUS PROCEDURES

7.2.

FORMAT CHANGE START-UP

8.

BLOWING ADJUSTMENTS

8.1.

PARAMETERS OF THE HEAT FIXATION PROCESS

8.2.

LIST OF SHAPING DEFECTS AND SOLUTIONS

9.

MAINTENANCE

9.1.

CHECKING THE BLOWING MACHINE

9.2.

LUBRICATING THE BLOWING MACHINE

9.3.

MECHANIC LINING-UP

Page 3 of 106

TMS

5001

1.

INTRODUCTION

GENERAL INFORMATION

The information on this leaflet belongs to Servicio Industrial de Electrónica, SA (henceforward SIDE, SA); their

unauthorised public communication or reproduction, either totally or partially, is strictly forbidden.

This manual contains the necessary information to install the machine model 5001xl and to use it to produce

PET (polyethylene terephthalate) preform bottles.

In order to make the most out of the machine and to prevent accidents, defects or malfunctions, we recommend

customers to read the instructions in this manual carefully, and to keep it always handy in order to solve any

doubts that might arise.

The machine has been designed according to the Machinery Directive issued by the EU Council.

It is important to read this manual through in order to prevent serious damage on the machine due to wrongful

use.

PURPOSE AND CONTENTS OF THE MANUAL

This manual is intended to provide the necessary information and instructions to install and operate the SIDE

Mould blowing machine correctly.

The manual is divided into three main sections:

Operation: Including Operation stages, Screen and Format Change. These sub-sections describe the

characteristics of the Mould blowing machine and its components and also how to operate it.

Blowing adjustments: This section explains the elements that must be adjusted and the parameters that must

be set in order to produce superior quality containers.

Maintenance manual: This section deals with the necessary maintenance works on the machine and its

components and it also explains when and how to implement them.

The issues are dealt with in different sections and the sections are divided into numbered parts and

subsections. Each section includes charts, figures, diagrams and pictures in order to help understand the

contents.

TIPS ON THE USE AND PRESERVATION OF THIS MANUAL

This manual is intended for operators using or monitoring the SIDE Mould blowing machine on a daily basis.

The manual does not replace the specific training of operators, who must have worked with SIDE Mould

blowing machines in the past or have taken part in a specific training course on this machine taught by the

SIDE, SA staff.

This manual is an important part of the machine and must be preserved for future reference during the

operating life of the machine.

It must always be kept in a safe place, away from dust and damp and it must be available for whoever needs

to take a look at it; if the manual gets damaged and this impairs reading, even partially, users must apply for a

new copy to the machine manufacturer.

Page 4 of 106

TMS

5001

SIDE, SA reserves its right to modify the data and technical features of this manual without previous notice,

as part of its continuous improvement programme concerning blowing machines and parts.

SIDE, SA is at the disposal of its customers and it will be willing to listen to any improvement proposals

concerning this manual, provided they serve to enhance the fulfilment of the purposes for which it was written

in the first place or to correct any mistakes in it.

TECHNICAL ASSISTANCE

The SIDE Technical Assistance Service has been conceived to provide its customers with information, spare

parts or on site assistance concerning the Mould blowing machine on demand.

Technical Assistance Service:

Servicio Industrial de Electrónica, SA

C/ Llinars s/n - Polígono Industrial Monguit,

08480 L’AmetlladelVallés

Spain

Phone no. +34 93 846 30 51

Fax no. +34 93 849 22 11

The document to apply for technical assistance or spare parts should include machine ID data, which appear

on its ID plate.

These data consist of information about the machine model and the FM number (see figure 1).

You should use original SIDE, SA spare parts only

CE MARK

The 5001xl machine has been awarded the CE approval, as stipulated in Council Directive 89/392/CE. The

mark is in the ID plate on the machine (Figure 1).

The original, signed “CE Declaration of Conformity” is handed in together with the Mould blowing machine; the

owner must keep this document and hand it in to the new owner should the machine be sold.

Page 5 of 106

TMS

5001

2.

GENERAL FACTS

INTRODUCTION

This section contains the essential information of the machinery directive for the observance of the safety

norms in general, the assessment of the risks deriving from the use of the machine and the determination of

the environmental requirements.

Failure to comply with the indications in this section or in other sections of this manual might impair the efficiency of

the safety devices on the machine, provoking accidents and damaging the operators.

REFERENCE STANDARDS

The TMS 1002e machine and its components have been designed in consonance with the CE standards in

force and also according to the European and national standards concerning this sector as listed in the Council

machinery directive (law 2006/42/CE).

The main harmonised standards applied to this project have been included next:

EN 422 2009

EN 954 2007

TEMPERATURE AND HUMIDITY

The SIDE Mould blowing machine should only be used in places with a 15ºC to 45ºC room temperature range

and with a relative humidity below 70%. The storage temperature must range between 5ºC and 50ºC.

OPERATING TEMPERATURE

The Mould blowing machine must be preserved from atmospheric agents (rain, hail, snow, fog, etc.).

Warning: in a corrosive atmosphere the maintenance methods and the frequency of the revisions must be

scheduled accordingly so as to avoid the excessive wear of the components.

This machine has not been designed for use in explosive or partially explosive atmospheres: thus, it is strictly

forbidden to use it under such conditions.

LIGHTING

Lighting in the workplace in which the machine has been installed must allow the identification of the buttons

and keys as well of the commands and emergency stop devices.

It must also guarantee safety during common maintenance works; the owner remains the sole responsible for

complying with the lighting levels established by the standards in force.

VIBRATIONS

Under normal operating conditions and provided the indications in this manual are met, the machine vibrations

will not provoke dangerous situations. If anomalous vibrations are noticed, stop the machine immediately and

call SIDE, SA technical assistance service.

WASTE AND ENVIRONMENTAL POLLUTION

Page 6 of 106

TMS

5001

Users should comply with the European standards and directives in force concerning the treatment and

disposal of the pneumatic oil and lubricants used on the machine.

MACHINE NOISE LEVEL

The noise emitted for the machine is 85dB.

For this, all the operator into the machine area must use obligatory audition protection.

GARMENT STANDARDS

The staff operating the machine or carrying out maintenance works on it should observe the essential national

safety requirements in force concerning clothing.

In general terms, safety slip resistant shoes and wearing moccasins, clogs, slippers and any other shoes

hindering the mobility of operators is banned.

Clothing should match each task: overalls or aprons must be made in natural fibre materials (such as cotton)

with a low ignition temperature and they should not be stained with lubricant.

When working in heat-radiating areas the protection gloves should be used. Splash proof goggles must be

worn in those areas in which molten material splash risks or chipping hazards may occur.

Note: while at work, operators should not wear bracelets, watches, rings or chains that might hinder their

mobility or get hooked in the machine components. When working near movable parts, operators must make

sure neither their clothes nor their hair is caught by them.

WARRANTY

The warranty terms and conditions and its duration have been set out in the purchase agreement subscribed

by the purchaser and SIDE, SA

COVERAGE

It will cover all the broken parts or those presenting an excessive wear due to the amount of operating hours.

Once a component under the warranty period has been replaced, it will have to be sent to SIDE, SA should

the latter ask the machine owner to do so for verification purposes.

The warranty concerning any peripheral equipment supplied through SIDE, SA and purchased from other

manufacturers will be that provided by the latter, but it will not exceed the terms and conditions of the warranty

set out and agreed on by the Seller and the Purchaser.

WARANTY EXCLUSION PROVISION

Machine failure due to natural wear (washers, detent bridles, belts...), wrongful manipulation, wrongful use,

collision, meteorological reasons, voltage changes or lack of maintenance according to the stipulations in this

manual will not be covered by the manufacturer during the warranty period.

In order to benefit from the warranty, it is a must to comply with the maintenance stipulations in the Mould

blowing machine manual.

The grease for the lubrication circuit must be KLUBER UH 1 14-1600 GREASE, in order to guarantee the good

operation of the system.

Page 7 of 106

TMS

5001

Repair works implemented by the Owner or by third parties without the previous explicit authorisation of the

Manufacturer will always fall within the responsibility of the Owner and it will void the Owner’s right to present

any claims against the Manufacturer.

Repair works implemented by technicians other than those appointed by the Manufacturer or without the

Manufacturer’s explicit authorisation will void the warranty.

The Manufacturer will only be liable for those issues concerning the Mould blowing machine described in this

Manual and any subsequent claim for damage or for any harms caused by the flaws or defects detected on

the machine.

Page 8 of 106

TMS

5001

3.

TECHNICAL DATA

3.1

BLOW MOULDING MACHINE SPECIFICATIONS

MAINS

Input voltage (+ground +neutral):

Three phase 380 V

Admissible volt drops:

+ / - 5%

Frequency:

50 / 60 Hz

Admissible variation:

+ / - 5%

Total installed power capacity (Kw):

150 (1)

Average power consumption (Kw):

80 (2)

(Other optional voltages and frequencies).

HIGH AIR PRESSURE

High air pressure (bar):

40

Air quality: Dry, cold, oil free (food processing quality).

LOW AIR PRESSURE

Low air pressure (bar):

7

Necessary flow rate (m3/h):

50

Air quality:

Dry

COOLING WATER

Cooling water pressure (bar):

10 (máx)

Cooling water temperature (ºC):

8-10

Cooling power (Kcal/h).

16000

GENERAL DATA

Workplace temperature (ºC)

15 / 45

Premises:

Indoors

Relative humidity (%):

25 / 70

Noise level: 85 dB

HEATING OVEN

Total heating power capacity (Kw):

102(3)

Number of heating modules:

5

Number of heating areas:

5x16

Number of bulbs per module:

16

Voltage adjustment range:

0 to 220 V

Page 9 of 106

TMS

5001

PRESS UNIT

Number of cavities:

1

Minimum distance between the trays

(Closed mould):

480 mm

Maximum distance between the trays

(Open mould):

905 mm

CONVEYOR SYSTEM

Number of units conveyed:

50/25

Size:

80 mm

STRECHING-BLOWING UNIT

Mould stretching course (mm):

800

Mould stretching strength (Kg):

1750

Impervious strength (Kg)

(at 10 bars):

4500

Pre-blowing pressure adjustment

Range (bar):

0 to 10

MIN / MÁX BOTTEL DIMENSIONS

Minimum volume

10 litres

Maximum volume

30 litres

Maximum volume 50 litres for XL

* Ask for further capacities

MACHINE DATA

Mechanical speed (cycles/hour):

950

Maximum height (preform elevator):

3350

Weight (Kg):

9500

Mould weight (Kg): 258

Tool for mould colocation weight (Kg): 43

(1) These may vary depending on the machine options.

(2) These parameters will vary according to bottle format and size, as well as to environmental conditions.

(3) Maximum power allowed by law.

Page 10 of 106

TMS

5001

3.2.

GENERAL INSTALLATION GUIDELINES

On receiving the SIDE blow moulding machine, the owner must check the packaging (if any); if it has suffered

any damaged during transport or if the consignment is not complete, the owner should contact SIDE, SA

technical assistance services immediately.

INSTALLATION, MAINTENANCE AND DISMANTLING

The blow moulding machine must be installed by the owner. The operation tests and the initial start-up must

be implemented by SIDE, SA technicians, except if otherwise stated in the purchase agreement.

It is the user who must plan, project, build up and check the operation of the facilities required for the machine

to function, namely: power feeding and distribution, air and water supplies for the cooling system.

The owner will have to replace both the blow-moulding machine and the auxiliary devices taking the

indications, recommendations and specifications provided in this manual into account and pursuant to the

sector directives and laws in force.

The following general indications are intended to facilitate the installation of the blow moulding machine

pursuant to the safety standards in force.

- Read this manual carefully.

- Make sure the facilities observe the corresponding safety standards.

- Make sure the facilities do not hinder the safety of the blow moulding machine.

- Make sure that the facilities that must be connected to the blow moulding machine meet the manufacturer

specifications.

- Make sure that the installation and maintenance staff – be it your own or outsourced – is specialised and has

received specific training.

REQUIREMENTS OF THE INSTALLATON PREMISES

The TMS 1002e blow-moulding machine must be placed upon a flat, solid surface able to support its weight

(see technical data).

The installation premises must allow the free circulation around the blow moulding machine and the

implementation of the different operation tasks. Make sure, in particular, that there is enough room to

implement mould change operations as well as to access the switch plate and the interior of the machine.

3.3

SAFETY

The machine has a series of devices to prevent occupational accidents that could harm the

operators or facilities.

All components of the line characterised as having inherent risks, either due to their structure or the processes

involved, have been analysed according to the directive 2006/42/EC and EN 422 2009. In each case, the most

appropriate measures to eliminate or reduce the risks for operators have been taken.

All process drivers should read the following information carefully, which describes the areas of risk and the

corresponding preventive measures, as well as the areas in which there is a degree of "residual risk".

THE SAFETY DEVICES SHOULD BE INSPECTED PERIODICALLY AND CONTINUE TO BE

EFFICIENT.

Page 11 of 106

TMS

5001

THEY MUST NOT BE REMOVED OR DISMANTLED FOR ANY REASON: ANYONE WHO

DELIBERATELY DISABLES OR ALTERS THE SAFETY DEVICES WILL BE RESPONSIBLE

FOR ANY OF THE OPERATIONS THAT ARE CARRIED OUT AFTER SAID MODIFICATION.

3.3.1

RISK AREAS

Operating the machine during the normal production cycle does not present a risk to personnel as the

protective cabins prevent accidental access to moving parts.

If maintenance must be carried out on parts located inside the cabin, the various "risk” areas must be analysed,

which are classified by functional groups in the following table.

THE RISK AREAS ARE CONSIDERED TO BE THE PARTS OF THE MACHINE IN WHICH THERE

IS A RISK OF DEATH, SERIOUS INJURY OR ACCIDENT FOR THE OPERATOR OR PERSONNEL

IN GENERAL, IF THEY ARE EXPOSED DIRECTLY AFTER HAVING REMOVED OR DISABLED

THE SAFETY PROTECTIONS AND DEVICES.

3.3.2

GROUP

FUNCTIONAL GROUP

RISK AREA

DE

SCRIPTION

Press

Press Area

- Moving parts: risk of impact,

entrainment or crushing.

Transport

All the areas of displacement

- Moving parts: risk of impact,

entrainment or crushing.

- Risk of falls from the walkways.

Blow mould

Blow mould area

- Moving parts: risk of impact,

entrainment or crushing.

Nailing

Nailing area

- Moving parts: risk of impact,

entrainment or crushing.

Furnace

Lamp holder area.

- Risk of burns by direct contact

with the furnace containers.

Stretching/blowing

Press area blowing.

Mould area blowing.

- Parts of the blowing press and

moulds in motion: risk of

entrainment or crushing.

Loading

Upper platform loading area.

- Risk of falls from the upper

platform loading area.

Unloading

Bottle unloading area.

- Moving parts: risk of impact,

entrainment or crushing.

Electrical cabinet

Cabinet area.

- Current: risk of electric shock.

Boilers

Baseplate area.

- Compressed air: risk of explosion.

Leads

Press area

- Compressed air: risk of whiplash.

Preforms Elevator Entrapment area -Rotatory parts: risk of entrapment

Expulsion system Entrapment area -Moving parts: risk of entrapment

TO REDUCE OR ELIMINATE THE RISK OF AUDITION DISEASE OR BURN WHEN MANIPULATE

THE OVEN SEE THE SECTION 3.4.6

Page 12 of 106

TMS

5001

3.3.3

AREAS OF RESIDUAL RISK

Since all the process operations are automatic the machine has no residual risks; even when operating in

manual mode it is fully fitted with safety devices and guards.

However, despite the measures taken, a certain hazard level is inevitable if the functionality of the line is not

reduced.

Therefore, this section details a series of general criteria to identify the areas of "residual risk".

THIS CATEGORY INCLUDES THE AREAS IN WHICH THE OPERATOR IS EXPOSED TO A RISK

OF DEATH, INJURY OR ACCIDENT IF THE DANGER SIGNS ARE IGNORED AND THE SAFETY

MEASURES DESCRIBED

IN SECTION 02 AND 2.6 ARE NOT APPLIED AND IF THE WORK IS NOT DONE WITH CAUTION.

1. The control panel area must be considered as one of residual risk because the operator cannot see the

entire machine from this area: Before sending a movement instruction the operator must ensure that no one

is working on the machine or close to it.

2. In addition the entire machine must be considered as a residual risk area due to the presence of electric

and pneumatic energy and high temperature parts.

3. For the same reasons the furnace area also presents a residual risk of burns.

4. The electrical cabinets are areas of residual risk because even when the cabinet doors are open and the

safety devices are activated, high voltage still passes through the terminals where the cabinet is connected to

the external network: if the operator touches these contacts they can die from electrocution.

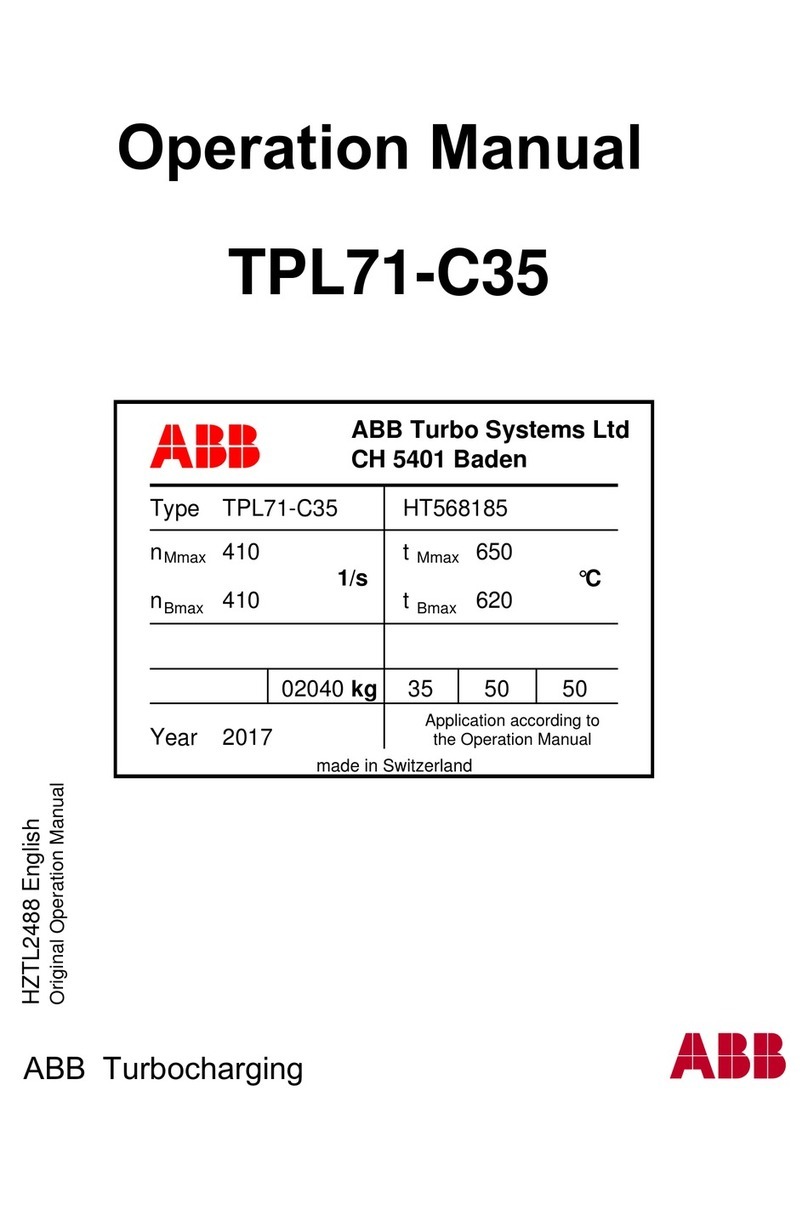

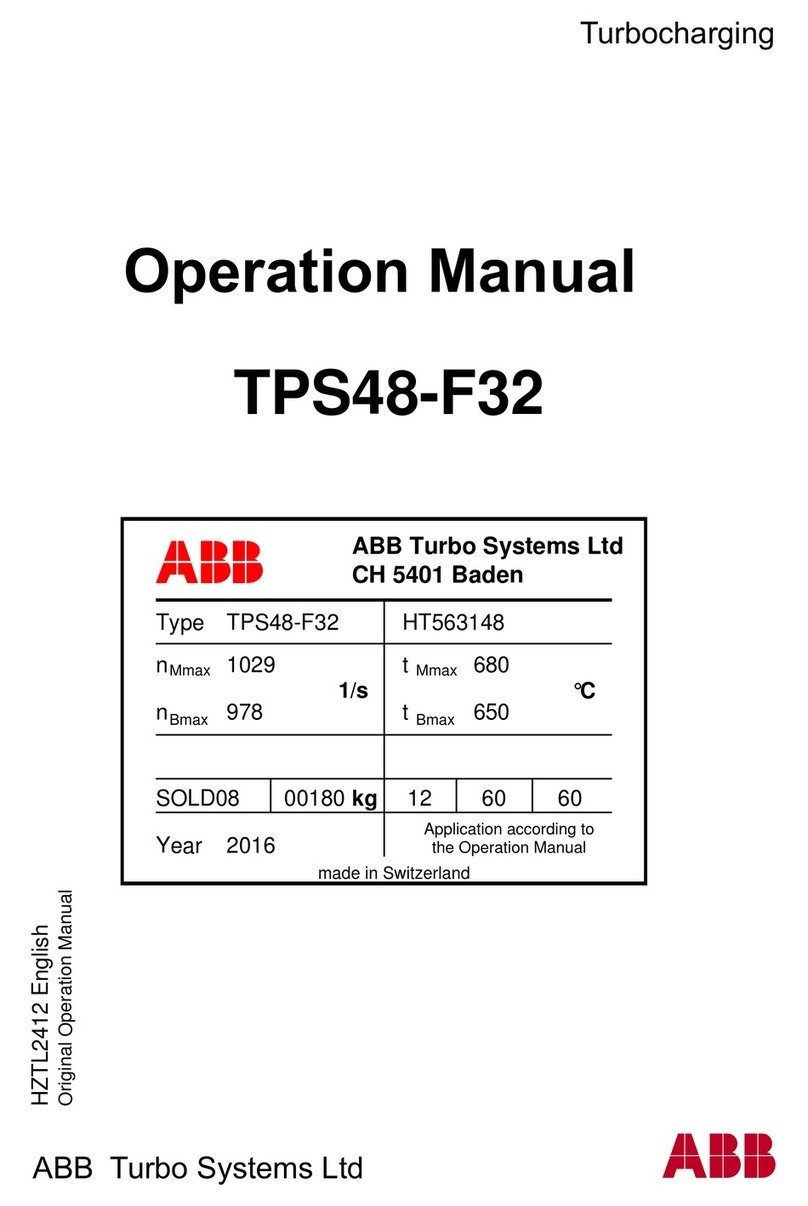

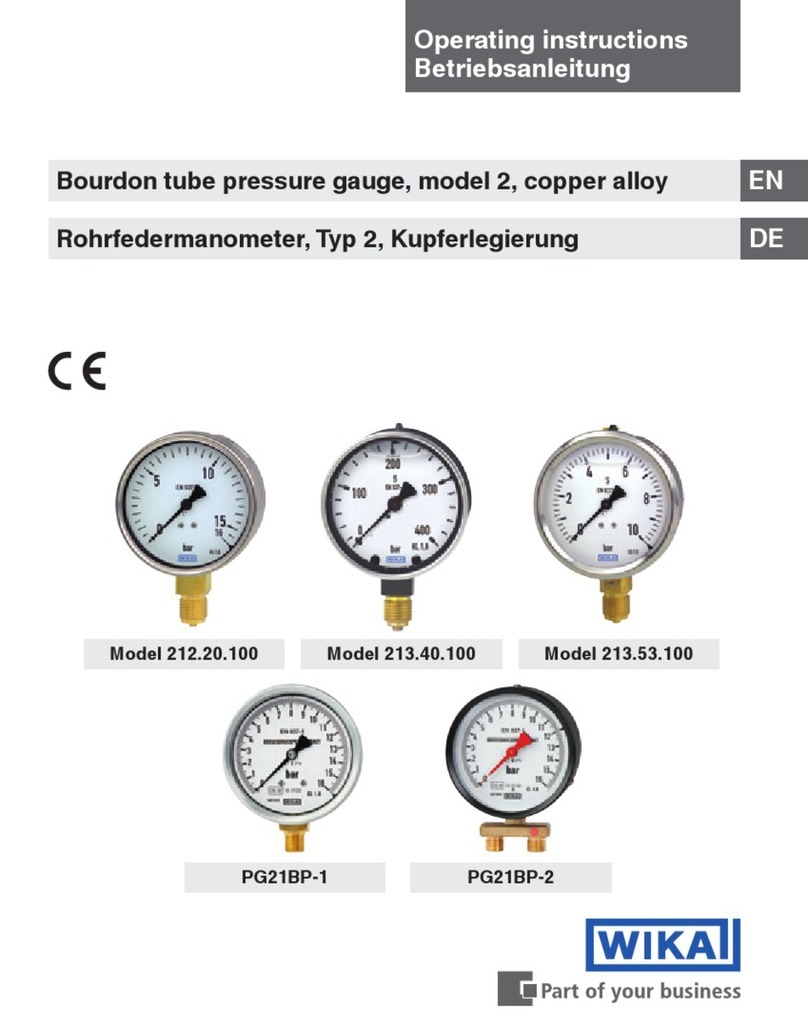

5. The pressure accumulator (40bar) and both the high pressure (40 bar) and low pressure (10bar) lines are

under pressure when the machine is ready to start the blowing cycle. If an emergency stop is activated these

are emptied automatically.

Before performing any operation, the isolation valves must be closed and the 40bar and 10bar lines

depressurized through the respective valves, verifying that the pressure gauges indicate "0".

THE PRESSURE GAUGES SHOULD READ “0”

3.4

SAFETY DEVICES

3.4.1

GENERAL INFORMATION

The machine has a series of built-in protections for the operator or other people exposed to inherent or residual

risks and hazards during the normal work cycle.

There are two types of safety devices:

- Passive safety devices: These are those that prevent the operator contact moving parts of the machine or

entering hazardous areas when the machine is operating automatically. (e.g. protective shell, fixed screens,

etc.).

Page 13 of 106

TMS

5001

- Active safety devices: These are the protective devices that block the machine when the necessary safe

conditions are not detected (e.g. limit switches, door safety center, etc.).

The coordination between both types of devices ensures compliance with the safety requirements needed to

protect personnel from possible risks and hazards.

SIDE S.A DOES NOT ACCEPT ANY RESPONSIBILITY IN CASE OF AN ACCIDENT WHERE A

SAFETY DEVICE IS ALTERED BY THE USER OR ANY OTHER DESIGNATED PERSON, THE

USER BEING SOLELY RESPONSIBLE BEFORE THE INSPECTION BODIES.

3.4.2

CABIN SAFETY DEVICES

ANY ALTERATION OF A SAFETY DEVICE BY THE USER EXEMPTS SIDE S.A FROM ANY RESPONSIBILITY

AND MAKES THE USER SOLELY RESPONSIBLE BEFORE THE COMPETENT INSTITUTIONS

IF THE MACHINE DOOR LIMIT SWITCHES FAIL THE EMERGENCY STOP IS ACTIVATED

REFERENCE

DESCRIPTION

PURPOSE

1

Anti-intrusion screens

(Typical)

- Panels of fixed screens on the machine

frame. Mechanical protection located in

areas where there is a risk to people.

2

Hinged doors.

- Hinged doors and limit switches are

activated when the door is closed.

3

Discharge valves (40bar)

Discharge valves (10bar)

- Valves responsible for emptying the air

from the machine in case of an emergency

stop.

4

Accumulator safety valve.

- Prevents overpressure within the

accumulator.

5

Blowing block switch.

-

OPENING THE DOORS WHEN THE AUTOMATIC CYCLE IS OPERATING CAUSES AN

INMEDIATE EMERGENCY STOP

3.4.3

EMERGENCY PUSH BUTTONS

These switches are located in different areas of the machine to allow the operator to immediately stop the

operation of the machine at any time:

- Cabin emergency push buttons.

- Internal emergency push buttons.

Page 14 of 106

TMS

5001

An emergency stop push button is a self-latching, red mushroom-headed button which transmits the

emergency stop command to the control system. When this button is activated the machine stops working

immediately.

Specifically, when activating an emergency stop push button:

- The electrical power is immediately disconnected.

- The upstream and downstream air supply circuit is interrupted.

While an emergency push button remains pressed it is not possible to carry out any operation; to

restore normal operation it must be unlocked by turning it in the direction of the arrow and

pressing the "EMERGENCY RESET" button located in the control panel.

A full description of the selectors can be found in section 6.1

THE EMERGENCY STOPS PUSH BUTTON MUST ONLY BE USED IN THE EVENT OF DANGER

TO THE OPERATOR OR MACHINE. USING IT TO STOP THE MACHINE WHEN THERE IS NO

DANGER PRESENT IS AGAINST THE SAFETY RULES AND CAN CAUSE DAMAGE TO THE

MACHINE

3.4.4

ELECTRICAL CABINET SAFETY DEVICES

3.4.4.1

ELECTRICAL CABINET DOOR SAFETY DEVICES

These safety devices interrupt the power supply to the entire machine in case of opening one of the master

cabinet doors.

The cabinet has a limit switch and a hardware device that automatically trigger the mains switch when a door

is opened.

3.4.4.2

FLASHING VOLTAGE INDICATORS

These indicator lights are located above the master and slave cabinet doors; they allow detecting if there is a

voltage in the cabinet when the door is open by remaining lit intermittently.

3.4.4.3

MAINS ISOLATION SWITCH WITH DOOR LOCK

It is located inside the cabinet and is activated from the outside using a control panel located on the cabinet door.

It has two positions, "0" (closed) and "1" (open); the cabinet can only be opened when the switch is set to "0", i.e., when

the cabinet is not energised.

•The full description of the selectors can be consulted in section 6.2.1

Page 15 of 106

TMS

5001

3.4.4.4

KEY SELECTORS

Some selectors, such as those which allow the machine to operate manually or which disable the cabin door

safety devices, can only be operated with a key; this safety measure prevents unauthorised personnel from

accessing the functions controlled by the selector.

•A full description of the selectors can be found in section 6.1

3.4.4.5

COLUMN LAMPS AND AUDIBLE SIGNALS

REFERENCE

DESCRIPTION

PURPOSE

1

Column Lamp

Flashing red - turned on to signal a

machine alarm condition.

Fixed green - turned on to signal the start of

machine cycle.

2

Indicator Light

- Machine alarm buzzer.

- Machine cycle start buzzer.

3.4.4.6

SECURITY KEYS SYSTEM

To achieve a succesful security procedure to protect to the operator from any posible accident or injury when

he needs to ge tinto the machine.

MUST FOLLOW THE NEXT PROTOCOL:

IT IS NECESSARY TO TURN OFF ONE OF THE TWO SECURITY KEYS (A OR B) TO SWITCH

OFF THE MACHINE AND GET INTO IT SAFELY.

IT IS A MANDATORY REQUIREMENT THAT THE OPERATOR TAKES WITH HIM ONE KEY (A

OR B) TO GUARANTEE THAT THE MACHINE DOESN’T WORK. IN THIS ACTION YOU CAN

ENSURE THAT ANY OTHER OPERATOR CAN’T TURN ON THE MACHINE WHILE ANOTHER

OPERATOR IS INSIDE IT.

A

B

Page 16 of 106

TMS

5001

3.4.5

WARNING, PROHIBITION AND MANDATORY SIGNS

Warning or prohibition signs designed according to ISO standards are placed to signal line areas in which work

should be done with caution or when it is considered that there is a residual risk.

IF USER REMOVES THESE SIGNS OR DOES NOT REPLACE THEM WHEN THEY ARE

DAMAGE, THEN, THEY BECOMA RESPONSIBLE FOR ANY DAMAGE ARISING FROM

FAILURE TO COMPLY WITH THE SAFETY MEASURES PROVIDED BY THE MANUFACTURER

3.4.5.1

WARNING SIGNS

The following warning signs are placed on the machine and on the tool for mold colocation:

-ELECTRIC CURRENT-

THERE IS HIGH VOLTAGE IN THE AREAS MARKED AND THEREFORE RISK OF ELECTRICAL

SHOCK, INJURY OR DEATH, THIS SIGN MAY INDICATE THE SUPPLY VOLTAGE VALUE

-MOVING MECHANISMS / PARTS-

INDICATES THAT THERE IS A DANGER OF INJURY OR DEATH

DUE TO THE PRESENCE OF MOVING MECHANISMS IF IT IS

OPERATED WITHOUT SAFETY DEVICES AND PROTECTIVE

ELEMENTS OR IF SUCH DEVICES ARE NOT EFFICIENT

-HIGH TEMPERATURE-

DANGER OR BURNS. THE HEATING LAMPS RADIATE HIGH TEMPERATURES.

3.4.6

OBLIGATORIES SIGNALS

Required signals are designed according to ISO standards are placed to signal line areas in wich work should

be done using a specific protection obligatori

-IS REQUIRED TO USE THE AUDITION PROTECTION WHEN THE MACHINE IS WORKING

-IS REQUIRED TO USE GLOVES RESISTANCE HOT SURFACES WHEN THE OPERATOR

WORKS TOUCHING THE OVEN

Page 17 of 106

TMS

5001

MACHINE

Page 18 of 106

TMS

5001

TOOL FOR MOULD COLOCATION

Block mould

Page 19 of 106

TMS

5001

4.

INSTALLATION ON THE USER’S PREMISES

4.1.

UNLOADING THE BLOWER

As has already been said, the machine must be installed following the indications provided by SIDE, SA in the

installation dossier. The instructions in this chapter are merely informative.

Maintenance tasks on the machine and its components must be implemented according to the following

indications:

- Prepare appropriate load lifting equipment with the

capacity to provide the safest working conditions.

- A crane, gantry crane or fork-lift truck must be used to

move or unload the blower.

- The blower has lifting points prepared for fixing hooks.

- When fitting fasteners (chains or strops), they must be

positioned so that the machine is always parallel to the

ground when being raised. Otherwise, loads at the joints

would exceed specifications, which could cause

damage to the machine.

4.2.

PLACING THE FEET ON THE MACHINE

The machine must be placed upon the adjustable feet, which will be

placed in advance making them coincided with the supports of the

machine frame.

LEVELLING

order

color

1

2

3

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

SMC Networks

SMC Networks MHZ2-10 Series Operation manual

BOSHART

BOSHART 850-WSP Operation, maintenance and installation manual

FLENDER

FLENDER FASTEX EC210 Assembly and operating instructions

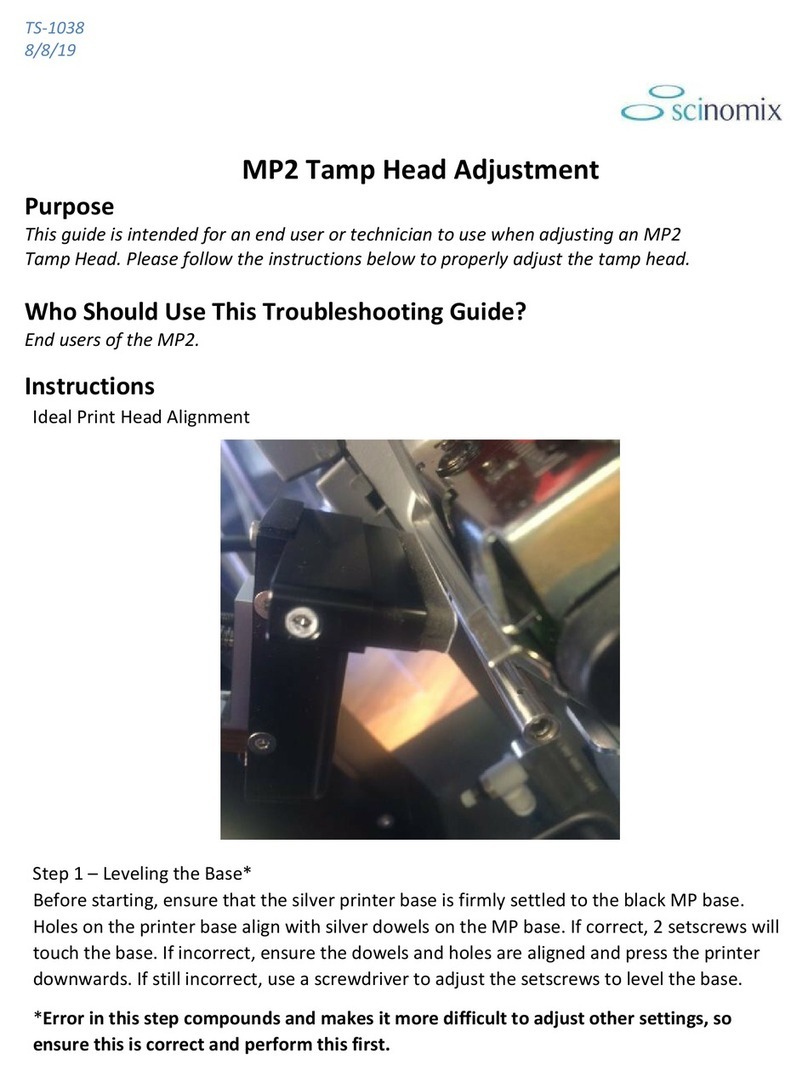

Scinomix

Scinomix MP2 troubleshooting guide

BOC Edwards

BOC Edwards 250 instruction manual

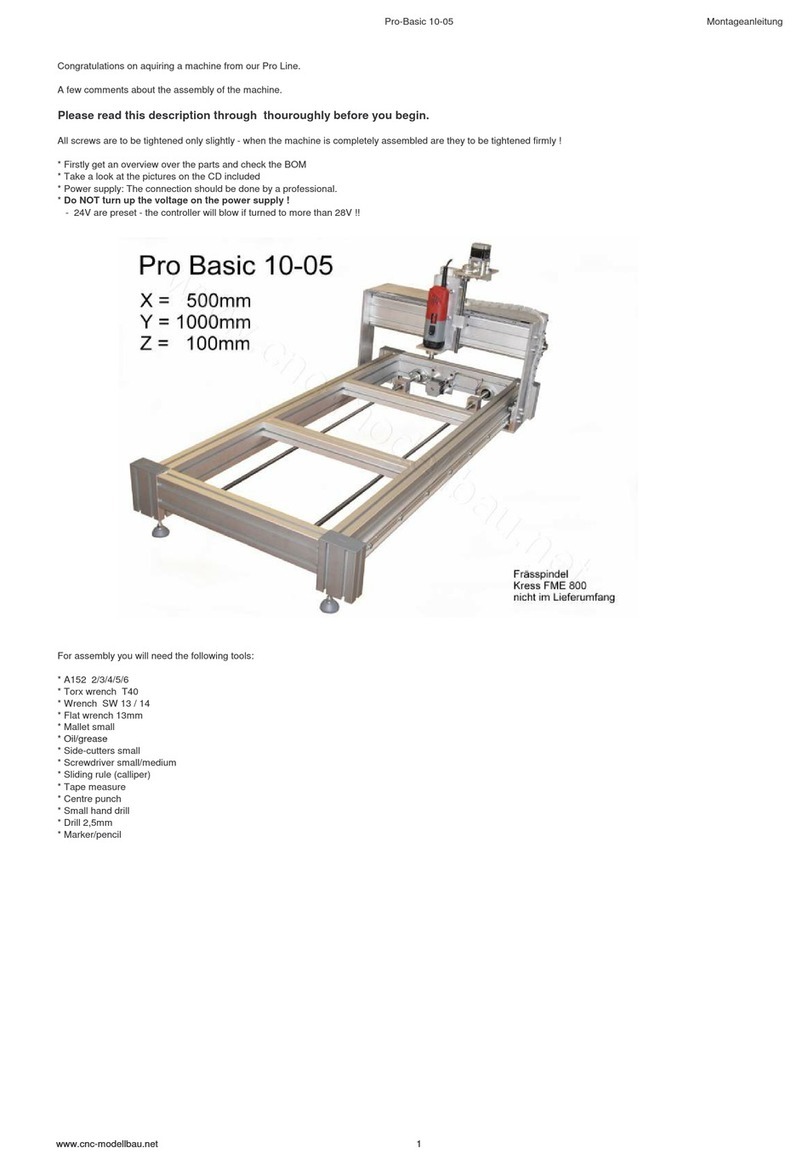

MechaPlus

MechaPlus Pro Basic Series manual