Contents ................................................................................................................... 1

I. Precautions before operation .......................................................................................... 2

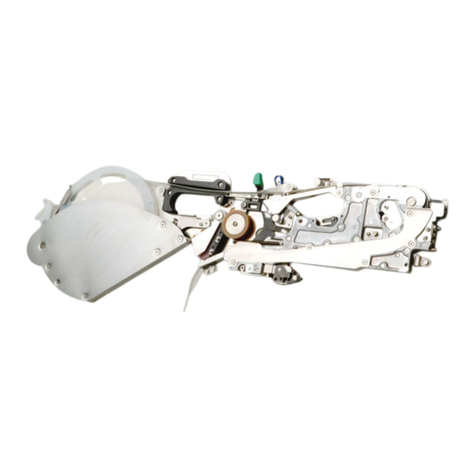

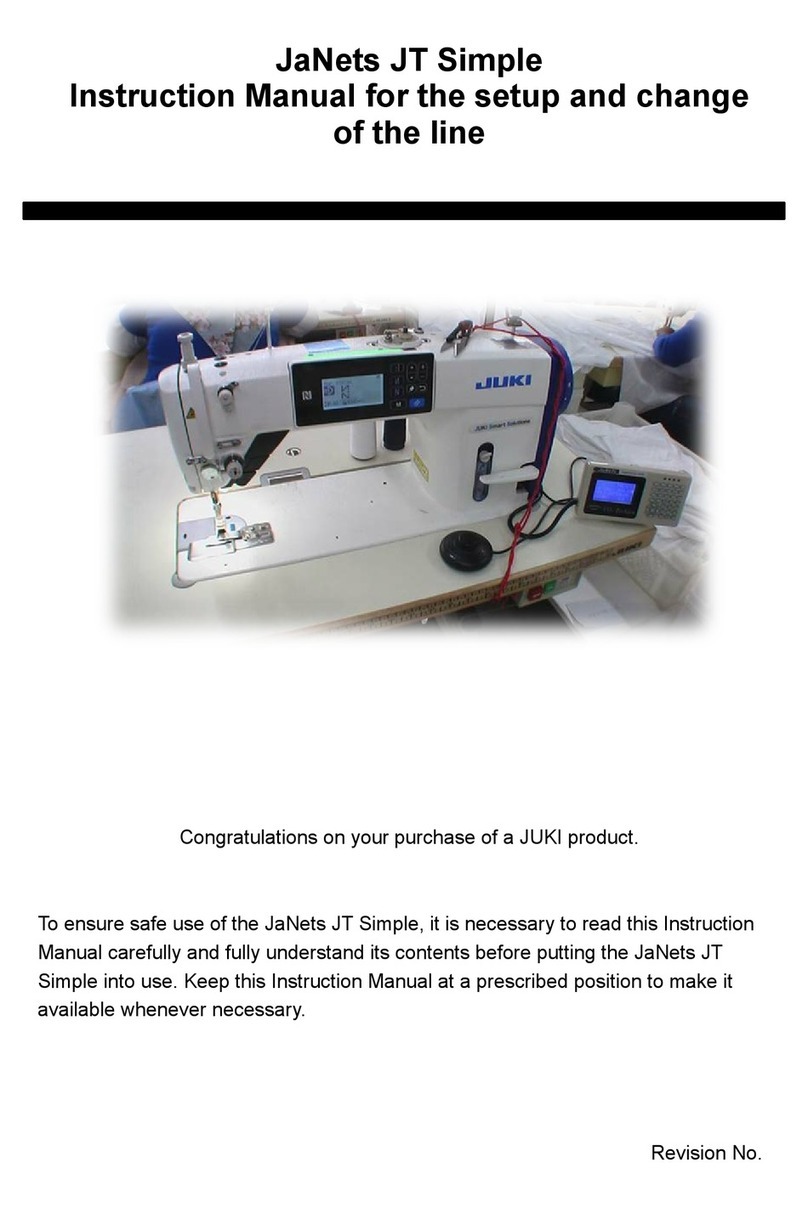

II. Name of main unit ............................................................................................. 2

1. Name of component ............................................................................................. 2

2. Standard accessories ................................................................................................ 3

Specifications ....................................................................................................... 4

IV. Installation ................................................................................................ 5

1. Removal of the needle .......................................................................................... 5

2. Removal of the feed bracket ................................................................................. 5

3. Removal of the work clamp foot ....................................................................................... 6

4. Mount the button sewing device on the feed bracket ............................................................ 6

5. Replacement of the needle guide .................................................................................... 7

6. Replacement of the feed plate .......................................................................................... 7

7. Install a feed bracket (with button sewing device) on the arm bed ............................ 7

8. Attach a needle .......................................................................................... 8

9. Replacement of lengthwise feed sensor slit .................................................................. 8

10. Origin Sensor Adjustment .................................................................................... 9

10.1 LK1900A/AN ........................................................................... 9

10.2 LK1900B .............................................................................. 11

V. Operation ....................................................................................................... 12

1. Preparation before Operation ....................................................................................... 12

1.1 Mount the button rising bar ........................................................................ 12

1.2 Changing the type of machine ....................................................................................... 12

1.3 Standard Pattern List ........................................................................... 14

2. Sewing procedure ....................................................................................... 15

VI. Maintenance ......................................................................................................... 16

.......................................................................................... 16