1 INTRODUCTION

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the BOC

Edwards Model 250 Water-Cooled Exhaust Trap. You must use the Exhaust Trap as specified in

this manual.

Read this manual before you install and operate the Exhaust Trap. Important safety information

is highlighted as WARNING and CAUTION instructions; you must obey these instructions. The

use of WARNINGS and CAUTIONS is defined below.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death

to people.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the

equipment, associated equipment and process.

The units used throughout this manual conform to the SI international system of units of

measurement.

1.2 Description

1.2.1 General

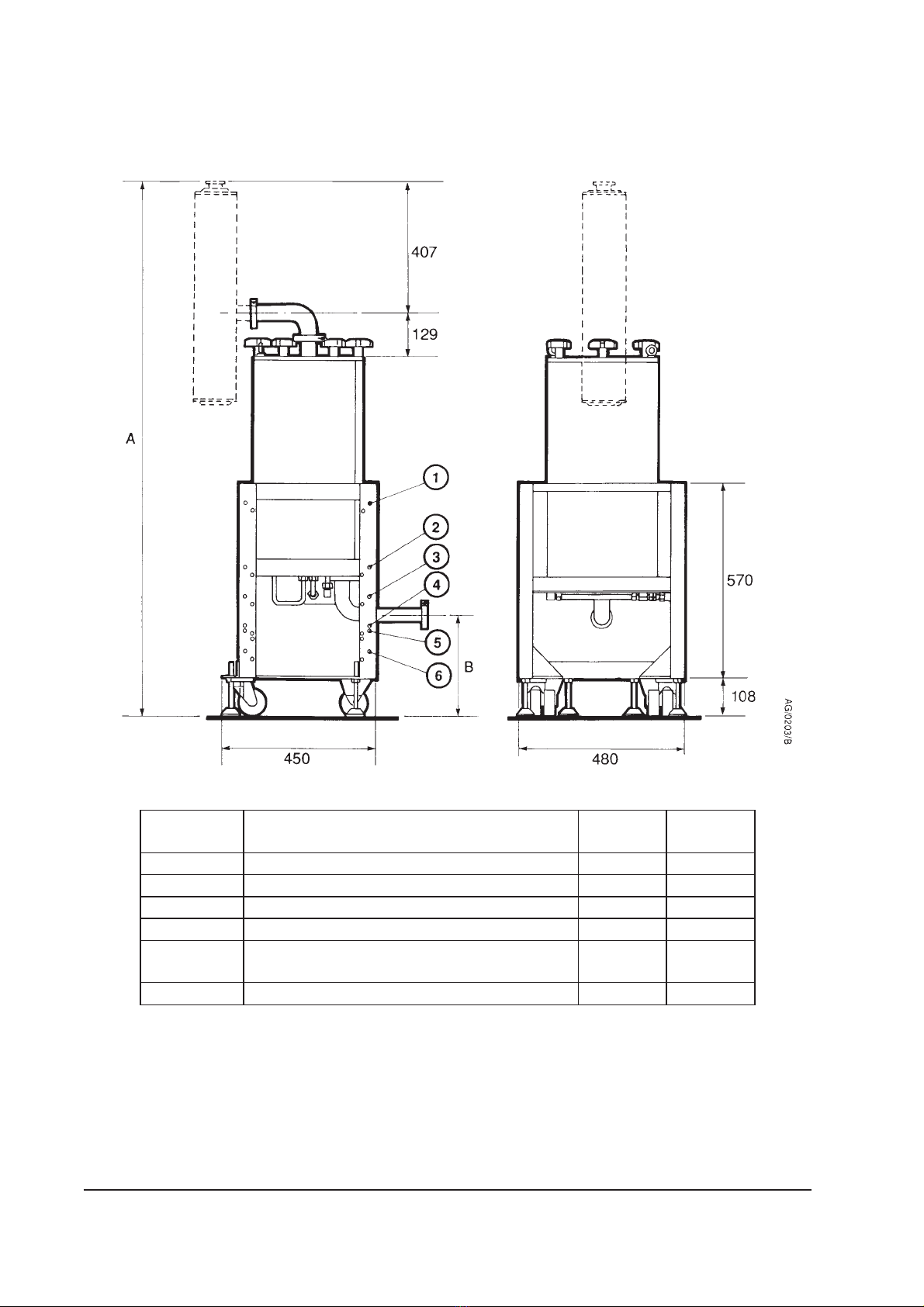

Refer to Figure 1. The Exhaust Trap cools the exhaust gases from the pump and causes

particulates to collect in the Exhaust Trap. This prevents the collection of particulates in the

exhaust-system. The Exhaust Trap is designed for connection to a pump which is used in an

LPCVD nitride process using dichlorosilane or hexachlorodisilane and ammonia. The

Exhaust Trap is not suitable for connection to a pump which is used in other processes.

The Exhaust Trap is designed to fit BOC Edwards CDP and QDP dry pumps and Drystar MKI,

MKII and QMKII dry pumping systems. Your system must incorporate a pressure switch to

shut-down the pump if the exhaust system becomes blocked.

The Exhaust Trap has a main outer body (6) which is mounted on a baseframe (12). You can

adjust the height of the trap-body in the baseframe to fit the Exhaust Trap to different pumps.

The baseframe has castors (10) for ease of movement of the Exhaust Trap and levelling feet (9) so

that you can securely locate the Exhaust Trap in its operating position.

Model 250 Water-Cooled Exhaust Trap 1