Siebring HEATWAVE HW150 User manual

WARM IT UP WITH AFREE SOURCE OF HEAT!

Siebring Manufacturing, Inc.

303 S. Main St. PO Box 658

George, IA. 51237

Ph. 712-475-3317

Fax 712-475-3490

www.siebringmfg.com

5-1-23

SECTION 1 - WARRANTY

1.1 KAGI WARRANTY. Kagi Heating Supplies & Manufacturing, Inc. (KHS) will warranty

parts and labor to the consumer for a period of twelve months from the date of purchase. KHS

warranties each burner sold will be free of defects in materials and workmanship under

normal use and service for a period of one year. Date of purchase will be date received by the

customer. See Kagi Burner manual for detailed warranty information.

1.2 HEATWAVE WARRANTY. HEATWAVE Warrants to the purchaser of this Multi-Oil Fueled

Heater Unit that it will repair or replace any part which in normal use proves to be defective in

material or workmanship within a period of ONE (1) YEAR from the date of purchase, provided

same is returned for factory inspection and warranty determination. The combustion chamber

(Limited Warranty) is warranted for a period of TEN (10) YEARS at a pro-rated schedule,

provided the heater is properly installed and maintained.

HEATWAVE does not warrant the paint finish as this is subject to abrasion, scratching, and

discoloration during installation and operation. The warranty does NOT cover any labor

charges involved with parts replacement or service unless preauthorized by Siebring Mfg., Inc.

in writing.

1.3 CONDITIONS THAT WILL VOID WARRANTY.

Using in the heater or adding to the storage tank substances, including, but not limited to the

following: paint, thinner, gasoline, other volatile liquids, or solvents, transformer oils, or gear

lubes. Some of these substances have a high chloride content which can oxidize HEATWAVE

stainless steel targets and chambers. It is illegal to mix any of these substances with waste oil

and doing so can cause a hazardous condition.

Tampering with internal components.

Not installing the heater properly as per instruction in this manual and/or according to local and

state codes.

Not maintaining the heater according to instructions in this manual or by authorized personnel.

Any part altered or abused.

Using parts other than those supplied by Siebring Mfg., Inc. to operate this heater

Over-firing the unit.

Warranty is limited to the original purchaser only, and is void if moved form original site of

installation.

SECTION 2 –GENERAL INFORMATION & HAZARDS

2.1 INTRODUCTION. The Heatwave heater by Siebring Mfg. provides the owner with a

dependable, versatile and simple means of burning # 1 and # 2 fuel oils, 10W –50W used

crank case oils and used automatic transmission fluid. Maintained correctly, the heater will

give years of service. Carefully read the owner’s manual before installing and using the unit.

In the event there is a problem with your heater or the installation of your heater, contact your

distributor for assistance.

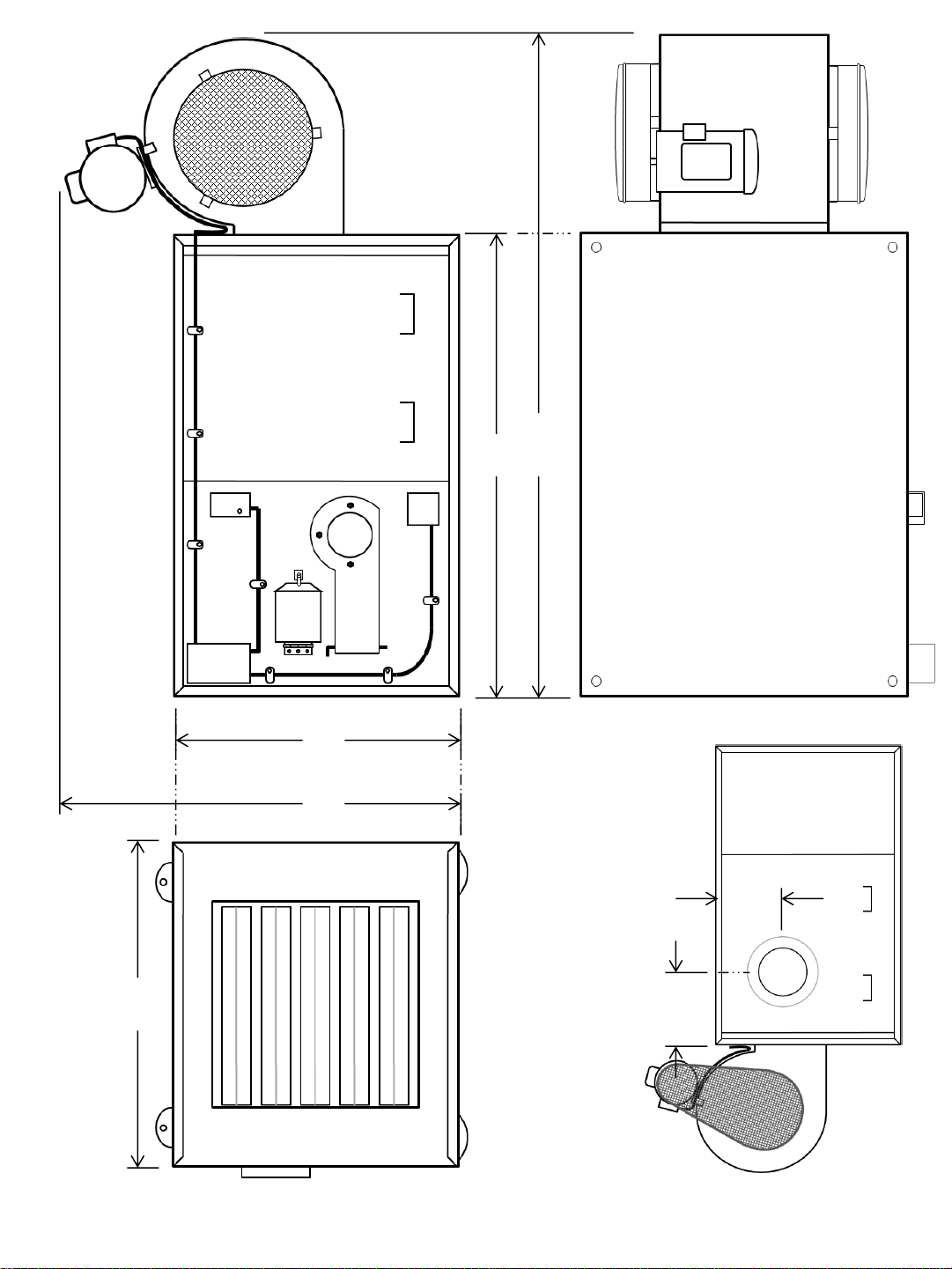

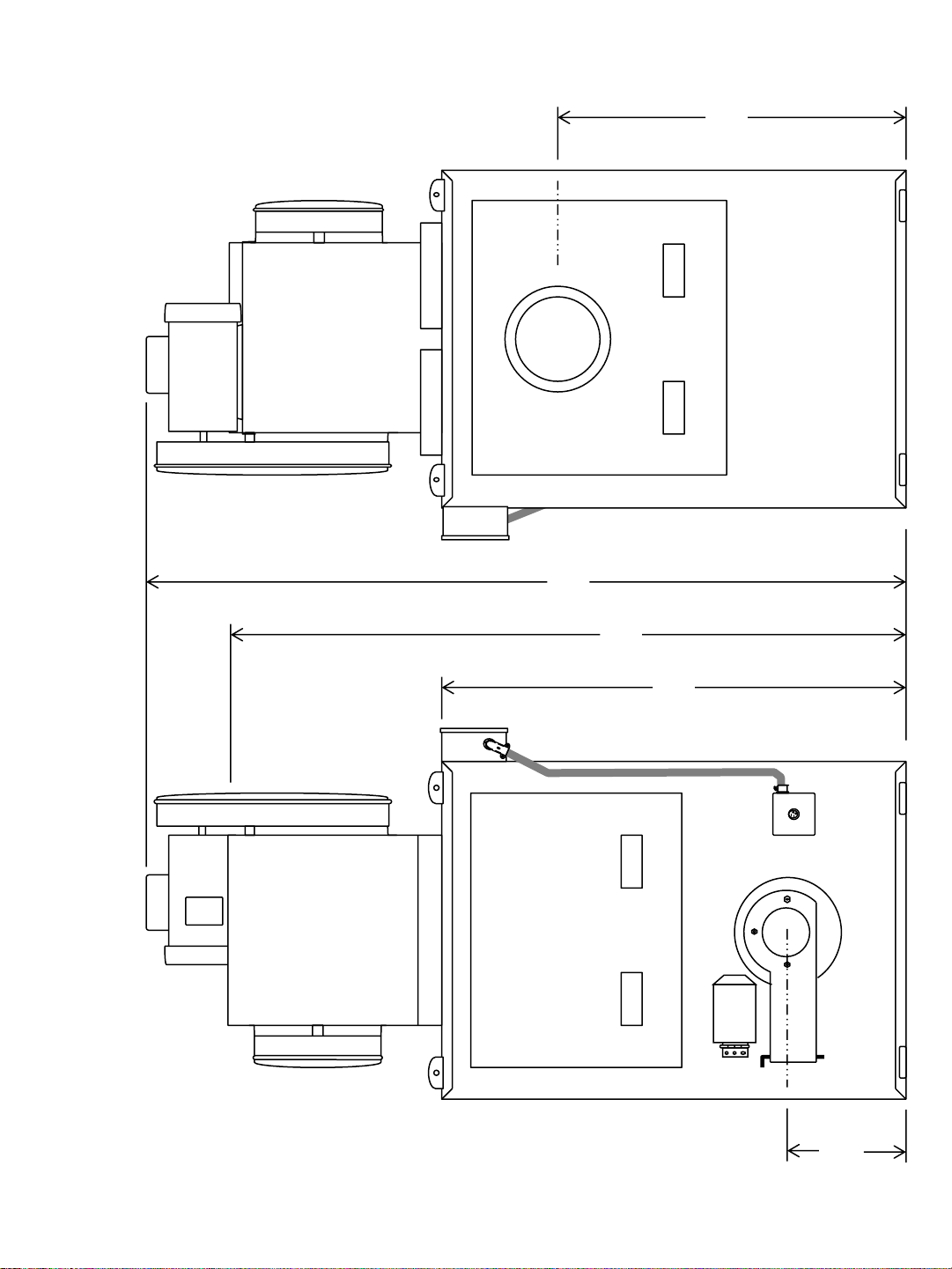

2.2 DIMENSIONS. Dimensions are calculated without the burner.

Heatwave 150 65” x 35” x 39”H Crated weight 700 lbs. (see figure 1)

Heatwave 250 75” x 36” x 49”H Crated weight 840 lbs. (see figure 2)

Heatwave 350 60” x 36” x 82”H Crated weight 1080 lbs. (see figure 3)

2.3 FIRING CAPACITIES.

Heatwave 150 1.1 –1.5 gallons per hour.

Heatwave 250 1.7 –2.0 gallons per hour.

Heatwave 350 2.5 –3.2 gallons per hour.

2.4 NON-RESIDENTIAL WARNING. This heater is for commercial and industrial use only.

This unit is NOT rated for residential use.

2.5 ADHERANCE TO CODES. Installation of this unit is to be done in accordance with all

state and local codes or authorized having jurisdiction over environmental control, fuel, fire and

electrical safety.

2.6 APPLICABLE CODES FOR HEATER INSTALLATION. National Fire Protection

Association (N.F.P.A.) codes for heater install.

NFPA 30 Flammable and Combustion Liquids Code

NFPA 31 Standards for the Installation of Oil-Burning Equipment Code

NFPA 70 National Electrical Code

NFPA 88A Standard for Parking Structures Code

NFPA 88B Standard for Repair Garages Code

NFPA 211 Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-BurningAppliances

The above codes available from the National Fire Protection Association,

1 Batterymarch Park, Quincy, MA. USA 02169-7471 Tel. 617 770-3000 www.nfpa.org

2.7 INSTALLATION. This heater and systems must be installed by an experienced, qualified

waste oil fired heater installer.

2.8 DUCTWORK. This heater is not designed for attachment or use with ductwork.

2.9 WARNING. Do not attempt to start the burner when excess oil, oil vapor or fumes have

accumulated. To prevent backfire that could harm personnel or possibly damage the unit,

NEVER press the reset on the primary control more than two times.

2.10 WARNING. Do not store gasoline or any other flammable liquids, or vapor producing

materials near the heater.

2.11 WARNING. This heater is not designed for use in hazardous atmospheres such as:

paint shops, feed mills, or any installations where explosive or flammable conditions are

present or could occur.

2.12 WARNING. Heatwave heaters by Siebring Mfg. rely on a natural gravity draft. Down

drafts (positive) pressures in the heater’s chimney will occur in buildings where negative

pressures are created by exhaust fans (car exhaust vents, spray booths, ventilation fans, etc.),

Do not try to use a power vent to overcome a downdraft pressure. An adequate air make-up

system is needed when exhaust fans are used.

SECTION 3 –HEATER INSTALLATION

3.1 Do not install heater on a combustible material of any kind.

3.2 Install heater in a location to utilize total heat throw.

3.3 Install heater in a location to permit a correct outdoor chimney exit to eliminate down

drafts, provide easy chimney installation and maintenance.

3.4 Install the heater in a location to permit as close as possible fuel supply.

3.5 Do not install heater more than 10 feet above top of fuel tank (see page ?? Learn about

special pump installations).

3.6 Before suspending the heater, check the supporting structure and reinforce if necessary

to support the heater/system. See figure 4 for unit weights.

3.7 Minimum clearances to combustibles:

Top 6” Chimneys 18”

Sides 18” Rear 18”

Front 24” Bottom 18”

3.8 Use threaded rod rated for applicable heater weight to suspend from a capable load

carrying ceiling structure.

3.9 Heater should be installed level for proper operation. Heater installed “not level” could

cause a hazardous situation in which personal injury or property damage could result.

3.10 When installing the heater, keep in mind that you must have reasonable access to the

unit for servicing.

3.11 Installation Diagram Page:

1. Chimney Cap 11. Electrical Service panel

2. Class “A” insulated pipe 12.Air Compressor (2.4 CFM+)

3. Barometric Damper 13. Pump with vacuum gauge

4. Capped Chimney “Tee” 14. Fill Pipe

5. Draft Reading Port 15. Water/sludge Drain

6. Oil Regulator (on burner) 16. Lenz Oil Filter

7. SecondaryAir Regulator 17. Vent Pipe

8. Burner 18. Check Valve

9. Room Thermostat 19. Oil Pick-up Strainer

10. Primary Air Regulator 20. Supply Tank

Notes:

-Do Not use compression fittings or unions on the suction side. Use flare fittings and threaded

fittings with thread compound.

-Do Not use Teflon tape.

-Do Not use air lines that have an automatic oiler.

-If shop air is 125 PSI or lower, the primary air regulator (item 10) is not required. If shop air is

125 PSI or greater, install primary air regulator and adjust air to 125 PSI or below.

-A moisture/water trap must be installed in the air line prior to the burner.

-Some state/local codes may require the supply tank to be vented outside (item 17).

4.1 Failure to provide proper venting of the heater exhaust gases could result in death, serious injury

and/or property damage.

4.2 Safe operation of any gravity vented heating equipment requires a proper air make-up system to

prevent heater exhaust gases from being drawn into the building which may cause death, serious

injury and/or property damage.

4.3 Never vent this heater into another heater’s chimney. This heater must have it’s own separate

chimney.

4.4 Inspect and maintain the chimney and air make-up system regularly.

4.5 Install a U.L. listed barometric draft control in chimney. Do not reduce or enlarge the vent pipe.

4.6 To prevent drawing exhaust gases into the building, keep barometric draft control at least two feet

form the heater, exhaust fans, etc.

4.7 Position draft control as shown in pages ??, gate hinge pins must be horizontal for proper

operation.

4.8 Secure all chimney/piping connections with 3 screws/rivets per joint.

4.9 Chimney clearance to combustibles –18 inches.

4.10 Do not install heat reclaimers, manual draft controls or any other type of restrictive controls in

the chimney.

4.11 Install an 8” diameter steel vent “tee” with a cap (for clean out) at the transition of the chimney.

4.12 Use 8” inside diameter class A insulated chimney pipe to vent exhaust gases through walls,

ceilings, attics, roofs, combustibles, etc. Consult state and local codes.

4.13 Vent chimney at least 3 feet above the roof and at least 3 feet higher than any portion of the

building, roof or obstruction within 10 feet of the chimney.

4.14 Do not use a rotating chimney cap. Use a non-restrictive cap.

4.15 Chimney caps should be at least 4 inches above chimney exit.

4.16 The chimney must be capable of producing a negative -.02 - .04 W.C. draft when hot as measured

between the heater and the draft control. Refer to section 5 “Draft.” Refer to section 3 for typical

chimney installation.

SECTION 4 –CHIMNEY INSTALLATION

SECTION 5 –DRAFT

SECTION 6 –FUEL SUPPLY TANK INSTALLATION

5. The chimney system connected to the Heatwave should have a negative -.02 - .04 W.C. draft

when hot (minimum of 10 minute run time) as measured between the heater and the draft control.

6.1 The fuel supply tank and supply line must be installed in accordance with the National Fire Protection

Association requirements, state and local codes and ordinances.

6.2 Regulations require oil storage tanks located inside the building not to exceed 275 gallons individually

and not to exceed 550 gallons in one building.

6.3 Locate fuel tank inside the building as close to the heater as possible. Not to exceed 25 feet to avoid oil

flow problems.

6.4 If possible, pitch/position fuel tank with the drain valve at the lowest point to drain off water. Sludge

may have to be removed manually.

6.5 Some areas may have special requirements for the fuel tank vent (exiting outdoors, above the roof line,

etc,) check local codes and ordinances. Keep vent clear.

Dimensional view of HW 150 (measurements) Figure 1

Dimensional view of HW 250 (measurements) Figure 2

Dimensional view of HW 350 (measurements) Figure 3

Dimensional view of HW 350 (continued) Figure 4

HeatWave Specifications Figure 5

Kagi Burner Drawing Figure 6

Furnace Installation Example Figure 7

Multi-Wall Chimney Installation Figure 8

Furnace Installation Example Drawing Figure 9

Floating Oil Pick-up (dirty tanks) Figure 10

Oil Primary Control Figure 11

Nozzle Exploded View Figure 12

ElectrodeAdjustment Figure 13

Air Regulator Exploded View Figure 14

Oil Regulator Exploded View Figure 15

Flame Characteristics Figure 16

Exploded view Air / Oil Solenoid Figure 17

Delta Pump Figure 18

Suntec J Pump Figure 19

Suntec 7740 Figure 20

Webster M17DN Pump Figure 21

Webster 1RR14 Figure 22

Pump / Motor Alignment Figure 23

Lenz Filter System Figure 24

Fan Belt Adjustment Figure 25

Breaker box Figure 26

Wiring Schematic Figure 27

Burner Wiring Diagram Figure 28

Wiring Burner Cord & Junction Box Figure 29

Honeywell Fan & Limit Control Figure 30

White-Rodgers Fan & Limit Control Figure 31

Terminal Strip Wiring Figure 32

Kagi Wiring - Drawing A Figure 33

Kagi Wiring - Drawing B Figure 34

Kagi Wiring - Drawing C Figure 35

Kagi Wiring - Drawing D Figure 36

Kagi Wiring - Drawing E Figure 37

Kagi Wiring - Drawing F Figure 38

Kagi Wiring - Drawing F (ICM) Figure 39

Kagi Wiring - Drawing F-1 Figure 40

Kagi Wiring - Drawing F-2 Figure 41

Air and Oil Pre-heaters Figure 42

Parts HW150/250 Figure 43

Parts HW350 Figure 44

HW Cleaning Figure 45

HW Cleaning(continued) Figure 46

Warning / Caution Decals Figure 47

Warning / Caution Decals (continued) Figure 48

Warning / Caution Decals (continued) Figure 49

INDEX OF DRAWINGS

Figure 1

150

45”

65”

28.5”39”

13”

11”

35”

Top View

Left Side ViewLouver End View

Right Side View

Heatwave150 –150,000 BTU

Crated = 69”L x 42”W x 45”H

Shipping weight = 700 lbs.

HW150

Figure 2

45”

Left Side View

Louver End View

33”

52”

74 ½”

Top View

11 ½”

13”

Right Side View

Heatwave250 –250,000 BTU

Crated = 80”L x 44”W x 50”H

Shipping weight = 800 lbs.

HW250

36”

Figure 3

350

Heatwave350 –350,000 BTU

Crated = 68”L x 45”W x 85”H

Shipping weight = 1080 lbs.

80”

60”

36”60”

Right Side View Top View

4 – 12” Ø Vents

HW350

12” Ø

48”

70.5”

80”

38”

13.5”

Heatwave350 –continued

8” Ø

Chimney

Chimney End ViewBurner End View

HW350

Figure 4

SIEBRING MANUFACTURING - HEATWAVE SPECIFICATIONS

28-Apr-09 D. Hollander

Model HW150 HW250 HW350

BTU Input 150,000 BTU 250,000 BTU 350,000-380,00 BTU max

Square Foot Coverage Up to 4,500 sq. ft.* Up to 6,000 sq. ft.* Up to 8,000 sq. ft.*

Hourly Fuel Usage 1.1 - 1.5 gallons 1.7 - 2.0 gallons 2.5 - 3.1 gallons

Compressed Air Requirements 2 CFM** 2.5 CFM** 3 CFM**

PSI Air 15 20 25

Flue Size 8 inches 8 inches 8 inches

Cabinet Size (w/o burner) 35" W x 45" L x 29" H 36" W x 52" L x 34" H 36" W x 60" L x 48" H

Width Overall (w/blower &

burner) 48 inches 48 inches 36 inches

Length Overall (w/blower &

burner) 65 inches 75 inches 70 inches

Height Overall (w/blower &

burner) 40 inches 49 inches 82 inches

Crated Dimensions 42" W x 69" L x 45" H 44" W x 80" L x 50" H 45" W x 70" L x 84" H

Ductable Heat Discharge Yes Yes 4 12" Elbows

Air Movement Type Belt Driven Blower Belt Driven Blower Belt Driven Blower

Blower CFM Free Air 3140 3950 4800

Blower Motor HP 3/4 HP 3/4 HP 2 HP

Plenum Dimensions 18 X 23 23 x 23 4 -12" or 22" X 22"+

Hanging Mount 5/8 " All Thread 5/8 " All Thread Floor / Stand

Mounting Design (Floor or tank

stand) Floor, ceiling hung or tank

stand Floor, ceiling hung or tank

stand Floor / Stand

Stand Mount / Oil Tank Yes Yes No

Electrical Voltage 115 Volt 60 Hz 115 Volt 60 Hz 115 Volt 60 Hz

Average Total Amperage Draw 12 - 13*** 15 - 16*** 19 - 20***

Weight (with blower & burner) 520 lbs. 700 900

Approximate Shipping Weight 700 lbs. 840 1,040

Warranty 1 yr burner, blower, controls.

10 yrs. Cabinet 1 yr burner, blower, controls.

10 yrs. Cabinet 1 yr burner, blower,

controls. 10 yrs. Cabinet

* Depending on building insulation, ** Owner must supply compressed air, *** Total Amps = Burner, blower and oil pump

Construction (All Models): 10 GA - Combustion chamber barrel, swing-out bracket 11 GA - Exchanger tube bulkheads

12GA 309 SS - Target

12 GA - Burner mount tube, cleanout doors 14 GA - Shell (case) bottom, pot tubes 16 GA - Shell (case) top 18 GA - Shell

(case) sides

Figure 5

PREHEATER ON

PUMP ON

OFF

KAGI

WASTE OIL BURNER

TECHNOLOGY

PUMP ON

OFF

ONOIL TEMP

LENZ

CARLIN

IGNITOR

(41000SOAR)

Air Pressure

12 PSI Minimum

SOFT START

AIR TANK

OIL

CONNECTION

OIL

REGULATOR

OIL

PRESSURE

AIR REGULATOR

AIR PRESSURE

AIR

SOLENOID

AIR CONNECTION

BLOWER

MOTOR

KAGI S250/500

WASTE OIL BURNER HINGED

COVER

HINGE

POWER

CORD

Figure 6

AIR

ADJUSTMENT

BAND

PREHEATER

SWITCH

20. Supply

Tank

19. Strainer

18. Check Valve

16. Filter 13. Pump w/vac gauge

15. Water/sludge

drain

14. Fill pipe

17. Vent pipe to

outside

4. Capped Tee for easy

chimney cleaning

1. Rain or Sail Cap

Avoid screen in cap Clearance 18+ inches

Chimney connector, ¼” rise per ft.

3. Barometric Dampner, 2 –3’ away

from forced air fan or drafts

Securely hang heater using ⅝” all-thread

9. Low voltage (24V)

room thermostat

11. Electrical Service &

disconnect panel:

-20 Amp service for

150,000 & 250,000 BTU

-30 Amp service for

350,000 BTU

Clearance to walls –refer

to local codes

5. Draft reading port

2. Class “A” chimney (insulated

pipe) See local codes

150,000/250,000 BTU Heater Installation Example

Note: Use flare fittings and threaded

fittings with thread compound.

Do not use compression fittings.

Do not use Teflon tape.

Barrier to protect from traffic damage

6. Oil Regulator (on burner)

7. Secondary Air Regulator (on burner)

8. Burner

10. Primary Air

Regulator

12. Compressor

Figure 7

18” min.

18” min.

to wall

RAIN CAP

STORM COLLAR

ADJ. ROOF

FLASHING

FIRE STOP

SPACER

WALL BAND

WALL RADIATION

SHIELD

WALL SUPPORT

FINISHING

ADAPTER

WALL ADAPTER

INSULATED TEE

2” min.

12” LENGTH

STOVE PIPE

INSTALL WALL SUPPORT TO LEAVE 2”

GAP BETWEEN INSULATED TEE & WALL

* Check footnote for

chimney clearances

Avoid screen in chimney cap.

Vent chimney at least 3 feet above the roof

and at least 3 feet higher than any portion

of the building, roof or obstruction within 10

feet of the chimney. The max height of the

assembly above the roof shall not exceed

6 feet. If the total length of the insulated

chimney exceeds 30 feet, install additional

supporting assemblies supplied by the

chimney manufacturers. Never locate a

joint inside walls or in a joist spacer.

*

JOIST

JOIST

STORM COLLAR

ADJ. ROOF

FLASHING

JOIST SPACER

I.C. PIPE LENGTHS

(INSULATED CHIMNEY)

N.B. CHIMNEY MUST BE

INSTALLED WITH AIR GAP AS

STATED ON EACH SECTION.

CEILING

SUPPORT

BLACK STOVE PIPE

MULTIPLE WALL INSULATED CHIMNEY INSTALLATION

Figure 8

FLOOR

ROOF

Oil Tank

5’ MIN.

36”

MIN.

18” MIN.

18” MIN.

30”

Floor clearance as required

by state/local code

RemovableTee

cap for cleaning

Removable Tee

cap for cleaning

Barometric

damper

Barometric

damper

Blower

Class “A” insulated pipe, may be

higher than drawing if more draft

is required

22 GA, MIN.

Rule of Thumb:

Estimate 2 feet of vertical

chimney for every 1 foot of

horizontal pipe.

Figure 9

Thin wall, gasoline proof,

flexible rubber hose

Thin wall, gasoline proof,

flexible rubber hose

Float

Float

Check valve

Check valve

Strainer

Strainer

Oil Tank

Oil Tank

Flow to

pump

Flow to

pump

Restrict hose length so

strainer cannot reach

the sludge on the

bottom of the tank.

FLOATING PICKUP SUMP FOR DIRTY STORAGE TANKS

Sludge level

Sludge level

Tank

Cross

View

Tank

Cross

View

Vent to

outside

Vent to

outside

Fill Pipe

Fill Pipe

10” min. to

avoid sludge

10” min. to

avoid sludge

Straight

through

gate valve

Figure 10

Oil Primary Control

F2

F1

T2

T1

F2

F1

T2

T1

F2

F1

T2

T1

Yellow wires to cad cell

The primary control provides 24

volt thermostat connections.

Use # 18-2 wire (Bell wire).

At unit start-up, a jumper wire can

temporarily be installed to by-pass cad

cell to allow for priming of oil lines and

pump. Additionally, jumper can be

reinstalled to check for cad cell

malfunction.

Note: Do not connect jumper up first as

burner will not start. Start burner

without jumper wire, then connect

jumper across F1 & F2 terminals to

keep burner and pump operating.

WARNING! Do not operate burner

continuously or unattended with jumper

connected. The safety shutdown will

be disabled in this configuration. Install

for troubleshooting only.

1500 ohm ½ watt resister to

check control cad cell circuitry.

Carlin Primary Control

Figure 11

RESET

Carlin Primary Control

Carlin Primary Control

RESET

RESET

HEATWAVE NOZZLE –TYPICAL (HAGO)

HEAD DISTRIBUTOR STEM O-RING

HEAD DISTRIBUTOR STEM O-RING

HEATWAVE NOZZLE –TYPICAL (DELAVAN)

SN

609-7

30609

- 7

Normal application: HW150 = 609-5, HW250 = 609-7, HW350 = 609-9

Figure 12

O-Ring - 007 = 5/32 I.D. x 9/32 O.D. x 1/16

O-Ring - 007 = 5/32 I.D. x 9/32 O.D. x 1/16

This manual suits for next models

2

Table of contents