Siegenia-AUBI KFV Genius User manual

Window hardware

Assembly instructions

Automated latch release

Automatic door lock

Sliding door hardware

Ventilation and building technology

Door hardware

1Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

Contents

Target group of this documentation............................................................... 2

Intended use................................................................................................. 2

Improper use................................................................................................ 2

Safety notes.................................................................................................. 2

Explanation of symbols................................................................................. 2

Installation.................................................................................................... 3

Connections................................................................................................... 4

Cable links.................................................................................................... 6

Fitting an internal release push-button (optional)........................................... 7

Fitting the infra-red eye (optional)................................................................. 7

Wiring diagram for type A automated latch release...................................... 8

Wiring diagram for type F automated latch release....................................... 9

Technical specifications.................................................................................. 10

Liability......................................................................................................... 10

2Last update: 01.08.2013

Automated latch release Assembly instructions

Target group of this documentation

This documentation is intended to be used by specialists only. All work described in this document is to be performed

by experienced professionals with training and practice in the assembly, installation and maintenance of the automa-

ted latch release and its individual components. Safe and proper assembly of this automated door lock is not possible

without expert knowledge.

Intended use

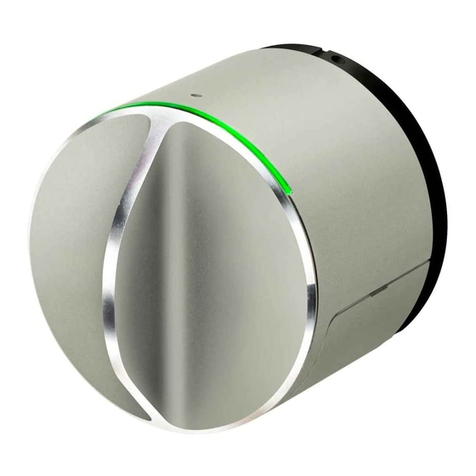

UÊ The automated latch release is used in combination with automatic locking systems to unlock doors electrically.

UÊ It is suitable for installation in timber, aluminium, steel and PVC front doors for residential and public buildings.

UÊ All assembly and electrical installation work must be carried out according to our assembly and installation instruc-

tions. Wiring the unit incorrectly can irreparably damage its electronic components.

UÊ The automated latch release can be connected to an external access control system (e.g. wireless, transponder or

fingerprint scanner system) via a voltage-free contact (switching time: min. 1 second).

UÊ Use the automated latch release only when it is in a technically sound condition. Do not modify the unit's components

in any way.

UÊ Use the automated latch release only with genuine KFV accessories.

Improper use

UÊ The automated latch release must not be installed in moisture-prone areas or areas with a corrosive atmosphere (e.g.

electroplating shops).

UÊ The length of the cable between the power supply and the automated latch release must not exceed 13 m.

Safety notes

UÊ Work on an 230 V AC mains power supply may only be performed by a qualified electrician.

UÊ All work on the 230 V AC mains power supply must be carried out in compliance with the current German VDE regu-

lations (e.g. VDE 0100) and any relevant country-specific requirements.

UÊ All-pole safety isolation should be used when fitting the power lead on-site.

UÊ Some external access control systems available on the market transmit a brief "open" signal when the operating

voltage is switched on. This can mean that the automated latch release will open the door following a power cut. If in

doubt, please contact the system manufacturer.

Explanation of symbols

Ø16

50

180

Milling cutter or drill diameter Groove depth from profile

Groove length

Where power supply cables are routed parallel to data cables (IDSN, DSL etc), interference can occur, eg: with

the data transfer speed.

Warning

3Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

Installation

Automated latch release

The automated latch release is supplied unassembled. Before it can be used it must be screwed onto the auto-

matic locking system.

3x

Fig. 1: Fitting the automated latch release

Fitting the power supply

UÊ The power supply ensures that the automated latch release is supplied with

the right voltage.

UÊ Its casing is designed to be fitted on a standard DIN EN 60715 mounting

rail.

UÊ One power supply can supply a maximum of 2 automated latch releases,

each connected to one KFV access control (wireless, transponder, infra-red

or fingerprint scanner) system.

UÊ The power supply comes with a permanent connection. A easily-accessible

means of disconnecting it must be integrated into the power supply circuit. Fig. 2: Power supply

Fitting cables

Various types of cable are available for connecting the power supply to the automated latch release.

Each cable is marked with a band to show where it must be plugged into the automated latch release.

Important:

UÊ When routing cables behind the secondary sash, ensure that they are not vulnerable to damage from the drive rod or

other moving parts.

UÊ The shield must be connected to earth on the power supply side. On the automated latch release side, connection of

the shield is not necessary.

4Last update: 01.08.2013

Automated latch release Assembly instructions

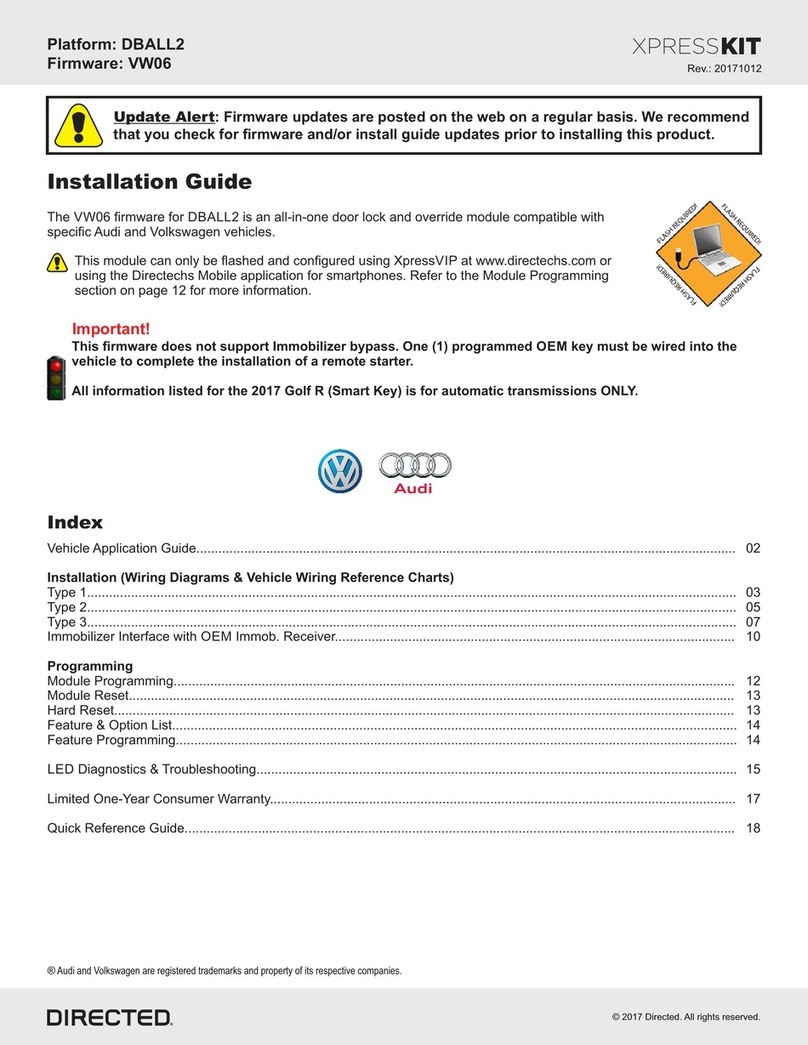

Connections

Connec-

tions

Type

A

Type

BFunction

A, B, C, D

B, C, D, 2

Connection for the infra-red eye, which

sends infra-red signals to the GENIUS

door lock

Connection for the KFV fingerprint

scanner

2, 3

24 V DC operating voltage

Terminal 2 = + (positive)

Terminal 3 = -- (negative)

4

External unlocking signal.

In both operating modes, if +24 V DC

is applied to this terminal for t1 s, the

door will be opened

Fig. 3: Automated latch release connections

Cable types

Type F

Always used together with type B.

0

1

2

3

4

7

Cable

no.

Band

colour

Cable

colour Function

0 Black Grey -

1 Brown Yellow -

2 Red White Operating voltage (+) 24 V DC

3 Blue Brown Operating voltage (--) negative

4 Yellow Green External "unlock" signal

7 Violet Pink -

Fig. 4: Cable type F (for connection of automated

latch release)

Type B

Always used together with type F.

0

1

4

7

+

-

Cable

no.

Band

colour

Cable

colour Function

0 Black Grey -

1 Brown Yellow -

4 Yellow Green External "unlock" signal

7 Violet Pink -

-- Blue Brown Operating voltage (--) negative

+ Red White Operating voltage (+) 24 V DC

White Blue Shield

Fig. 5: Cable type B (for connection of power

supply)

5Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

Type K

Cable

no.

Band

colour

Cable

colour Function

4 Yellow Green External "unlock" signal

-- Blue Brown Operating voltage (--) negative

+ Red White Operating voltage (+) 24 V DC

White Blue Shield

Fig. 6: Cable type K

(connects automated latch release to

power supply)

Type E

Fig. 7: Cable type E (connects automated latch

release to power supply) -type A only-

0

1

2

3

4

7

0

1

4

7

+

-

4

+

4

+

Cable plugs for the automated latch release

UÊ To facilitate installation of the automated latch release, the plug can be removed by pulling it upwards.

UÊ There are letters on the plug to indicate where the various cables should be plugged in.

234

234

ABCD

Type A automated latch release Type F automated latch release

Fig 8: Cable plugs for the automated latch release

Cable

no.

Band

colour

Cable

colour Function

0 Black Grey -

1 Brown Yellow -

4 Yellow Green External "unlock" signal

7 Violet Pink -

-- /3 Blue Brown Operating voltage (--) negative

+/2 Red White Operating voltage (+) 24 V DC

White Blue Shield

6Last update: 01.08.2013

Automated latch release Assembly instructions

Cable links

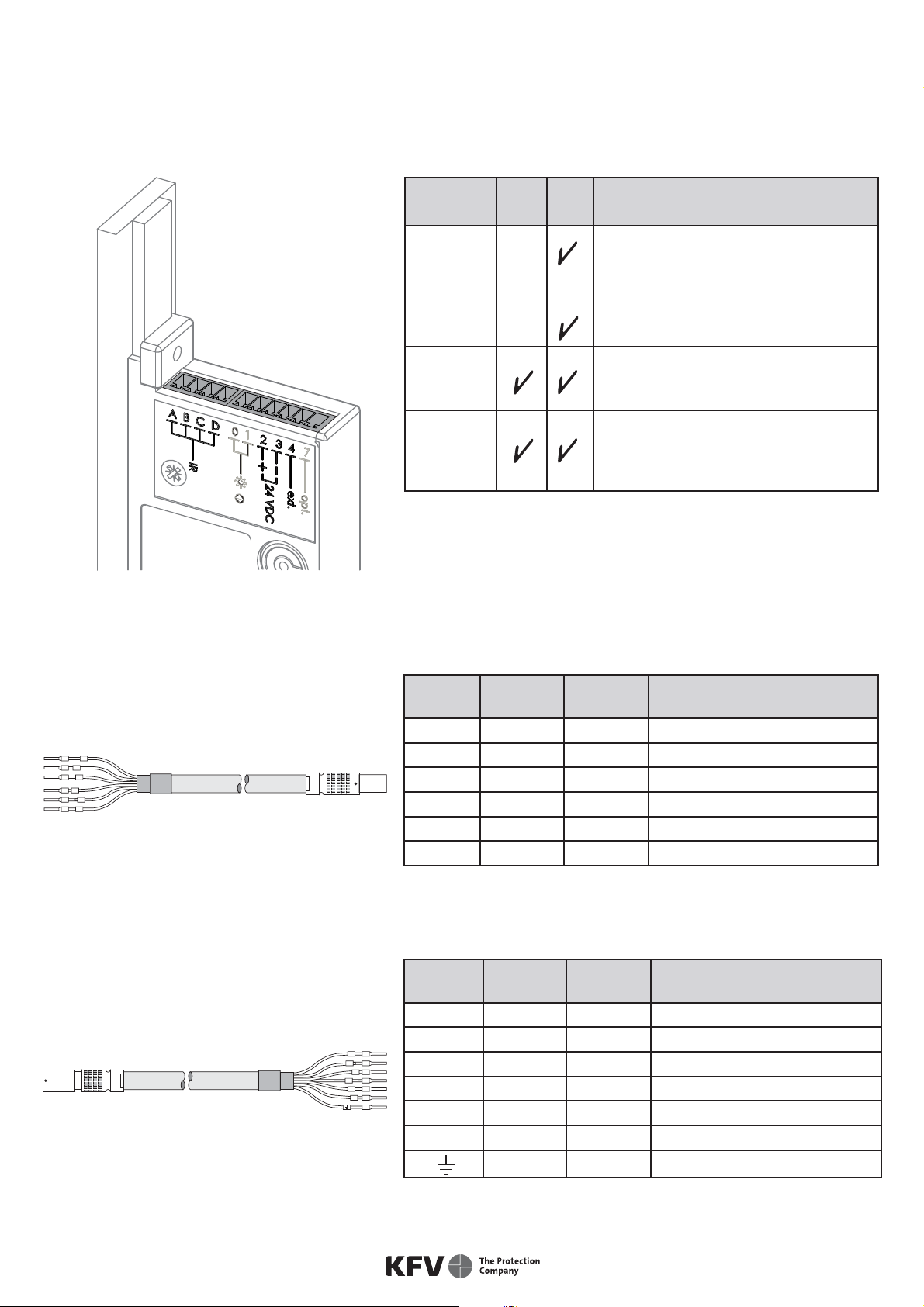

Visible cable link

UÊ The visible cable link should be fitted to the inside of the door on the hinge side.

UÊ If this cable link is used, unhinging the door leaf requires substantial effort.

Fig. 9: Visible cable link

Concealed cable links

100° and 180° concealed cable link

UÊ The casing is fitted in the door frame or leaf.

UÊ Allows the door leaf to be unhinged where cable types

B/F are used.

Fig. 10: Concealed cable link, not disconnectable

This cable link is used for routing cables invisibly in the door rebate.

Fig. 11: Concealed cable link

100° and 180° concealed cable link, disconnectable

Cable link is easy to disconnect using the plug connector in the

area of the rebate.

UÊ The casing is fitted in the door frame or leaf.

UÊ The disconnectable cable link permits easy unhinging of

the door leaf. Fig. 12: Concealed cable link, disconnectable

7Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

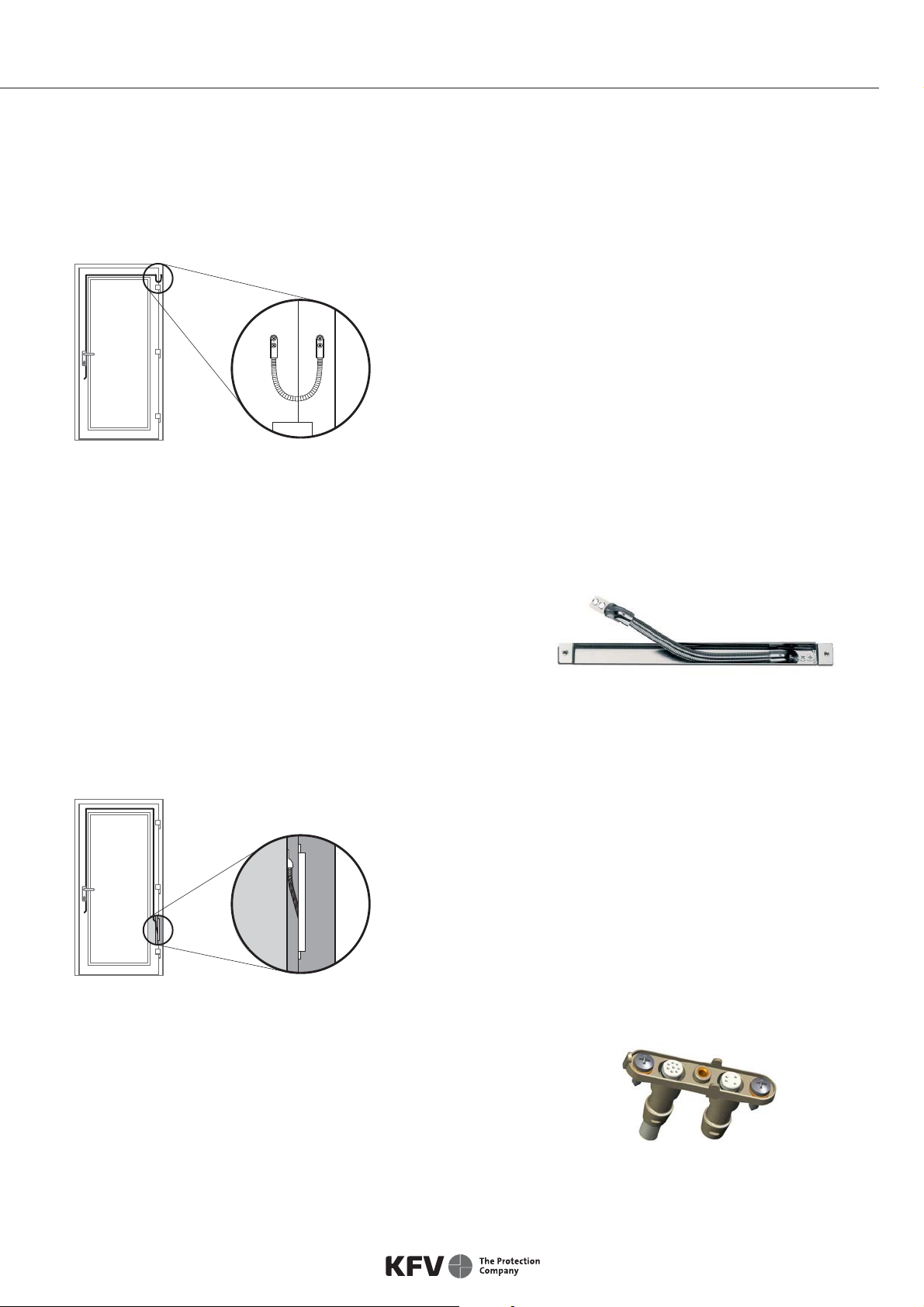

Fitting an internal release push-button (optional)

The internal release push-button can be used to open the door without a

conventional key.

› Connect the cable (length: 750 mm) to terminals 2 and 4 on the auto-

mated latch release.

› Drill an 18 mm (without anchor) or 20 mm (with anchor) drill hole.

Supplied with an anchor for "snap-in" installation.

Anti-intruder advice: To effectively prevent intruders from operating the push-button from the outside, it should be

ensured that any glass panes and infill panels in the door are suitably burglar-resistant.

The infra-red eye acts as a receiver for the infra-red code transmitted by

an infra-red access key or infra-red master key. It comes with an installa-

tion anchor suitable for use in any door material.

› Drill a hole of diameter 20 mm (tolerance ±0.2 mm).

› Push the infra-red eye into the anchor, guiding the cable

(length: 750 mm) in first.

› Guide the cable from the infra-red eye to the automated latch release

and connect it to the terminals on the (4-pin) plug on the automated

latch release.

Fitting the infra-red eye (optional)

8Last update: 01.08.2013

Automated latch release Assembly instructions

Wiring diagram for type A automated latch release

DSP 30

24V DC

Kl. 4 Fl.

( +24 V DC)

234

24VDC

2

4

3

5

6

7

8

1

No. Description

1 230 V AC supply line (L; N; PE)

2 Power supply

3 Wireless receiver (optional)

4 External unlocking (optional)

5 Line length max. 50 metres (external unlocking)

6 Line length max. 13 metres (from automated latch release to power supply)

7 Internal release push-button (optional)

8 Type A automated latch release

9Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

Wiring diagram for type F automated latch release

2

2

3

4

1

37

4

24VDC

45

6

8

7

9

AB CD01

DSP 30

24V DC

Kl. 4 Fl.

( +24 V DC)

2

3

1

No. Description

1 230 V AC supply line (L; N; PE)

2 Power supply

3 Wireless receiver (optional)

4 External unlocking (optional)

5 Line length max. 50 metres (external unlocking)

6 Line length max. 13 metres (from automated latch release to power supply)

7 Infrared eye (optional)

8 Internal release push-button (optional)

9 Type F automated latch release

10 Last update: 01.08.2013

Automated latch release Assembly instructions

Liability

Intended use

Any use of this product that is not in accordance with its intended use, or any adaptation of or modification to the product

and its associated components for which our express consent has not been obtained, is strictly prohibited. We accept no

liability whatsoever for any material losses or injury to people caused by failure to comply with this stipulation.

Product liability

Our products are warranted – subject to correct installation and proper use – for a period of one year from the date of re-

ceipt by a company (according to our general terms and conditions) or as otherwise agreed, and for a period of two years

for end consumers, in accordance with statutory provisions. As part of our ongoing improvements, we reserve the right to

replace individual components or entire products. Consequential losses resulting from defects are excluded from the war-

ranty within the limits of the law. The warranty shall become void if modifications that are unauthorized by us or have not

been described in this documentation are performed on the product and/or individual components, or if the product and/or

individual components is/are dismantled or partly dismantled, and the defect is due to the changes made.

Exclusion of liability

The product and its components are subject to stringent quality controls. As a result, they function reliably and safely when

used correctly. Our liability for consequential losses and/or claims for damages is excluded, except in the case of wilful mis-

conduct or gross negligence, or where we are responsible for injury to life, limb or health. Strict liability under the German

Product Liability Act (Produkthaftungsgesetz) remains unaffected. Liability for the culpable violation of significant contractual

obligations also remains unaffected; liability in this case is limited to losses that are specific to the contract and that could

have been foreseen. The above regulations do not imply a change in the burden of proof to the detriment of the consumer.

Environmental protection

Although our products do not fall within the scope of the German Electrical and Electronic Equipment Act (ElektroG), KFV

will continue to meet the requirements of this Act and will endeavour to completely eliminate the use of substances that are

hazardous to the environment as soon as this becomes technically feasible. Electrical products should not be disposed of as

household waste.

Feedback on documentation

We welcome your comments and suggestions on how to improve our documentation. Please send us your feedback by e-

mail to dokumentation@kfv.de.

We, KFV KG, declare under our own responsibility that this product complies with the provisions of

Directives 2008/108/EC and 2006/95/EC of the Council of the European Union.

EU Declaration of Conformity

Technical specifications

Relative humidity 20 % bis 80 %

Ambient temperature in door -- 10 bis + 45 °C

Dimensions Width 16 mm, length approx. 252 mm, depth 49 mm + width of face plate

Supply voltage 24 V DC max. 500 mA

Cable types

Type LIYCY

Ambient temperature, non-fixed -- 5 bis + 50 °C

Ambient temperature, fixed -- 20 bis + 70 °C

11Last update: 01.08.2013

Assembly instructions Automated latch release

ENGLISH

Contact your dealer:

KFV Karl Fliether GmbH & Co. KG

Siemensstraße 10

42551 Velbert

GERMANY

Telefon: +49 2051 278-0

Telefax: +49 2051 278-167

www.siegenia-aubi.com

SIEGENIA-AUBI worldwide:

Austria Phone: +43 6225 8301

Belarus Phone: +375 17 312 1168

Benelux Phone: +32 9281 1312

China Phone: +86 316 5998198

France Phone: +33 38961 8131

Germany Phone: +49 271 3931-0

Great Britain Phone: +44 2476 622000

Hungary Phone: +36 76 500810

Italy Phone: +39 02 935 3601

Poland Phone: +48 7744 77700

Russia Phone: +7 495 7211762

South Korea Phone: +82 31 7985590

Switzerland Phone: +41 33 346 10 10

Turkey Phone: +90 216 593 4151

Ukraine Phone: +380 44 4637979

H39.ELEKKFV0003EN/2013-08/0

Table of contents

Other Siegenia-AUBI Door Lock manuals