Siegenia-AUBI KFV EE99 Series User manual

Assembly Instructions

WINDOW FITTINGS

DOOR FITTINGS

SLIDING DOOR FITTINGS

VENTILATION AND BUILDING TECHNOLOGY

Emergency Exit and Panic Door Locks:

First leaf (active leaf)

Last update: 30.8.2011 1

Assembly Instructions Emergency Exit and Panic Door Locks

Table of Contents

Feedback on Documentation

We welcome your comments and suggestions on how to improve our documentation. Please send us your

Area of Application of this Document

This documentation is valid for the following listed emergency exit and panic door locks:

• All articles of the series EE99..., EE166..., EE930..., EE950..., EE960...

• All articles of the series PE99..., PE166..., PE930..., PE950..., PE960...

• All articles of the series EP99..., EP166..., EP930..., EP950..., EP960...

• All articles of the series EE25-2F..., PE25-2F..., EP25-2F..., EE26-2F..., PE26-2F..., EP26-2F...

Target Group of this Documentation ................................................................................................. 2

Correct Use ................................................................................................................................... 2

Incorrect Use ................................................................................................................................. 4

Explanation of Symbols................................................................................................................... 4

Screw Recommendation.................................................................................................................. 4

Installation..................................................................................................................................... 5

Assembly Step 1 - Cutting the Door Leaf............................................................................................ 6

Assembly Step 2 - (optional) Predrilling Operating Lever ..................................................................... 7

Assembly Step 3 - (optional) Changing the DIN and Escape Direction .................................................. 8

Assembly Step 4 - Cutting the Door Frame......................................................................................... 9

Assembly Step 5 - Screw Mounting of Components .......................................................................... 10

Assembly Step 6 - Adjusting Strike Plate or Locking Plates.................................................................. 11

Liability....................................................................................................................................... 12

EU Declaration of Conformity ........................................................................................................ 12

Appendix 1: Certificate DIN EN 179 ............................................................................................. 13

Appendix 2: Certificate DIN EN 1125 ........................................................................................... 20

2Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Target Group of this Documentation

This documentation is intended to by used by specialists only. All work described in this document is to be

performed by experienced professionals with training and practice in the assembly, installation and mainte-

nance of emergency exit and panic door locks in the corresponding doors. Safe and proper assembly of

these locks is not possible without expert knowledge.

Correct Use

Installation location

• The lock may only be installed in vertically plumb emergency exit or panic doors in stationary buildings.

The following door dimensions must be observed together with the matching lock size:

Door height and width

Handle height Min. door

height Max. door

height Max. door

width

1,020 mm 2,009 mm 2,490 mm 1,320 mm

1,050 mm 2,039 mm 2,520 mm 1,320 mm

Door weight (for classification index, see label on lock case)

Classification index Class Door weight

3rd digit 5max. 100 kg

3rd digit 6max. 200 kg

• The lock may only be installed in doors that have been assembled in a technically sound manner. Door seals

and warping must not result in excessive operating values that would impede the escape function of the lock.

• The door design must permit use of the lock. It is therefore mandatory that you check the following:

- when used in a fire rated or smoke rated door, the lock is suitable for the door according to its certification.

- for double-leaf panic doors with a door closer, especially fire rated and smoke rated doors, a closing

sequence regulator according to EN 1158 and a catch flap are installed to ensure the correct closing

sequence.

- for double-leaf panic doors with a rebated central joint and escapedoor locks fitted on both leafs, it must be

possible to open either leaf with its own lock and to open both leafs when both locks are operated together.

• Most emergency exits and panic doors are installed on the building exterior and open outwards; there are

few exceptions. Ensure construction measures such as erecting a canopy that the lock is not permanently

exposed to the weather so that the function of the lock is not impaired.

• The lock must not be installed:

- in doors made of Accoya

- in swing doors

- in doors of rooms or buildings with an aggressive atmosphere

- in doors of rooms/buildings directly on the coast

Last update: 30.8.2011 3

Assembly Instructions Emergency Exit and Panic Door Locks

Lock, handle/fitting

• The lock forms a unit with the handle/fitting. Only locks and fittings that have been tested together and certified

may be installed. It is not permitted to make changes to such a combination (even partially), or to change the

lock.

• The use of any additional devices to keep the door closed (except a door closer) is not permitted. If a door

closer is installed, it may not impede operation of the door by children, the elderly or infirm.

• Do not attempt to repair the lock. If the lock is damaged, it must be replaced by KFV or repaired by a service

agent authorized by KFV.

•The entire lock must be replaced once it reaches the service life indicated below.

First leaf (“active leaf”) – 1- and 2-leaf doors: 200,000 operations of the handle

Second leaf (“inactive leaf”) – 2-leaf doors: 20,000 operations of the handle

• Replace cylinder locks and keys as soon as there are problems inserting and removing the key despite regular

maintenance.

Cylinder lock

You may use:

• Cylinder lock with free-running lobe in which the lobe can always be freely turned.

• Cylinder lock with rigid lobe in which the lobe is locked in the key removal position within a

range of -30 ° to +30 °.

Fig. 1: Permitted key removal position

You may not use:

• Cylinder locks with rigid lobe in which the lobe is locked in a key removal position outside the range of -30 °

to +30 °. This includes cylinder locks in which the lobe position can be adjusted manually so that a lobe

position outside of the range from -30 ° to +30 ° is possible to reach.

Opening/Closing/Locking

• It must be possible to open and close the door easily. A protruding latch and/or locking bolt must not impede

the opening of the door.

• The locking elements must always engage freely in the perforations of the locking parts.

4Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Incorrect Use

A misuse/improper use of the lock is present if, for example:

• foreign objects are inserted into the lock, its fittings or frame parts (closing plate or locking rail).

• alterations are made to the lock, its fittings or frame parts that affect the operation, design or function of the

lock.

• the activated locking bolt is misused to hold the door open.

•moving or adjustable parts of the lock (e.g. locking bolt, latch), fitting or frame are treated after installation in

a way that impairs their function (e.g. varnishing the parts).

• loads in excess of normal manual force are applied to the lever handle or operating handle.

• unsuitable closing means are used, e.g. deviating in dimension or with the incorrect setting.

• the clearance between the door and the frame increases or decreases when the lock, fitting or frame is

adjusted, or when the door is lowered.

• a 2-leaf door not suitable for the purpose its forced open by the second leaf (“inactive leaf”).

• objects are inserted between door leaf and door frame when the door is closing.

• the door is opened simultaneously with the lever handle and the key,

• the door is carried by the lever handle or fitting when being transported.

• force is applied to the lock, fitting or frame parts.

Explanation of Symbols

Ø16

cutter or drill diameter through hole

180

groove length for metal profiles

50

groove depth from component for wood profiles

50

groove depth from profile for plastic profiles

Screw Recommendation

3,9

4,0

3,9

Last update: 30.8.2011 5

Assembly Instructions Emergency Exit and Panic Door Locks

Installation

Installation conditions and requirements

Local building laws and regulations must be observed before and during door installation in addition to the

following requirements and conditions:

• Before installing the lock, check the dimensional accuracy of the door and the door frame. The lock must not

be installed if the door or the frame is warped and/or damaged.

• Install the lock and accessories (e.g. rotary spring) according to our assembly instructions. Use the supplied

fastening material for assembly.

• Remove any waste material from the lock mortise after cutting.

• Do not perform mechanical work on the door (e.g. drilling, cutting) when the lock is installed. Never drill or

drill through the main lock.

• Observe the specified positions and sizes when drilling the holes. Use the supplied jig when drilling the holes

manually.

• Follow the information of the fitting manufacturer when drilling the holes for the operating lever/fitting.

• Install fittings and cylinder flush without overtightening the screws or screwing them in at an angle.

• Fasten handle set only by hand and do not use force when installing the spindle.

• Install the horizontal operating lever between 900 and 1,100 mm above the finished floor level with the door

closed. If it is known that the users of the building are mainly small children, adjust the installation height of the

operating lever based on a risk analysis and in cooperation with the responsible authorities.

• Fix the horizontal operating lever so that the maximum possible effective handle length is achieved.

• Install any stop elements and stop counterparts so that the handle can be safely engaged. Free movement of

the door must not be impeded by projection of the stop elements in the retracted position.

• Keep the distance between the face plate and locking parts: for 1-leaf doors: 2 to 6 mm

for 2-leaf doors: 4 to 6 mm

• Operating elements may not impede each other.

• Check the correct setting of any existing filling.

• Adjusted hinges and interlocking leafs must make it possible to open both door leafs at the same time.

• Surface treatment of the door and door frame must take place before the lock is installed. Treating the surface

at a later stage can reduce the functional capacity of the lock.

• Use only acid-free vulcanized sealants to prevent corrosion of components and/or the door.

Dimensions

All dimensions given in this documentation are in mm.

6Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

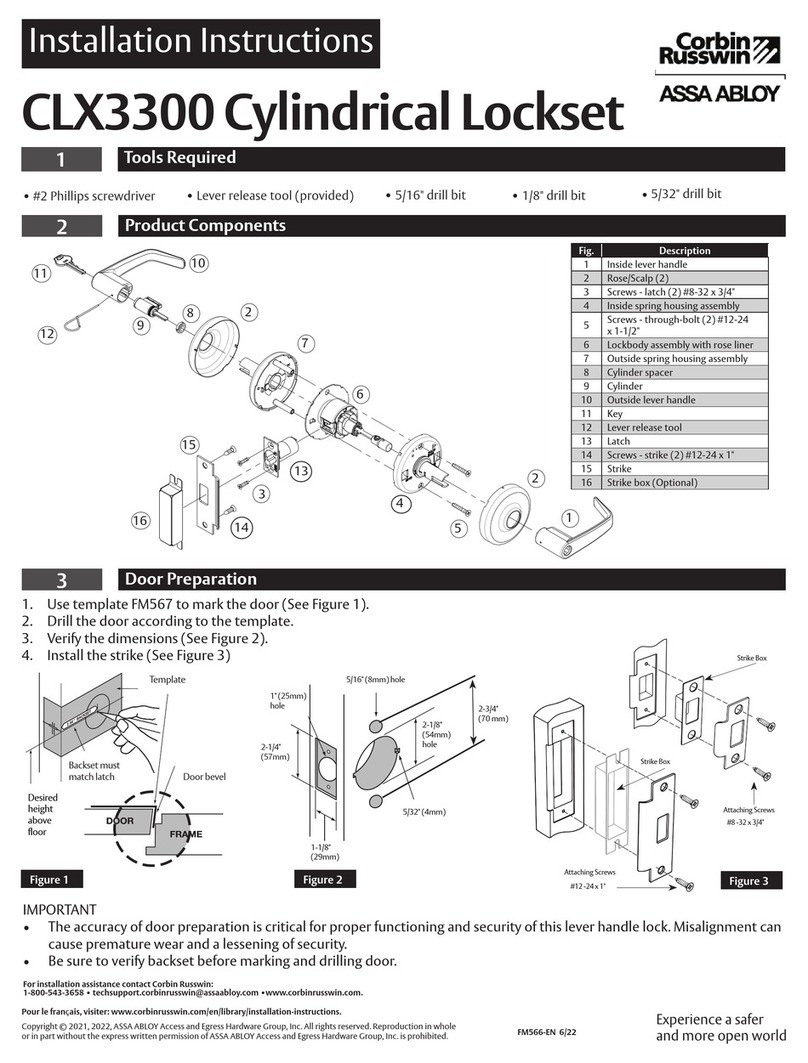

Assembly Step 1 - Cutting the Door Leaf

BC

G

A

D

20

50

180

Ø16

Ø 18

Ø 11

145

D+20

250

Ø16

50

180

Ø16

Dimensions

B version A B C G

B001 2170 760 730 1020

B002 2170 760 730 1050

B003 2400 760 980 1020

B039 1700 760 355 952

B041 1700 760 605 952

B166 1855 760 730 952

B253 2170 760 980 952

B296 2170 760 355 1020

B298 2170 760 605 1020

Last update: 30.8.2011 7

Assembly Instructions Emergency Exit and Panic Door Locks

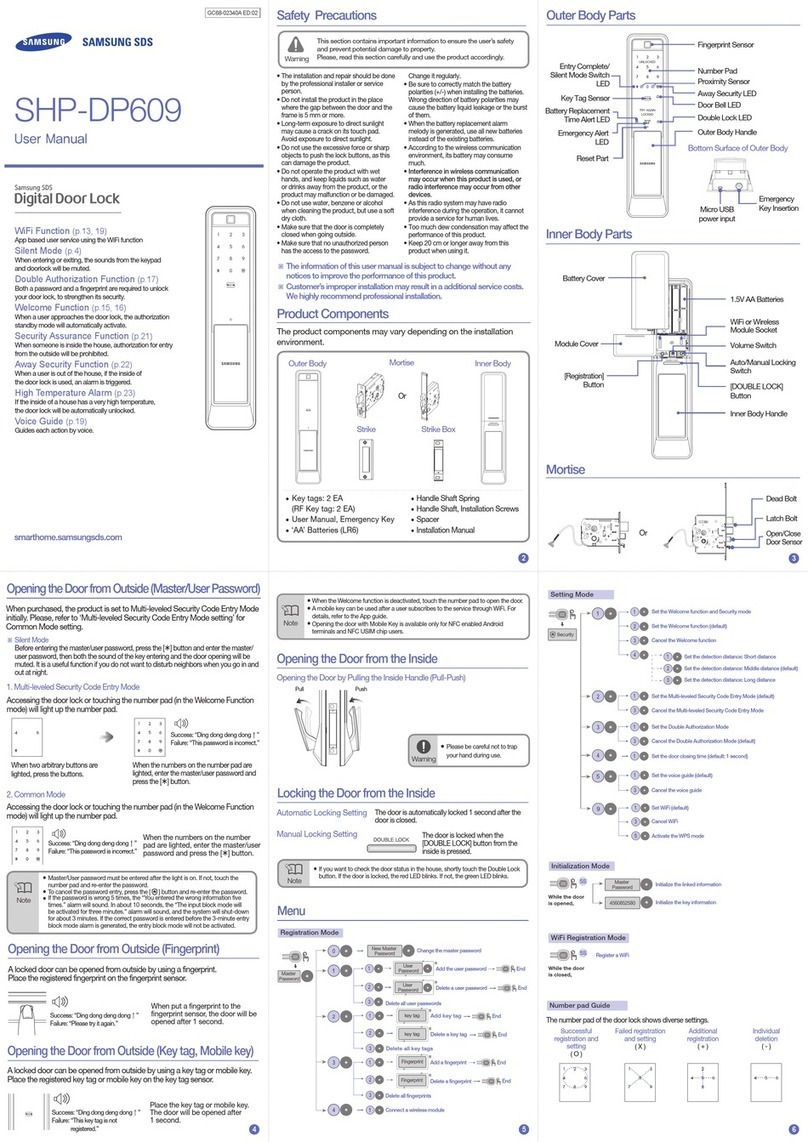

Assembly Step 2 - (optional) Predrilling Operating Lever

4

Ø 5

Assemblyaccordingtothefitting

manufacturer's instructions.

8Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

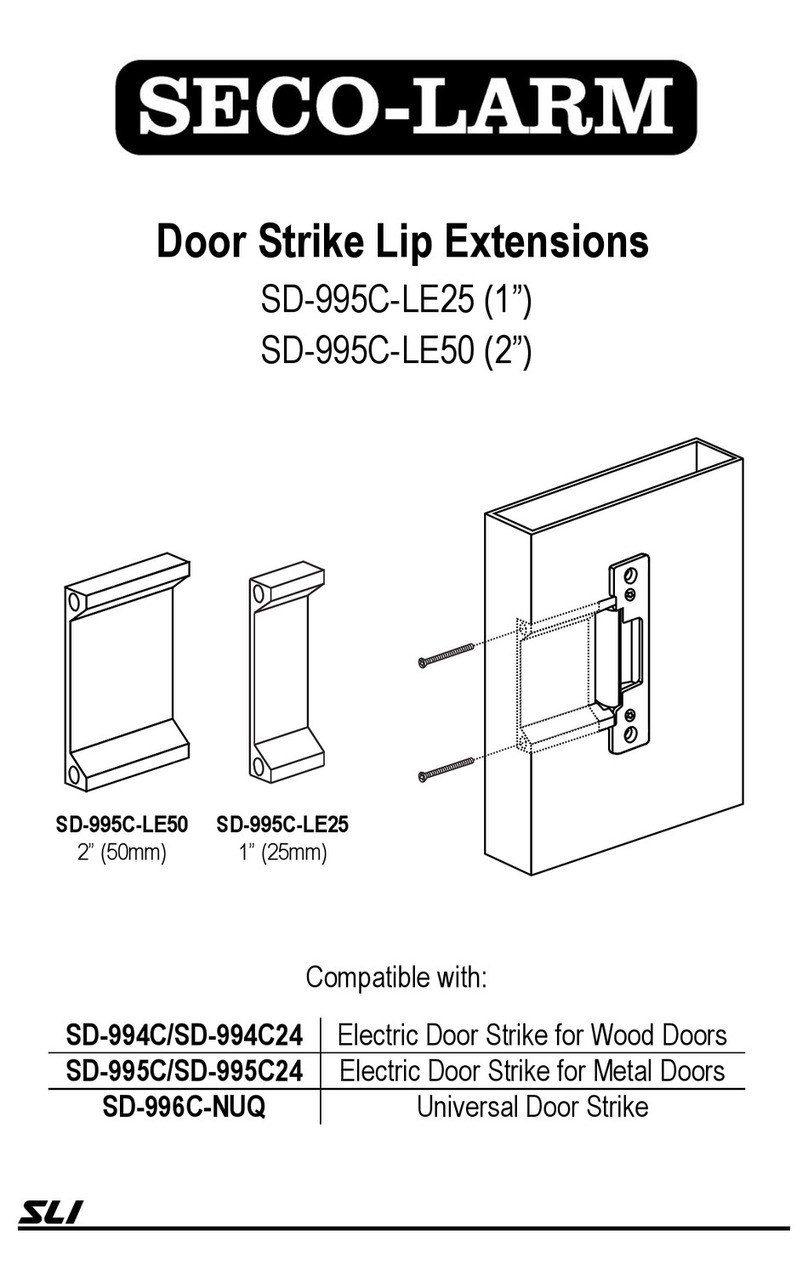

Assembly Step 3 - (optional) Changing the DIN and Escape Direction

180°

4 - 5 x

1.

2.

3.

4.

DIN direction (changing the latch) Changing the escape direction

1.

2.

3.

4.

Last update: 30.8.2011 9

Assembly Instructions Emergency Exit and Panic Door Locks

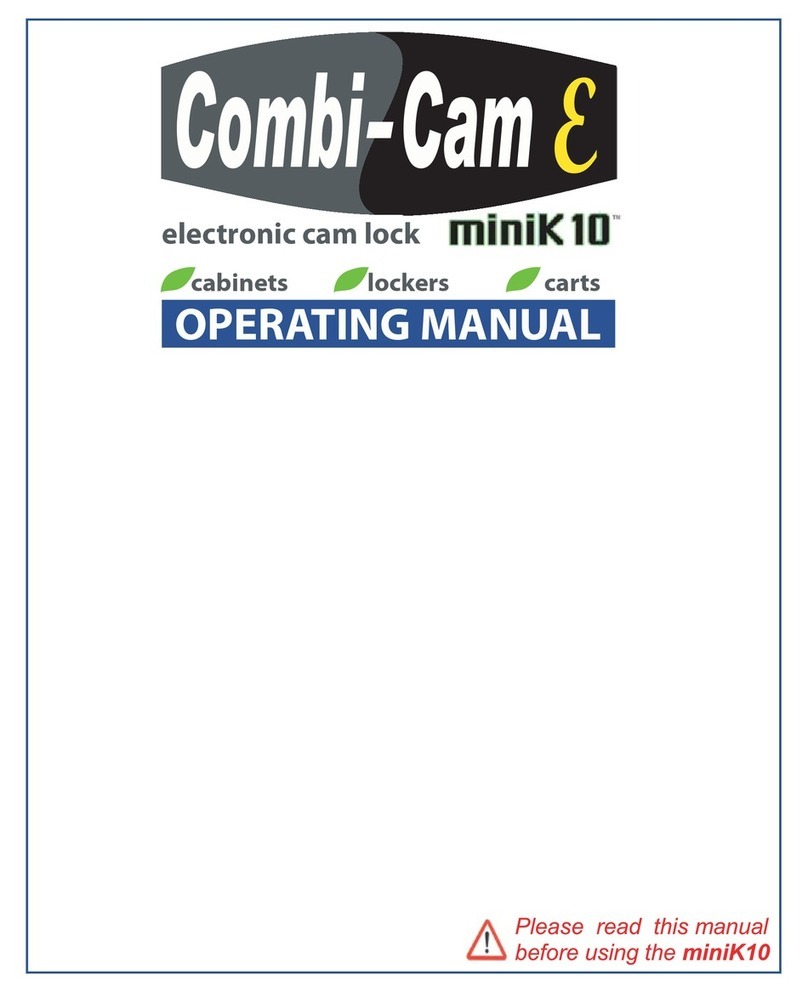

Assembly Step 4 - Cutting the Door Frame

21

21

23

BC

30

135

Ø16

30

72

Ø16

30

62

Ø16

30

135

Ø16

Dimensions

B version B C

B001 760 730

B002 760 730

B003 760 980

B039 760 355

B041 760 605

B166 760 730

B253 760 980

B296 760 355

B298 760 605

10 Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Assembly Step 5 - Screw Mounting of Components

Strike plate or locking plates Multipoint lock

Last update: 30.8.2011 11

Assembly Instructions Emergency Exit and Panic Door Locks

Assembly Step 6 - Adjusting Strike Plate or Locking Plates

± 2,5

2,5

2,5

2,5

1.

2.

3.

12 Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Liability

Intended use

Any use or application of this product that is not in accordance with its intended purpose, or any adaptation

of or modification to the product and its associated components, for which the express consent of us has not

been obtained, are strictly prohibited. We are not liable for any damages to material or persons if these

directions are not observed.

Product liability

Provided that they are properly installed and correctly handled, our products are subject to warranty for

1 year after receipt of goods by companies (according to our general terms and conditions), or as otherwise

agreed, and for 2 years for end consumers according to statutory law. As part of our ongoing improvements,

we reserve the right to replace individual components or entire products. Consequential losses resulting from

a failing in the unit are excluded from the warranty within the limits of the law. The warranty shall become

void if modifications that are unauthorized by us or have not been described in this documentation are made

to the product and/or individual components, or if the product and/or individual components is/are disman-

tled or partly dismantled.

Disclaimer of liability

The product and its components are subject to stringent quality controls. As a result, they function reliably and

safely when used properly. Our liability for consequential losses and/or claims for damages is excluded,

except in the case of wilful misconduct or gross negligence, or where we are responsible for injury to life,

limb or health. Strict liability under the German Product Liability Act (Produkthaftungsgesetz) remains unaf-

fected. Liability for the culpable violation of significant contractual obligations also remains unaffected; lia-

bility in this case is limited to losses that are specific to the contract and that could have been foreseen. The

above regulations do not imply a change in the burden of proof to the detriment of the consumer.

EU Declaration of Conformity

We, KFV Karl Fliether GmbH & Co. KG, declare under sole responsibility that the product

meets the regulations of Directive 93/68/CEE of the Council of the European Union.

Last update: 30.8.2011 13

Assembly Instructions Emergency Exit and Panic Door Locks

Appendix 1: Certificate DIN EN 179

14 Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Last update: 30.8.2011 15

Assembly Instructions Emergency Exit and Panic Door Locks

16 Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

Last update: 30.8.2011 17

Assembly Instructions Emergency Exit and Panic Door Locks

18 Last update: 30.8.2011

Emergency Exit and Panic Door Locks Assembly Instructions

This manual suits for next models

19

Table of contents

Other Siegenia-AUBI Door Lock manuals