siegling blizzard HC120/40 User manual

Siegling – total belting solutions

USER MANUAL

Blizzard Heating

Clamp HC 120/40

Contents

3 English manual

17 Betriebsanleitung

siegling blizzard

splicing equipment

TM

2

Dieses Gerät darf nur von Personen

in Betrieb genommen werden, die

die nachfolgende deutsche oder englische

Betriebsanleitung gelesen und verstanden haben.

Този уред се допуска да се въвежда в

експлоатация само от лица, които са

прочели и разбрали следващото немско или

английско ръководство за експлоатация.

Dette apparat må kun sættes i drift af

personer, som har læst og forstået den

følgende tyske eller engelske driftsvejledning.

This device should only be used by those

personnel who have read and understood

the following German or English user manual.

Seda seadet tohivad kasutusse võtta vaid

inimesed, kes on lugenud allpool esitatud

saksa- või eestikeelseid kasutujuhiseid ning neist

aru saanud.

Tämän laitteen saavat ottaa käyttöön vain

sellaiset henkilöt, jotka ovat lukeneet ja

ymmärtäneet seuraavan saksan- tai englanninkieli-

sen käyttöohjeen.

Cet appareil ne doit être mis en service

que par des personnes ayant lu et compris

les instructions de service ci-après en allemand ou

en anglais.

Αυτή η συσκευή επιτρέπεται να τεθεί

σε λειτουργία όνο από άτοα που έχουν

διαβάσει και κατανοήσει τι οδηγίε χρήση που

ακολουθούν στα Γερανικά ή στα Αγγλικά.

Questo dispositivo può essere utilizzato

solo da persone che hanno letto e com-

preso il seguente manuale in tedesco o inglese.

Ovaj uređaj smiju puštati u rad samo

osobe koje su pročitale i razumjele upute

za uporabu u nastavku koje su napisane na

njemačkom ili engleskom jeziku.

Šo ierīci drīkst lietot tikai personas, kuras

ir izlasījušas un iepazinušās ar turpmāk

redzamo lietošanas instrukciju vācu vai angļu

valodā.

Šį prietaisą leidžiama pradėti eksploatuoti

tik asmenims, perskaičiusiems ir supra-

tusiems toliau pateiktą vokišką arba anglišką

instrukcijų žinyną.

Dit apparaat mag alleen door personen

in gebruik worden genomen die de

volgende Duitse of Engelse gebruiksaanwijzing

hebben gelezen en begrepen.

To urządzenie może być użytkowane

tylko przez osoby, które przeczytały i

zrozumiały następującą niemiecką lub angielską

instrukcję obsługi.

Este aparelho só pode utilizado por

pessoas, que tenham lido e compreendi-

do o Manual de instruções em alemão ou inglês

que se segue.

Acest aparat poate fi pus în funcţiune

doar de către persoanele care au citit și

au înţeles instrucţiunile de utilizare de mai jos în

limba germană sau engleză.

Bara personer som har läst och förstått

den här bruksanvisningen på tyska eller

engelska får ta den här apparaten i drift.

Toto zariadenie môžu uviesť do pre-

vádzky len osoby, ktoré si prečítali nas-

ledujúci návod na použitie v nemeckom alebo

anglickom jazyku a porozumeli jeho obsahu.

To napravo smejo zagnati samo osebe,

ki so prebrale in razumele naslednja

nemška ali angleška navodila za uporabo.

Este aparato solo deben emplearlo las

personas que hayan leído y comprendido

las siguientes instrucciones de uso (en alemán o

inglés).

Tento přístroj smějí uvádět do provozu

pouze osoby, které si přečetly následující

návod k obsluze v německém nebo anglickém

jazyce a rozumějí mu.

A készülék üzembe helyezését csak olyan

személyek végezhetik, akik elolvasták

az alábbi német vagy angol nyelvű használati

utasítást és megértették annak tartalmát.

3

USER MANUAL

Blizzard Heating Clamp HC 120/40

ENGLISH

Contents

4 General information

5 Safety

6 Description

10 Operation

15 Manufacturer’s notification/

Customer service/

EC Declaration of Conformity

4

1 GENERAL INFORMATION

All descriptions in these instructions are intended for trained

operating personnel. Incorrect or improper use of this heat-

ing clamp may damage the heating clamp or result in injury

to the operator or other persons.

Please read this document carefully and only use the

Blizzard heating clamp when you have fully understood the

instructions.

This document contains safety instructions. Please keep it

accessible for other users so they may read the instructions

prior to using the heating clamp.

Important instructions are indicated in the text as follows:

Note

This indicates technical features that require the user’s

attention.

Caution

This indicates that work procedures must be followed

precisely to prevent damage to the device or to ensure the

success of the heating process.

Stop

This indicates that notes and/or work procedures must be

followed precisely to prevent damage to the device and/or

eliminate the possibility of danger to the user or other

persons.

5

2 SAFETY

2.1 Intended use

The Siegling Blizzard heating clamp is used for the endless

splicing of belts.

– Width from 10 to 40 mm

– Thickness from 1.3 to 3.2 mm

– Splicing length 35/70/110 mm

Any other use is considered improper.

2.2 General safety instructions

The Blizzard heating clamp is a state-of-the-art device which

complies with the recognized safety regulations. Improper

use may result in danger.

Only operate the Blizzard heating clamp if it is in faultless

condition. To exclude the possibility of putting the user or

other persons at risk and to avoid damage, only trained per-

sonnel may operate the equipment.

Any work involving the Blizzard heating clamp must be per-

formed in accordance with

– this manual,

– the technical documentation accompanying the

machinery (when making belts endless in machinery),

– any relevant FMS splicing data sheets,

– all relevant statutory provisions and safety regulations.

Stop

During operation the heating plates on the heating clamp

and the inserted splice guide may reach a temperature of

210 °C. Injury may occur. (Fig. 2.2.1)

2.3 Operating conditions

The Siegling Blizzard heating clamp may only be operated

under the following ambient conditions:

– Normal atmosphere (no oil or gas atmospheres,

no corrosive atmospheric constituents).

Stop

The device is not splash-proof.

The device is not explosion-proof.

Operation under improper conditions can lead to serious

damage to the device and injury to the operator (electric

shock, burns, explosion damage).

Fig. 2.2.1

Heating plates

Splice guide

6

3 DESCRIPTION

3.1 Components/main dimensions

310 (12.2)

145 (5.7)130 (5.2)

Main dimensions in mm and inches (in).

All measurements in inches are rounded.

Upper heating plate

Lower heating plate

inserted belt

Control unit

with digital display

and buttons

Lower part of heating clamp

Lower part of splice guide

Eye bolts (2)

Upper part of heating clamp

Upper part of splice guide

7

3.2 Technical data

Type designation Blizzard

HC 120/40

Maximum belt width [mm] 40

Belt thickness [mm] 1.3 – 3.2

Z-splices [mm] 35:5.75 / 35:11.5 / 70:11.5 / 110:11.5

Maximum heating temperature [°C] 210

Total weight [kg] 2.0

Dimensions (L x W x H) [mm] 310 x 145 x 130

Connection requirements (alternative)

1 Phase (Item no. 870103) [V/Hz] 230/50

1 Phase (Item no. 870109) [V/Hz] 115/60

The Siegling Blizzard heating clamp is a compact solution

used to splice (heat and cool) thermoplastic belts (e.g. PVC,

polyurethane). No other accessories are required, such as an

external control unit or cooling clamp.

The Siegling Blizzard heating clamp is electrically heated

and air-cooled using fans. The heating and subsequent

cooling processes run automatically according to the previ-

ously entered values.

3.3 Operating principle

Fig. 3.3.1

Diagram of operating modes.

After the heating clamp has been switched on, three operating modes

are run through in sequence. From the start mode, a setting mode and

calibration mode for the heating and cooling parameters can be started if

necessary.

Operating modes

Start mode

Heating mode

including holding time

Cooling mode

Setting mode

Calibration mode

8

Caution

Do not operate the heating clamp upside down.

Potential problem: The trapped heat may damage the heating clamp housing.

Action: If the housing gets extremely hot, shut off the device and let it cool down.

– Prepare device and workstation.

– Connect the heating clamp to the power supply.

– Start the device.

After it is switched on, the device is in start mode. The heating plates are automatically heated to the most

recently set “cooling temperature”.

– Adjust the heating clamp settings in calibration mode if necessary.

– Set and save the splicing parameters in setting mode.

· Heating temperature

· Holding time

· Cooling temperature

– Insert the prepared splice guide into the heating clamp.

– Start heating cycle.

Heating plates are heated to the previously set heating temperature.

· Once the heating temperature has been reached, the holding time starts automatically.

· Once the holding time is complete, the cooling process starts automatically.

– When the preset cooling temperature has been reached, remove the splice guide and the finished splice.

– Insert other splice guides into the heating clamp to continue splicing or switch off the heating clamp.

Note

If approx. 2 minutes pass without any button being pressed, the device switches off.

3.4 Basic belt splicing procedure

9

3.5 Control panel

“ON/OFF” button > hold down to switch the device on or off.

The device is now in start mode.

“SELECT” button > press briefly to start setting mode. Press briefly again

to run through the three adjustable parameters for the heating

clamp in a sequential loop.

Heating temperature [°C or °F]

Holding time [s]

Cooling temperature [°C or °F]

hold down to toggle between the units used

(from “°C” to “°F” or vice versa) for the parameter displayed.

“CONFIRM” > press briefly

– to save the previously entered parameter values in setting mode

and to terminate setting mode,

or – to save the previously entered calibration values in calibration mode

and to terminate calibration mode,

or – to terminate heating up mode and start heating mode

or – to stop the countdown during holding time.

The countdown continues when the button is pressed again or

automatically after 60 seconds.

The function executed depends on the operating mode.

“+” or “–” button > press briefly

to change the displayed parameter in small increments

(1 °C/°F or 10 s),

hold down

to change the displayed parameter in large increments

(5°C/°F or 1 min).

(Only active in setting mode after pressing the “SELECT” button.)

“+” and “–” button > hold down

to put the device in calibration mode.

Fig. 3.5.1 – Control panel

10

4 OPERATION

4.1 Prepare device and workstation

– Ensure that the workstation is clean and tidy.

A heat-resistant surface on which to safely place the Siegling Blizzard heating clamp during operation must be available.

Stop

The device is not splash-proof. The device is not explosion-proof.

Operation under improper conditions can lead to serious damage to the device and injury to the operator

(electric shock, burns, explosion damage).

– Carefully check the heating clamp and power cable for damage (visual inspection).

The Siegling Blizzard heating clamp may only be operated if it is in faultless condition.

Stop

Operating a damaged device can cause further damage to the device and result in injury to the user (electric shock,

burns, crushing, cuts).

– Ensure that both heating plates are free of dirt and deposits.

Carefully remove any dirt or deposits by wiping with a clean cloth moistened with ammonia.

Stop

Clean heating plates only when cold and do not use flammable cleaning solutions.

Risk of severe burns and high fire risk!

4.2 Connect to the power supply

– Compare the connection values of your heating clamp to those of the power supply.

– Only connect to the power supply if the values are the same 230V/ 50Hz or 115 V /60Hz.

Caution

Operating the heating clamp with the wrong voltage can cause serious damage to the device.

Caution

Avoid connecting the heating clamp to machine sockets.

Potential problem: When starting up the machine there is a risk of voltage peaks,

which may damage the heating clamp electronics.

Action: Connect the heating clamp to an on-site power supply.

11

4.3 Check and adjust heating parameters

To do this, the heating clamp must be in start mode. See Section 3.

Stop

During operation the heating plates on the heating clamp (1) and the inserted splice guide (2) may reach a temperature of

210 °C. Injury may occur. (Fig. 2.2.1)

– Briefly press the “SELECT” button to switch to setting mode.

Briefly pressing the “SELECT” button again displays the adjustable heating parameters in sequence.

Order: > Heating temperature [°C or °F]

> Holding time [s]

> Cooling temperature [°C or °F]

This loop can be repeated as many times as desired.

Holding down the “SELECT” button toggles between “°C” and “°F”.

Pressing the “+” or “–” button changes the value that is displayed.

Heating temperature: press briefly > changes by 1°C/°F hold down > changes by 5 °C/°F

Holding time: press briefly > changes by 10 s hold down > changes by 1 min

Cooling temperature: press briefly > changes by 1°C/°F hold down > changes by 5 °C/°F

Note

When setting the heating parameter and no entry is made within 3 seconds, the device switches back to start mode.

– Press the “CONFIRM” button to save the previously entered heating parameters and terminate setting mode.

The device now starts automatically in heating mode.

12

4.4 Calibrate the heating clamp

Forbo Siegling recommends calibrating the heating clamp twice a year.

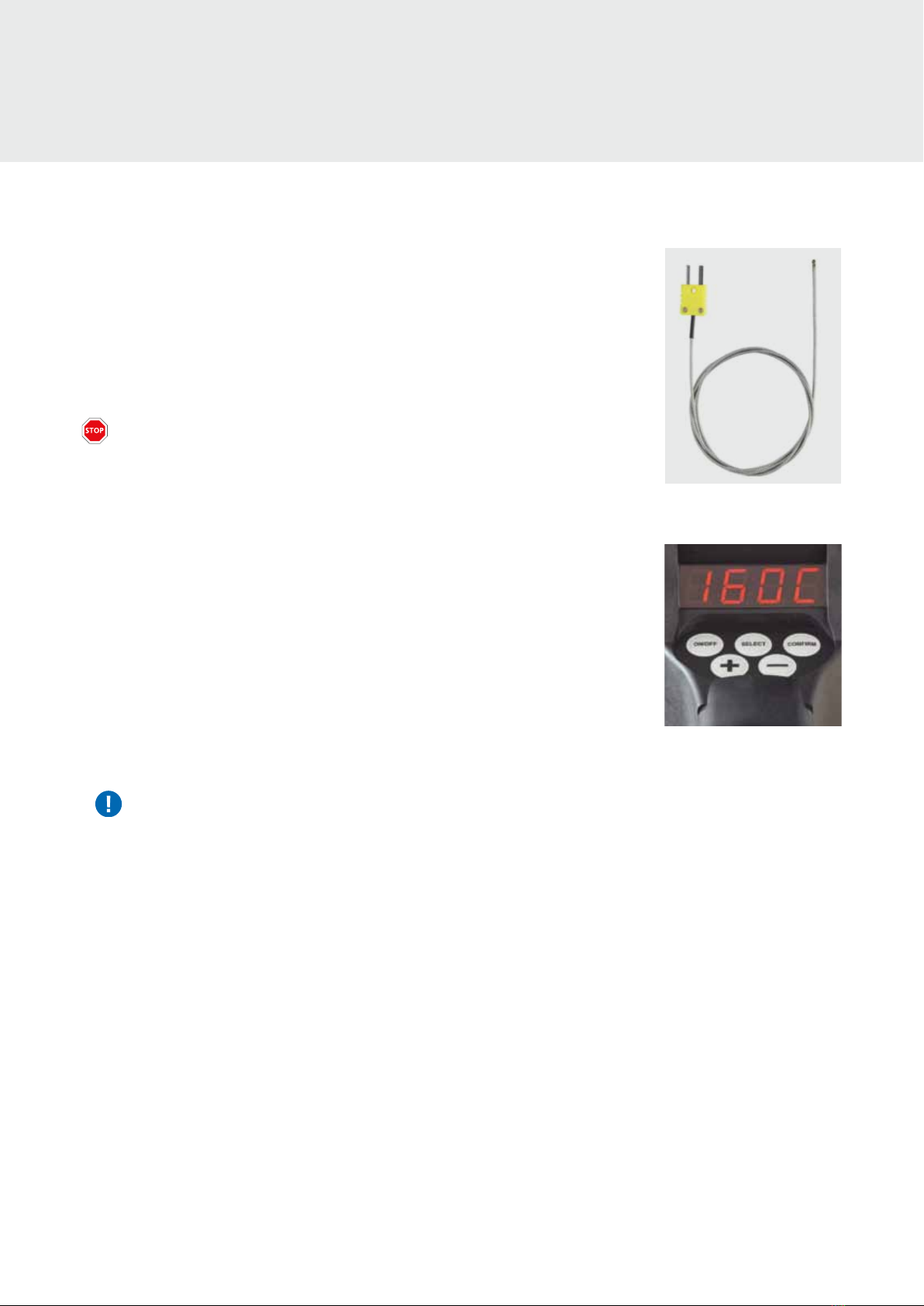

Required tools

– Temperature measuring device (accuracy ± 1°C)

– Temperature sensor (Fig. 4.4.1) max. diameter 2 mm

The heating clamp must be in start mode to calibrate. See Section 3

Stop

During operation the heating plates on the heating clamp (1) and the inserted splice

guide (2) may reach a temperature of 210 °C. Injury may occur. (Fig. 2.2.1)

– Set the heating parameters if necessary (see Section 4.3).

– Start calibration mode by simultaneously holding down the “+” and “–” buttons.

The heating clamp then emits an audible signal approximately every second. (Fig. 4.4.2)

– Wait until the heating clamp reaches the selected heating temperature and holds steady

(duration approx. 5 minutes). Signal frequency increases to approx. 2–3 times per second.

– Insert the temperature sensor into the hole on the side of the heating plate.

– Compare the temperature of the measuring device to what is indicated on the display

of the heating clamp.

– If there is a discrepancy in the readings, press the “+” or “–” button on the heating clamp

until the external measuring device indicates the correct temperature as set on the

heating clamp.

Note

The temperature is adjusted following each correction with a slight time lag.

– Save the setting by pressing the “CONFIRM” button.

The heating clamp is now in start mode again.

– Switch the device off by holding down the “ON/OFF” button or continue working.

Fig. 4.4.1

Fig. 4.4.2

13

Fig. 4.5.1

Fig. 4.5.2

4.5 Creating endless splices

– Hold down the “ON/OFF” button until the display turns on. (Fig. 4.5.1)

The heating clamp then automatically switches to start mode and heats up the heating

plates to the most recently set cooling temperature.

Stop

During operation the heating plates on the heating clamp (1) and the inserted splice

guide (2) may reach a temperature of 210 °C. Injury may occur. (Fig. 2.2.1)

– Set the heating parameters if necessary (see Section 4.3).

Caution

Operating the heating clamp with incorrect heating parameters can result in poor splicing

results, making the spliced area of the belt unusable.

– Insert the splice guide and prepared belt ends into the middle of the heating clamp.

Positioning is facilitated by the locking device on the splice guide. (Fig. 4.5.2)

– Press the “CONFIRM” button to start heating mode. The inserted splice guide and belt are

cold. That is why the temperature on the display briefly falls and the heating clamp heats

the splice guide and the belt to the preset heating temperature.

The preset holding time begins to run automatically as soon as the preset heating

temperature has been reached.

Note

Pressing the “CONFIRM” button a second time interrupts the countdown. The countdown

automatically continues when the button is pushed again (or after 60 seconds at the latest).

– At the end of the preset holding time an audible signal is emitted and the device automati-

cally switches to cooling mode (fans start).

– Once the preset cooling temperature has been reached, an audible signal is emitted and

the device switches back to start mode. Display “––––”. The splice guide can be removed.

– If approx. 2 minutes pass without any button being pressed, the device switches off.

14

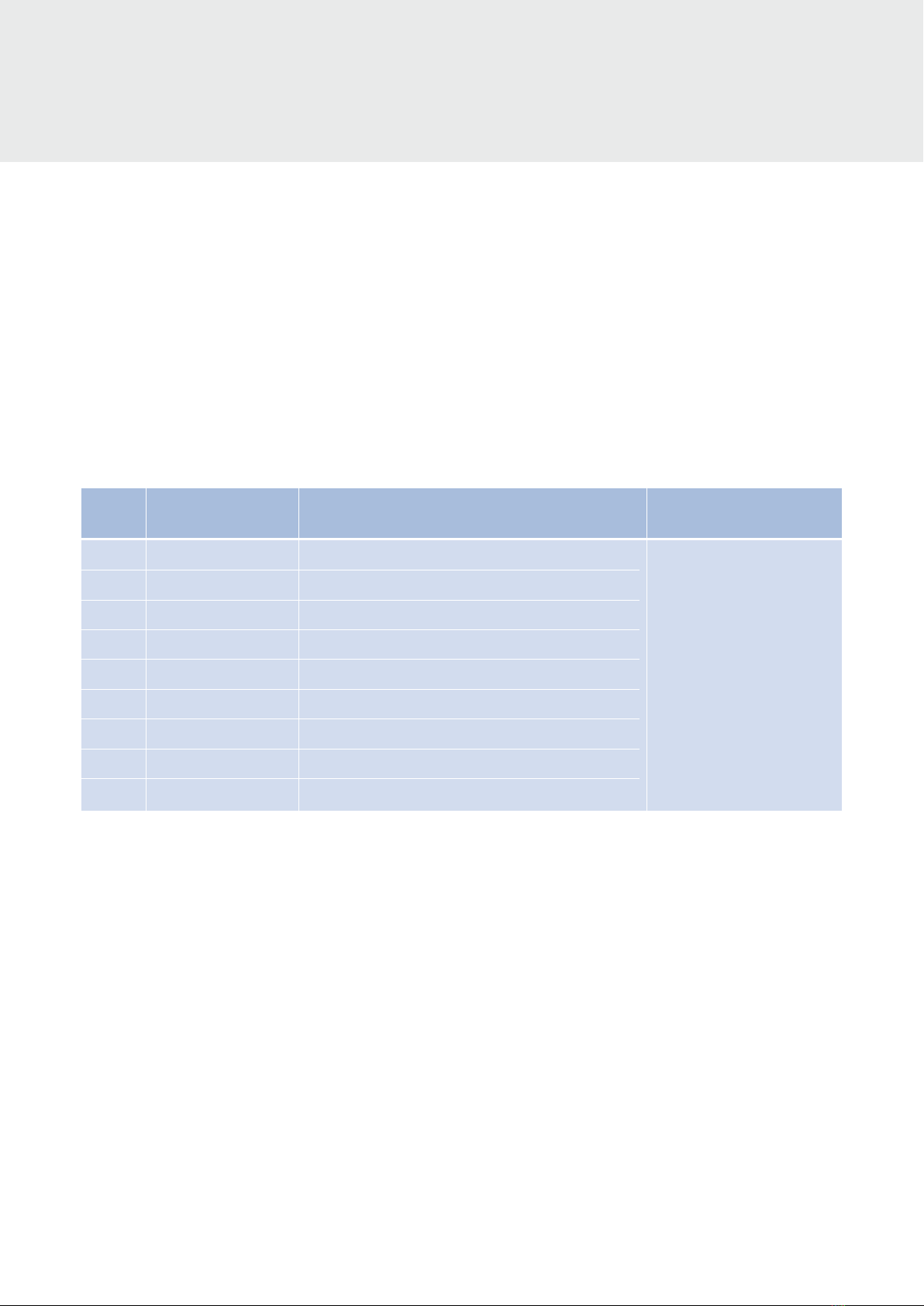

Error Error Error

Message Name Description Remedy

E001 HEATERS_DRIVING_CIRCUIT The heating plates are over 260°C

E002 NO_HEATING_UP Heating plates are not heating up

E003 HEAT_UP_TOO_SLOW Heating plates are heating up too slowly

E004 EEPROM_READ Calibration offset is out of the ±100°C range

E005 COOLING Cooling is too slow

E006 TOP_SIDE_HEATERS The top side heating plate does not heat up properly

E007 BOTTOM_SIDE_HEATERS The bottom side heating plate does not heat up properly

E008 TOP_SIDE_FANS The top side heating plate does not cool down properly

E009 BOTTOM_SIDE_FANS The bottom side heating plate does not cool down properly

4.6 Error during heating clamp operation

The heating clamp is equipped with error diagnostics. If an error occurs during operation, an error code appears in

the display.

– When an error occurs, acknowledge it with any button.

Following acknowledgment, the control unit on the device attempts to resume the current mode at the spot in

which the error occurred.

– If the error occurs again: Let the heating clamp cool down completely and restart.

– If the error occurs again: Make a note of the error code, switch the device off and disconnect it from the power supply.

Send the device, including the error code, to Forbo Customer Service for servicing.

Allow the heating clamp to cool

down completely and restart.

If the error occurs again:

Send heating clamp including

error message to Forbo

Customer Service.

15

MANUFACTURER’S NOTE/CUSTOMER

SERVICE/EC DECLARATION OF CONFORMITY

EC Declaration of Conformity

Hoover Dam Technology Asia Limited

Office B2, 16/F., Legend Tower

7 Shing Yip Street, Kwuan Tong, Hong Kong

This is to certify that the Siegling Blizzard HC 120/40 heating

clamp, used in the splicing of thermoplastic conveyor belt

material, meets the following EC directives:

• EN 61000 - 6 - 3:2007 + A1:2011 + AC:2012

• EN 61000 - 3 - 2:2014

• EN 61000 - 3 - 3:2013

• EN 61000 - 6 - 1:2007

• EN 61335 – 1:2012 + A11:2014

• EN 61335 - 2 - 45:2002 + A1:2008 + A2:2012

• EN 62233:2008

Forbo Siegling GmbH, Hanover

November 2016

Bernd Westermann

Manufacturer’s note/Customer

service

The Siegling Blizzard HC 120/40 heating clamp is

assembled in Germany and distributed by

Forbo Siegling GmbH

Lilienthalstraße 6/8

30179 Hanover ·

Germany.

Should you require technical support or replacement

parts, please contact customer service: www.forbo-

siegling.com

16

17

BETRIEBSANLEITUNG

Blizzard Heizzange HC 120/40

DEUTSCH

Inhalt

18 Allgemeines

19 Sicherheit

20 Beschreibung

24 Bedienung

29 Kundendienst/

Herstellerhinweis

EG-Konformitätserklärung

18

1 ALLGEMEINES

Alle Beschreibungen in dieser Anleitung sind für fachlich

geschultes Bedienungspersonal erstellt. Eine falsche oder

unsachgemäße Anwendung dieser Heizzange kann zu

Schäden an der Heizzange und zu Verletzungen des

Bedieners und anderer Personen führen.

Bitte lesen Sie dieses Dokument sorgfältig durch und

gebrauchen Sie die Blizzard Heizzange erst wenn Sie die

Beschreibungen verstanden haben.

Dieses Dokument enthält Sicherheitsanweisungen. Halten

Sie es auch für andere Nutzer griffbereit, damit sie es vor

Benutzung der Heizzange lesen können.

Im Text sind wichtige Anweisungen wie folgt gestaltet:

Hinweis

Hier müssen technische Besonderheiten vom Benutzer

beachtet werden.

Achtung

Hier müssen Arbeitsverfahren genau eingehalten werden,

um eine Beschädigung des Gerätes zu verhindern oder das

Gelingen des Heizvorganges sicher zu stellen.

Stopp

Hier müssen Hinweise und/oder Arbeitsverfahren genau

eingehalten werden, um eine Beschädigung des Gerätes zu

verhindern und/oder die Gefährdung des Benutzers oder

anderer Personen auszuschließen.

19

2 SICHERHEIT

2.1 Bestimmungsgemäße

Verwendung

Die Siegling Blizzard Heizzange dient zum Endlosheizen

von Bändern und Riemen.

– Breite von 10 bis 40 mm

– Dicke von 1,3 bis 3,2 mm

– Verbindungslänge 35/70/ 110 mm

Eine andere Nutzung ist nicht bestimmungsgemäß.

2.2 Allgemeine Sicherheitshinweise

Die Blizzard Heizzange entspricht dem Stand der Technik

und den anerkannten sicherheitstechnischen Regeln. Bei

unsachgemäßem Einsatz können Gefahren entstehen.

Die Blizzard Heizzange darf nur in einwandfreiem Zustand

betrieben werden. Um Gefährdungen des Benutzers oder

anderer Personen auszuschließen und Beschädigungen zu

vermeiden darf sie nur von fachlich geschultem Personal

betrieben werden.

Alle Arbeiten mit der Blizzard Heizzange müssen in

Übereinstimmung erfolgen mit

– dieser Anleitung,

– der Technischen Dokumentation der Anlage (beim

Endlosmachen von Bändern und Riemen in einer Anlage),

– den jeweils relevanten Verbindungsdatenblättern von

Forbo Movement Systems,

– allen relevanten gesetzlichen Vorschriften und sicherheits-

technischen Regeln.

Stopp

Während des Betriebes können die Heizplatten der

Heizzange und der eingesetzte Formschuh eine Temperatur

von 210 °C erreichen. Es besteht Verletzungsgefahr.

(Abb. 2.2.1)

2.3 Betriebsbedingungen

Die Siegling Blizzard Heizzange wird ausschließlich unter

den folgenden Umweltbedingungen betrieben:

– normale Atmosphäre (keine Öl- oder Gasatmosphären,

keine korrosiven Atmosphärenbestandteile)

Stopp

Das Gerät ist nicht spritzwassergeschützt.

Das Gerät ist nicht explosionsgeschützt.

Der Betrieb unter unzulässigen Betriebsbedingungen kann

schwere Schäden am Gerät und für den Bediener hervor-

rufen (Stromschlag, Verbrennung, Explosionsschaden).

Abb. 2.2.1

Heizplatten

Formschuh

20

3 BESCHREIBUNG

3.1 Bauteile/Hauptmaße

eingelegtes Band

Steuerung

mit Digitalanzeige

und Stellknöpfen

Heizzangenunterteil

Formschuhunterteil

Aufhängeösen (2 x)

Heizzangenoberteil

Formschuhoberteil

310 (12.2)

145 (5.7)130 (5.2)

Hauptmaße in mm und Zoll (in).

Alle zölligen Maße sind gerundet.

untere Heizplatte

obere Heizplatte

Table of contents

Languages: