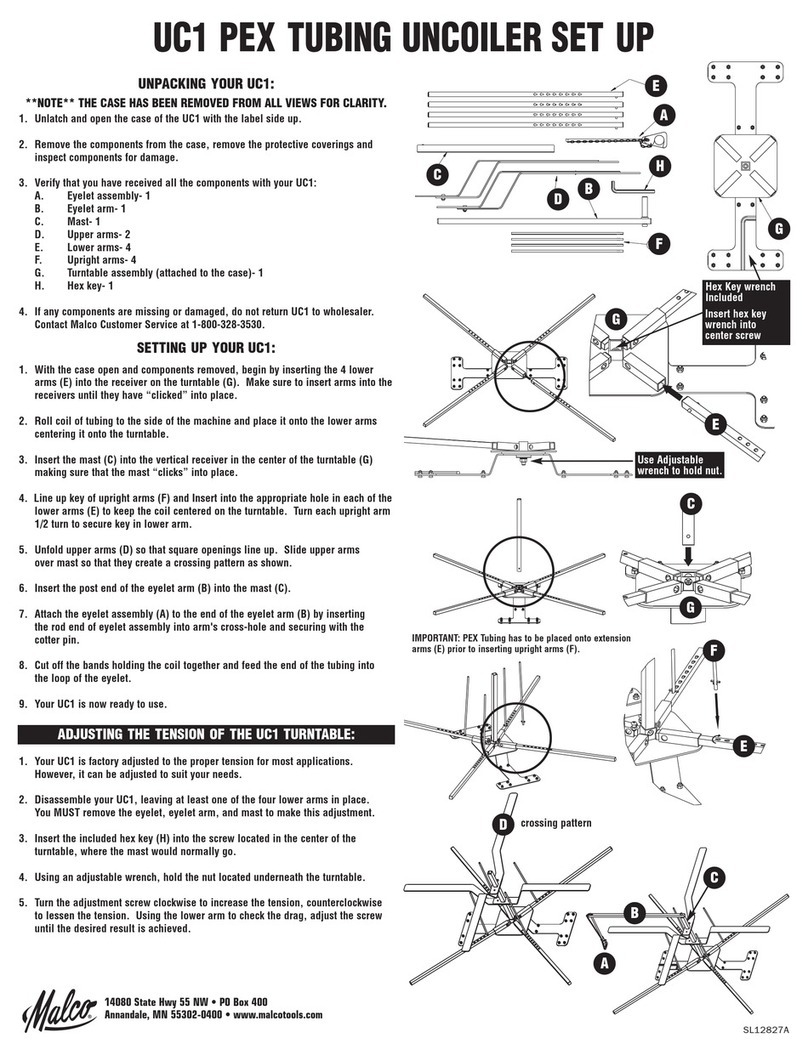

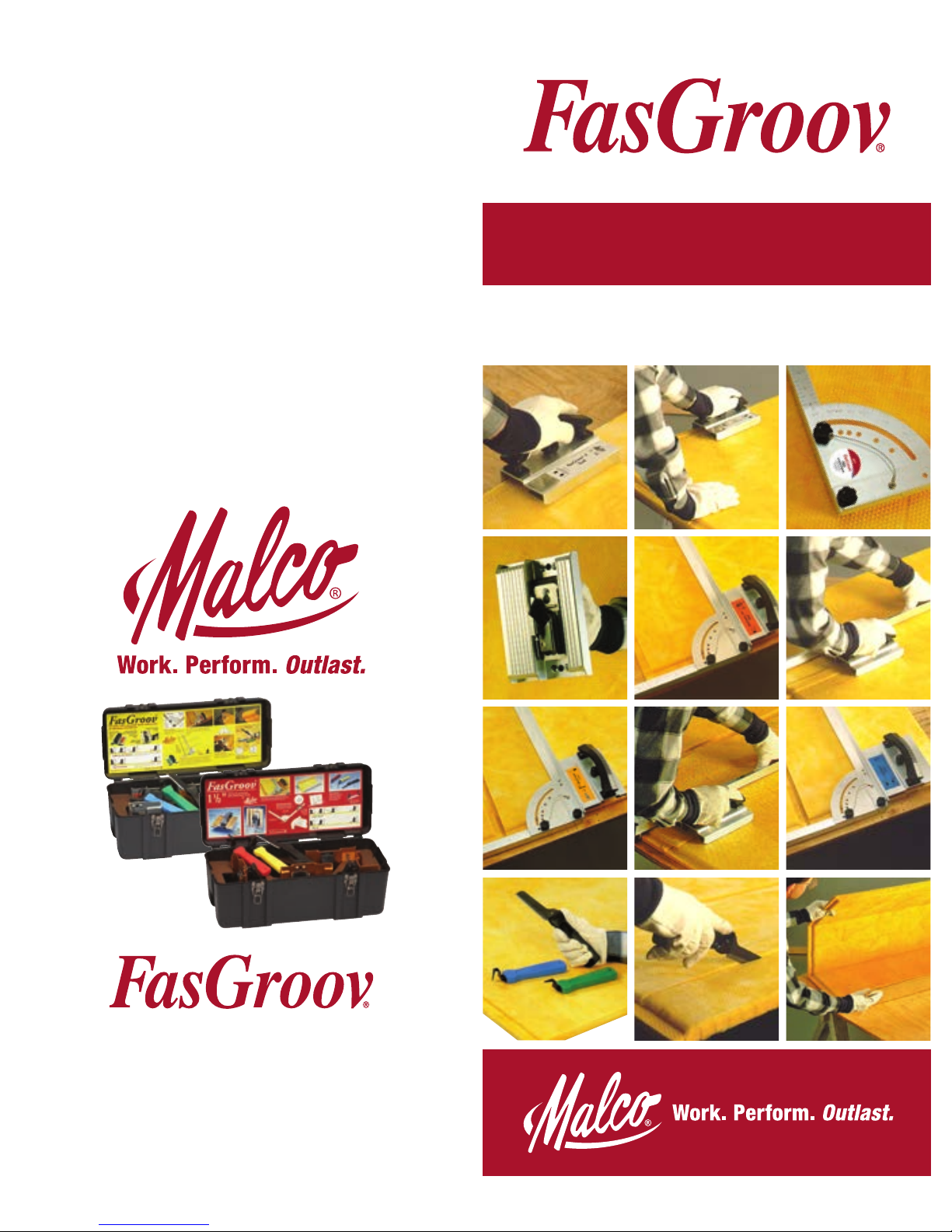

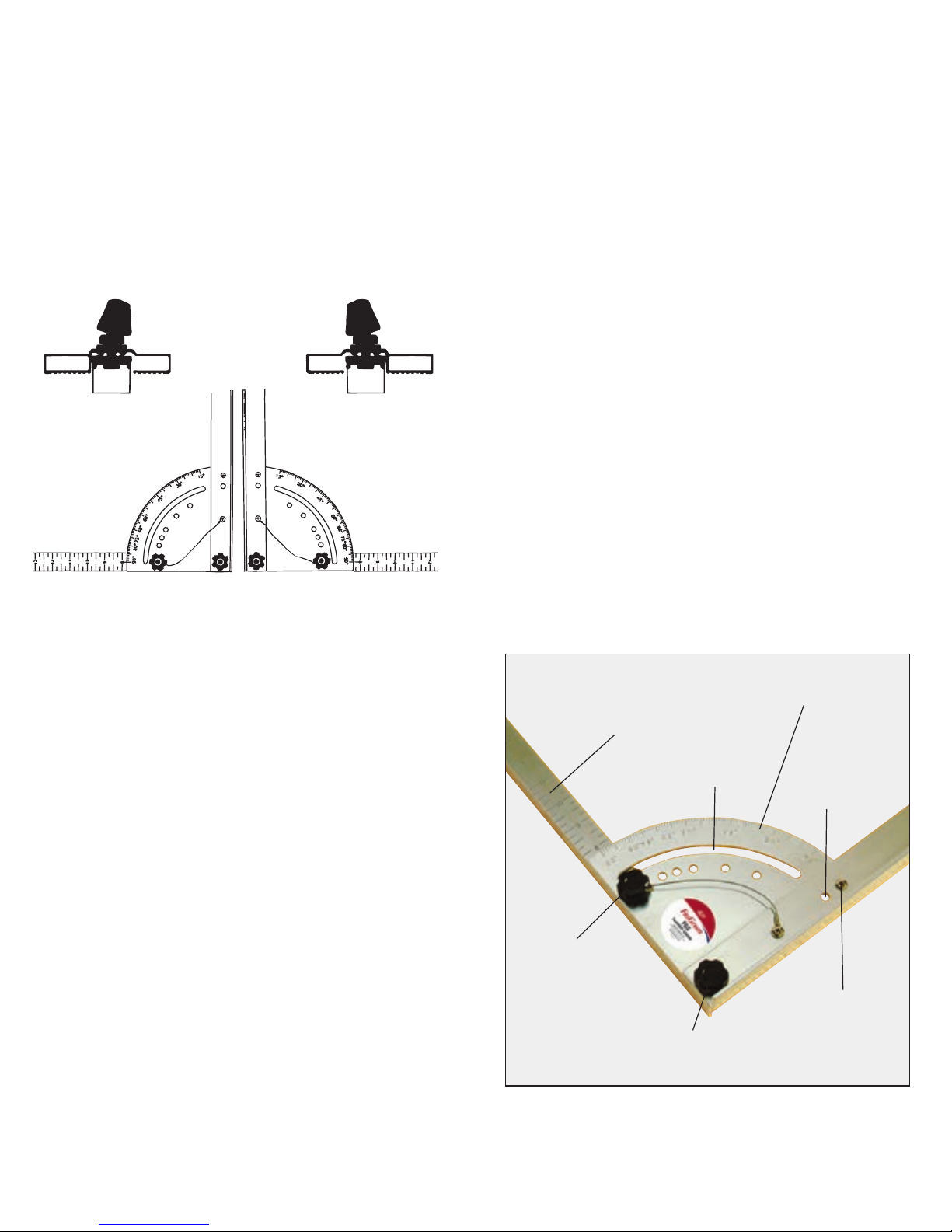

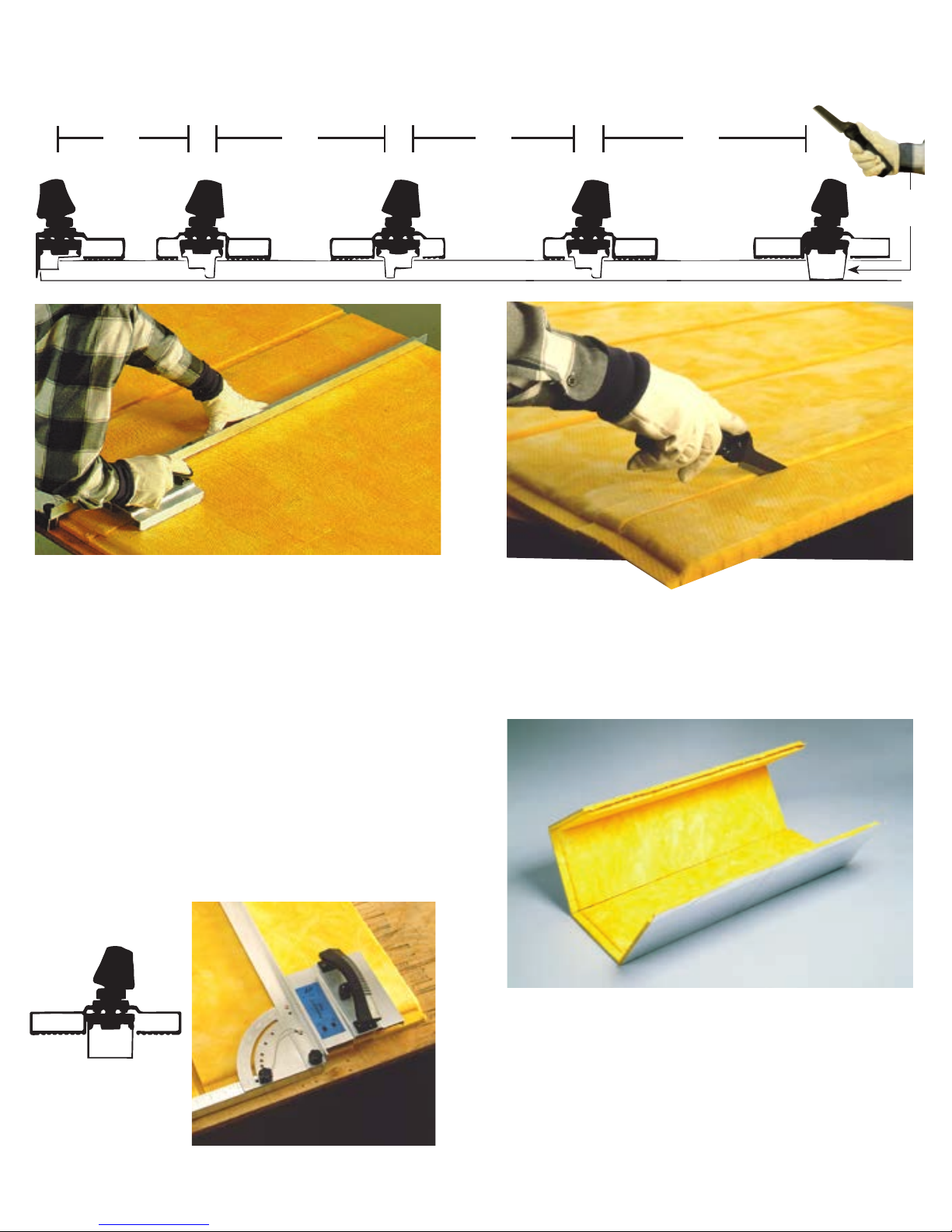

For right or left hand use:

• Right hand orientation of 1” kits is easily changed

by converting #5 Tool and FasGroov Square for left

hand fabrication. Tool handles may also be turned

around to provide left hand grip angle.

Right hand

operation.

Left hand

operation.

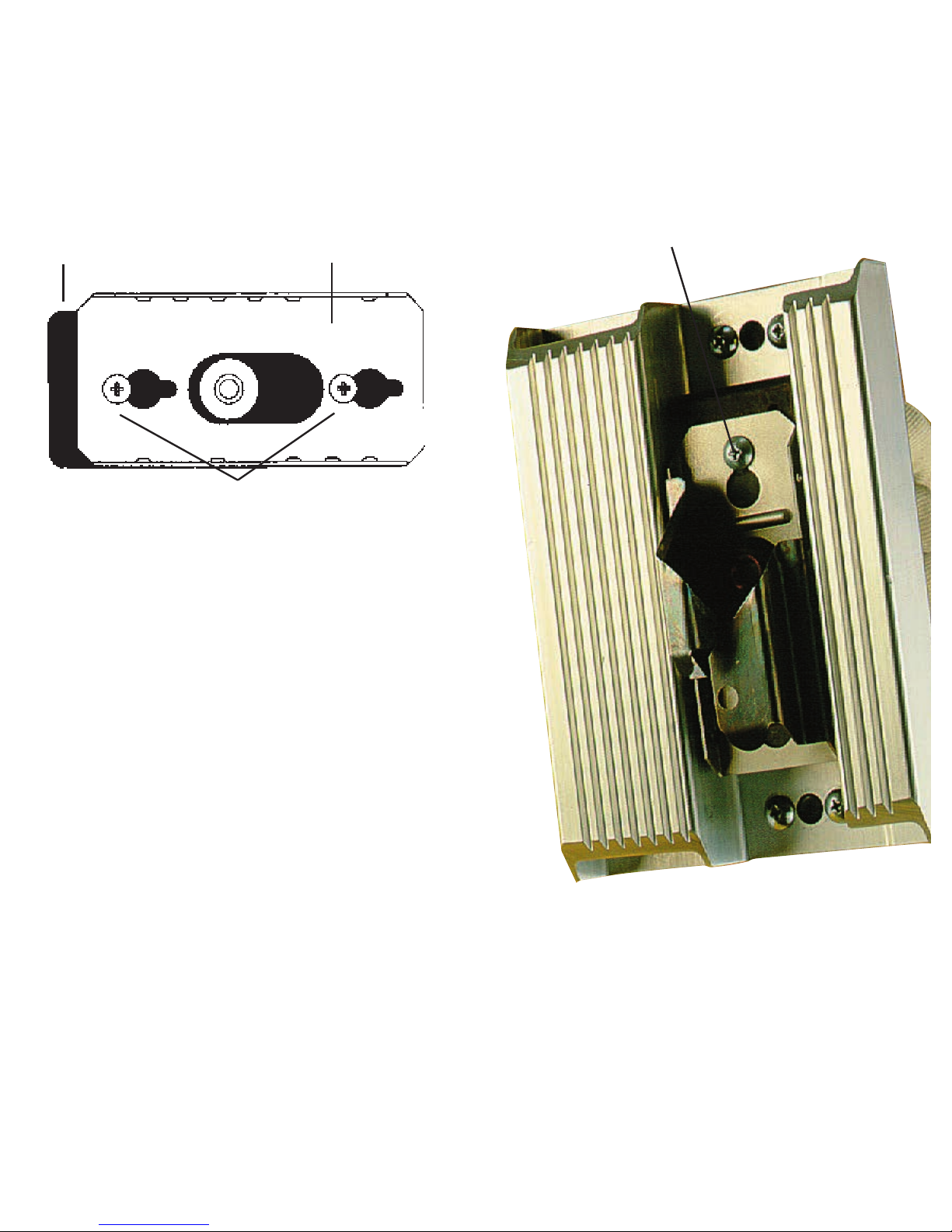

CONVERTING FASGROOV

SQUARE FOR LEFT HAND USE.

1. Remove the angle adjustment knob and the end pivot knob.

2. Position the ruler stamped leg so that the 3 holes are to

your left. (Rule reads left to right.)

3. Remove the protractor for the “L” shaped leg by removing

the two screws.

4. Flip the protractor over and install on the opposite end of the

“L” shaped leg.

5. Place the “L” leg/protractor assembly on top of the ruled leg.

6. Align the pivot knob holes and install the pivot knob.

7. Install the angle adjustment knob in any of the fixed positions

or the sliding position.

8. After converting your square for left hand use, double check

the accuracy in the fixed 90° position with a roofing square.

Built-in manufacturing hole tolerances will allow you

to true the square.

Note: 1-1/2” Kits cannot be converted for left hand use.

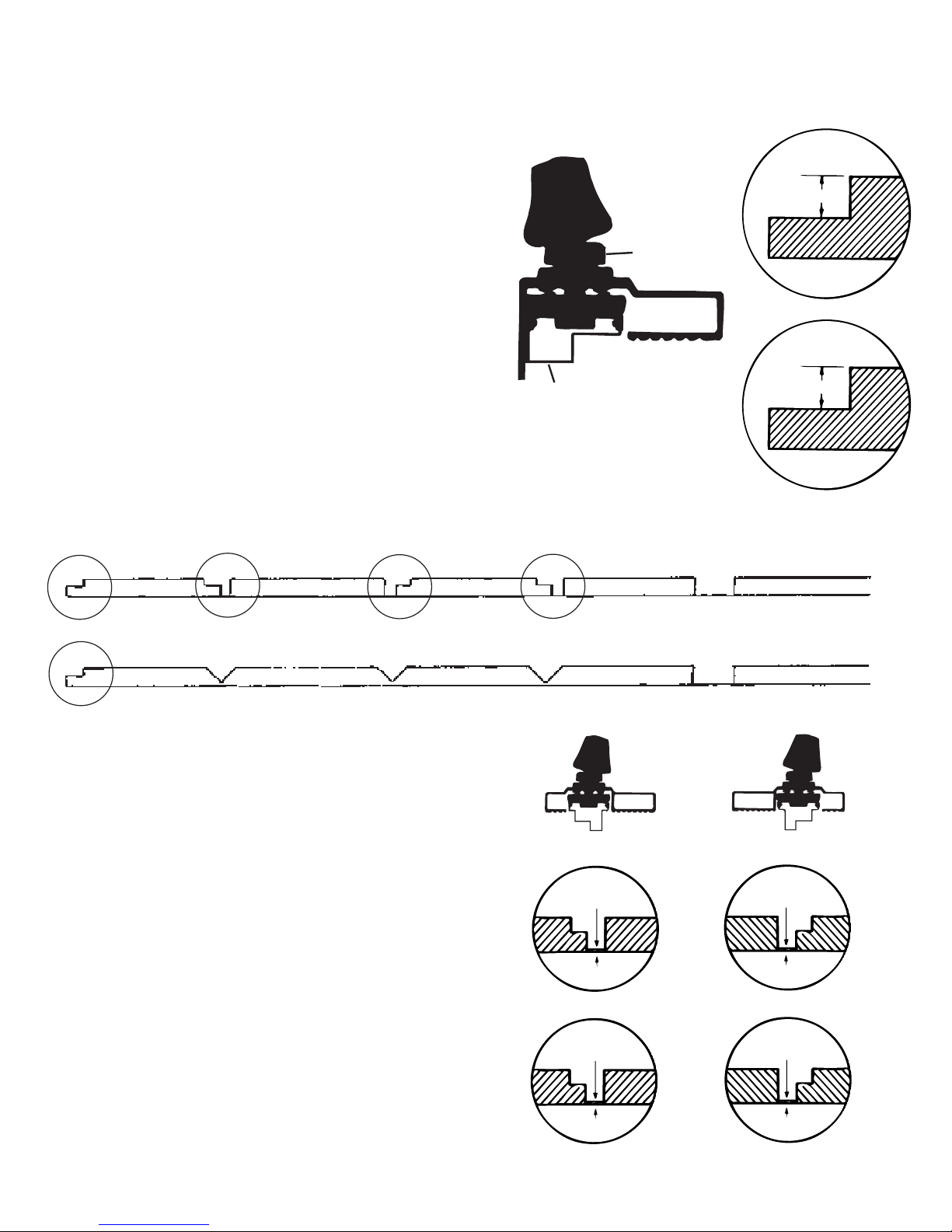

SETTING UP TOOL

Adjusting Fasgroov Square:

PREDETERMINED SETTINGS

Place adjustment knob into hole corresponding

to most used angles.

OTHER ANGLES

Place adjustment screw into protractor

adjustment slot and tighten at desired angle.

STORAGE

Step 1:

Remove angle adjustment knob and

fold ends of FasGroov Square together.

Step 2:

Place angle adjustment knob into the

storage hole and tighten.

Ruler stamped leg.

Pivot knob.

Angle adjustment

knob shown here in

90° predetermined

hole setting.

Adjustment slot

for other angles. Storage Hole

for angle

adjustment knob.

Screws holding

protractor to “L”

shaped leg.

Protractor scale etched 2 sides

for right or left hand use.

8 9