Siegmund 009950 Operational manual

Translation of the original operating manual

Rotating table

height adjustable

009950 (stationary) 009955 (mobile)

Bernd Siegmund GmbH

Keep for future reference! V1.0 / 01.10.2019

Operating manual –Rotating table 1 General information

2 / 15

Imprint

Manufacturer (service address)

Bernd Siegmund GmbH

Landsberger Strasse 180

86507 Oberottmarshausen

Germany

This operating manual contains descriptions and instructions to enable you to operate the rotating table and to

perform simple upkeep tasks.

It does not describe any complicated upkeep or repair work on the machine and components. For such activities,

please contact Bernd Siegmund GmbH.

You have further questions or requirements? We will be happy to help.

Warranty

The legal warranty obligations and periods shall apply.

All warranty claims shall become void if the product is used in a manner not corresponding to its intended purpose,

is subjected to unauthorised technical alterations or is opened (modification).

Bernd Siegmund GmbH shall not be liable for any damage or accidents that are attributable to use in a manner not

corresponding to the product’s intended purpose, to unauthorised modification of the product or to non-observance

of this operating manual.

© 2019 Bernd Siegmund GmbH

This operating manual, its reproduction by electronic means and on paper as well as translations of this operating

manual are protected by copyright.

Operating manual –Rotating table 1 General information

3 / 15

Contents

1General information ............................................................................................................................ 4

1.1 Target group.......................................................................................................................................... 4

1.2 Copyright ............................................................................................................................................... 4

2Safety.................................................................................................................................................... 4

2.1 Explanation of safety instructions and warning notices......................................................................... 4

2.2 Obligations of owner and personnel...................................................................................................... 6

2.2.1 Obligations of owner, organisational measures..................................................................................... 6

2.2.2 Obligations of personnel........................................................................................................................ 6

2.3 General safety instructions.................................................................................................................... 7

3Product................................................................................................................................................. 8

3.1 Product description................................................................................................................................ 8

3.2 Operator positions ................................................................................................................................. 8

3.3 Specifications ........................................................................................................................................ 9

3.4 Safety equipment .................................................................................................................................. 9

3.5 Intended use........................................................................................................................................ 10

3.6 Foreseeable misuse ............................................................................................................................ 10

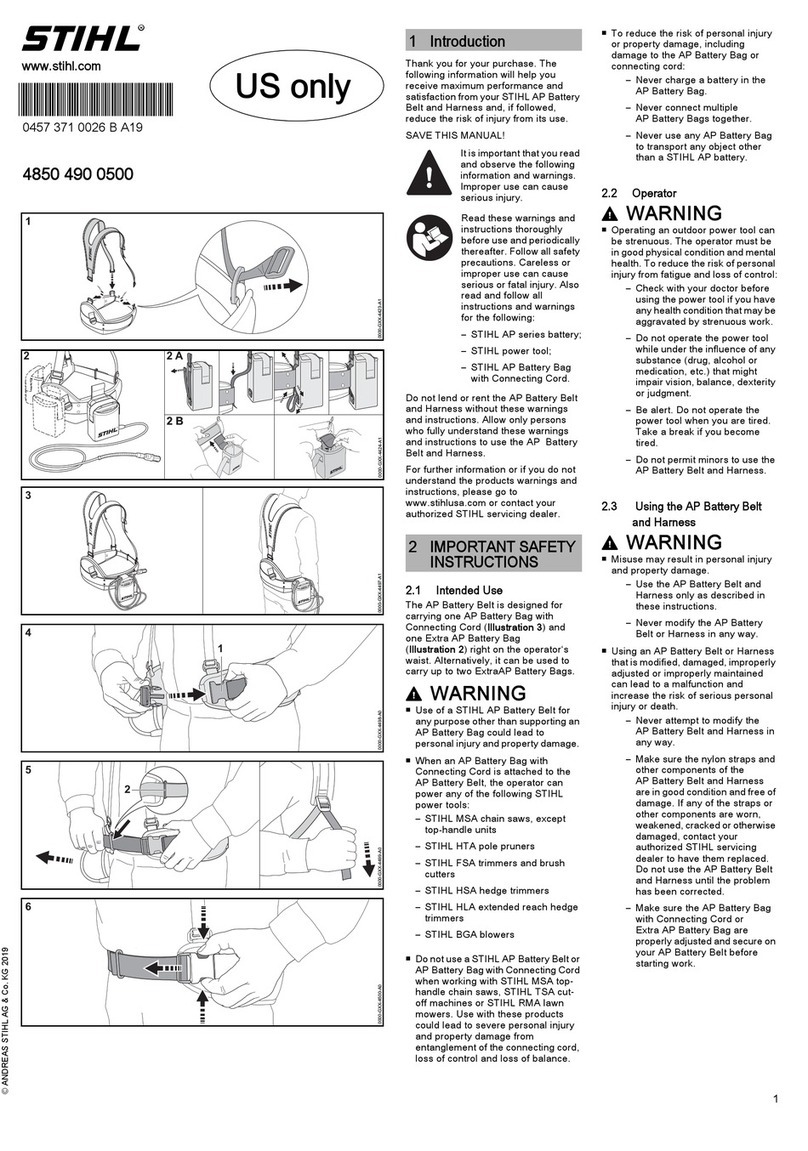

3.7 Rating plates ....................................................................................................................................... 11

3.7.1 Article-Nr. 009950 (stationary)..............................................................................................................11

3.7.2 Article-Nr. 009955 (mobile)...................................................................................................................11

4Transport............................................................................................................................................ 11

4.1 Delivery ............................................................................................................................................... 11

4.2 Safety .................................................................................................................................................. 11

4.3 Mounting and removing perforated plate............................................................................................. 12

5Operation ........................................................................................................................................... 13

5.1 Safety .................................................................................................................................................. 13

5.2 Raising and lowering rotating table ..................................................................................................... 13

5.3 Mounting components ......................................................................................................................... 13

6Upkeep and maintenance................................................................................................................. 13

6.1 Servicing.............................................................................................................................................. 13

6.2 Lubrication........................................................................................................................................... 14

6.3 Safety .................................................................................................................................................. 14

7Decommissioning ............................................................................................................................. 14

8Declaration of conformity................................................................................................................. 15

Operating manual –Rotating table 1 General information

4 / 15

1General information

IMPORTANT

Read carefully before use!

Keep for future reference!

This operating manual contains information on how to safely use the rotating table (article number 009950 or

009955), which is a machine used for raising and lowering perforated plates on which components to be welded or

otherwise processed are mounted.

The height adjustable rotating table is referred to below as “rotating table” or “machine”.

Before commencing their activities, all persons who are tasked by the owner with the operation, maintenance or

repair of the machine must have read and understood the operating manual, in particular "2 Safety". This especially

applies to personnel who are only occasionally tasked with work on the machine, e.g. maintenance technicians and

external personnel.

WARNING

Observe the operating manual:

•All persons who operate the rotating table must have read the operating manual beforehand.

The owner must ensure that at least one copy of the operating manual is available at the machine and accessible to

the target persons who handle the product.

The operating manual is part of the machine and must be kept throughout its service life.

The operating manual must be passed on to every subsequent owner or user of the machine.

The manufacturer shall not be liable for injuries and damage that are attributable to non-observance of the

operating manual and in particular of the safety instructions given in the operating manual.

1.1 Target group

The target group of this operating manual are all persons who are tasked by the owner with activities (e.g.

operation, setup, cleaning, maintenance, repair) on the rotating table. This also applies to external personnel.

1.2 Copyright

This operating manual as well as the operating documents remain the intellectual property of Bernd Siegmund

GmbH. They are supplied to the customer/owner as an integral part of the product.

Without our explicit consent, these documents may be neither duplicated nor made available to third-party

companies, in particular competing companies.

2Safety

2.1 Explanation of safety instructions and warning notices

This operating manual contains safety instructions and warning notices which are intended to prevent injury and

damage. It is essential to observe the warning notices. Failure to observe these notices can lead to injury, damage,

destruction of components and to inoperability of the rotating table.

Presentation of safety instructions and warning notices

Safety instructions and warning notices are clearly highlighted. They have the following structure:

Operating manual –Rotating table 2 Safety

5 / 15

WARNING

Type of hazard

Description, cause and source of the hazard

•Measure to avert the hazard

optional: sub measure

The following signal words are used:

WARNING

Warns of potential severe injury or risk to life

Indicates a potentially hazardous situation that can lead to death or

severe injury if the safety measures are not observed.

CAUTI ON

Warns of a hazard

Indicates a potentially hazardous situation that can lead to minor or slight

injury if the safety measures are not observed.

N O T E

Warns of damage

Failure to observe this notice can result in damage to the machine or its

surroundings.

Simplified safety instructions and warning notices

Safety instructions and warning notices may deviate from the form shown above if they are also understandable

and actually more succinct in simplified form.

Simplified safety instructions and warning notices consist of

−Signal word with coloured background corresponding to the warning levels

−Information text

Example of a simplified warning notice, "Warning" hazard level:

Warning symbols

The following symbols indicate hazards:

General hazard

Hand injuries hazard

Suspended loads hazard

Fall hazard

Personal protective equipment

The following symbols indicate that personal protective equipment must be worn:

Use hand protection

Use foot protection

WARNING

•Text of the simplified safety instruction and warning notice

Operating manual –Rotating table 2 Safety

6 / 15

2.2 Obligations of owner and personnel

2.2.1 Obligations of owner, organisational measures

The owner tasks in-house personnel or external personnel with the operation, maintenance, repair, etc. of the

rotating table.

Hazard notices

The owner must ensure that the safety instructions and warning notices for the product are observed and that the

safety instructions and warning notices as well as the information signs are in a clearly legible condition.

Modifications

Without the consent of the manufacturer, it is not permitted to make any modifications (retrofits, additions) to the

machine if such modifications may impair safety. This also applies to the installation of safety devices.

Checks, servicing

The servicing as specified in section "6 Upkeep and maintenance" must be observed.

Personnel selection, personnel qualification

Work on the machine may be performed only by reliable personnel authorised by the owner. Activities at the

rotating table require the knowledge of a skilled and trained person; additionally, an appropriate technical

qualification is required for certain activities.

−The owner must establish the responsibilities of the operating personnel, also with regard to safety-

compliant conduct, and empower the operating personnel to refuse to carry out unsafe activities.

−Personnel who are in the training, instruction, learning or onboarding phase, as well as persons under the

age of 18 may work on the rotating table only if they are under the constant supervision of an experienced

person.

The owner must take organisational and instructive measures to ensure that the relevant safety standards and

safety rules are observed by persons who are tasked with operation, maintenance and repair of the machine.

Personal protective equipment

The owner is obliged to provide personnel with the required personal protective equipment, e.g. protective gloves

and safety footwear.

The owner must ensure that only personnel with the required protective equipment work on the rotating table.

2.2.2 Obligations of personnel

All persons who are tasked with working on the machine are obliged

−to conduct themselves in a safe and responsible manner at all times in order to ensure occupational health

and safety;

−to follow and comply with national laws and regulations as well as the applicable in-plant regulations

defined by the owner with respect to accident prevention, work safety and firefighting;

−to perform the following if the operating behaviour of the machine changes and if malfunctions occur which

jeopardise the safety of persons or endanger the machine:

–immediately shut down the machine;

–immediately report the faults to the relevant authority / person; and

–notify the affected personnel.

Operating manual –Rotating table 2 Safety

7 / 15

2.3 General safety instructions

The rotating table may be used only if it is fully functional and in a technically flawless condition.

The rotating table must undergo a visual inspection before each use to ensure that it is in perfect working order.

−Check for

–damage;

–corrosion; and

Also observe the following basic rules:

−In the event of unusual operating behaviour, noises, etc., find the cause immediately.

WARNING

•Wear personal protective equipment on the machine: protective gloves, safety footwear

-When moving the rotating table on its castors and when positioning:

-Move the rotating table slowly.

-Be particularly careful on sloping surfaces; take additional safety measures if

necessary (e.g. request the assistance of additional persons).

-Always position the rotating table on a level surface. After positioning, secure the

rotating table using the brakes to prevent it from rolling away.

WARNING

Crushing hazard

Components or the perforated plate may fall off the rotating table if they are unstable and not

fastened securely.

•Position the perforated plate centrally and screw it down. Use only perforated plates with

mounting holes supplied by the manufacturer. Other perforated plates must be approved

by the manufacturer.

•Transporting using a crane: Leave the perforated plate secured to the crane until the

perforated plate has been screwed to the rotating table.

•Securely clamp all components to the perforated plate. Distribute the components evenly

on the perforated plate.

•Nominal load: 1.000 kg. The perforated plate and the components mounted on it must not

exceed the nominal load.

WARNING

Crushing hazard

By raising or lowering through rotation of the rotating table fingers can be crushed by the

spindle.

•Do not reach into the spindle.

•While rotating do not crawl into the area below the perforated plate. Head is not to be put

on the same height as the rotating perforated plate.

•Ensure that there are no other persons at the rotating table while it is being raised or

lowered.

CAUTI ON

Fall hazard

Persons may fall from the rotating table if they climb onto it.

•It is forbidden to walk on and climb onto the rotating table.

Operating manual –Rotating table 3 Product

8 / 15

WARNING

Crushing hazard

Persons can be crushed while the perforated plate is being lowered into position. There is also

a danger of crushing if the perforated plate tips or falls off.

•The perforated plate should be transported using a crane where possible:

Attach the perforated plate securely to the transport equipment: Mount the transport

brackets to the perforated plate; with 1 transport bracket, mount it centrally; with several

transport brackets, mount them in such a way that the perforated plate remains stable

and level during transport.

Insert the slings into the transport brackets.

Use only transport equipment, rotating gear and slings that are suitable for the load.

Observe the weight specification of the perforated plate.

Observe the applicable regulations regarding transport using a crane.

•Ensure that the perforated plate is transported safely:

Ensure that the perforated plate is not tilted when lifted.

Move the load slowly and smoothly.

Avoid unstable positioning of the load on the transport equipment; avoid rocking and

swinging.

Set down the load slowly.

•The perforated plate must be transported by trained, authorised personnel only.

•Only those persons required for the work are allowed to be in the danger area. Do not stand

below suspended loads.

3Product

3.1 Product description

Different perforated plates on which components are secured for manual welding work or other processing

operations (e.g. milling, sawing or grinding) are mounted on the rotating table. These components can then be

moved to the desired working height by raising or lowering the rotating table by turning the rotation-unit/perforated

plate.

The rotating table 009955 is mobile and can be moved on its castors. It can therefore also be used to transport the

components.

3.2 Operator positions

Operator positions are

−on all sides of the perforated plate for

–positioning and mounting the components to be welded and/or processed;

–welding or other processing operations; and

–positioning and screwing down the perforated plate.

−at the locking-unit

–Locking the rotation of the rotation-unit/perforated plate

–raising and lowering the work surface.

−on the castors with brakes for

–locking the castors; and

–releasing the castor brakes.

Operating manual –Rotating table 3 Product

9 / 15

The machine consists of the following components and systems:

No.

Product component

Article-Nr. 009950

(stationary)

Article-Nr. 009955

(mobile)

1

Perforated plate

X

X

2

Rotation-unit

X

X

3

Underframe

X

X

4

Locking-unit

X

X

5

Grease nipple

X

X

6

Castors with brakes

-

X

7

Baseplate

X

-

3.3 Specifications

Article-Nr. 009950

(stationary)

Article-Nr. 009955

(mobile)

Dimensions, approx.

(length x width x height)

785 x 785 x 740 - 1.100 [mm]

(excl. perforated plate)

795 x 795 x 740 - 1.100 [mm]

(excl. perforated plate)

Weight (approx..)

70 kg (excl. perforated plate)

Operating environment

Industrial and commercial sectors

Nominal load

1.000 kg

grease

3.4 Safety equipment

The machine has the following safety equipments:

Description

Location

Locking unit

Front

Brakes

Castors

1

2

3

4

5

6

7

Operating manual –Rotating table 3 Product

10 / 15

3.5 Intended use

The rotating table is used for mounting components for manual welding work or other operations (e.g. sawing,

milling), for adjusting their height (and for transporting them).

The rotating table 009955 has castors for moving the rotating table. By turning the rotation-unit, the perforated plate

(i.e. the work surface on which the components are mounted) can be moved to the correct height.

The perforated plates can be replaced. Only perforated plates approved by the manufacturer may be mounted on

the rotating table.

Only perforated plates from Bernd Siegmund GmbH may be mounted. Perforated plates from other manufacturers

as well as perforated plates that have features different to those specified above must also be approved beforehand

by the manufacturer of the rotating table.

Each perforated plate must be mounted centrally on the rotating table. Only perforated plates that can be mounted

centrally are permissible.

Components may be transported, welded or otherwise processed on the rotating table only if they are in a stable

position and screwed or clamped securely to the perforated plate. Where possible, the weight of the components

must be distributed centrally and uniformly on the perforated plate.

Nominal load: 1.000 kg. The combined weight of the perforated plate and components must not exceed the nominal

load.

If used outdoors, the rotating table must be protected from moisture and, if necessary, must be dried in order to

prevent corrosion.

The machine and its components must not be modified without first consulting the manufacturer.

Intended use also includes:

−use of the rotating table only when it is in perfect working order;

−compliance with the operating and ambient conditions specified by the manufacturer; and

−compliance with the procedures described in this operating manual and observance of all safety

instructions.

WARNING

•Use the rotating table and its components only in accordance with their intended use and

specifications.

The manufacturer shall not accept liability for injuries and damage resulting from inappropriate

use of the rotating table.

3.6 Foreseeable misuse

Misuse arises if

−impermissible perforated plates or perforated plates not approved by the manufacturer are mounted on the

rotating table

−the perforated plate is not or cannot be mounted centrally on the rotating table;

−the components not secured to the rotating table in such a way that their weight is distributed uniformly on

the perforated plate.

WARNING

•Do not use the rotating table if the rotating table or its components are damaged.

Operating manual –Rotating table 4 Transport

11 / 15

3.7 Rating plates

3.7.1 Article-Nr. 009950 (stationary)

3.7.2 Article-Nr. 009955 (mobile)

4Transport

4.1 Delivery

The rotating table is delivered by the manufacturer or a forwarding agent with appropriately qualified personnel.

4.2 Safety

When the rotating table is moved on its castors, the perforated plate is replaced, the rotating table is transported

using other transport equipment, individual components are transported (e.g. for repair or replacement) or

components to be processed are transported, injuries may be caused by the rotating table, perforated plate or

falling or tipping components. Therefore, observe the following safety instructions:

−When moving the rotating table on its castors:

–Push the rotating table slowly. Be particularly careful on sloping surfaces; take additional safety

measures if necessary (e.g. request the assistance of a second person).

–Do not pull the rotating table.

−Always position the rotating table on a level surface. After positioning, secure the rotating table using the

brakes to prevent it from rolling away; secure using additional means (e.g. wheel chocks) where necessary.

−Before transporting: Remove any components not mounted on the perforated plate

−When replacing the perforated plate and transporting the rotating table or components, observe the

following safety measures, e.g.

–attach the perforated plate, rotating table and components to be transported securely to the transport

equipment.

–Use transport brackets suitable for replacing the perforated plate.

–Secure the rotating table to the crane using straps;

–Move the load slowly and smoothly.

–Avoid unstable positioning of the load on the transport equipment and avoid rocking.

–Use only transport equipment, rotating gear and slings suitable for the load (perforated plate, rotating

table or component). Observe the weight specifications of the components to be moved.

−Only authorised and trained or suitably qualified persons are allowed to transport the perforated plate,

rotating table or individual components. They are responsible for correct and safe transport.

−All persons who are not required for the work must leave the danger area. Do not stand below suspended

loads!

Operating manual –Rotating table 4 Transport

12 / 15

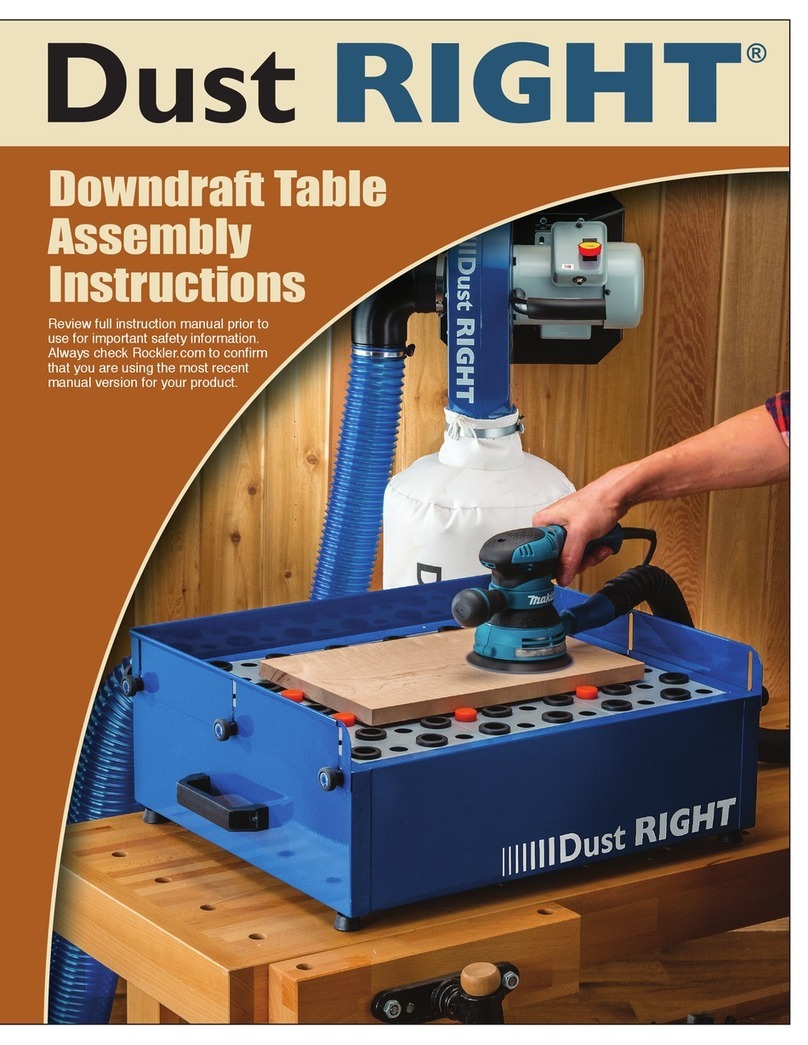

4.3 Mounting and removing perforated plate

To mount the perforated plate:

−Choose fitting fixture points for each perforated plate (according to the figure below)

▪16: Fixture points for system 16

•all cleared sizes of perforated plates

▪22&28 (<1500x1000): Fixture points for systems 22 and 28

•Size of perforated plate: smaller than1500x1000 [mm]

▪22&28 (1500x1000): Fixture points for system 22 and 28

•Size of perforated plate: 1500x1000 [mm]

−Move the perforated plate to the rotating table using suitable transport equipment (e.g. crane).

−Position the perforated plate centrally above the rotating table.

−Slowly lower the perforated plate.

−When the perforated plate is located immediately above the adjustment screws where it will be attached,

pull the perforated plate to the precise position by hand if necessary.

−Set the perforated plate down onto the adjustment screws.

−Secure the mounting screws on the adjustment screws.

−The perforated plate should remain secured to the transport equipment until the perforated plate has been

securely attached.

−Use the adjustment screws to precisely adjust the perforated plate so that it is as horizontal and level as

possible.

To remove a perforated plate:

−Remove all components from the perforated plate.

−Attach the transport bracket(s) to the perforated plate.

−Insert slings through the transport bracket(s).

−Raise the transport equipment until the rotating gear is slightly tensioned and then secure the perforated

plate to the transport equipment.

−Undo all mounting screws securing the perforated plate to the adjustment screws.

−Lift off the perforated plate.

WARNING

•Avoid rotating off at an angle; the pulling force must be applied vertically upwards.

•Avoid swinging and rocking when rotating and transporting.

Operating manual –Rotating table 5 Operation

13 / 15

5Operation

5.1 Safety

Observe the following safety instructions:

−The rotating table 009955 is mobile and can be moved on its castors. If the rotating table is to be moved to

a different installation location, observe the safety instructions in section 4.

−Always position the rotating table on a level surface. After positioning, secure the rotating table using the

brakes to prevent it from rolling away.

−Provide sufficient space at the installation location.

−Visually inspect the rotating table before each use to ensure that it is in perfect working order.

–The rotating table must not be damaged and must not exhibit any significant corrosion. It must be fully

functional and in a technically flawless condition.

–The perforated plate must be securely attached.

Only authorised and trained persons are allowed to use the rotating table. They are responsible

for ensuring that the rotating table is used correctly and safely.

5.2 Raising and lowering rotating table

The rotating table is raised by turning the rotating unit/perforated plate counter clockwise until the desired height is

reached. Turning the upper part clockwise lowers the rotating table.

5.3 Mounting components

Components are best mounted on the perforated plate when the perforated plate is already set to the appropriate

working height. It is, however, possible to adjust the height later.

When the components come to rest on the perforated plate, they must be fixed in place using suitable clamping and

fastening elements.

Components, clamping and fastening elements can be mounted securely using the system holes in the perforated

plate. The clamping and fastening elements must be suitable for the components and their weight as well as for

attachment to the perforated plate. They must be able to fix the components in a stable position that prevents them

from tipping or slipping.

When mounting the components on the perforated plate, observe the following safety instructions:

−The safety instructions in sections 4 and 5.1 apply when transporting the components.

−Before components are mounted, the rotating table must be on a level surface and secured using the castor

brakes to prevent it from rolling away.

−During mounting, all components on the perforated plate must be secured to prevent them from tipping over

and falling off.

−Ensure that there is nobody in the danger area: Only those persons required for the activity are allowed to

remain at the rotating table.

6Upkeep and maintenance

Upkeep and maintenance ensure that the rotating table is always safe to use.

6.1 Servicing

Rotating table at regular, e.g. monthly, intervals:

−Check for damage, wear and corrosion.

−Check that all connections are tight. Refasten loose connections as necessary. All components must be

mounted securely.

−Replace any defective components.

Operating manual –Rotating table 7 Decommissioning

14 / 15

WARNING

•Maintenance work on the rotating table that is not performed promptly or is performed

incorrectly may pose a risk to persons after the rotating table is put back into regular

operation.

6.2 Lubrication

To ensure low-noise and low-wear operation of the rotating table, regular lubrication is required (grease nipple).

The interval depends on the frequency and intensity of use. Lubrication at least once a year is recommended.

Interval (recommended)

Annually

Grease (minimum requirement)

DIN 51502 K2K-30

6.3 Safety

Before commencing work (e.g. maintenance or repairs), the rotating table must be secured using the castor brakes

to prevent it from rolling away.

Maintenance and repair work may only be performed if there are no components on the table.

WARNING

Unsuitable replacement parts may result in injuries to persons and damage to the rotating table.

•Use only original replacement parts from the manufacturer.

•If you require replacement parts, contact the service address.

Correct upkeep of the rotating table requires appropriately trained specialist personnel. All maintenance and upkeep

work may be performed only by trained and authorised specialist personnel qualified to carry out the tasks

concerned.

The owner is responsible for assigning specialist personnel and for providing the appropriate training.

Contact Bernd Siegmund GmbH in the case of defective components or modifications to the rotating table.

Maintenance staff and specialist personnel are responsible for ensuring that the work is performed safely and that

the appropriate health and safety measures are taken. They must have read and understood the relevant

regulations before starting work.

7Decommissioning

Disassembly may be performed by specialist personnel only.

WARNING

•Lower the rotating table to its lowest position

N O T E

Final decommissioning and disposal require complete scrapping.

The product is dismantled into its component parts.

The parts must be recycled, disposed of in accordance with local regulations or returned to the

manufacturer.

Any residual media collected in suitable containers and disposed of properly.

Operating manual –Rotating table 8 Declaration of conformity

15 / 15

8Declaration of conformity

This manual suits for next models

1

Table of contents