Siemens Energy DigiTRONf DFRV Series User manual

Unrestricted

Lorem ipsum l Veribus

dolorpro

DigiTRONf

Installation, Operations and

Maintenance Manual

IOM-008 Rev 5

DigiTRONfEFL’s, Jumpers and Harness Assemblies

Protection, Storage, Shipment, Unpacking, Deployment and

Maintenance Instructions

siemens-energy.com

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

2 of 43

Unrestricted

DigiTRONfEFL’s, Jumpers and Harness Assemblies

Protection, Storage, Shipment, Unpacking, Deployment and

Maintenance Instructions

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

3 of 43

Unrestricted

Thank you for purchasing a Siemens Energy Subsea product. The information contained in this

document is an overview including the protection, storage, shipment, unpacking, deployment and

maintenance for DigiTRON connector product range.

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

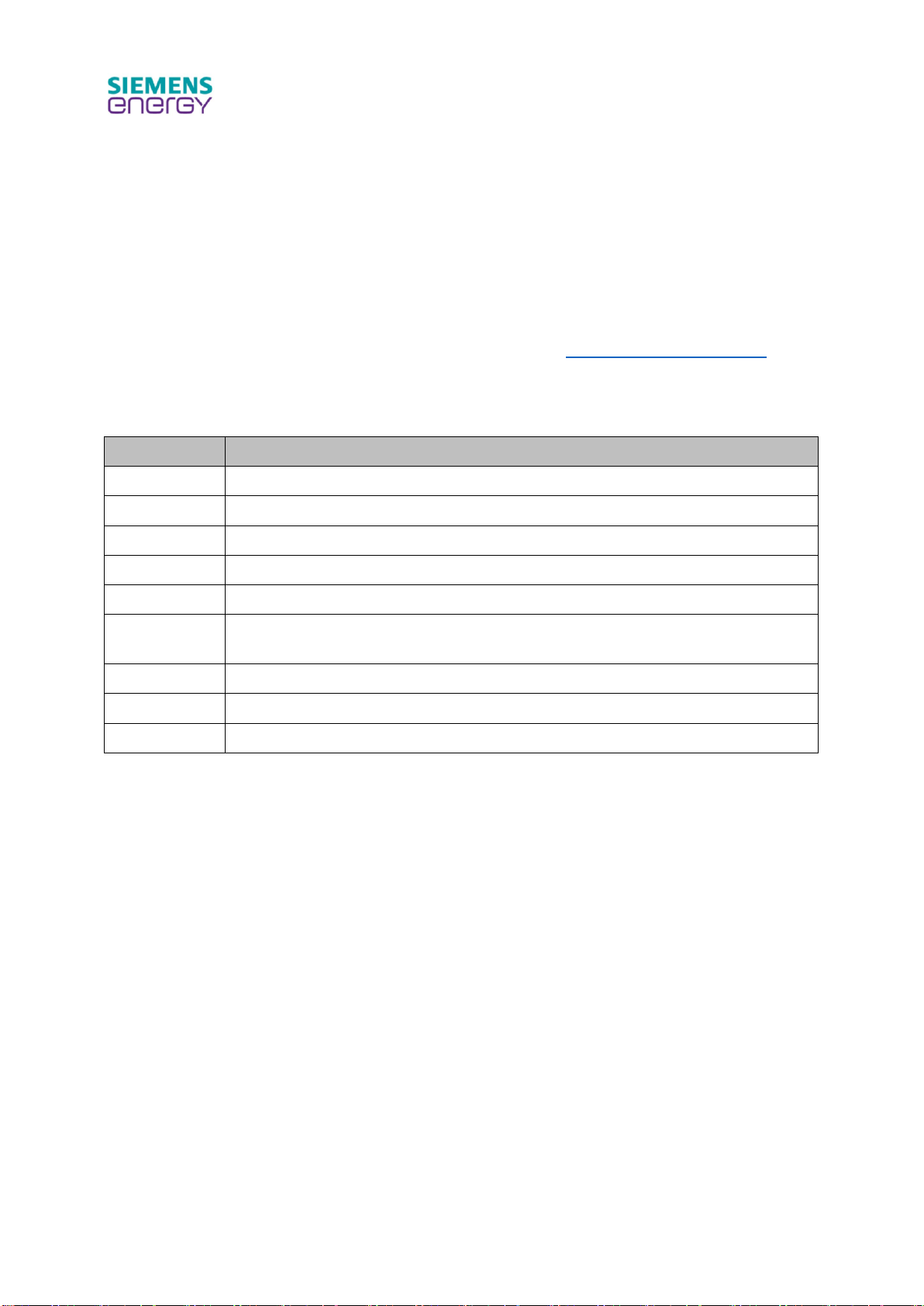

Rev

Compiled

by

Date

Approved

by

Issue Date

Page(s) Affected/Remarks

01

M Tucker

09.11.2020

R Wyatt

09.11.2020

First issue

02

J.Pridmore

23/08/2021

M.Tucker

23/08/2021

Etching detail updated

Connector Specification updated with

Physical Contact type and No. of ways

Extra abbreviations added to section 4

Images updated to show latest paddle handle

Storage Temperature range added for

Mate/De-mate tool

03

J.Pridmore

31/08/2021

M.Tucker

31/08/2021

Junction Box interface drawing changed to

10199114

04

R Wyatt

27/06/2022

R Wyatt

27/06/2022

Sections affected: 2.4 3.3.5 5.1 5.2 6.3

6.4.1 6.4.2 6.4.3 7.3.2 7.3.3

Siemens Energy front and back cover pages

added.

05

R Wyatt

17/03/2023

JP Smith

17/03/2023

Sections affected: 2.2, 6.1, 6.2, 6.4, 7.4, 8.2, 9.5

9.7, 9.8. Information added or changed:

temperature limits for storage 50°C air temp.

Outdoor storage of wooden crates. Bend radius

guage and protection from crate edges. Check for

test connectors, incl gauge for bent pins. Inspection

for corrosion, damage to front seals added.

Cleaning with IPA added. Visibility of lipseal

indicator from side view.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

4 of 43

Unrestricted

Contents

1PRODUCTS COVERED BY THIS MANUAL..............................................................6

2BASIC INFORMATION & QUICK REFERENCE........................................................7

2.1 Product overview..............................................................................................7

2.2 Product specification and certification...........................................................8

2.3 Contact details and feedback ..........................................................................9

2.4 Product advice label.........................................................................................9

2.5 Product marking .............................................................................................10

2.6 Product examples...........................................................................................11

3PRODUCT SAFETY .................................................................................................13

3.1 Action-related warnings.................................................................................13

3.2 Intended use....................................................................................................13

3.3 General safety information.............................................................................14

3.4 Related documents.........................................................................................16

3.5 Control of substances hazardous to health (COSHH).................................17

4ABBREVIATIONS.....................................................................................................18

5SPECIFICATIONS ....................................................................................................19

5.1 Connector Specification.................................................................................19

5.2 Siemens Energy AquaTRON pressure-balanced oil-filled hose

specification ............................................................................................................20

6PREPARING PRODUCT FOR USE OR STORAGE ................................................21

6.1 Product protection and packaging................................................................21

6.2 Unpacking........................................................................................................22

6.3 Lifting of harnesses and OFLs ......................................................................22

6.4 Storage, protection and end of life................................................................23

7INSTALLATION AND ASSEMBLY ..........................................................................26

7.1 Pre-installation checks for OFL’s ..................................................................26

7.2 Cathodic protection........................................................................................26

7.3 Installation of harnesses with flanged connectors and / or Fiber

Marshalling Unit ......................................................................................................26

7.4 TESTING OF OFL’S.........................................................................................30

8USER INFORMATION DURING NORMAL OPERATION AND FAULT CONDITIONS

..................................................................................................................................32

8.1 Visible/audible signals ...................................................................................32

8.2 Normal and faulty/dangerous operation.......................................................32

8.3 Troubleshooting..............................................................................................32

9PRODUCT OPERATION AND MAINTENANCE ......................................................33

9.1 Safety precautions..........................................................................................33

9.2 Product maintenance and servicing .............................................................33

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

5 of 43

Unrestricted

9.3 Product protection; caps and dummy connectors ......................................33

9.4 Live Mate / De-mate ........................................................................................34

9.5 Inspection and cleaning of connector products ..........................................34

9.6 Removal of marine growth and calcareous deposits ..................................34

9.7 Checks before mating the product................................................................36

9.8 ROV connectors mating and de-mating........................................................36

9.9 Manual (hand) mating and demating of the connectors..............................38

10 CUSTOMER COMMENTS/FEEDBACK...................................................................42

Tables

Table 1 List of other Installation, Operation and Maintenance manuals related to

DigiTRON product range..................................................................................................... 6

Table 2 DigiTRONf product range identification......................................................7

Table 3 DigiTRONf product specification and certification.....................................8

Table 4 DigiTRON product contact details............................................................... 9

Table 5 AquaTRON oil-filled hose specification.....................................................20

Table 6 Troubleshooting product contact details.................................................. 32

Illustrations

Figure 1 Product advice label ................................................................................... 10

Figure 2 Product marking on DigiTRON product.....................................................10

Figure 3 Typical OFL (Optical Flying Lead)..............................................................11

Figure 4 Example of OFL........................................................................................... 11

Figure 5 Typical multi-leg OFL or harness assembly.............................................. 12

Figure 6 Typical AFT to Receptacle (1out harness) assembly ............................... 12

Figure 7 Examples of DigiTRONf oil hose connectors............................................12

Figure 8 AquaTRON hose, size 50 (1/2” bore), and size 75 (3/4” bore) .................. 20

Figure 9 Acceptable packaging for shipment.......................................................... 21

Figure 10 Unacceptable packaging and storage ....................................................... 22

Figure 11 Minimum bend radius gauges.................................................................... 22

Figure 12 Illustration of strapping points for lifting hose assemblies.....................23

Figure 13 Installation of compliant flange-mount ROV receptacle........................... 27

Figure 14 Sectional view of installation and parts of compliant mount connector. 27

Figure 15 Junction box mounting horizontal (left) and vertical (right) ....................28

Figure 16 Junction box mounting bracket assembly................................................ 29

Figure 17 FMU correctly installed on structure......................................................... 29

Figure 18 Test harnesses............................................................................................ 31

Figure 19 Transport Caps (left) and Protective Caps (right)..................................... 33

Figure 20 Typical subsea protection caps................................................................. 34

Figure 21 Permissible Water Jetting ..........................................................................35

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

6 of 43

Unrestricted

1 PRODUCTS COVERED BY THIS MANUAL

This manual includes information on DigiTRONfproduct range of optical flying leads (OFL), jumper

and harnesses, including connectors that are part thereof, their optical andmechanical specification.

Also this manual provides details of installing the DigiTRON product range of connectors that are

fitted as part of an oil filled hose or cable assembly.

Installation, Operation and Maintenance manuals for other DigiTRON products not covered by this

document can be found on Siemens Energy Subsea website www.siemens-energy.com /search

Subsea, as listed in Table 1.

If a non-Siemens connector is fitted as part of the OFL or harness, then the manufacturer of that

product should be contacted for the IOM manual.

DOC. No.

PRODUCT

IOM-002

DigiTRON single connectors

IOM-003

Obsoleted, replaced by IOM-002.

IOM-004

Not used

IOM-005

Retrievable Electrical Distribution unit (REDU), 2nd generation

IOM-006

Retrievable Electrical Distribution unit (REDU), 1st generation

IOM-007

Disconnectable junction boxes type TC3A-107 and similar Electrical

Distribution Units (EDUs).

IOM-009

DigiTRONf single connectors

00003075

Subsea PT/TT sensors

00007464

Differential Pressure sensors SDP-6 / SDP-8

Table 1 List of other Installation, Operation and Maintenance manuals related to DigiTRON

product range

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

7 of 43

Unrestricted

2 BASIC INFORMATION & QUICK REFERENCE

2.1 Product overview

DigiTRONfconnectors, optical flying leads (OFLs), jumpers and harness assemblies intended use

is to provide communications and optical data links between pieces of optical equipment that are

submerged in water, e.g. subsea.

The DigiTRONfrange of connectors have been developed for long term reliable optical

communications in subsea applications. The underwater mateable capacity of these connectors is

achieved using pressure compensated optical inserts employing the ‘controlled environment’ CE

principle.

An OFL is completely independent of other equipment, and is fitted with ROV or Diver installable

connectors at each end. All OFL’s are oil filled pressure compensated hose assemblies and are

supplied as complete finished product from the factory.

All OFL’s should be retrievable and when installed should not cross-over each other.

Some illustrations are shown in section 2.6 to help identify an OFL and jumper (harness).

Table 2 below identifies each product type in the DigiTRONf product range.

The products look very similar, so it is important to note the identifier for each product type.

Product

range

Description

Typical part number

(etched on the connector)

DigiTRONf

12-way fibre optic

wet-mate connector

DFRV-….….

DFST-.…….

DFDV- ........

Table 2 DigiTRONf product range identification

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

8 of 43

Unrestricted

2.2 Product specification and certification

Basic specifications relating to all products covered by this manual are below in Table 3. Additional

specifications can be found in section 5.

Design Life:

30 years in subsea environment

Optical Performance

1550nm and 1625nm

Insertion loss - typically ≤0.2dB [max 0.5dB, 75% ≤0.4dB]

Return loss - typically ≥70dB [min 45dB, 75% ≥55dB]

Cross-talk ≤ -60dB

Rated number of

operations

1000 (750dry/250wet) mate / de-mate cycles

Water depth

4,000 m (13,123ft)

Storage temperature

-40°C +70°C (-40°F +158°F) (upper limit is surface temperature of the

product and includes solar gain from bright sunlight)

Recommended maximum ambient air temperature +50°C (122°F).

Operational temp

Subsea: -5°C +50°C (+23°F +122°F)

In air: -20°C +50°C (-4°F +122°F)

Product Certification:

Standard

Description

API-17F

Standard for Subsea Production Control Systems

Note: Self-certified via in-house testing.

Table 3 DigiTRONf product specification and certification

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

9 of 43

Unrestricted

2.3 Contact details and feedback

For additional information or questions regards the products visit the Siemens Energy Subsea

website https://www.siemens-energy.com /search Subsea, or contact the following

Department

E-mail address

Product Safety Officer

subsea.connectors.productsafety.gb@siemens-

energy.com

Technical Support

connectortechnicalsupport.gb@siemens-energy.com

Service (Site Team)

susultlcmsupport.gb@siemens-energy.com

Sales

connectorsales.gb@siemens-energy.com

Table 4 DigiTRON product contact details

Any information, records, or Health and Safety feedback that needs to be detailed can be recorded

in section 10 of this document and sent to the relevant department in Table 4

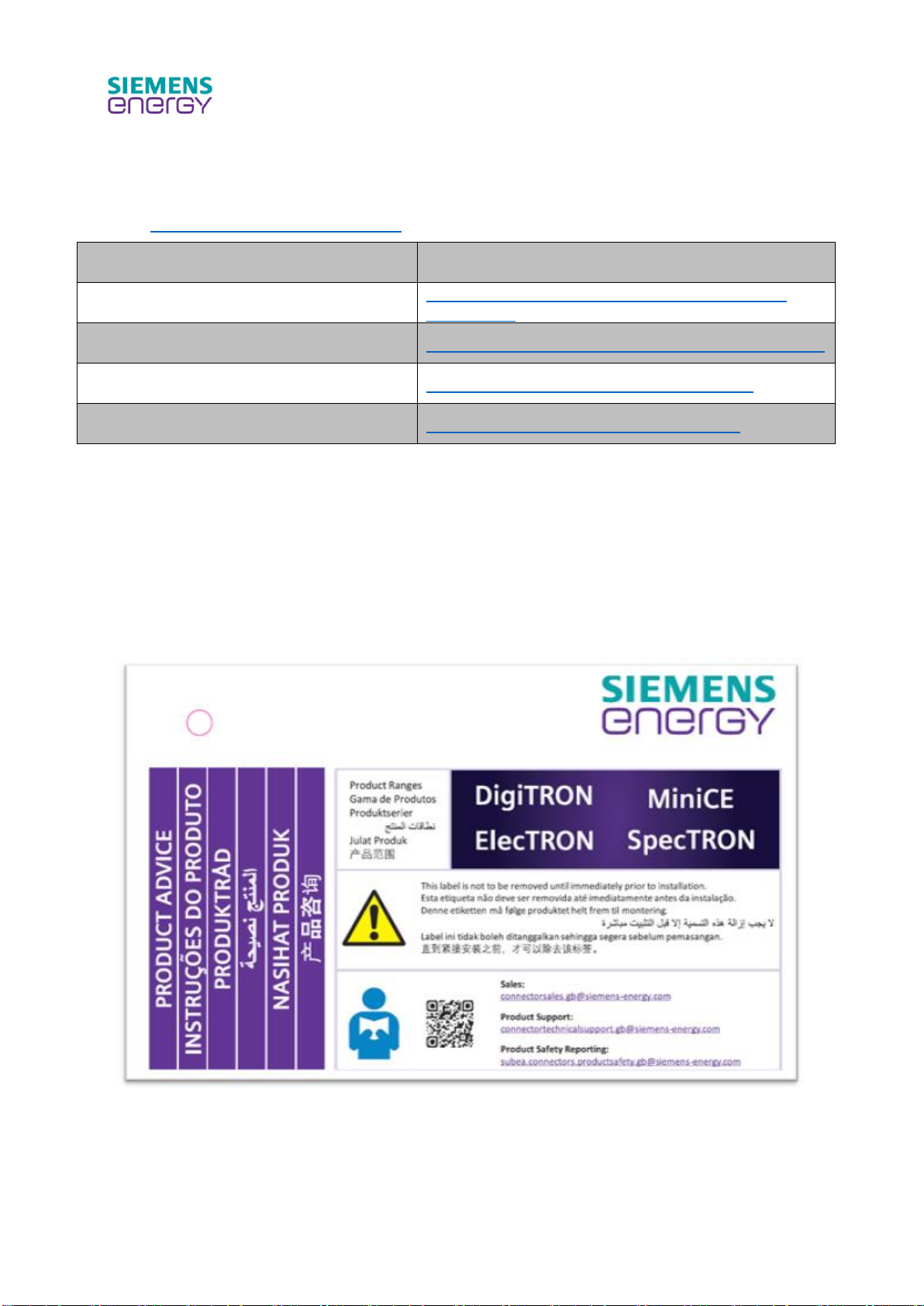

2.4 Product advice label

The following product advice label is supplied with all Siemens Energy Subsea products.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

10 of 43

Unrestricted

Figure 1 Product advice label

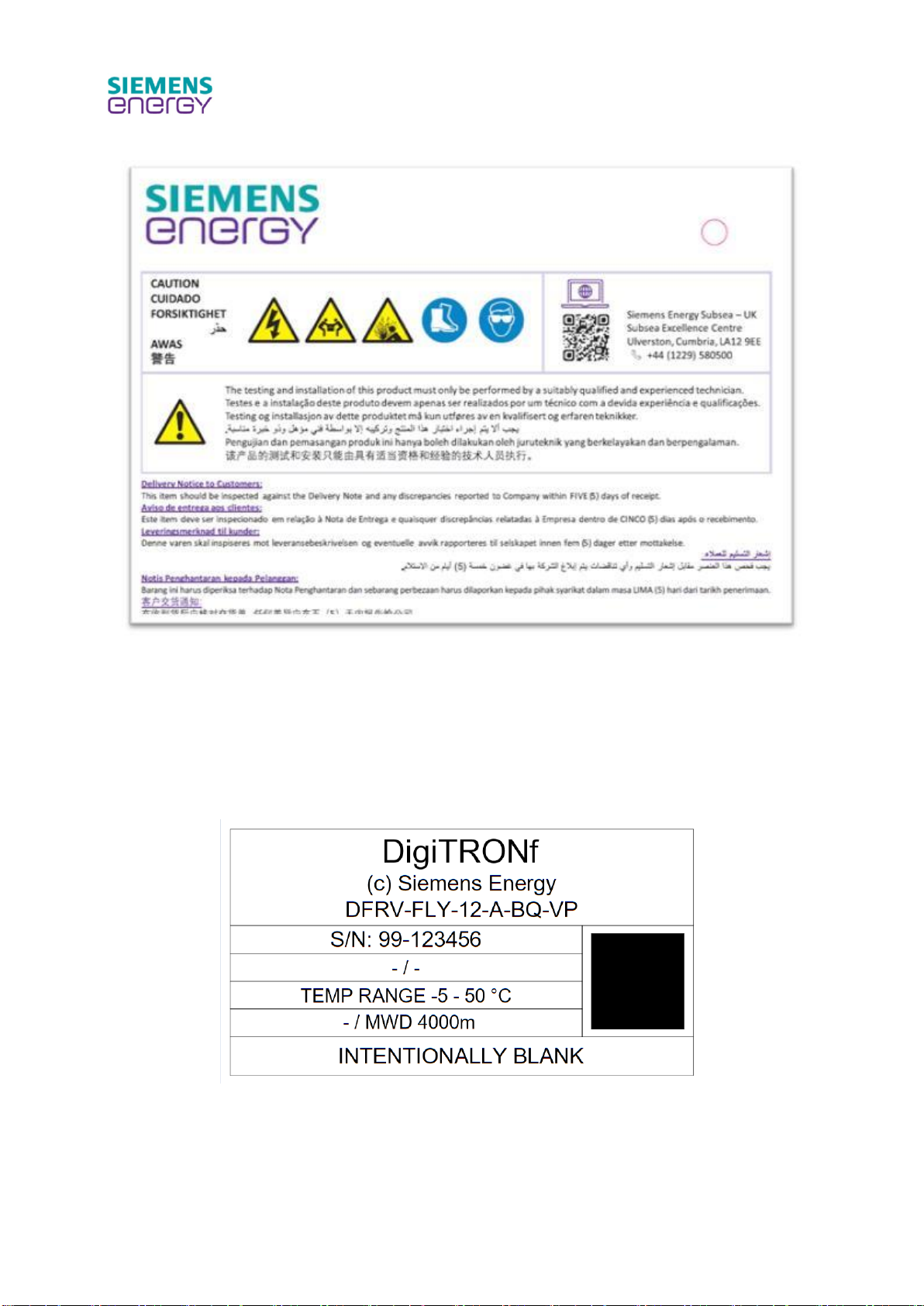

2.5 Product marking

Siemens Energy Subsea DigiTRON products are marked with the Siemens Energy part number and

unique serial number. Also, the voltage, temperature andwater depth ratings areindicated. Marking

locations are typically on the metal bodies of the connectors. Refer to Figure 2.

Figure 2 Product marking on DigiTRON product

Harnesses are also marked with the Siemens Energy Subsea unique serial number.

Labels are typically black text on a yellow background underneath a clear protective wrap and are

typically located at each end of the harness and centrally. Often client’s own information is added

to these labels.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

11 of 43

Unrestricted

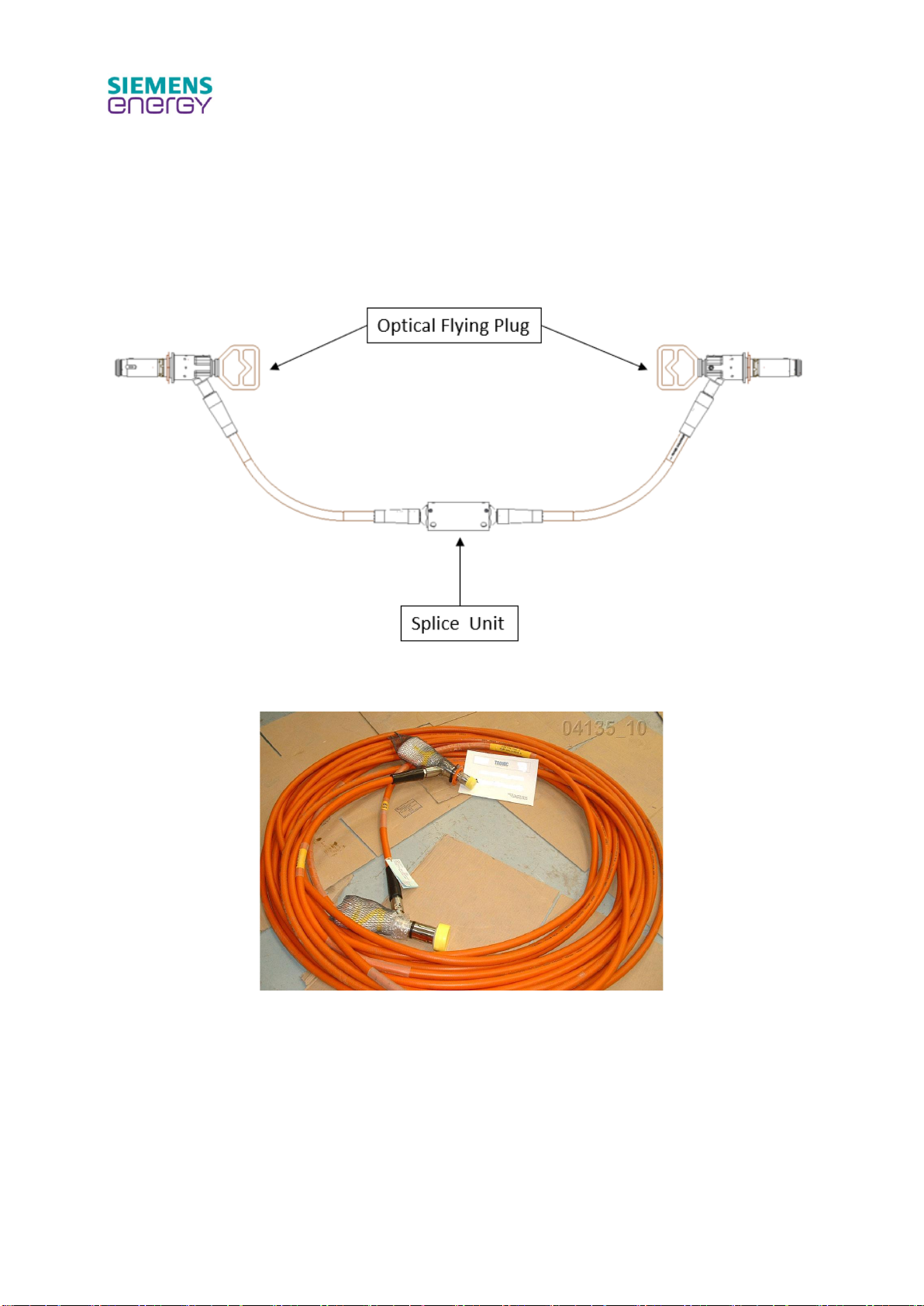

2.6 Product examples

An OFL shown in Figure 3 and Figure 4 always has at least on splice unit, which could be located at

different positions along the hose. Two splice units are needed for lengths in excess of 45m (150

ft).

Figure 3 Typical OFL (Optical Flying Lead)

Figure 4 Example of OFL

Multi-legged harness is shown in Figure 5. There can be up to four legs on each side of the Fiber

Marshalling Unit (FMU). Each hose can be fitted with a flying plug or a flange-mounted receptacle.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

12 of 43

Unrestricted

Figure 5 Typical multi-leg OFL or harness assembly

To terminate FOcables laid up in an umbilical cable (e.g. steel orcopper tubes containing the optical

fibers) an Advanced Fiber Termination Unit (AFT) is used. This crosses over from the umbilical

cable to the oil-filled hose system. The AFT can have up to 4 hose outputs. Single output example

is shown in Figure 6

Figure 6 Typical AFT to Receptacle (1out harness) assembly

Figure 7 Examples of DigiTRONf oil hose connectors

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

13 of 43

Unrestricted

3 PRODUCT SAFETY

Siemens Energy Subsea recommends the termination of all equipment shall only be undertaken by

trained, suitably qualified and experienced personnel (SQEP) i.e. competent person.

Following installation, commissioning or deployment of product, if you have any feedback please

complete and return the Customer Comments/Feedback form (Section 10). Please e-mail completed

form to the Product Safety Officer at subsea.connectors.productsafety.gb@siemens-energy.com

3.1 Action-related warnings

Classification of action-related warnings

The action related warnings are classified in accordance with the severity of the possible danger

using the following warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal injury

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

3.2 Intended use

The product is intended as a Low fibre optic connection system for subsea use

There is a risk of injury or death to the user or others, or of damage to the product and other property

in the event of improper use or use for which it is not intended.

Intended use includes the following:

- observance of the installation and operating instructions included for the product and any other

system components.

- compliance with all inspection and maintenance conditions listed in the instructions.

- use of all recommended tooling appropriate for specific tasks.

- all activities to be undertaken by a competent person (see 3.3.1 for definition).

Any other use that is not specified in this document or covered in installation and operating

instructions, or beyond that specified in this document shall be considered improper use.

Danger! Risk of imminent danger to life or risk of severe personal injury.

Sudden release of stored pressure.

DigiTRON products are not intended for use as a penetration for fixed top-side or land-

based pressure vessels. They are not designed to comply with the requirements of the

Pressure Equipment Directive (2014/68/EU). They are intended for integration into

subsea equipment only.

All pressure testing of DigiTRON product must be undertaken by a competent person.

Caution. Risk of material or environmental damage, improper use of any kind is prohibited.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

14 of 43

Unrestricted

3.3 General safety information

Installation by competent persons only

The installation, inspection, maintenance and repair of the product shall be undertaken by trained,

suitably qualified and experienced personnel (SQEP) i.e. competent person, to carry out a specified

activity. Installation, inspection, maintenance and repair of products by untrained and deemed non-

competent persons could invalidate the product warranty.

For further information contact Siemens Energy Lifecycle Management (Site Team)

susultlcmsupport[email protected]

Personal protective equipment (PPE)

Personal Protective Equipment (PPE) is legally defined as ‘all equipment (including clothing affording

protection against the weather) which is intended to be worn or held by a person at work and which

protects the user against one or more risks to their health or safety’.

In the hierarchy of risk control, PPE is considered to rank lowest and represent the option of last

resort. PPE is only appropriate where the hazard in question cannot be totally removed or controlled

in such a way that harm is unlikely (for example by isolating the hazard or reducing the risk at source

to an acceptable level).

All company personnel and operators should wear appropriate Personal Protective Equipment(PPE)

defined as a result of relevant risk assessments in accordance with the Personal Protective

Equipment (PPE) Regulations.

Wear appropriate PPE according to the product safety advice given in this document

Danger caused by improper operation and foreseeable misuse

Improper operation and foreseeable misuse may present a danger to you and others and cause

material damage. Carefully read the enclosed instructions and all other applicable documents,

particularly the “Safety” section and the warnings.

Danger! Risk of imminent danger to life, risk of severe personal injury caused by a shuttle

pin projectile due to damage caused to shuttle pins e.g. with a screwdriver (foreseeable

misuse).

- Maintenance and testing activities must only be carried out by a competent person.

- Correct tools must always be used.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

15 of 43

Unrestricted

Risk of injury and material damage due to testing, maintenance and repairs

carried out incorrectly or not at all

The oil-filled hoses and connectors are non-serviceable by the user. In case of suspected faults with

the product (refer to section 8.2), do not use the product and contact Siemens Energy Technical

Support or Siemens Energy Product Safety for advice. Never attempt to carry out maintenance work

or repairs on the product yourself.

Danger! Risk of imminent danger to life, risk of severe personal injury caused by released

pressure and or projectile due to incorrectly installed pressure retaining product, (e.g.bulk-

head connector or penetrator) during system pressure test, or the rated differential

pressure of the product is exceeded

- Ensure all product assembly and testing activities are completed by competent

persons.

- Do not exceed the maximum differential pressure rating of the product installed.

- Individual products have different differential pressure ratings, refer to the specific

product datasheet or contact Siemens Energy Technical Support

Danger! Risk of severe personal eye injury due topressurised oil squirting out of damaged

hose or removal of fill/vent screw.

- Ensure all testing of products both factory and deployed in-field have been completed

by competent persons.

Warning. Risk of eye/bodily injury caused by released pressure during product

disassembly, in the event of retrieval from subsea with a fault that causes depth pressure

to be trapped inside the product.

- Ensure all product disassembly activities are completed by competent persons in

accordance with relevant procedures and using relevant personal protective

equipment (PPE).

Warning. Risk of bodily injury caused by pressure retaining parts becoming projectile due

to user over-pressurising the system, e.g. during Site Installation Test (SIT).

- Ensure all product SIT activities are completed by competent persons in accordance

with relevant procedures.

Risk of injury and material damage due to manual handling

Manual handling, lifting and carrying are known to be one of the largest contributors to occupational

ill-health. Ensure mechanical handling aids are used wherever possible to avoid manual handling.

Where manual handling is considered appropriate for the task, safe lifting guidelines must be

followed, e.g. adopt correct posture, consider team lifting, employ safe lifting technique, etc. Only

competent persons are permitted to perform tasks without supervision, if in doubt ask.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

16 of 43

Unrestricted

Warning. Risk of musculoskeletal injury from hand-mating or de-mating connectors.

- Referring to the mate / demate forces specified herein, ensure suitable manual

handling precautions are taken. It is recommended to use the mate/demate tool

designed for this purpose (refer to section 9.9).

- Ensure all product testing activities are completed by competent persons in

accordance with relevant procedures.

Warning. Risk of musculoskeletal injury from manual handling of heavy products. Refer to

shipping information or product datasheet for weights of the product.

- Ensure mechanical handling aids are used wherever possible to avoid manual

handling.

- Where manual handling is considered appropriate for the task, safe lifting guidelines

must be followed, e.g. adopt correct posture, consider team lifting, employ safe lifting

technique, etc.

- Only competent persons are permitted to perform tasks without supervision, if in doubt

ask.

Warning. Risk of bodily injury from heavy product falling during lift with machinery.

- Local regulations for mechanically-aided lifting operations and lifting equipment must

be adhered to, e.g. ‘LOLER’ in the UK.

Warning. Risk of minor personal injury to persons with sensitivities to silicone or mineral

based oils.

- There is a small risk that oil could leak from the product if faulty. Wear appropriate hand

protection when handling products or mineral or synthetic based oils in case oils leak

from the connector due to a fault.

Warning. Risk of minor personal injury and material damage due to slips, trips and falls.

-Good housekeeping avoids slips, trips and falls, keep all work areas clean and tidy.

3.4 Related documents

Installers shall carryout a full site risk assessment and put into place all necessary steps and

procedures to comply with applicable area, regional, national or international health and safety

legislation, e.g. The Health and Safety at Work Act (HASAWA) in the United Kingdom (UK) and

ensure safety of themselves and others regarding manual handling and working at height

requirements.

During the product installation (and any subsequent work) it will be necessary to employ caution. All

installers and operatives involved from unloading the product until it is deployed in its final installed

location must exercise a full duty of care for themselves and others regarding safety. When lifting

and handling this product, operatives should employ assistance if required. In certain situations, it

may be necessary to use mechanical handling aids. Take care to avoid trip hazards, slippery or wet

surfaces.

Employers and installers should refer to the Health and Safety Executive (HSE) web site in the UK

for full advice and manual handling assessment charts (MAC) tool.

In addition, where no specific instructions are given then reference shall be made, but not restricted

to, where applicable, British Standards and codes of practice such as the following:

- The Health and Safety at Work Act.

- COSHH Control of substances hazardous to health.

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

17 of 43

Unrestricted

It is the operator’s and installers responsibility to comply with current Company, area, regional,

national or international health and safety legislation.

3.5 Control of substances hazardous to health (COSHH)

Hazardous substances, Control of substances hazardous to health (COSHH) Assessments regards

to materials such as elastomers and oils, etc. used in DigiTRON products are available on request

from the Product Safety Officer at subsea.connectors.productsafety.gb@siemens-energy.com

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

18 of 43

Unrestricted

4 ABBREVIATIONS

AFT Advanced Fibre Termination

APC Angled Physical Contact

Assy Assembly

API American Petroleum Institute

°C Degree Celsius

°F Degree Fahrenheit

CE Community European

COSHH Control of substances hazardous to health

CP Cathodic Protection

DWG Drawing

FAT Factory Acceptance Test

FMU Fibre Management Unit

FO Fibreoptic

HASAWA Health and Safety at Work Act

HSE Health and Safety Executive

IL Insertion Loss

LBF Pound Force

In Inch

ISO International Organization for Standardization

ITP Inspection Test Plan

LB Pound

LTC Long Term Cover/Cap

m Metres

Max. Maximum

Min. Minimum

No. Number

OFL Optical Flying Leads

PPE Personal Protective Equipment

RL Return Loss

ROV Remotely Operated Vehicle

SI Standard International

SIT Site Installation Test

SQEP Suitably Qualified Experienced Persons

SRT Site Received Test

SST Stainless Steel

TBD To Be Defined

UNS Unified Numbering System for Metals and Alloys

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

19 of 43

Unrestricted

5 SPECIFICATIONS

The following is a basic specification for DigiTRON products. Actual product may vary. Please refer

to product specific data sheet(s), website https://www.siemens-energy.com /search Subsea, or

contact Siemens Energy Technical Support connectortechnicalsupport.gb@siemens-energy.com

for more detailed information.

General specification of the product is listed in section 2.2. Additional specifications are as follows.

5.1 Connector Specification

ROV operated

Misalignment

(Compliant mounted receptacle):

Rotational (0º)

±12º

Radial

±20mm (0.787”)

Angular

±5º

Misalignment

(Bulkhead-mounted receptacle):

Rotational (0º)

±9 º

Radial

±8mm (0.315”)

Angular

±6º

Mate force

<800N (179 lbs)

Demate force

<800N (179 lbs)

Overload withstand:

Axial load

<5000N (1124 lb)

Bending load

<1250N (281 lbs)

Maximum mate speed

Maximum de-mate speed

0.5m/s (1.6ft/s)

1m/s (3.3ft/s)

Deployment rate

350m/min (1149ft/min)

Physical Contact Type

APC

Maximum No. of lines

12

Document No:

IOM-008

Issue Date:

17/03/2023

Revision:

05

Page:

20 of 43

Unrestricted

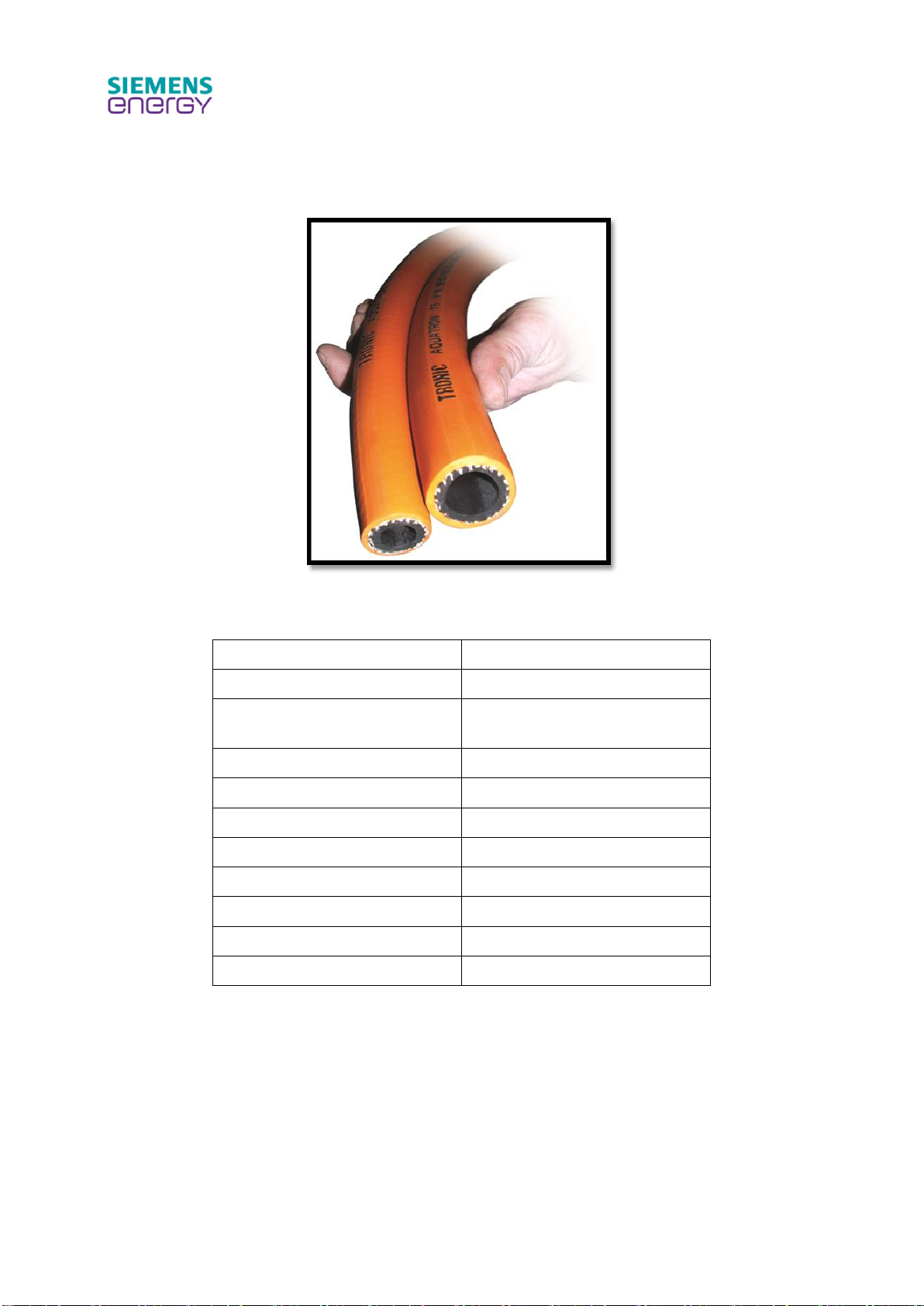

5.2 Siemens Energy AquaTRON pressure-balanced oil-filled hose

specification

Figure 8 AquaTRON hose, size 50 (1/2” bore), and size 75 (3/4” bore)

Hose type

AquaTRON 50

Diameter

Ø50mm OD, ½” bore

Min bend radius (static and

dynamic)

125mm (4.9”)

Maximum axial load

5,000N (1,121 lb)

Maximum twisting

180° per 5m (16.4ft) length

Mass (air)

0.66kg/m (0.44lb/ft)

Mass (water)

0.14kg/m (0.09lb/ft)

Max water depth

4,000m (13,123ft)

Oil fill pressure

15 bar (218 psi)

Filling Medium

Dow Corning 200 Silicone Oil

Deployment rate

350m/min (1149ft/min)

Table 5 AquaTRON oil-filled hose specification

This manual suits for next models

2

Table of contents

Other Siemens Energy Cables And Connectors manuals