8 Operation....................................................................................................................................................65

8.1 Switching on the machine......................................................................................................66

8.2 Regreasing roller bearings.....................................................................................................67

8.3 Deactivating...........................................................................................................................67

8.4 Switching on again after an emergency switching-off............................................................67

8.5 Stoppages..............................................................................................................................67

8.5.1 Measures in non-operational periods.....................................................................................68

8.5.2 Avoidance of damage to roller bearings during stoppages....................................................69

8.5.3 Measurement of the insulation resistance after an extended stoppage.................................69

8.6 Decommissioning the machine..............................................................................................70

8.7 Re-commissioning the machine.............................................................................................70

8.8 Special operating conditions..................................................................................................70

8.9 Faults ....................................................................................................................................71

8.9.1 Inspections in the event of faults............................................................................................71

8.9.2 Faults in operation..................................................................................................................72

8.9.3 Roller bearing faults...............................................................................................................73

8.9.4 Brush faults............................................................................................................................74

8.9.5 Commutator faults..................................................................................................................75

9 Maintenance...............................................................................................................................................77

9.1 Inspection and maintenance..................................................................................................77

9.1.1 Initial inspection......................................................................................................................78

9.1.2 MTTR.....................................................................................................................................80

9.1.3 Main inspection......................................................................................................................80

9.1.4 Regreasing rolling-contact bearings.......................................................................................81

9.1.5 Regreasing intervals and grease types..................................................................................82

9.1.6 Clean the machine.................................................................................................................83

9.1.7 Checking the carbon brushes................................................................................................83

9.1.8 Replacing the carbon brushes...............................................................................................84

9.1.9 Setting the brush rocker and brush holder.............................................................................85

9.1.10 Maintaining the commutator...................................................................................................85

9.1.11 Maintaining terminal boxes....................................................................................................87

9.1.12 Touch up any damaged paintwork.........................................................................................88

9.2 Repair.....................................................................................................................................88

9.2.1 Prepare servicing work...........................................................................................................89

9.2.2 Disassembling the machine...................................................................................................90

9.2.3 Removing rolling-contact bearings.........................................................................................91

9.2.4 Installing the machine............................................................................................................91

9.2.5 Mounting the rolling-contact bearings....................................................................................92

9.2.6 Replacing the speed encoder................................................................................................93

9.2.6.1 Speed sensor with conical hub..............................................................................................93

9.2.6.2 Speed sensor for overhung mounting....................................................................................94

9.2.6.3 Speed sensor for construction type IM B5.............................................................................96

10 Spare Parts.................................................................................................................................................99

10.1 Ordering data.........................................................................................................................99

Table of contents

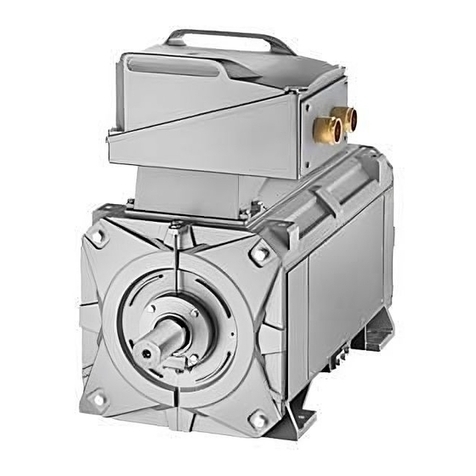

SIMOTICS DC 1GH5

Operating Instructions 02/2016 7