SIG SIGRC95ARF Fokker D.VII User manual

Assembly Instructions

Easily the most feared German fighter aircraft of World War One ...

The Fokker D.VII was hurriedly developed in late 1917 and began flying over the front lines in late March of 1918. The airplane very

quickly earned favor with its pilots because of its outstanding speed, climb and maneuverability characteristics. In addition, it was also

well armed with two forward firing 7.92mm Spandau machine guns and 500 rounds of ammunition. Early D.VII aircraft were

powered with 6-cylinder 160-hp D.III Mercedes Benz engines. A later variant, the D.VIIF, used the more powerful 185-hp B.M.W.

D.IIIa engine. This engine increased the airplane’s performance even further, placing the D.VIIF in high demand from all German

fighter groups. Fortunately for the allies, these engines could not be built fast enough, and the war ended before the B.M.W. powered

D.VIIF could be delivered in mass quantities.

The Fokker D.VII was so feared by the allies, that when the armistice treaty that ended World War I was signed in November 1918, the

Fokker D.VII was the only aircraft specifically mentioned in Aricle IV as a weapon that must be entirely destroyed or confiscated.

The SIG Fokker D.VII represents the aircraft flown by Lt. August von Raben, Commanding Officer of Jasta 18 from March to

November 1918. This fighter group was called the "Raben" (Raven) squadron and all of their fighter aircraft, including the Fokker

D.VII fighters, were painted in the distinctive red and white color scheme depicted on your model.

Your SIG Fokker D.VII is a very nice replica of this famous WWI fighter aircraft. It flies very nicely with fighter-like

maneuverability and flight characteristics. It is a true "parkflyer" type model that can be flown in smaller areas. The airframe is

lightweight and tough and should provide you with many enjoyable missions. To get the most out of your Fokker D.VII, take your

time and follow the assembly instructions carefully.

SIG FOKKER D.VII SPECIFICATIONS:

Wing Span: 32-3/4” (83.2 cm)

Wing Area: 273 sq.in. (1761 sq.cm.)

Power System: 180 Class with 4.4:1 Gear Box

Propeller: E.M.I. 8.5” x 8” Propeller (215.9 x 203mm)

Battery: 6-cell 720 mAh NiMH Square Pack, or

7-cell 300 mAh NiMH "Folded" Pack

Flying Weight: 11 oz. (w/ 6-cell 720 mAh pack)

10.3 oz. (w/ 7-cell 300 mAh pack)

Wing Loading: 5.8 oz./sq. ft. (w/ 6-cell 720 mAh pack)

5.4 oz./sq. ft. (w/ 7-cell 300 mAh pack)

Radio Requirements:

(1) 3 or more channel transmitter on “Aircraft” Frequency

(1) Micro Receiver

(2) Micro Servos

(1) 5amp Electronic Speed Control (ESC)

2

Lineup of Fokker D.VIIs belonging to Jasta 18. Note first airplane has

fuselage painted red all the way back to the stabilizer, while the

second airplane has red to back of cockpit, like the Sig Fokker D.VII.

3

Bag #1: SIGRPFU295

1 . . .Fokker Left Fuselage Side

1 . . .Fokker Right Fuselage Side

Bag #5: SIGRPWB295

1 . . .Fokker Wood Parts Die-Cut Sheet

Bag #6: SIGRPPROP293

2 . . .E.M.I. 8.5 x 8" Propeller

Bag #7: SIGRPMGDU293

1 . . .SIG 180 Class Power System

3 . . #3 x 10mm Phillips-Head Screws

Bag #8: SIGRPWC295

1 . . .Fokker Molded Plastic Wheel Covers

2 . . .50mm Dia. Molded Plastic Main Wheels

4 . . .Metal Wheel Retainer Washers

Bag #4: SIGRPTF295

1 . . .Fokker Horizontal Stabilizer and Elevators

1 . . .Fokker Vertical Fin and Rudder

Kit Contents: Do a complete inventory of your kit before starting assembly.

Bag #2: SIGRPWK295

1 . . .Fokker Top Wing

1 . . .Fokker Bottom Wing

1 . . .Fokker L/G Spreader Wing

2 . . .Wing Reinforcing Strips (1-1/4” x 20-1/4”)

Bag #3:

1 . . .Fokker Molded Plastic Hatch Cover SIGRPCC295

1 . . .Fokker Molded Plastic Cowl SIGRPCW295

4

Bag #9: SIGRPHP293

4 . . .Wing Attach Rubber Bands (#32)

2 . . .#2 x 8mm Phillips-Head Screws (cowl attach)

1 . . .Velcro®Strip (cockpit cover attach)

2 . . .Molded Plastic Control Horn

2 . . .Molded Plastic Control Horn Retainer

2 . . .Molded Plastic Control Horn Clevis

2 . . .Molded Plastic Control Horn Clevis Retainer

2 . . .4mm OD x 75mm Aluminum Wing Tubes

Loose Packed in Box:

1 . . .Fokker Decal Sheet SIGDKM295

2 . . .Fokker Wire Pushrods With "Z" Bend at One End

1 . . .Fokker Wire Main Landing Gear SIGRPBM295

1 . . .Fokker Instruction Manual (not shown)

Additional Items Needed To Complete This Model

Tools and Supplies:

-Small Phillips Screwdriver -Hobby Knife With #11 Blade -Needle Nose Pliers -Small Side Cutting Pliers -Scissors

-Sig Thin C/A Glue -1/16” Drill Bit -Small 90OSquare -1” Paint Brush -12” Ruler

-Sig 5-Minute Epoxy -3/4” wide Scotch®Tape -220 Grit Sandpaper -Rubbing Alcohol -Straight Pins

-Sig 30-Minute Epoxy -#32 Rubber Bands or Low Tack Drafting Tape -3/4” wide Filament Packing Tape

-Soft Foam Rubber

Radio Equipment:

Airborne Radio Components...

A good, reliable radio system is essential to the enjoyment and safe operation of your Fokker D.VII.

We use and highly recommend Hitec radio equipment for this model. We show the installation of Hitec HS-55 micro servos in this

manual. These servos are both extremely small and powerful for their size. We use dual conversion receivers for our models because

they allow us to fly our airplanes with other modelers without fear of 3rd order interference, a common problem with single

conversion receivers. There are several very good dual conversion micro receivers on the market, such as the Hitec Electron 6 and the

FMA M5. If you decide to use the Hitec Electron 6 receiver, you can easily remove the plastic case, as we did, saving even more weight.

Of course, there are a number of other small receivers and servos on the market that can be substituted with equally good results. Select

components that have specifications similar to the HiTEC equipment listed. Watch the weight of components carefully as using

heavier than recommended equipment will have a very detrimental effect on the flight performance of your Sig Fokker D.VII.

Electronic Speed Control (ESC)... We show the installation and use of a MAXX Products MX-9105 ESC in this manual. Other ESC

units may be used, provided they have a minimum rating of 5 amps.

Flight Battery Pack:

The flight battery supplies power to both the radio system and the motor. We have had good success with two different battery packs:

a) 6-Cell 720 mAh NiMH (Nickel Metal Hydride) rechargeable pack, in the "square" configuration.

b) 7-Cell 300 mAh NiMH (Nickel Metal Hydride) rechargeable pack, in the "folded" configuration.

Both of these battery pack types will fly your Fokker D.VII well. The difference is that the 6-cell 720mah pack will fly the airplane a

little slower but with longer flight times - up to 13 minutes with throttle management. The smaller and lighter 7-cell 300maH pack will

fly your Fokker D.VII with greater power but for less flight time - about 6-7 minutes with throttle management.

MAXX Products MX-9105 Electronic Speed Control 6-Cell 720 mAh NiMh Battery Pack (square) 7-Cell 300 mAh NiMh Battery Pack (folded)

Battery Charger:

The charger for the flight battery pack is one of the most critical pieces of equipment for flying electric powered airplanes. Having the

correct charger and using it properly can make the difference between an electric airplane that flies well and one that can’t even get

off the ground. Failure to select the appropriate charger, or using it improperly, will cause performance related problems and

unsatisfactory results. By far, the majority of performance related problems we see with electric powered models are almost always

traced directly to an improperly or incompletely charged flight battery pack.

To correctly charge the recommended battery packs you MUST have a charger that is capable of performing “peak detection” charging

of NiMH (Nickel Metal Hydride) batteries. We use the ASTRO FLIGHT 115D charger, a top-of-the-line AC/DC peak detection

charger. This unit is capable of fast-charging or slow-charging either Nicad or NiMH battery packs at selected rates and is very versatile

in its operation. Obviously other brands of chargers can also be used, as long as they have capabilities similar to the Astro Flight 115D

unit -- i.e. most importantly, “peak detection” charging of NiMH batteries. An old R/C car battery charger WILL NOT work!

Before Beginning Assembly

Take your time and follow the assembly instructions carefully. The foam parts of your Fokker D.VII can be dented easily so be

gentle. To help protect your model during assembly, cover your work bench with an old towel or a sheet of foam rubber. Use only the

glues specified or you will damage the parts. Specifically, DO NOT use C/A Glue on any of the foam parts or they will be damaged.

5

Twist tube to bevel

Slight bevel on inside

Fuselage

Straight Fuselage

Bent

Fuselage side (cross section)

Apply epoxy sparingly to inside

edge of one fuselage side

as shown.

GOOD BAD

Assembly Starts Here:

1...Use a small piece of 220 grit sandpaper to remove any

burrs from the ends of the two 4mm x 3-11/16” Aluminum

Wing Tubes. Now use your hobby knife to slightly

bevel/sharpen the inside of one end of one tube as shown.

2...Prepare the fuselage halves for assembly by using the

sharpened end of the aluminum tube to open up the four

required wing dowel holes in the fuselage sides. Lay the

fuselage half on a firm surface and gently press the tube into

the hole with a twisting motion to finish cutting through the

fuselage sides. Next, use your hobby knife to open up the

pushrod exit holes in the rear of each fuselage half. Last,

lightly sand the mating surfaces of both fuselage halves to

remove any molding flash from the foam.

3...Carefully apply 30 minute epoxy to one of the fuselage

sides as shown. Since the epoxy is many times stronger than

the foam, you only need to use a small amount to bond the

fuselage sides together. By applying the epoxy in this manner

you will eliminate having a lot of epoxy squeezing out on the

outside of the model. We recommend using #32 rubber bands

to hold the fuselage sides together until the epoxy cures. Use

care to make sure that the fuselage is straight and not bent or

twisted. NOTE: You can also use low-tack drafting tape to

hold the fuselage sides together if preferred. However, use

caution because tape can pull the paint off the model if the

adhesive is too tacky. Use tape only on areas of the model that

will not be seen after it is completely assembled.

Remove burrs from ends

Rubber Bands Tape

6

Servo Tray

Firewall &

Cowl Mounts

Wing Tubes

Tail Skid

4...Use 5-minute epoxy to glue the

plywood Firewall, the 2 Cowl Mounts,

the Servo Tray, the Tailskid, and the 2

Aluminum Wing Tubes in place in the

fuselage.

NOTE: Be sure the firewall is firmly

seated into the recess molded into the

front of the fuselage. This recess has

been molded to provide the correct right

and down-thrust for the motor.

Glue the servo tray in place with the

grain running across the fuselage.

The wing tubes should be centered, so

that an equal amount sticks out on each

side of the fuselage.

5...Use 3/4" wide 3M Scotch®Crystal Clear Tape to hinge

the tail surfaces. Apply a strip of tape to the top of the

Horizontal Stabilizer, centered over the hinge line. Turn the

stabilizer/elevator assembly over and apply another strip of

tape, again centered over the hinge line. Repeat this process

with the Vertical Fin/Rudder assembly.

NOTE: 3/4” wide tape is available at most office supply

stores. Use only clear tranparent tape. Do not use frosted

Scotch®Magic Tape.

6...Use a sharp hobby knife to trim and remove the

unwanted foam bridges from the Stabilizer/Elevator

assembly and the Fin/Rudder assembly. There are 5 bridges

to remove:

A. Trim 2 foam bridges connecting Stabilizer to Elevator.

B. Trim foam bridge connecting top of Rudder to Fin.

C. Trim foam bridge connecting bottom of Rudder to Tab.

D. Trim foam bridge connecting bottom of Fin to Tab.

7...Use a small diameter dowel with a smooth rounded end,

similar object, to indent the tape on each side of the tail

surface until the two pieces of tape contact each other in the

middle of the hinge gap, creating the finished hinge.

8...Now is the best time to apply all the decals to the various model parts, before the parts are glued together and become more

cumbersome to handle. Use the box label and the assembly manual pictures for proper positioning of the decals.

DECAL APPLICATION NOTES: The decals provided in this kit are a type of water transfer decal that you may not have used

before. They are extremely thin and light, and when they are on the model they look like they’re painted on. Notice that the decals

are printed on the paper carrier upside down. There is a thin clear plastic sheet over the decals that protects a low tack adhesive.

9...Use your hobby knife to open the control

horn slots in both the rudder and elevators.

Insert the rudder control horn through the

slot so that the arm sticks out on the left side

of the rudder. Insert the elevator control

horn from the top so that the arm sticks

down from the bottom of the right elevator.

Now slide the retainer plates onto the horns

with their locating pins facing the foam.

Firmly press the clip in place until you hear

or feel two "clicks", indicating that the clip

is securely locked in place.

7

GOOD

BAD

BAD

90O

GOOD

To apply the decals, leave the clear plastic in

position while you cut the individual mark-

ing from the main sheet. When ready to

apply the decal, remove the clear plastic and

place the decal in the desired location, adhe-

sive side down. Make sure you get the decal

exactly where you want it. The light tack

adhesive allows the decal to be picked up

and repositioned if necessary. With the

decal in the proper position, use a brush or a

12...Plug the airborne electronics together and test for proper function. The two servos are plugged into channel 1 (normally

aileron) and channel 2 (normally elevator) on the receiver. The electronic speed control plugs into channel 3 on the receiver. When

doing this, make very sure that you have installed the three plugs with the correct polarity! Then plug the motor, without the

propeller, into the “motor" side of the ESC. Make sure your transmitter and airborne battery pack are fully charged.

soft rag to generously apply cold tap water to the paper. The paper will immediately begin to soak up the water. Let the paper com-

pletely soak for at least 1-2 minutes. Now gently SLIDE paper from the top of the decal. DO NOT try to move the decal on the

model's surface. The decal is very thin and fragile. If the decal has air bubbles under it, use a soft cloth to gently pat out the bub-

ble, making sure you pat straight up and down, not sideways. DO NOT try to push the bubbles sideways from beneath the decal.

While these decals are more fragile than normal decals, the end result is a marking that looks as if it were painted on. Allow the

decals to completely dry for at least an hour or two before handling.

10... Temporarily attach the lower wing to the fuselage with

two rubber bands. Use 5-minute epoxy to glue the

stabilizer and elevator assembly in place on the fuselage.

The stabilizer should be roughly parallel to the wing and

should not be tilting to the left or right. The slot in the

stabilizer should be centered with glue seam in the fuselage

and must remain free of glue. Use straight pins to hold the

stabilizer in position until the epoxy sets. After the glue

dries, the bottom wing can be removed.

11...Use 5-minute epoxy to glue the fin and rudder

assembly in place. The bottom of the fin must be glued on

top of the stabilizer, while you simultaneously glue

the "tab" at the bottom front of the rudder into the

corresponding slot at the rear of the fuselage. Make sure

the fin and rudder are 90O to the horizontal and does not tilt

to the left or right. Use straight pins to hold the fin in place

until the epoxy sets.

8

13...Install the rudder and elevator servos into the plywood

servo tray in the fuselage. Viewing the model from the rear,

the rudder servo is mounted on the right side and the elevator

servo is mounted on the left side. The servo output arms

should be at the rear end of the servo body, as shown.

14...Install the Wire Pushrod for the rudder into the fuselage.

Start by inserting the “Z” bend end of the wire into the left

pushrod exit hole at the rear of the fuselage (again viewing

the fuselage from the rear). Run the pushrod all the way up

to the rudder servo, which is on the right side of the fuselage.

Remove the control arm from the rudder servo, slip it onto the

“Z” bend, and then reinstall the control arm back onto the

servo. Be sure to tighten the servo arm screw.

Install the elevator pushrod in the same manner. Insert it into

the right exit hole at the rear of the fuselage, and run it

forward to the elevator servo on the left side of the fuselage.

Install the elevator servo control arm to the “Z” bend.

15...Slide a plastic Control Horn Clevis Retainer onto the

rudder pushrod wire. Snap a plastic Control Horn Clevis into

the rudder horn, with its open side facing outward, as shown.

Hold the rudder in neutral while you lay the threaded end of

the pushrod wire into the groove in the plastic clevis. Push

the wire down firmly into the groove.

16...Slide the Clevis Retainer onto the Clevis, trapping the

pushrod wire in place. Check to be sure that the rudder is still

in the neutral position. If it is not, unsnap the clevis from the

control horn and adjust the pushrod length by screwing the

clevis in or out on the threads. Then repeat this process to

attach the elevator pushrod to the elevator control horn.

Clevis

To operate the system, first turn on the

transmitter and place the throttle stick in the

full low position. Now plug the airborne

battery pack into the "battery" side of the ESC.

The system should now be operational (see

NOTE below). Test the system by moving the

right stick on the transmitter, which should

move the rudder and elevator servos.

Typically, with most ESCs, the motor is not

"armed" and will not function when you first

turn on the power, for safety reasons. To arm

the motor, the throttle stick must be moved

all the way up and all the way back, one or

possibly two times. Be sure to read the

instructions that came with your particular ESC

to learn the manufacturer's arming method.

Once the ESC is armed, the motor should function and react to movements of the throttle stick. Make sure everything is

functioning properly on your workbench BEFORE you install any of the components into the model. While the radio system is

still on, make sure the rudder and elevator trim levers on the transmitter are centered in neutral position. This ensures that the

servos are centered. Unplug the battery from the ESC to turn the airborne system off and then turn off the transmitter.

NOTE: Some radio manufacturers provide a small micro-size Switch Harness. We suggest that you not use the switch harness to

save weight. It is very easy to turn the airborne system on and off by simply plugging in and unplugging the battery pack.

Clevis

Retainer

Elevator Servo

Rudder Servo

Notice that elevator & rudder pushrods

cross each other in rear of fuselage.

Push

Motor

Battery

ESC

Receiver

Elevator Servo

Rudder Servo

9

17...Plug the two servos and the ESC back into the correct

receptacles in the receiver. Place the receiver on the bottom

of the fuselage, in front of the servos. Cut a piece of soft

foam rubber (not furnished) to fit over the receiver and hold

the receiver in place. Install the ESC on top of the foam

rubber. Poke the ESC’s motor plug through the hole in the

front of the fuselage and into the motor compartment. Make

sure the ESC’s battery plug will be accessible at the top of

the battery compartment.

Turn on your transmitter and then plug the battery pack into

the ESC. Stow the battery pack in the radio compartment,

right up against the back of the foam firewall. Cut another

piece of soft foam rubber to put between the battery pack

and the front of the servos, to keep the battery from moving

around. Check the radio for proper operation. If the servos

move in the wrong direction, use the servo reversing on your

transmitter to change the direction of travel.

Adjust the control throws to the following measurements:

Rudder: 3/4” Right 3/4” Left

Elevator: 1/2” Up 1/2” Down

18...Drill a 1/16" dia. hole in the bottom of the fuselage, just

behind the rear wing dowel, as shown. Feed the receiver

antenna through this hole. Pull the antenna back to the rear

of the fuselage and hold it in place with a small piece of

Scotch®Tape just behind the tailskid. Allow the full length

of the antenna to trail behind the model. Do not cut the

antenna to shorten it. That will reduce the radio range.

19...Remove the cabane struts from the die-cut plywood

sheet. Note that there are two inner cabane struts and two

outer cabane struts.

a. Use 5-minute epoxy to glue the two inner cabane struts

into the appropriate pockets molded into the fuselage sides.

Note that the pockets are pre-molded at the correct angles.

Hold the struts in place until the glue dries.

b. Use 5-minute epoxy to glue the two outer cabane struts

into the appropriate pockets in the fuselage sides. Let dry.

c. Glue the tops of each set of inner and outer cabane

struts together, being careful to match up the top edges of

the struts to create a smooth wing saddle.

Tape

Antenna Exit Hole Receiver Is Under Foam

ESC

Inner Cabane Struts Outer Cabane Struts

22..Apply the Wing Reinforcing Tape (14mm X 43mm) to the

leading edge of both the top and bottom wing. The tape should be

centered on the leading edge left and right and should be applied

so that it wraps around the leading edge with half on the top of the

wing and half on the bottom of the wing.

Apply the two star decals to the top of the top wing and allow to

dry.

Remove the two plywood wing struts from the die cut sheet. Insert

the struts through the bottom wing. Use 5 minute epoxy to attach

the struts to the bottom wing. The struts should be aligned vertical.

Now glue the top stubs into the top wing with 5 minute epoxy. Align the wings square and allow the epoxy to dry.

22..Use 5 minute epoxy to glue the two die cut plywood landing gear inserts into position on the landing gear. The short one goes at

the front of the landing gear and the taller one is at the rear.

Trim the two Molded Plastic Wheel Covers as shown. Use a 1/16”

drill bit to drill a hole for the axle in the center of each cover.

Press one Wheel Retainer on each axle and slide all of the way in.

Now place the wheel, wheel cover and outer Wheel Retainer into

position. The outer wheel retainer should spaced so that the wheel

turns freely.

23..Attach the wing on the model using 4 rubber bands. Now install the landing gear by pressing the front and rear upper ends com-

pletely into the slots in the fuselage. Attach the number decals to the fuselage sides between the wing and the tail surfaces.

24...Plug the speed control into the receiver. Charge and connect the airborne battery and test the radio and power system WITH-

OUT THE PROPELLER ATTACHED.

Make sure that all of the controls and the throttle function properly.

When everything checks out, securely attach the propeller onto the power system.

25...Place the battery in the model and install the Plastic Cockpit Cover. Check the balance of the model. To do this, turn the model

upside down and support the model on your finger tips placed 1/2” back from the leading edge of the bottom wing. Hold your fin-

gers close to the

10

20...Trim the plastic Hatch Cover as shown. Test fit the

trimmed Hatch Cover onto the top of the fuselage and adjust as

needed for a good fit. Note:A sharp hobby knife and miniature

snips are very good tools for this job.

Seperate the two parts of the Velcro®strip provided.

Remove the paper backing from one part of the Velcro®, and

adhere that piece of Velcro®to the top of the fuselage.

Remove the paper backing from the other half of the Velcro®

and adhere it to the underside of the Hatch Cover, making sure

it lines up with the Velcro®on top of the fuselage.

21...Pre-drill the three motor mount holes in the plywood

firewall with a 1/16" dia. drill bit. Use the three #3 x 10mm

Phillips-Head Sheet Metal Screws to attach the motor to the

front of the model. Feed the motor connector through the hole

in the front of the fuselage and connect it to the electronic

speed controller.

22...Trim and install the molded plastic Cowl as follows:

a. Use a sharp hobby knife or a small pair of snips to trim

3/16” off the base of the cowl as shown.

b. Sand the trimmed rear edge of the cowl against a piece of

fine grit sandpaper to make the rear edge truly flat.

c. Carefully cut out the three openings in the front of the

cowl as shown. A sharp hobby knife and sandpaper are good

tools for this job.

d. Fit the cowl onto the front of the fuselage to check the fit.

Make any required adjustments. The cowl is mounted to the

fuselage using two #2 x 8mm Phillips Head Sheet Metal

Screws. Hold the cowl in position on the fuselage while you

drill 1/32” dia. pilot holes through the cowl and into the

plywood cowl mounts on each side of the nose. Then mount

the cowl to the fuselage with the two screws.

Velcro®Velcro®

Step 22a

Step 22b

Step 22c Step 22d

3/16”Cutoff

11

23...Apply the Wing Reinforcing Strips (1-1/4” x 20-1/4”) onto

the leading edges of both the top and bottom wings. The strips

should be centered left-to-right on the leading edge, and should

be applied so that it wraps around the leading edge, with half its

width on top and half its width on the bottom of the wing.

24...Remove the two plywood wing struts from the die-cut

sheet. Smooth the edges of the struts with sandpaper. Use

5-minute epoxy to glue the struts in place on the bottom wing.

Make sure the struts are perpendicular (90O) to the top of the

wing surface and allow the glue to dry.

Now glue the top wing in place on top of the plywood struts

with 5-minute epoxy. Align the wings square and hold in

position until the epoxy to dries.

25...Reinforce the wings to withstand high +G aerobatic

maneuvers by running a strip of 3/4" wide filament packing

tape (such as Scotch®#893) spanwise on the bottom of both

wings. Cut a strip of filament tape to fit between the outer wing

strut locations and lay it in place on the bottom of each wing, at

the high point of the airfoil. Press the tape firmly in place.

Remove

flange

Wing Reinforcing Strip

26...Use 5-minute epoxy to glue the two die-cut plywood landing gear inserts into

position on the Wire Main Landing Gear. Use small strips of tape to hold them in

place while the glue dries.

Trim the flange off of the two Molded Plastic Wheel Covers as shown. Use a 1/16”

dia. drill bit to drill a hole for the axle in the center of each wheel cover.

Press one Wheel Retainer Washer onto each axle, and slide it all of the way in as far

as possible. Now slide on the wheel and then the plastic wheel cover. Finally, install

the outer Wheel Retainer Washer. Make sure the wheels turn freely.

Use clear Scotch®tape to fasten the foam L.G. Spreader Wing in place on top of the

wire gear between the landing gear legs.

Tape

Plywood

Inserts

Filament Tape

12

27...Attach the wings to the fuselage using 4 rubber bands - 2

for the top wing and 2 for the bottom wing. Begin by sliding

the wing set over the tail surfaces and into position. Secure

the bottom wing first, being careful to line-up the slot in the

bottom wing with the corresponding slot in the fuselage as

you put on the 2 rubber bands. Then install the landing gear,

pressing the front and rear upper ends of the gear completely

into the slots in the bottom of the fuselage. Last, rubber band

the top wing to the cabane struts.

28...Install the propeller on the motor shaft. The proper order

of installation on the shaft is; first the rear shaft nut, then the

propeller, then the shaft washer, and then the front shaft nut.

When properly installed, the prop shaft should have just a

little bit (1/16” - 1/8") of fore and aft "play". Finally, slip the

rubber Prop Shaft Protector over the prop shaft and nut, up

against propeller. The model is now ready to balance.

29...BALANCING YOUR FOKKER IS IMPORTANT!

Place the flight battery in the model (do not plug it into the

ESC at this time) and attach the plastic hatch cover. Check

the balance of the model by turning it upside down and

supporting it on your finger tips placed 1/2” back from the

leading edge of the bottom wing. Hold your fingers close to

the fuselage sides. Supported this way your model should

hang perfectly level. If the model hangs tail low, you must

move the receiver and battery forward in the fuselage, or if

they are already as far forward as possible, add weight to the

nose of the model until it hangs level. If the model hangs nose

low, you must move the receiver and battery towards the rear,

or add weight to the tail of the model until it hangs level.

30...Always pre-flight your model thoroughly before each flight. It is your responsibility to verify that your model is airworthy.

Always follow established safety guidelines while installing the battery, operating the motor, radio, and while flying the model.

FLYING YOUR FOKKER

Test fly your Fokker D.VII on a day when there is no wind. This allows you to better evaluate and trim the model correctly. The

Fokker is a small, light model and should not be flown on breezy days. Because the Fokker is a small model with small wheels,

it is normally not practical to take off from a typical grass field. While the Fokker will take off from the ground nicely, it needs

a smooth surface to do so. If the grass at your flying area is too long, then you will probably need to hand launch the airplane.

This is done by holding the model level, running the motor up to high throttle, and then tossing the model straight ahead at flight

speed. NEVER throw the airplane in a nose up attitude or tilted to one side or the other. Throw it perfectly level! If you’ve never

hand launched an R/C model before, make your first hand launches over tall (knee high) grass. The grass will protect your model

from damage in the event of a bad launch. Fly the model to a safe altitude before trimming it out.

GOOD LUCK AND SAFE FLYING!

WARNING! THIS IS NOT A TOY!

Flying machines are not toys! Because of the speeds that airplanes must achieve in order

to fly, they are capable of causing bodily harm and property damage if they crash. IT

IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble this model airplane

correctly according to the instructions, to ground test the finished model before each flight

to make sure it is completely airworthy, and to always fly your model in a safe location and

in a safe manner. JOIN THE AMA

The governing body for R/C model airplanes in the United States is the ACADEMY OF

MODEL AERONAUTICS. The AMA provides guidelines for the safe operation of R/C

model airplanes. While AMA membership is not mandatory, it is required by most R/C

flying clubs in the U.S.and provides you with important liability insurance in case your R/C

model should ever cause property damage or personal injury to someone else.

For more information contact: ACADEMY OF MODEL AERONAUTICS

5161 East Memorial Drive; Muncie, IN 47302

Telephone: (765) 287-1256

AMA WEB SITE: modelaircraft.org

CUSTOMER SERVICE

Should you encounter any problem building this kit, or discover any missing or

damaged parts, please feel free to contact us by mail or telephone.

SIG MANUFACTURING COMPANY, INC.

P.O. Box 520

Montezuma, IA 50171-0520

SIG MODELER’S ORDERLINE: 1-800-247-5008 (to order parts)

SIG MODELER’S HOTLINE: 1-641-623-0215 (for tech support)

SIG WEB SITE: www.sigmfg.com

LIMIT OF LIABILITY

The craftsmanship, attention to detail, and actions of the builder/flyer of this model airplane

kit will ultimately determine the airworthiness, flight performance, and safety of the finished

model. SIG MFG. CO.’s obligation shall be to replace those parts of the kit proven to be

defective or missing. The user shall determine the suitability of the product for his or her

intended use and shall assume all risk and liability in connection therewith.

KIT CONTENTS SUBJECT TO CHANGE WITHOUT NOTICE.

Do not attempt to fly your Fokker

until it is properly balanced!

Balance 1/2” back from leading edge of bottom wing.

Rubber

Prop Shaft

Protector

Table of contents

Other SIG Toy manuals

SIG

SIG Piper J3 Cub Instruction Manual

SIG

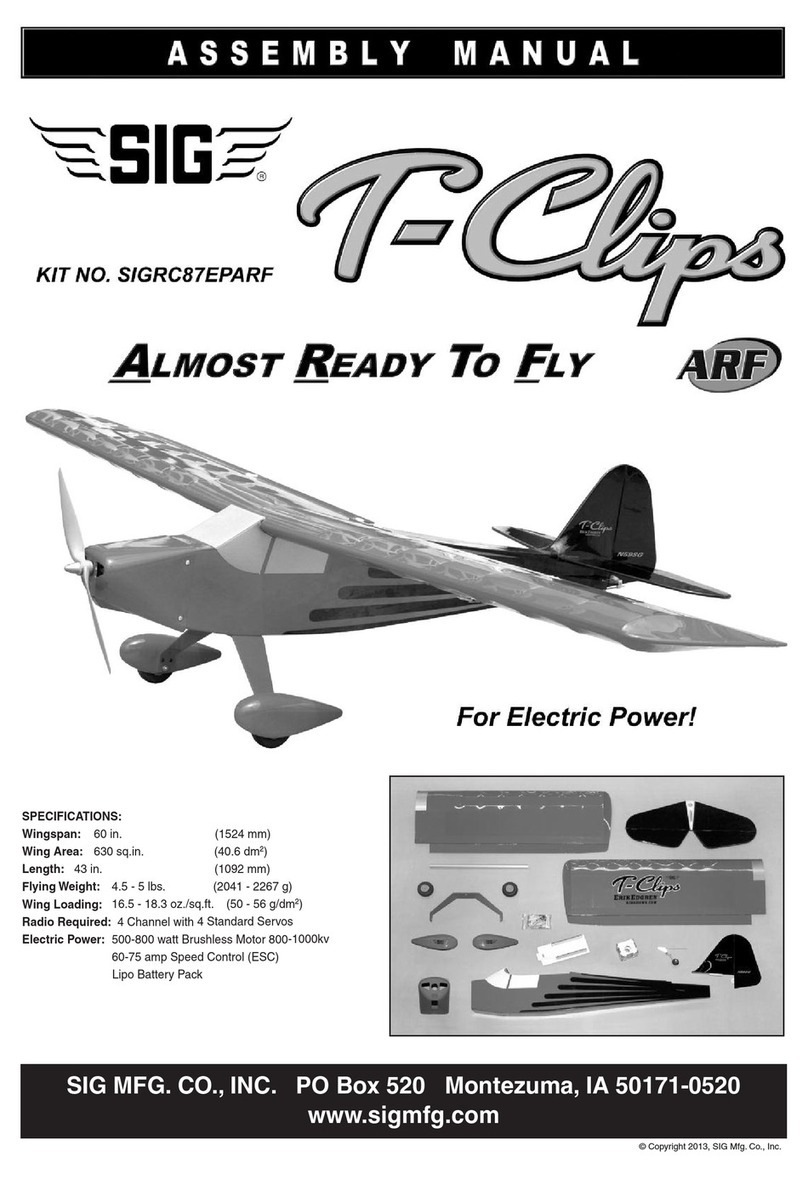

SIG T-Clips EP ARF User manual

SIG

SIG RASCAL ARF User manual

SIG

SIG LIL' RASCAL User manual

SIG

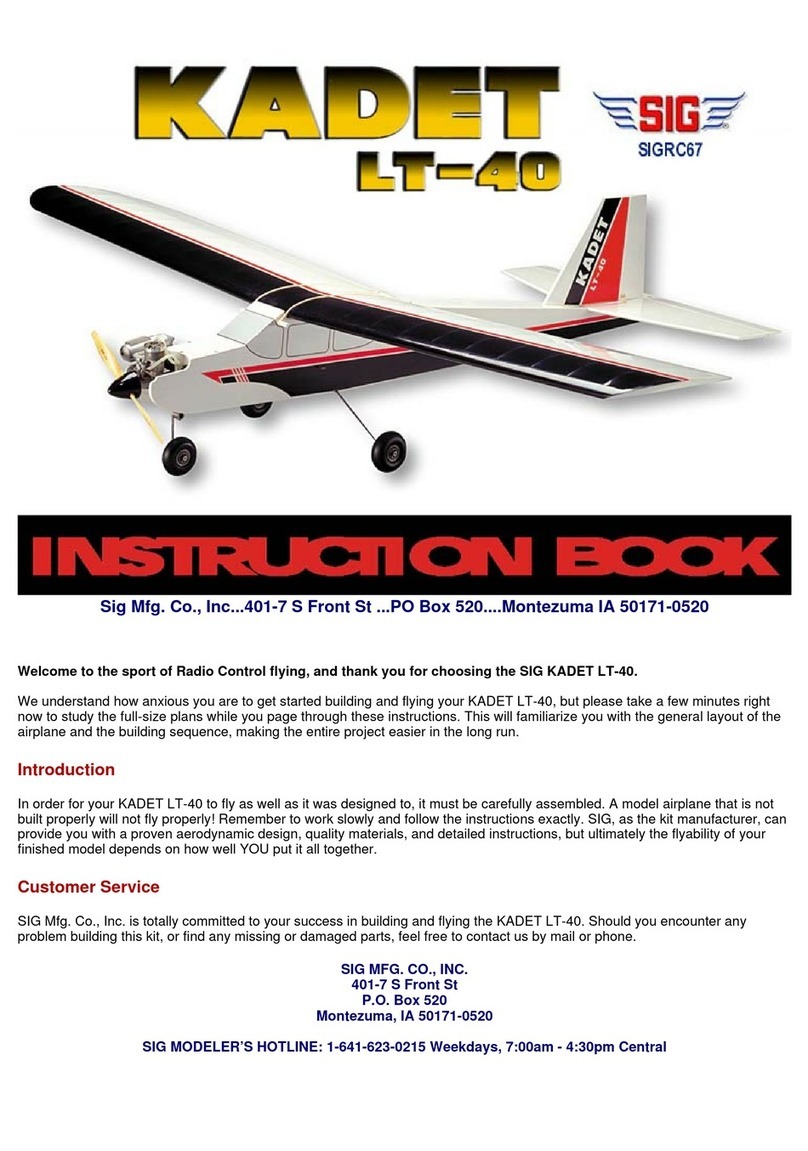

SIG KADET EP-42B User manual

SIG

SIG KADET LT-25 User manual

SIG

SIG 4-STAR 60 Instruction Manual

SIG

SIG Piper J3 Cub User manual

SIG

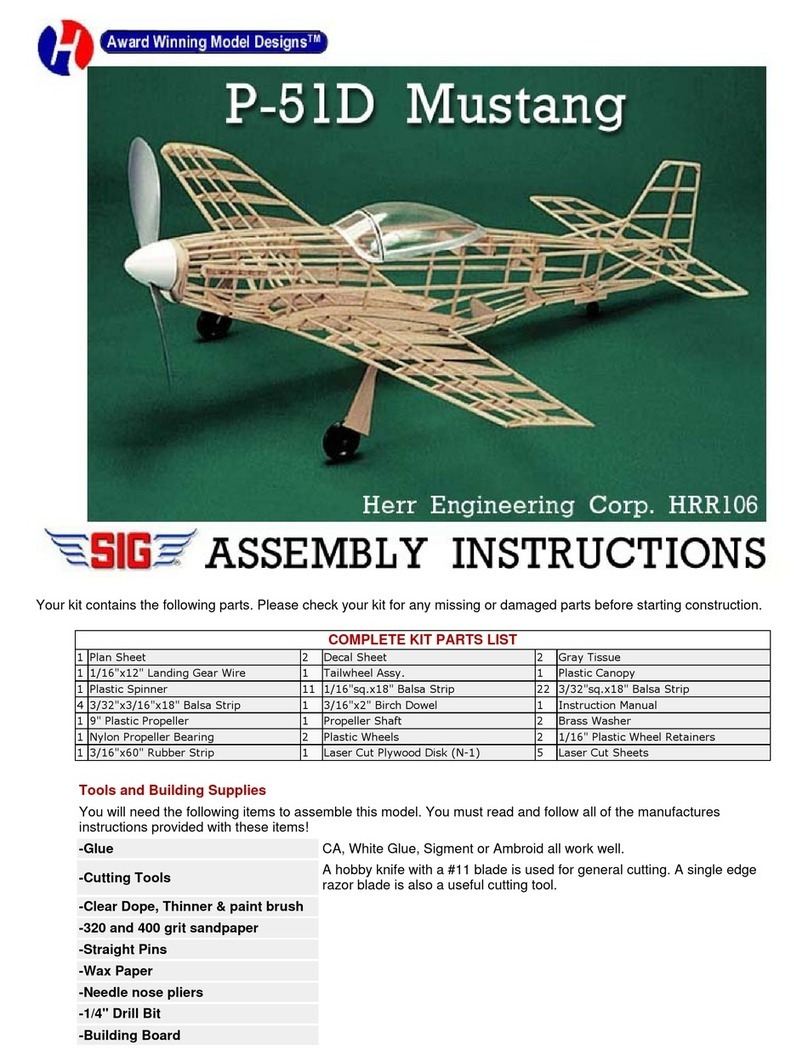

SIG Award Winning Model Designs P-51D Mustang User manual

SIG

SIG Somethin' EXTRA N477SC User manual

SIG

SIG Wonder Instruction Manual

SIG

SIG DORN IER Do 217 User manual

SIG

SIG HUMMER RC-50 Instruction Manual

SIG

SIG MESSERSCHMITT Bf-109 User manual

SIG

SIG King Kobra Instruction Manual

SIG

SIG KADET EP-42 User manual

SIG

SIG SIGRC76EGARFG User manual

SIG

SIG SIGRC44 User manual

SIG

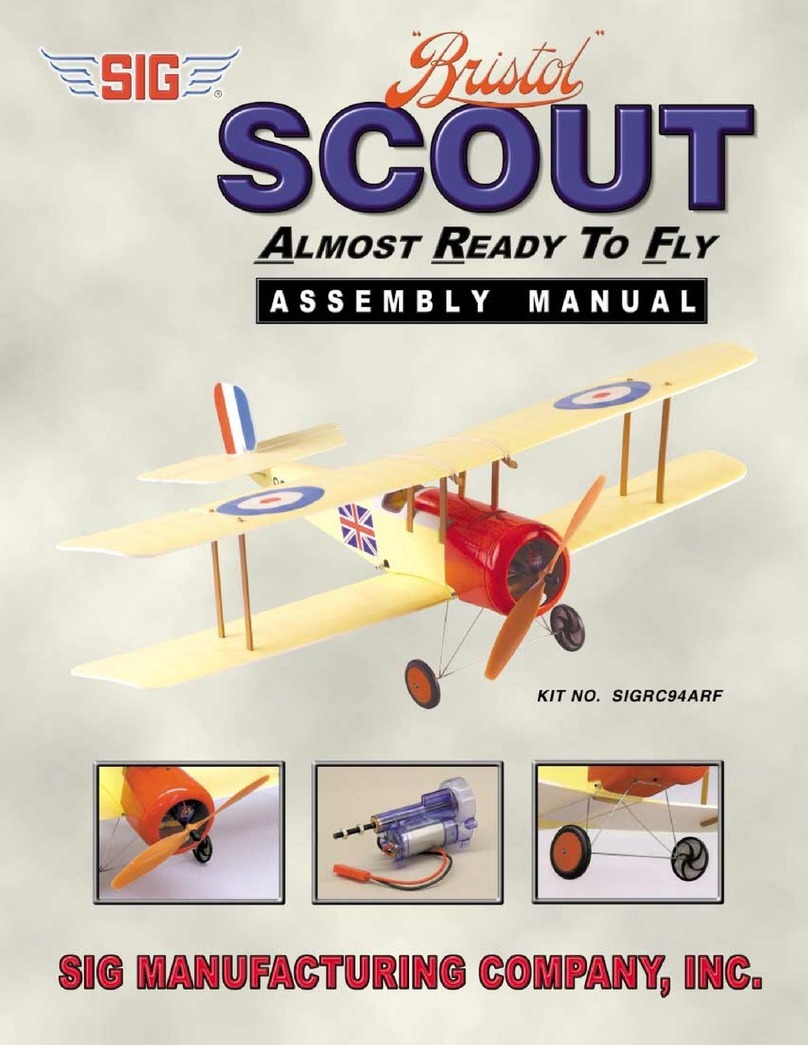

SIG Bristol Scout User manual

SIG

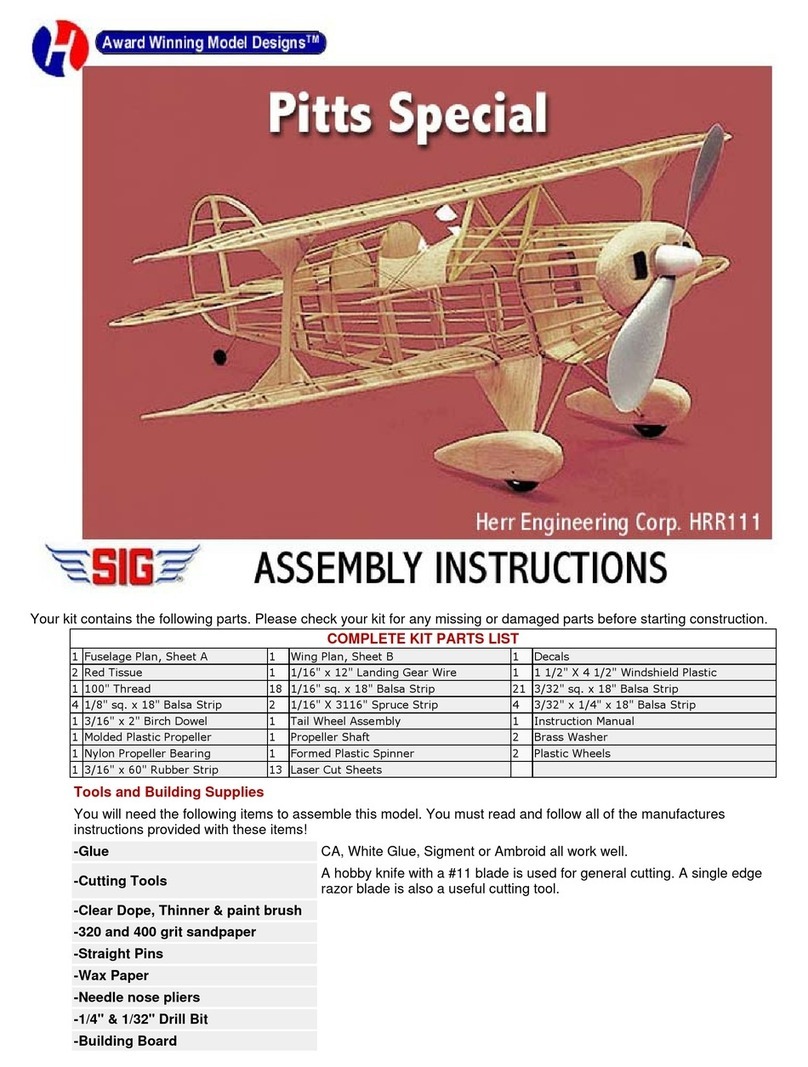

SIG HRR111 User manual