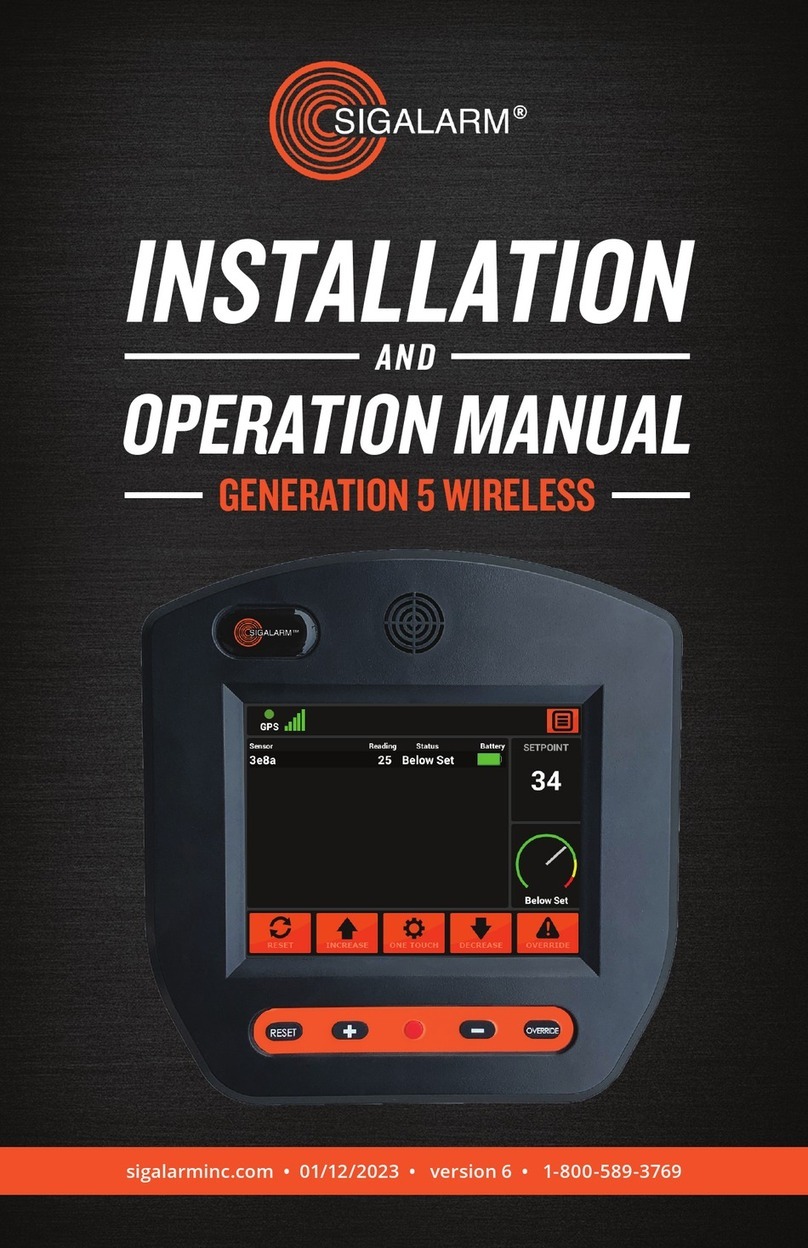

SIGALARM INSTALLATION AND OPERATION MANUAL / GENERATION 4 WIRELESS

4

1. OVERVIEW....................................................5

1.1 Understanding E Field Detection ............5

1.2 Safety Regulations ....................................5

1.3 Safety Warnings ........................................5

2. INSTALLATION ...........................................6

2.1 Standard Packing List ...............................6

2.2 Installation Precautions ...........................6

2.3 Installation of the Control Module .........6

2.4 Connecting to a Power Source ................7

2.5 Installation of the Wireless Sensor(s) .....8

2.6 Installation of the Speaker .......................12

2.7 Relay Options .........................................13

2.8 Testing/Troubleshooting

the Installation ........................................14

3.MENU DISPLAY IDENTIFICATION..........15

3.1 Home screen/ Detail Overview ...............15

3.2ToolBar......................................................16

3.3SensorDashboard....................................16

3.4 Set Point Display .......................................16

3.5 Sensor Status Gauge ................................16

3.6 Work Zone Indicator ..............................16

(Coming soon)

3.7TouchScreenIcons...................................17

3.8 Knobs and Buttons ...................................17

3.9ActionsScreenOverview..........................18

3.10Admin ......................................................19

3.11 Display Setting ........................................21

3.12SetupDefaults.........................................21

3.13 Manage Sensors .....................................22

3.14ManageDevice........................................22

Information furnished by Allied Safety Systems Inc. DBA Sigalarm in this document is believed to be accurate.

Allied Safety Systems Inc. makes no warranty, express, statutory and implied or by description, regarding

the information set forth herein. Allied Safety Systems Inc. reserves the right to change specications at

any time and without notice. Allied Safety Systems Inc. products are intended for use in normal commercial

and industrial applications. Applications requiring extended temperature range or unusual environmental

requirements such as military, medical life-support or life sustaining equipment are specically not recom-

mended without additional testing on such application. Allied Safety Systems Inc. reserves the right to make

periodic modications of this product without obligation to notify any person or entity of such revision.

Copying, duplicating, selling, or otherwise distributing any part of this manual without the prior consent of

an authorized representative of Allied Safety Systems Inc. is prohibited.

Copyright 2017 Allied Safety Systems Inc. All rights reserved.

4. GETTING STARTED ..................................23

4.1 Initial Control Module Set Up ................23

5. OPERATIONS ............................................24

5.1 Warnings ..................................................24

5.2 Operating Procedures ............................24

5.3 Adjust the Set Point ................................25

5.4 Remote Control Operations ..................27

(Coming soon)

5.5 System Reset ...........................................27

5.6 Override Feature ....................................27

6. DATA MANAGEMENT ..............................28

6.1 Data logger ..............................................28

6.2 Downloading Data (Coming soon) ........28

6.3 Dashboard (Coming soon) .....................28

7. SPECIFICATIONS .....................................29

7.1 Dimensions .............................................29

7.2 Material ....................................................29

7.3 Power Supply Requirements .................29

7.4 E-eld Detection .....................................29

7.5 Range of Eectiveness ...........................29

7.6 Sensor Battery ........................................29

7.7 Control Module Screen ..........................30

7.8 Temperature Specications ..................30

7.9 Speaker ....................................................30

8. TROUBLE SHOOTING ..............................31

8.1 Control module trouble shooting .........31

8.2 Sensor trouble shooting ........................31

CONTENTS