2

301

300

207

258

206

213

217

200

100

010

009 012 101

101 012 009

01 1

203

001

- 8 10 12

15 10 10 12

20 15 10 29

25 20 24 29

32 25 24 58

40 32 48 58

50 40 48 100

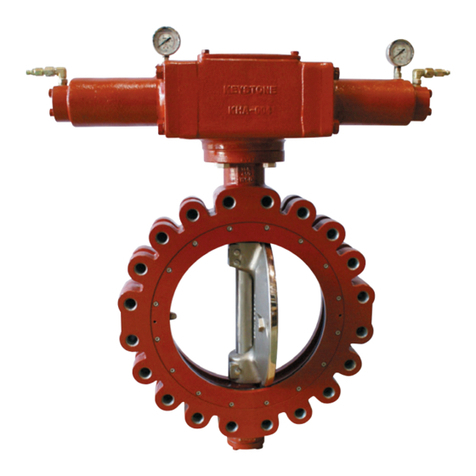

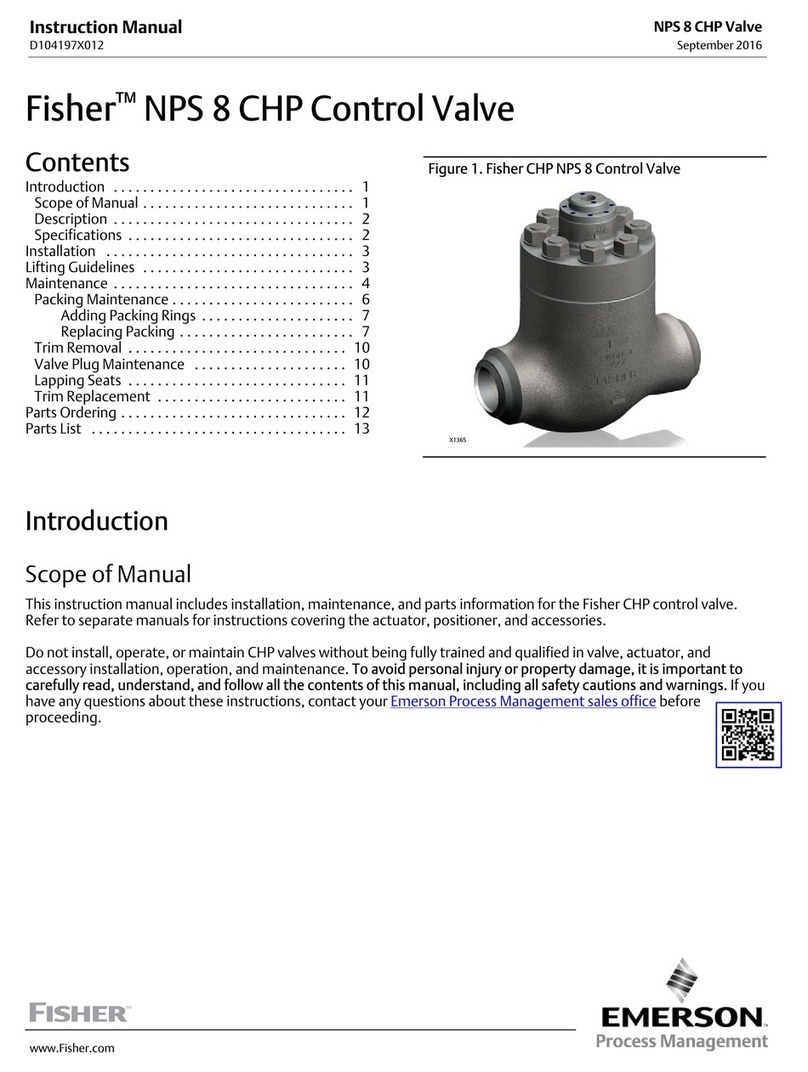

Note: R382 valve illustrated

WELDING INSTRUCTIONS

CAUTION: failure to follow these instructions

could result in serious damage to the valve seats

and seals.

1. To prevent weld splatter damaging the ball

surface and to facilitate the later removal of

the center section, ensure the valve is in the

open position.

2. Locate the valve in the pipeline and tackweld

the valve in position.

3. Loosen and remove the body bolts (010)

and nuts (011), allowing the body (001) to

be removed from between end connectors

(009). For R384 and R394 valves only - extra

care must be exercised at this stage as the

body will not slide out from between the

end connectors unless the pipe ends are

separated sufficiently to give clearance for

the raised fire lip and the spigot on the end

connectors. Damage to either the fire lip

or the spigot will effect the integrity of the

valves body seal (012) and the secondary

metal to metal seal of the ball and fire lip in

a fire condition.

When removing the body (001), ensure the

body seal (012) and seats (101) remain in the

original locations.

OPERATION

All Emerson ball valves are quarter turn.

Handle operated valves provide visual

indication of the valve position. When the

handle is across the line of the valve, the valve

is closed, and when the handle is in line with

the valve, the valve is open. Stops are integral

with the valve and only Emerson handles must

be used.

Actuated valves are available and Emerson

has various options of pneumatic and electric

actuators.

For further details on fitting actuator, refer

tothe mounting instruction sheet.

TORQUE VALUES (Nm)

Valve size

R382/ R392 R384/R394

R382/R384 R392/R394

DN DN Body bolts Body bolts

KTM RICHARDS FIGURE R382/R384/R392/R394 BALL VALVES

INSTALLATION AND OPERATING INSTRUCTIONS

4. Complete welding process, taking care

to protect the sealing faces of the end

connectors from weld splatter. Allow

cooling of the ends before reassembly.

5. Reassembly:

a) Check the body seal (012), seats (101) and

ball (100), making sure they are clean,

undamaged and in original locations and

that the ball is in the open position.

b) Check sealing faces of end connectors

(009) to ensure the surface is clean and

not damaged by weld splatter.

c) Relocate the body (001) between end

connectors (009), taking care that the

pipe ends are sufficiently apart to provide

clearance to slide the center section into

position between the ends. For R384 and

R394 valves only - care should be taken

not to damage the fire lip and spigot on

the ends. Make sure the end connector

spigots fit in the body seal grooves.

Replace body bolts (010) and nuts (011)

and retighten to recommended torques.

6. Inspect for leakage at plant start-up and

adjust if necessary.

CAUTION: if seats or seals are in any way

damaged, do not reassemble valve without

replacing damaged components.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

KTM is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson and

the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl