Sigineer Power 48V60 User manual

MPPT Solar Charge

Controller

Version: 1.2

User Manual

Table Of Contents

Information on this Manual..................................................................................................................................................................1

Validity...........................................................................................................................................................................................1

Scope ..............................................................................................................................................................................................1

Target Group...................................................................................................................................................................................1

Safety Instructions ..........................................................................................................................................................................1

Introduction ...........................................................................................................................................................................................2

Solar Power System........................................................................................................................................................................2

Features...........................................................................................................................................................................................2

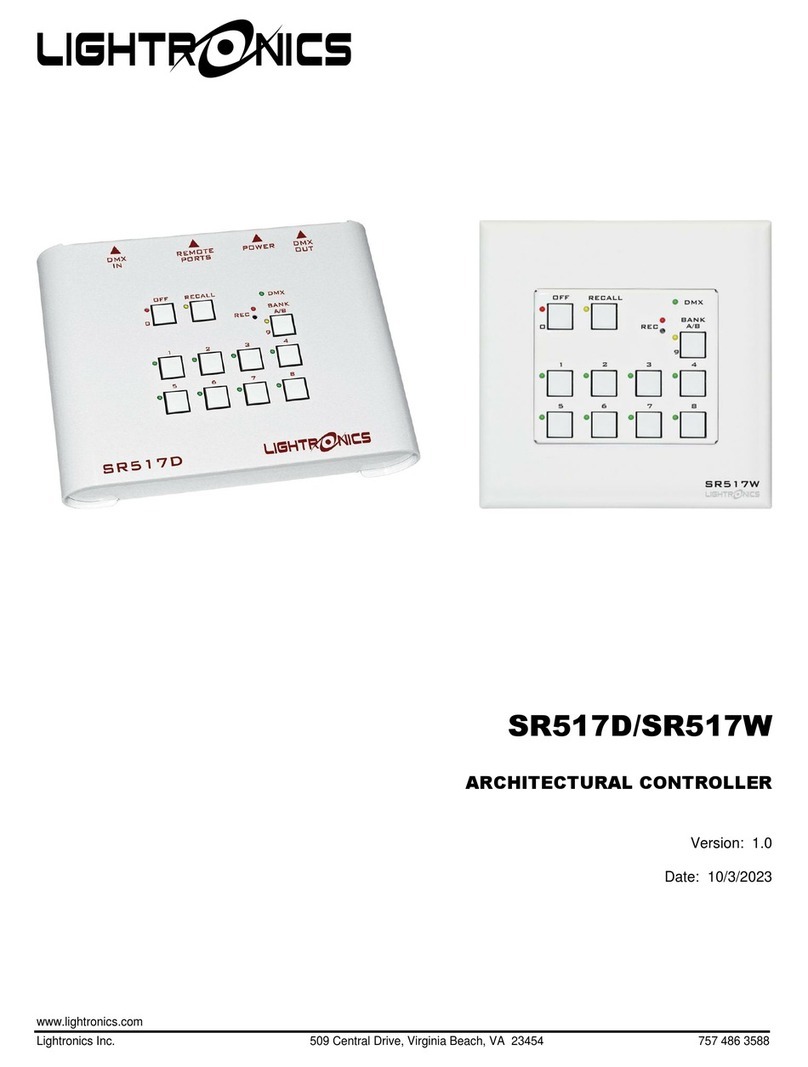

Product Overview ...........................................................................................................................................................................3

Installation .............................................................................................................................................................................................4

Unpacking and Inspection ..............................................................................................................................................................4

Mounting the Unit...........................................................................................................................................................................4

Battery Connection .........................................................................................................................................................................5

Inverter Connection ........................................................................................................................................................................7

PV Connection................................................................................................................................................................................9

Operation .............................................................................................................................................................................................10

Operation and Display Panel ........................................................................................................................................................10

LCD Display Information.............................................................................................................................................................15

Fault Code.....................................................................................................................................................................................17

Warning Code...............................................................................................................................................................................17

Battery Equalization ...........................................................................................................................................................................17

Trouble Shooting .................................................................................................................................................................................19

Specifications .......................................................................................................................................................................................20

1

Information on this Manual

Validity

This manual is valid for the following devices:

MPPT solar charge controller 48V60

MPPT solar charge controller 48V80

MPPT solar charge controller 48V100

MPPT solar charge controller 48V120

Scope

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read this manual

carefully before installations and operations.

Target Group

This document is intended for qualified persons and end users. Tasks that do not require any particular qualification

can also be performed by end users. Qualified persons must have the following skills:

Knowledge of how a solar charge controller works and is operated

Training in how to deal with the dangers and risks associated with installing and using electrical devices

and installations

Training in the installation and commissioning of electrical devices and installations

Knowledge of the applicable standards and directives

Knowledge of and compliance with this document and all safety information

Safety Instructions

WARNING: This chapter contains important safety and operating instructions.

Read and keep this manual for future reference.

1.

CAUTION –Only qualified personnel can install this device with battery.

2.

Before using the unit, read all instructions and caution marks on the unit, understand the batteries and all

appropriate sections of this manual.

3.

CAUTION --Toreduce risk of injury, charge only deep-cycle lead acid type rechargeable batteries. Other types

of batteries may burst, causing personal injury and damage.

4.

NEVER charge a frozen battery.

5.

Do not disassemble the unit. Take it to a qualified service center when service or repair is required. Incorrect

re-assembly may result in a risk of electric shock or fire.

6.

To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning. Turning

off the unit will not reduce this risk.

7.

Be very cautious when working with metal tools on or around batteries. A potential risk, such as dropping a tool

to spark or short circuit batteries or other electrical parts, could cause anexplosion.

8.

Please strictly follow installation procedure when you want to disconnect terminals. Please refer to

INSTALLATION section of this manual for the details.

9.

Warning!! Only qualified service persons are able to service this device. If errors still persist after following

troubleshooting table, please send this solar charge controller back to local dealer or service center for

maintenance.

2

Monitoring

APP

Introduction

Solar Power System

This MPPT solar controller is an advanced maximum power point tracking solar battery charger. The controller features a

smart tracking algorithm that finds and maintains operation at the solar array peak power point, maximizing energy

converting efficiency.

The MPPT solar controller charging process has been optimized for long battery life and improved system performance.

Self-diagnostics and electronic error protections prevent damage when installation mistakes or system faults occur. The

WiFi / GPRS module is a plug-and-play monitoring device to be installed on the controller. With this device, users can

monitor the status of the PV system from the mobile phone or from the website anytime anywhere.

Features

12V/24V/48V auto work, parallel design

Multi-stage charging optimizes battery performance

MPPT tracking efficiency >99.5%, peak conversion efficiency 98%

Compatible with gel, AGM flooded, sealed lead acid and lithium battery

Comprehensive protection

WiFi/GPRS Monitoring (optional)

Communication Port for BMS (optional)

Product Overview

AC Loads

Solar Panel

MPPT Solar

Controller

WiFi/GPRS

Module

Internet

Power Inverter

Battery

Monitoring

Web

3

1. LCD Display

6.

7. PV1±input

2. Warning indicator

7.

8. PV2±input

3. Fault indicator

8.

9. Battery input

4. Charging indicator

9.

10. WiFi/GPRS communication port

5. Function buttons

11. BTS

6. On/Off switch

12 12. BMS communication port

4

Installation

Unpacking and Inspection

Before installation, please inspect the unit. Be sure that nothing inside the package is damaged. You should have received

the following items in the package:

The unit x 1

User manual x1

Communication wire x1

BTS temperature control wire(optional)x1

Cube WiFi/GPRS(optional)x1

Mounting the Unit

Consider the following points before selecting where to install:

Do not mount the controller on flammableconstruction

materials.

Mount on a solid surface

Install this controller at eye level in order to allow theLCD

display to be read at all times.

The ambient temperature should be between 0°C and55°C to

ensure optimal operation.

The recommended installation position is to be adhered to the

wall vertically.

Be sure to keep other objects and surfaces as shown inthe right

diagram to guarantee sufficient heat dissipation and to have

enough space for removing wires.

SUITABLE FOR MOUNTING ON CONCRETE OR

OTHER NON-COMBUSTIBLE SURFACE ONLY.

Dimension & Structure

5

Battery Connection

CAUTION: For safetyoperation and regulation compliance, it’s requested to install a separate DC over-current

protector or disconnect device between battery and controller. It may not be requested to have a disconnect device in

some applications, however, it’s still requested to have over-current protection installed. Please refer to typical

amperage in below table as required fuse or breaker size.

Ring terminal:

WARNING! All wiring must be performed by a qualified person.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for battery connection. To reduce risk of injury, please use the

proper recommended cable and terminal size as below.

Note: For the lead acid battery, the recommended charge current is 0.2C(C-battery capacity). Please follow below steps to

implement lead-acid battery connection:

1. Assemble battery right terminal based on recommended battery cable and terminal size.

2. Connect all battery packs as units requires. It’s suggested to connect at least 550Ah capacity battery for 48V/120A model.

Model

48V60

48V80

48V100

48V120

Capacity of battery

250Ah

350Ah

450Ah

550Ah

Insert the ring terminal of battery cable flatly into battery connector of controller and make sure the bolts are tightened with

torque of 2-3Nm. Make sure polarity at both the battery and the controller is correctly connected and ring terminals are tightly

screwed to the battery terminals.

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the controller terminal and the ring

terminal. Otherwise, overheating may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are connected

tightly.

CAUTION!! Before making the final DC connection or closing DC breaker, be sure positive (+) must

be connected to positive (+) and negative (-) must be connected to negative (-).

Recommended cable size:

Model

Copper Wire Type

Recommended Size

Minimum Size

60A

Copper

5AWG

6AWG

80A

Copper

4AWG

5AWG

100A

Copper

2AWG

3AWG

120A

Copper

2AWG

2AWG

Lithium Battery Connection

6

If choosing lithium battery for the controller, you are allowed to use the lithium battery only which have configured. There're

two connectors on the lithium battery, RJ45 port of BMS and power cable.

Please follow below steps to implement lithium battery connection:

1. Assemble battery ring terminal based on recommended battery cable and terminal size (same as Lead acid, see section

Lead-acid Battery connection for details) .

2. Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the bolts are tightened with

torque of 2-3Nm. Make sure polarity at both the battery and the inverter/charge is correctly connected and ring terminals are

tightly screwed to the battery terminals.

3. Connect the end of RJ45 of battery to the communication port of the controller.

4. The other end of RJ45 insert to battery comm port.

Note: If choosing lithium battery, make sure to connect the BMS communication cable between the battery and the controller.

You need to choose battery type as “lithium battery”

Lithium battery communication and setting

In order to communicate with battery BMS, you should set the battery type to “LI” in Program 2. Then the LCD will switch to

Program 21, which is to set the protocol type. There are several RS485 protocols in the controller which can match some

customized battery, Please consult with supplier first before you choosing the battery model.

1. Connecting the communication port between the controller and battery

Make sure the lithium battery BMS port connects to the controller is Pin to Pin, the controller communication port pin

assignment shown as below (“COM” port on the controller, support RS485 or CAN protocol).

Pin number

RS485

CAN

1

RS485B

--

2

RS485A

--

3

--

--

4

--

CANH

5

--

CANL

6

--

--

7

--

--

8

--

--

2. LCD setting

To connect battery BMS, need to set the battery type as “LI” in Program 02. After set “LI” in Program 02, it will switch to

Program 21 to choose battery type. There will be some options under Program 21.

7

When the battery type set to Li, the setting option 07 will change to display percent.

Note: When the battery type set as “Li”, the Maximum charge current can’t be modified by the

user. When the communication fail , the inverter will cut off output.

Inverter Connection

Some specific off grid inverters and this controller can communicate to summarize data. Make sure the inverter connect to the

controller Pin to Pin as below by communication port (“COM” port on the controller).

Pin number

RS485

CAN

1

RS485B

--

2

RS485A

--

3

--

--

4

--

CANH

5

--

CANL

6

--

--

7

--

--

8

--

--

There will be 2 options to connect with inverter in Program 08. Set to mode CL1 if you select RS485 communication, set to CL2

if you select CAN communication. Details as below:

02

Battery type

AGM (default)

Flooded

User-Defined

If “User-Defined” is selected, battery charge voltage and low DC cut-off voltage can be

set up in program 05,06 and 07.

User-Defined 2

Suitable for lithium battery when inverter not communicated with BMS.

If “US2” is selected, battery charge voltage and low DC cut-off voltage can be set up in

program 05,06 and 07.

Lithium

Only suitable for lithium battery when inverter communicated with BMS.

The lithium battery BMS communication protocol options:

……

07

Low DC cut-off SOC. If “Li” is selected

in program 2, this program can be set up.

Default 20%, 5%~50% Settable.

8

Communication operation between one inverter and one controller

Set parameters on the controller: Program 08 as CL1, Program 09 as Protocol 2.

Communication operation between one inverter and two controllers

Set parameters on the first controller: Program 08 as CL1, Program 09 as Protocol 2.

Set parameters on the second controller: Program 08 as CL1, Program 09 as Protocol 3.

There will be a RS485/CAN Hub needed to converge the communication cables from the controllers to the inverter.

RS485/CAN Hub:

08

Communication model

SIG (default), used to communicate with upper computer

CL1, used to communicate through RS485

CL2, used to communicate through CAN.

09

RS485

Communication

Address

Address 1 (default)

Used to communicate with controller in CL1 or CL2, or used to

communicate with upper computer in SIG

9

Note: The battery type should be set as the same for the inverter and controllers.

PV Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker between controller and PV

modules.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It'’ very important for system safety and efficient operation to use appropriate cable for PV module connection.

Toreduce risk of injury, please use the proper recommended cable size as below.

PV Module Selection:

When selecting proper PV modules, please be sure to consider below parameters:

1.

Open circuit Voltage (Voc) of PV modules not exceeds max. PV array open circuit voltage ofcontroller.

2.

Open circuit Voltage (Voc) of PV modules should be higher than min. battery voltage.

MPPT CONTROLLER MODEL

60A / 80A / 100A / 120A

Max. PV Array Open Circuit Voltage

150Vdc max

PV Array MPPT Voltage Range

60~145Vdc

Please follow below steps to implement PV module connection:

1.

Remove insulation sleeve 10 mm for positive and negative conductors.

2.

Check correct polarity of connection cable from PV modules and PV

input connectors. Peel the plastic tube 10mm from the positive polarity

end of the wire. Insert the wire into the ring terminal and crimp the edges

by tools. Then connect the wire to the PV Input port "PV+" of the controller.

Also use the same method to connect the PV Input port "PV-".

3.

Make sure the wires are securely connected.

10

Operation

Operation and Display Panel

The operation and display panel, shown in below chart, is on the front panel of the controller. It includes three

indicators, three function keys and a LCD display, indicating the operating status and input/output power

information.

Power ON/OFF

Press the “ON/OFF” button to turn on or turn off the system.

LED Indicator

LED Indicator

Messages

CHARGING

Green

Solid On

System is running fine, but not charging now

Flashing

During charging now

FAULT

Red

Solid On

An error occurs

Flashing

A warning occurs

WIRING FAULT

Red

Solid On

Battery wiring reversed

Function Buttons

Button

Description

ESC

To exit setting mode

UP/DOWM

To change selection

ENTER

To confirm the selection in setting mode or enter setting mode

11

LCD Display Icons

Icon

Function Description

System Parameters Information

Indicates the battery

Indicates the PV input

Indicate PV voltage, battery voltage, charging current etc.

Configuration Program and Fault Information

Indicates the setting programs.

Warning: flashing with warning code.

Fault: lighting with fault code

System Status Information

Indicates battery level by 0-24%, 25-49%, 50-74% and 75-100% in battery mode

and charging status in line mode.

Indicates SLA battery

Indicates Lithium battery

Indicates unit connects to the PV panel.

Indicates the DC/DC circuit is working.

Indicates unit alarm is disabled.

12

LCD Setting

After pressing and holding ENTER button for 3 seconds, the unit will enter setting mode. Press “UP/DOWN” button to

select setting programs. And then, press “ENTER” button to confirm the selection or ESC button to exit.

Program

Description

Setting Option

01

Maximum charging

current

120A model: Default 60A, 10A~120A Settable

100A model: Default 60A, 10A~100A Settable

80A model: Default 60A, 10A~80A Settable

60A model: Default 60A, 10A~60A Settable

(If Li is selected in program 2, this program can’t be set up)

02

Battery type

AGM (default)

Flooded

User-Defined

If “User-Defined” is selected, battery charge voltage and low DC

cut-off voltage can be set up in program 05,06 and 07.

User-Defined 2

Suitable for lithium battery when inverter not communicated with

BMS.

If “US2” is selected, battery charge voltage and low DC cut-off

voltage can be set up in program 05,06 and 07.

Lithium

Only suitable for lithium battery when inverter communicated with

BMS.

The lithium battery BMS communication protocol options:

……

03

Buzzer

Buzzer on (default)

Buzzer off

04

Backlight Control

Backlight on (default)

Backlight off

13

05

Bulk charging voltage

(C.V voltage)

48V mode: default 56.4V, 48.0V~58.4V Settable

24V mode: default 28.2V, 24.0V~29.2V Settable

12V mode: default 14.1V, 12.0V~14.6V Settable

If “Li” is selected ,it can’t be set up

06

Floating charging

voltage

48V mode: default 54.0V, 48.0V~58.4V Settable

24V mode: default 27.0V, 24.0V~29.2V Settable

12V mode: default 13.5V, 12.0V~14.6V Settable

If “Li” is selected ,it can’t be set up

07

Low DC cut-off voltage

48V mode: default 42.0V, 40.0V~48.0V Settable

24V mode: default 21.0V, 20.0V~24.0V Settable

12V mode: default 10.5V, 10.0V~12.0V Settable

48V Li model: default 20%,5%~50% Settable

08

Communication mode

SIG (default), used to communicate with upper computer

CL1, used to communicate through RS485

CL2, used to communicate through CAN.

09

RS485

Communication

Address

Protocol 1 (default)

Used to communicate with controller in CL1 or CL2, or used to

communicate with upper computer in SIG

10

Battery equalization

If ”Flooded” or ”User-Defined” is selected in program this program can

be set up.

14

LCD Display Information

11

Battery equalization

voltage

48.0V model: default 58.0V,48~60V Settable

12

Battery equalization

time

Setting range is from 5 min to 900 min. Increment of each click is 1 min.

13

Battery equalization

timeout

Setting range is from 5 min to 900 min. Increment of each click is 1 min.

14

Equalization interval

Setting range is from 1 to 30 days.

Increment of each dick is 1 day.

15

Equalization activated

immediately

If equalization function is enabled in program 10,this program can be

set up. If “Enable” is selected in this program, It’s to activate battery

equalization immediately and LCD main page will show ”Eq”, If

“Disable” is selected, it will cancel equalization function until next

activated equalization time arrives based on program 14 setting. At this

time, “Eq” will not be shown in LCD main page.

15

The LCD display information will be switched in turns by pressing “UP/DOWN” key. The selectable information is

switched as below order.

Setting Information

LCD display

Charging voltage

Battery charging/discharging current

Battery charging/discharging power

Battery temperature sensor (BTS)

PV input voltage

For 48V60 and 48V80

For 48V100 and 48V120

16

PV generated current

For 48V60 and 48V80

For 48V100 and 48V120

PV generated power

Total PV generated energy

PV controller temperature

Battery SOC

Battery Equalization

17

Fault Code

Fault Code

Fault Event

Icon On

01

Fan is locked when controller is off.

02

Over temperature

03

Battery voltage is too high

20

BMS communication loss

63

Can’t communicate with the inverter

Warning Code

Warning Code

Warning Event

Icon Flashing

04

Battery voltage is too low

06

PV input voltage is too high

07

Overload

Battery Equalization

Equalization function is added into charge controller. It reverses the buildup of negative chemical effects like stratification, a

condition where acid concentration is greater at the bottom of the battery than at the top. Equalization also helps to remove

sulfate crystals that might have built up on the plates. If left unchecked, this condition, called sulfation, will reduce the

overall capacity of the battery. Therefore, it’s recommended to equalize battery periodically.

How to Apply Equalization Function

You must enable battery equalization function in monitoring LCD setting program 10 first. Then, you may apply this

function in device by either one of following methods:

1. Setting equalization interval in program 14.

2. Active equalization immediately in program 15.

When to Equalize

In float stage, when the setting equalization interval (battery equalization cycle) is arrived, or equalization is active

immediately, the controller will start to enter Equalize stage.

18

Equalize charging time and timeout

In Equalize stage, the controller will supply power to charge battery as much as possible until battery voltage raises to

battery equalization voltage. Then, constant-voltage regulation is applied to maintain battery voltage at the battery

equalization voltage. The battery will remain in the Equalize stage until setting battery equalized time is arrived.

However, in Equalize stage, when battery equalized time is expired and battery voltage doesn’t rise to battery equalization

voltage point, the charge controller will extend the battery equalized time until battery voltage achieves battery equalization

voltage. If battery voltage is still lower than battery equalization voltage when battery equalized timeout setting is over, the

charge controller will stop equalization and return to float stage.

This manual suits for next models

3

Table of contents

Other Sigineer Power Controllers manuals