SIGRIST FireGuard 2 Integral User manual

Document number: 13543E

Version: 3

Valid from: SW V129

REFERENCE HANDBOOK

FireGuard 2

Tunnel smoke detector

Copyright© SIGRIST-PHOTOMETER AG, subject to technical changes without notice 5/2020

SIGRIST-PHOTOMETER AG

Hofurlistrasse 1

CH-6373 Ennetbürgen

Switzerland

Tel. +41 41 624 54 54

Fax +41 41 624 54 55

info@photometer.com

www.photometer.com

Contents Reference Handbook FireGuard 2

13543E/3 3

Contents

1General user information...............................................................................................5

1.1 Terms used in this document (glossary).............................................................5

1.2 Purpose of the Reference Manual .....................................................................5

1.3 Target group of the documentation..................................................................5

1.4 Additional documentation ................................................................................5

1.5 Copyright provisions .........................................................................................5

1.6 Document storage location...............................................................................5

1.7 Order document ...............................................................................................6

1.8 Meaning of the safety symbols .........................................................................6

1.9 Meaning of the pictograms...............................................................................7

2Outputs with StromRel module (optional)......................................................................8

3Description of menu functions.......................................................................................9

3.1 General information on the menu description...................................................9

3.2 Menu: Display.................................................................................................10

3.2.1 Submenu: Display\D1 .. n ..........................................................................10

3.3 Menu: Recalibration........................................................................................10

3.3.1 Submenu: Recalibration\General................................................................10

3.3.2 Submenu: Recalibration\C .........................................................................11

3.4 Menu: Sensor check .......................................................................................12

3.5 Menu: Simulation ...........................................................................................12

3.6 Menu: Limits\L1 .. n ........................................................................................13

3.7 Menu: Curr. outputs.......................................................................................14

3.7.1 Submenu: Curr. outputs\General...............................................................14

3.7.2 Submenu: Curr. outputs\S1/2 ....................................................................16

3.7.2.1 Lin/Log function –linear or logarithmic signal output .......................... 17

3.8 Menu: Inp./outputs.........................................................................................17

3.9 Menu: Digi. interf. ..........................................................................................18

3.9.1 Submenu: General.....................................................................................18

3.9.2 Submenu: Modbus RTU (optional) .............................................................19

3.9.3 Submenu: Profibus DP (optional) ...............................................................20

3.9.4 Submenu: Profinet IO (optional).................................................................20

3.10 Menu: Configuration ......................................................................................21

3.11 Menu: Meas.channels \ Cn .............................................................................23

3.11.1 Submenu: Channel C1 Turb ......................................................................23

3.11.1.1 Integration .......................................................................................... 24

3.11.2 Submenu: Channel C2 Turb.Gr..................................................................24

3.11.3 Submenu: Channel C3 Temp.....................................................................25

3.11.4 Submenu: Channel C4 Temp.Gr ................................................................25

3.12 Menu: Spec. function .....................................................................................25

3.13 Menu: Meas. info ...........................................................................................27

3.14 Menu: History.................................................................................................28

3.14.1 History\Fault ..............................................................................................28

3.14.2 Structure of the error messages .................................................................29

3.14.3 History\Adjustment ....................................................................................30

3.15 Menu: System info..........................................................................................31

4Working with the web user interface...........................................................................33

4.1 Working with the web user interface via WLAN..............................................33

4.2 Changing the IP address on PCs with Windows 10 .........................................34

4.3 Start page in measuring operation..................................................................35

4.4 Setting the operating language with web user interface .................................36

4.5 Switching to service operation in the web user interface.................................36

4.6 Button functions in service operation..............................................................37

Reference Handbook FireGuard 2 Contents

4 13543E/3

5Field bus interface .......................................................................................................38

5.1 General...........................................................................................................38

5.1.1 Introduction...............................................................................................38

5.1.2 Fault codes ................................................................................................38

5.2 Modbus RTU / TCP..........................................................................................39

5.2.1 Modbus RTU, general settings ...................................................................39

5.2.2 Address list on the Modbus RTU................................................................39

5.2.3 Function of the live bit in the Modbus .......................................................42

5.3 Profibus DP.....................................................................................................42

5.3.1 Profibus DP, general settings .....................................................................42

5.3.2 Address list on the Profibus DP ..................................................................42

5.3.3 Function of the live fields in the Profibus DP ..............................................45

5.4 Profinet IO ......................................................................................................45

5.4.1 Profinet IO, general settings.......................................................................45

5.4.2 Address list on the Profinet IO (FireGuard 2) ..............................................45

5.4.2.1 GSD file (GSDML-V2.33-SIGRIST-NG PROFINET-20180115.xml)........... 45

5.4.2.2 Measuring data (slot 5: inputs / slot 1: outputs)................................... 46

5.4.2.3 Diagnosis data (slot 6) ......................................................................... 48

5.4.2.4 Configuration data (slot 7: inputs / slot 3: outputs).............................. 48

5.4.2.5 Threshold values (slot 8: inputs / slot 4: outputs) ................................. 49

5.5 HART ..............................................................................................................51

5.5.1 HART, general settings ..............................................................................51

5.5.2 HART process variables ..............................................................................51

5.5.3 Operating several FireGuard 2 units via the SICON M ................................52

6Repair work .................................................................................................................53

6.1 General information on repair work................................................................53

6.2 Replacing the 250 V microfuse on the SIPORT 2 .............................................53

6.3 Replacing the SIPORT 2...................................................................................54

6.4 Replacing the FireGuard 2...............................................................................54

6.5 Replacing the instrument cable on the FireGuard 2.........................................56

7Menu structure & factory settings................................................................................58

8Index ...........................................................................................................................62

Makro

Makro

General user information Reference Handbook FireGuard 2

13543E/3 5

1General user information

1.1 Terms used in this document (glossary)

Please refer to our website for specialist terms: www.photometer.com/en/glossary/

1.2 Purpose of the Reference Manual

This reference manual provides the user with more detailed information that supplements

the Instruction Manual.

1.3 Target group of the documentation

The Reference Manual is intended for all persons who are familiar with the contents of the

Instruction Manual and require detailed information about subjects such as design, configu-

ration, repairs etc.

1.4 Additional documentation

DOC. NO.

TITLE

CONTENT

13542E

Instruction Manual

Contains the most important information about

the overall life cycle of the instrument.

13544E

Brief Instructions

The most important functions and the servicing

schedule.

13654E

Data Sheet

Descriptions and technical data about the instru-

ment.

13545E

Service Manual

Repair and conversion instructions for service en-

gineers.

13692DEF

Declaration of Confor-

mity

Compliance with the underlying directives and

standards.

1.5 Copyright provisions

This document has been written by SIGRIST-PHOTOMETER AG. Copying or modifying the

content or giving this document to third parties is permitted only with the express consent of

SIGRIST-PHOTOMETER AG.

1.6 Document storage location

This document is part of the product. It should be stored in a safe place and always be close

at hand for the user.

Reference Handbook FireGuard 2 General user information

6 13543E/3

1.7 Order document

The most recent version of this document can be downloaded at www.photometer.com

(first time registration required).

It can also be ordered from a SIGRIST representative in your country (→Instruction Manual

“Customer service information”).

1.8 Meaning of the safety symbols

All danger symbols used in this document are explained below:

DANGER!

Danger due to electrical shock that may result in serious bodily injury or death.

Non-observance of this notice may lead to electrical shocks and death.

EXPLOSION

HAZARD!

Danger due to explosion that may result in serious bodily injury or death.

Non-observance of this notice may cause explosions resulting in serious property damage

and death.

WARNING!

Warning about bodily injury or hazards to health with long-term effects.

Non-observance of this warning may lead to injuries with possible long-term effects.

CAUTION!

Notice about possible material damage.

Non-observance of this notice may cause material damage to the instrument and its

peripherals.

General user information Reference Handbook FireGuard 2

13543E/3 7

1.9 Meaning of the pictograms

All pictograms used in this document are explained below:

Additional information about the current topic.

Practical procedures when working with the FireGuard 2.

Manipulations on the touchscreen.

Work on the PC.

The screenshot is an example and may differ from current device.

Reference Handbook FireGuard 2 Outputs with StromRel module (optional)

8 13543E/3

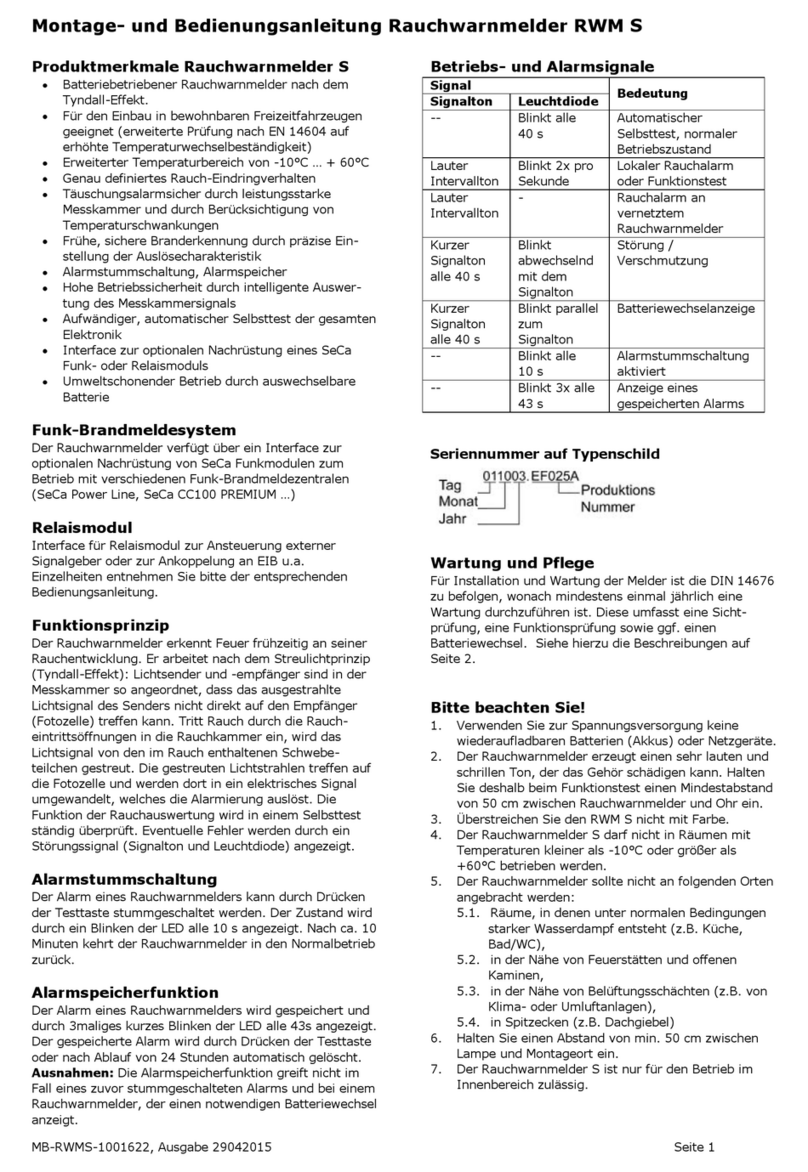

2Outputs with StromRel module (optional)

The StromRel module has two galvanically iso-

lated current outputs (0/4 .. 20 mA). The mi-

nus poles of these outputs are connected to-

gether. The maximum load is 500 Ω.

There are also three semiconductor relays,

which are also galvanically isolated. These are

designed for voltages of up to 30 V and cur-

rents of up to 0.12 A. With the contact clo-

sed, the resistance is 25 Ω.

The functions described in the Instruc-

tion Manual can be assigned to the outputs.

Only two of the three outputs are active (C1

and C2).

Figure 1: Outputs diagram

Two galvanically isolated cur-

rent outputs mA1/2

Galvanically isolated semiconductor re-

lays C1 .. C3

Description of menu functions Reference Handbook FireGuard 2

13543E/3 9

3Description of menu functions

3.1 General information on the menu description

The menus for photometer operation and the web user interface are generally identical.

Differences between the two operation possibilities are separately described in the relevant

sections (e.g. “Setting the operating language” or “Switching to service mode”).

SYMBOL

MEANING

Indicates functions that cannot be changed by the user.

The menu structure with the factory settings is found in the Section 7.

Reference Handbook FireGuard 2 Description of menu functions

10 13543E/3

3.2 Menu: Display

3.2.1 Submenu: Display\D1 .. n

Source

Functions / Values / Parameters

Setting the sequence for displaying the

measuring channels.

The source refers to the channels defined

in the Meas. channels menu.

C1 .. n

▪D1 Turb

▪D2 Turb.Gr

▪D3 Temp

▪D4 Temp.Gr

Inactive

The channel is inactive.

Resolution

Functions / Values / Parameters

Setting the number of decimal points to

be used for the display of small measuring

values.

1, 1.2, 1.23, 1.234

3.3 Menu: Recalibration

3.3.1 Submenu: Recalibration\General

Auto start recal.

Functions / Values / Parameters

Setting whether the recalibration should

be started automatically or not after the

checking unit is inserted.

Inactive

Recalibration is not started

when the checking unit is

inserted.

Active

Recalibration is started au-

tomatically when the

checking unit is inserted.

Cont.1 name

Functions / Values / Parameters

Name of the main checking unit

KStab 1

A maximum of 7

characters can be defined.

Cont.1 value

Functions / Values / Parameters

Nominal value on the main checking unit

Instrument

specific

Value recorded during cali-

bration at the factory.

Cont.2 name

Functions / Values / Parameters

Name of the reserve checking unit

KStab 2

A maximum of 7

characters can be defined.

Cont.2 value

Functions / Values / Parameters

Nominal value on the reserve checking

unit

Instrument

specific

Value recorded during cali-

bration at the factory.

Description of menu functions Reference Handbook FireGuard 2

13543E/3 11

3.3.2 Submenu: Recalibration\C1

Cont. active

Functions / Values / Parameters

Selection of the checking unit to be used

(main/reserve checking unit)

KStab 1

Main checking unit

KStab 2

Reserve checking unit

Nom. val.

Functions / Values / Parameters

Value on the checking unit belonging to

the instrument.

... (instrument specific)

See also:

▪Instruction Manual

...(i nstrume nts pecific)

Act. val.

Functions / Values / Parameters

Current measured value.

... (instrument specific)

See also:

▪Instruction Manual

Adjustment

Functions / Values / Parameters

Initiates adjustment. A new correction fac-

tor is calculated from the actual value and

nominal value.

initiate...

See also:

▪Instruction Manual

Curr. corr.

Functions / Values / Parameters

Current correction factor that specifies the

deviation to the factory settings.

1.000

See also:

▪Instruction Manual

Soiling

Functions / Values / Parameters

Displays the current level of soiling on the

instrument.

▪0% indicates a clean instrument.

▪At 100%, the fouling limit is reached

and a warning message is output on

the instrument.

0 .. 100%

Reference Handbook FireGuard 2 Description of menu functions

12 13543E/3

3.4 Menu: Sensor check

Sensor check

Functions / Values / Parameters

The sensor check includes the inspection

of the entire measuring electronics, plus

all light receivers.

During the check, the actual measu-

rement is not in operation and all output

signals remain frozen in their current

state.

start... .

3.5 Menu: Simulation

Meas.value mode

Functions / Values / Parameters

Measuring values can be simulated on the

outputs with this function.

To be able to clearly differentiate the indi-

vidual measuring values, each channel has

its own multiplication factor for the base

simulation value.

Off

Deactivates the function.

Static

The base simulation value

is 1.

Dynamic

The base simulation value

switches between values

1 to 2.

Simu value

The base simulation value is

taken from the Simu value

parameter.

Simu value

Functions / Values / Parameters

If the function Simu value is adjusted in

the Meas.value mode menu, the value

specified here is taken as the base simula-

tion value.

1.000

See also:

▪Instruction Manual

▪Meas.value mode

Fault mode

Functions / Values / Parameters

All fault messages can be simulated on

the digital interfaces with this function.

Off

Deactivates the function.

See also:

▪Instruction Manual

Description of menu functions Reference Handbook FireGuard 2

13543E/3 13

Curr. outputs

Functions / Values / Parameters

Certain values can be output to the cur-

rent outputs with this function.

Off

Deactivates the function.

0 mA, 4 mA,

8 mA, 10 mA,

12 mA, 16

mA, 20 mA

Electrical current to be out-

put to the outputs.

See also:

▪Instruction Manual

Outputs

Functions / Values / Parameters

Certain states can be output to the digital

outputs with this function.

Off

Deactivates the function.

All Off

All outputs are on 0.

All On

All outputs are on 1.

1 .. n On

Set single output to 1.

Light source

Functions / Values / Parameters

This function can be used to switch the

light source on and off manually for tes-

ting or isolating a fault.

Off

Light source is switched off.

1

Light source is switched on.

3.6 Menu: Limits\L1 .. n

The procedure for setting the limits is described in detail in the Instruction Manual.

For each limit (L1 .. n) the following parameters are available:

Source

Functions / Values / Parameters

Setting the source for the corresponding

limit channel.

L1 Turb

Channel 1

L2 Turb.Gr

Channel 2

L3 Temp

Channel 3

L4 Temp.Gr

Channel 4

Upper limit

Functions / Values / Parameters

Setting the upper threshold value.

... (instrument specific)

See also:

▪Instruction Manual

Reference Handbook FireGuard 2 Description of menu functions

14 13543E/3

Cut in delay

Functions / Values / Parameters

Cut in delay: Setting the time span for

how long the limit has to be exceeded be-

fore a signal is output to the outputs and

appears in the display.

6 s for limit 1 .. 4

8 s for limit 5 .. 8

Value in seconds

See also:

▪Instruction Manual

Cut out delay

Functions / Values / Parameters

Cut out delay: Setting the time span of

how long the limit has to be undershot

before the signal from the outputs drops

out and the limit display disappears from

the display.

0 s

Value in seconds

See also:

▪Instruction Manual

3.7 Menu: Curr. outputs

This menu is active only when a StromRel module is integrated and the module type is set

to StromRel in the Digi. interf. menu under General.

3.7.1 Submenu: Curr. outputs\General

Range

Functions / Values / Parameters

Setting the measuring range MR1 .. MR8.

It is also possible to define the measuring

ranges via inputs In 1/2 or automatically

via Auto 1/2.

MR1 .. MR8

Fixed measuring range

In 1/2

Measuring range switching

via inputs Section 3.8

Auto 1/2

Automatic switching

0/4 mA .. 20 mA

Functions / Values / Parameters

Setting the current range for the reading

output. The output is scaled to each cur-

rent measuring range.

0-20mA

0% measuring value = 0mA,

100% measuring value =

20mA

4-20mA

0% measuring value = 4mA,

100% measuring value =

20mA

See also:

▪Instruction Manual

Description of menu functions Reference Handbook FireGuard 2

13543E/3 15

For service

Functions / Values / Parameters

Setting the measuring value output in ser-

vice mode.

0 Value

During service mode, the

measuring value output is

set to the value that corres-

ponds to measuring value

0. This value depends on

the current range.

Last value

During service mode, the

measuring value output re-

mains (frozen) on the last

valid measuring value.

Recalibr.

During service mode, the

measuring value output re-

mains (frozen) on the last

valid measuring value. Fol-

lowing a manually initiated

calibration check (ad-

justment), a value corres-

ponding to the correction

value is output for 10 se-

conds (see the following

table).

0..20 mA

4..20 mA

Correction value

20 mA

20 mA

1.5

10 mA

12 mA

1.0

0 mA

4 mA

0.5

Measure

The measurement conti-

nues to run normally in ser-

vice mode and the regular

measuring value output is

available. If you are in a

sensor menu, the last va-

lues are maintained.

See also:

▪Instruction Manual

Max. value

Functions / Values / Parameters

Setting the highest possible electrical cur-

rent on the measuring value output. Cur-

rent values over 20.0 mA correspond to

more than 100 % measuring value of the

current measuring range.

21 mA

Adjustable range

20.0 .. 21.0 mA

See also:

▪Instruction Manual

Reference Handbook FireGuard 2 Description of menu functions

16 13543E/3

If fault

Functions / Values / Parameters

Electrical current value that should be out-

put in the event of an error.

This setting is relevant only if 4 mA

.. 20 mA was set as electrical current

range (see above).

2 mA

Adjustable range

0 .. 4 mA

See also:

▪Instruction Manual

3.7.2 Submenu: Curr. outputs\S1/2

The following functions are available for each current output:

Source

Functions / Values / Parameters

Setting the source of the corresponding

current output.

The source refers to the channels defined

in the Meas.channels menus.

Chan. 1 .. 4

Depending on selected

configuration.

Inactive

Range

Functions / Values / Parameters

Setting the measuring range MR1 .. MR8.

MR1 .. MR8

Fixed measuring range

Lin / Log

Functions / Values / Parameters

Setting whether a linear or logarithmic si-

gnal is output on the current output. The

Log value is calculated as follows (see

box):

Log value = log10 (Lin value / MR from) /

log10 (MR to / MR from). MR from has a

minimum value of 0.001 here.

Lin

Linear output

Log

Logarithmic output

See also:

▪Section 3.7.2.1

Description of menu functions Reference Handbook FireGuard 2

13543E/3 17

3.7.2.1 Lin/Log function –linear or logarithmic signal output

The Lin/Log function is used to set whether the current signal is output in linear (Lin) or lo-

garithmic (Log) form.

This can be useful if very large measuring ranges are to be represented, for example

(Example: FireGuard 0.1 .. 3000 mE/m). With the logarithmic signal output, the Measuring

range can have a minimum value of 0.001.

If a lower value was set in the “From” column in the Measuring range menu, then the si-

gnal is output according to this minimum value (there is no underflow). The measuring range

is transferred in a logarithmic range of 0 .. 1. The measuring range is then output as a cur-

rent range of 0/4 .. 20 mA.

The measuring value is converted into a current value as follows:

Log value = log10 (Lin value / MR from) / log10 (MR to / MR from)

Current (4-20mA) = Log value * 16 + 4 [mA]

The current value is converted back into a measuring value as follows:

Log value = (current (4-20mA) –4) / 16

Lin value = MR from * (MR to / MR from) Log value

Example: MR from = 0.1, MR actual = 3000

Lin -> Log -> Current

Current -> Log -> Lin

Lin value

Log value

Current (4 .. 20)

Log value

Lin value

0.1

0.00

4.0

0.00

0.1

1

0.22

7.6

0.22

1

10

0.45

11.1

0.45

10

100

0.67

14.7

0.67

100

1000

0.89

18.3

0.89

1000

3000

1.00

20.0

1.00

3000

3.8 Menu: Inp./outputs

The procedure for setting the outputs is described in detail in the Instruction Manual.

Outputs

Functions / Values / Parameters

O1 Limits

Invert

Invert function.

Fault

Active if a fault has oc-

curred.

O2 Fault

Invert

Invert function.

Reference Handbook FireGuard 2 Description of menu functions

18 13543E/3

3.9 Menu: Digi. interf.

The digital interfaces can be configured here. The available parameters are dependent on the

integrated interface modules (Modbus RTU / Profibus DP/HART).

After changing these options, the instrument must be switched off and then switched on

again. The Modbus RTU/Profibus / Profinet IO / HART menus are displayed only if the con-

cerned modules are installed. →Instruction Manual

3.9.1 Submenu: General

Modul type

Functions / Values / Parameters

Selection of the integrated interface mo-

dule (add-on module).

Auto.

Automatic detection of the

modules after starting the

software.

This does not work

for the HART or StromRel

modules, or when the mo-

dule is integrated in a

connection box such as

SIPORT 2. In such cases, the

Modul type has to be sel-

ected manually.

Module

name…

The selectable modules are

listed according to the

specific instrument (e.g.

Modbus RTU, Profibus DP

etc.)

See also:

▪Instruction Manual

Module location

Functions / Values / Parameters

Selecting the instrument where the inter-

face module was integrated.

Local

If the corresponding mo-

dule is integrated in the Fi-

reGuard 2.

…Name of the

connection

box…

If the corresponding mo-

dule is integrated in a con-

nection box.

See also:

▪Instruction Manual

WLAN-Key

Functions / Values / Parameters

This menu item is only displayed when a

WLAN module is integrated. Entry of the

WLAN security key.

12345678

A maximum of 14

characters can be defined.

Description of menu functions Reference Handbook FireGuard 2

13543E/3 19

3.9.2 Submenu: Modbus RTU (optional)

This menu item is only available when a Modbus module is installed.

Slave no.

Functions / Values / Parameters

Definition of the slave number with which

the photometer is addressed in the con-

trol system.

1

Values between 1 and 240

are permissible.

See also:

▪Instruction Manual

Baud rate

Functions / Values / Parameters

Setting of the baud rate of the Modbus

interface.

115200 Baud

Baud rate in bits/s

Other available values:

4800, 9600, 19200,

38400, 57600, 230400

Baud

Parity

Functions / Values / Parameters

Setting the parity bits of the Modbus in-

terface.

None

No parity bit (NONE)

Even

Even parity bit (EVEN)

Odd

Odd parity bit (ODD)

Stopbit

Functions / Values / Parameters

Setting the number of stopbits on the

Modbus interface.

1

1 stopbit

2

2 stopbits

FireGuard Comp.

Functions / Values / Parameters

Setting the compatibility with the pre-

vious FireGuard version via the Modbus

connection.

If a FireGuard is connected to a

SICON M via the Modbus-Rep pcb, Fire-

Guard Comp. must be deactivated.

Active

Modbus access compatible

with previous version

Inactive

Modbus access compatible

with SICON M

Reference Handbook FireGuard 2 Description of menu functions

20 13543E/3

3.9.3 Submenu: Profibus DP (optional)

This menu item is only available when a Profibus module is installed.

Control

Functions / Values / Parameters

Set whether values can only be read or

can also be written via Profibus.

Local

Values can only be read.

External

Reading and writing the

values. The photometer can

be controlled via Profibus.

Slave no.

Functions / Values / Parameters

Definition of the Profibus slave number.

1

Values between 1 and 240

are permissible.

See also:

▪Instruction Manual

3.9.4 Submenu: Profinet IO (optional)

This menu item is only available when a Profinet IO module is installed.

Control

Functions / Values / Parameters

Setting whether values can only be read

or can also be written via Profinet.

Local

Values can only be read.

External

Values can be read and

written. The photometer

can be controlled via Profi-

net.

Station name

Functions / Values / Parameters

Load the current station name.

Loading the station name results in

a brief interruption in communication.

load...

Other manuals for FireGuard 2 Integral

2

Table of contents

Other SIGRIST Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

Zipato

Zipato Z-Wave PH-PSG01 Quick installation guide

Universal Security Instruments

Universal Security Instruments HEAT ALARM USI-2430 owner's manual

olympia electronics

olympia electronics BS- 657/A quick start guide

Brooks

Brooks Electronics EIB603CX user guide

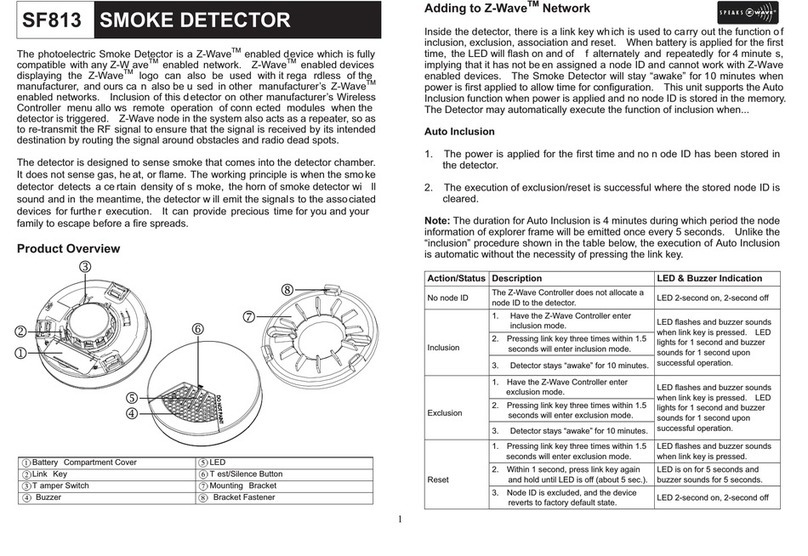

Z-Wave

Z-Wave SF813 manual

Seca

Seca Model S Installation and operating instruction