Simatec SIEM9750 User manual

Page 1of 90

SIEM9750

Release 1.0

Chassis (FRU) Information and

Troubleshooting Guide

Issue: 02

Date: 2011-11-07

Page 2of 90

This document is intended for Symantec support personnel, IBM, or other authorized Symantec Service

Partners.

Symantec Corporation

Address: 350 Ellis St., Mountain View, CA 94043

Website: http://www.symantec.com

Copyright © Symantec Corporation. 2011. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Symantec Corporation.

Trademarks and Permissions

and other Symantec trademarks are trademarks of Symantec Corporation.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Symantec

and the customer. All or part of the products, services and features described in this document may not

be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all

statements, information, and recommendation in this document are provided “AS IS” without warranties,

guarantees or representation of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Page 3of 90

Table of Contents

1. Safety Notice and Warnings.................................................................................................................. 5

2. Ratings................................................................................................................................................... 6

3. Electrical and General Safety Guidelines .............................................................................................. 7

4. Prerequisites for All Hardware Replacement Procedures .................................................................... 9

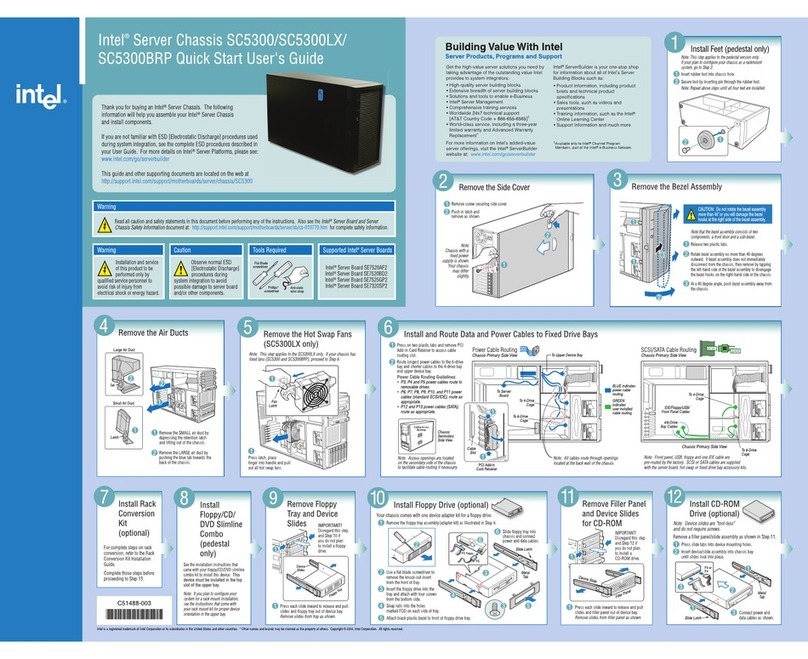

5. Hardware Configuration of the SIEM 9750.........................................................................................10

6. Front and Rear Pics of Server.............................................................................................................. 11

7. FRU 2U Base Chassis – Local Control Panel ........................................................................................ 13

8. Intel® Local Control Panel Menus ....................................................................................................... 15

9. Symptoms of a Failed Local Control Panel.......................................................................................... 19

10. FRU 2U Base Chassis – System Status LED......................................................................................20

11. Hard Disk Drive Support..................................................................................................................23

12. FRU 2U Base Chassis – Power Subsystem.......................................................................................25

13. PCI Riser Cage.................................................................................................................................. 29

14. Add In Cards and On-Board NICs ....................................................................................................30

16. Hard Drive / RAID Management – BIOS Level RAID Utilities ..........................................................35

17. BIOS Level RAID Utility – RAID Controller Event Log File ................................................................41

18. RAID Priorities .................................................................................................................................43

19. Cooling Sub-System.........................................................................................................................44

20. FRU 2U Base Chassis – Server Board............................................................................................... 48

21. Memory........................................................................................................................................... 52

22. Processers (CPUs)............................................................................................................................ 54

23. Intel®Remote Management Module 3 - Overview .......................................................................55

24. Intel®Remote Management Module 3 – Viewing Field Replaceable Unit (FRU) Information...... 57

25. Active Midplane ..............................................................................................................................62

26. SAS / SATA Backplane Layout ......................................................................................................... 64

28. Server Diagnostics and Troubleshooting ........................................................................................ 65

28. POST Code Diagnostic LED Decoder................................................................................................69

29. All Possible LED Codes..................................................................................................................... 71

30. Video POST Code Errors..................................................................................................................76

31. POST Error Beep Codes ...................................................................................................................81

32. List of Acronyms.............................................................................................................................. 82

Page 5of 90

1. Safety Notice and Warnings

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

No Telecommunications Network Voltage (TNV)-connected PCBs shall be installed. This class A

digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.

VCCI Warning

This is a product of VCCI Class A Compliance.

Environmental Warning

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

This notice is required by California Code of Regulations, Title 22, Division 4.5, Chapter 33: Best

Management Practices for Perchlorate Materials. This product/part includes a battery that contains

Perchlorate material.

Page 6of 90

2. Ratings

POWER INPUT:

Volts:

100 - 240 VAC (auto-range); 50-60 Hz

Amps:

12 - 6 amps

VA:

960

PFC Watts:

960

OUTPUT:

Watts:

750W

BTUs/hr:

2550

% Efficiency of the Power Supplies:* 80%

* Typical and varies with load

ENVIRONMENT:

Temperature:

• Operating temperature range: 50 to 95oF (10 to 35oC)

• Non-operating temperature range: -40 to 158oF (-40 to 70oC)

Humidity:

• Operating humidity range: 8 to 90% non-condensing at 35oC

• Non-operating humidity range: 5 to 95% non-condensing

DIMENSIONS:

Form Factor: 2U rack mount

Height: 3.5” (88.9 mm)

Width: 16.9” (430 mm)

Depth: 29.5” (749.3 mm)

Weight: Typical - 71 lbs. (32.2 kg) when fully configured (2 PSUs, 8 HDDs)

Page 7of 90

3. Electrical and General Safety Guidelines

CAUTION

This appliance is intended for installation in restricted areas only. Initial setup and maintenance should be

performed by qualified personnel.

CAUTION

Power down the appliance following the operating system’s proper power down procedure from the

front panel. Unplug all AC power cord(s) before servicing.

CAUTION

To avoid electrical shock, check the power cords as follows.

• This product is to be installed in Restricted Access Location only.

• Use the exact type of power cords required.

• Use power cord(s) that came with safety certifications.

• Power cord(s) must comply with AC voltage requirements in your region.

• The power cord plug cap must have an electrical current rating that is at least 125% of the electrical

current rating of this product.

• The power cord plug cap that plugs into the AC receptacle on the power supply must be an IEC 320,

sheet C13, type female connector.

• Plug the power cord(s) into a socket that is properly grounded before turning on the power.

CAUTION

Required operating conditions for the appliance are -

• Temperature: 10 to 35oC.

• Humidity, non-condensing: 8 to 90%.

CAUTION

Risk of explosion if the battery is installed upside down or is replaced by an incorrect type. Dispose

of used batteries according to the instructions.

DISPOSING OF BATTERY BACKUP UNITS - IF APPLICABLE WARNING

If the BBU is damaged in any way, toxic chemicals may be released. The material in the battery pack

contains heavy metals that can contaminate the environment. Federal, state, and local regulations

prohibit the disposal of rechargeable batteries in public landfills. Be sure to recycle the old battery packs

properly. Comply with all applicable battery disposal and hazardous material handling laws and

regulations in the country or other jurisdiction where you are using the BBU.

WARNING

There is danger of an explosion if the battery is incorrectly replaced. Replace it only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Page 8of 90

3. Electrical and General Safety Guidelines (continued)

WARNING

Disconnect the power supply at the circuit breaker before accessing any components. Turning off

the system power supply switch does not reduce the risk of electrical shock from the power supply

terminal block.

CAUTION

• To prevent the unit from overheating, never install the appliance in an enclosed area that is not properly

ventilated or cooled. For proper airflow, keep the front and back sides of the appliance clear of

obstructions and away from the exhaust of other equipment.

• Be aware of the locations of the power switches on the chassis and in the room, so you can disconnect

the power supply if an accident occurs.

• Take extra precautionary measures when working with high voltage components. Do not work alone.

• Before removing or installing main system components, be sure to disconnect the power first. Turn off

the system before you disconnect the power supply.

• Use only one hand when working with powered-on electrical equipment to avoid possible electrical

shock.

• Use rubber mats specifically designed as electrical insulators when working with computer systems.

• The power supply or power cord must include a grounding plug and must be plugged into grounded

outlets.

CAUTION

Electric Static Discharge (ESD) can damage electronic components. To prevent damage to your system

board, it is important to handle it very carefully. The following measures can prevent ESD damage to

critical components.

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their antistatic bags until ready for use.

• Touch a grounded metal object before removing the board from the antistatic bag.

• Do not let components or PCBs come into contact with your clothing, which may retain a charge even if

you are wearing a wrist strap.

• Handle a board by its edges only; do not touch its components, peripheral chips, memory modules or

contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their antistatic bags when not in use.

• For grounding purposes, make sure your computer chassis provides excellent conductivity between the

power supply, the case, the mounting fasteners and the motherboard.

Page 9of 90

4. Prerequisites for All Hardware Replacement Procedures

1. Technician that is performing the hardware replacement must be statically grounded and observe ESD

compliance practices.

2. All hardware replacements should be performed with the Server Chassis/Enclosure powered off and

power cables removed. The only exception to this will be Hot Swap components: HDD hard drives

and power supplies, Cooling Fans.

3. All externally connected device cables should be labeled so that they can be plugged into their exact

same position/ports if replacement is needed.

4, If the Server is installed in a rack, the technician must determine if the Server, as installed, needs to be

removed completely or partially for parts replacement. Space limitations and cable lengths will determine

if the replacement swap can be done without removing the machine from the rack.

Foot Strap for ESD Protection

Wrist Strap for ESD Protection

Page 10 of 90

5. Hardware Configuration of the SIEM 9750

Components: Details

Main features: 2U (1 U = 44.45 mm (1.75”))

Eight customer removable disk slots on the front panel

Two non removable solid state drives on the mainboard

Processor : Two quad-core E5640 CPUs

Memory : Memory:16 GB – eight 2 GB DIMMs

Disks : 8 x 600 GB, 7,200 rpm SAS (Serial Attached SCSI) data disks

Two 120 GB solid state drives

RAID: RAID 1 and RAID 5

System disk: RAID 1 (software RAID)

Data disk: RAID 5 (RAID chip on mainboard)

Access ports

Front panel: Two USB 2.0 ports on the control panel

Rear panel: One 100 Mbit/s IPMI management network port

One Video Graphics Array (VGA) port

One RJ-11 serial port, with a transfer rate of 115,200 baud

Four Universal Serial Bus (USB) 2.0 ports

One GE Gigabit Ethernet service network port, with RJ-45 connector and link/active

indicator LEDs

One GE Gigabit Ethernet private network port, with RJ-45 connector and link/active

indicator LEDs3

Page 11 of 90

6. Front and Rear Pics of Server

Front view

Front and top view

Rear view

Page 12 of 90

6. Front and Rear Pics of Server (continued)

Page 13 of 90

7. FRU 2U Base Chassis – Local Control Panel

The Intel® Local Control Panel is an optional accessory installed in the SIEM 9750 that enhances the

manageability of the Server Board in the chassis. Combined with the installed Remote Management

Module, the Local Control Panel allows a user to monitor the health of an Intel® Server or configure an

Intel® Server for remote IPMI management. This allows for monitoring, configuration and control of the

Server, independently from the Operating System. Perhaps the most useful feature of the control panel is

the ability to view the events of the System Event Log (SEL) without having to reboot the system.

NOTE: The following parts within the

SIEM9750 are not FRUs and therefore

when they fail, a replacement Base

Chassis will be installed instead.

•Local Control Panel (LCD Display)

•CPUs

•Server Board

•Power Distribution Module

•RAID Activation Key for Active

Midplane

•Memory Module on Active Midplane

•Intel® Remote Management Module 3

•SAS Backplane

•PCI Riser Card Cage

•Any I/O ports on the Server such as

Onboard NICs, USB and Video ports

Page 14 of 90

7. FRU 2U Base Chassis – Local Control Panel(continued)

[Source: Intel SR2625UR Service Guide]

Page 15 of 90

8. Intel® Local Control Panel Menus

The root menu of the Intel® Local Control Panel is the Intel® Local Control Panel main menu. This menu

appears after power on or reset, and after the user presses a button to stop the Intel® Local Control

Panel monitor. The following sections are organized based on the menu structure of the Intel® Local

Control Panel.

8.1 Intel® Local Control Panel Main Menu

This menu includes a help screen that describes each of the symbols used by the Intel® Local Control

Panel display. The help screen does not have sub-menus.

Page 16 of 90

8. Intel® Local Control Panel Menus (continued)

8.2 Table – Help Symbols

8.3 Server Monitoring Menu

This menu item provides options for monitoring the current server status such as sensors, chassis status,

and viewing the System Event Log (SEL).

Page 17 of 90

8. Intel® Local Control Panel Menus (continued)

8.4 System Event Log (SEL)

This menu item displays the system event log. When this menu item is selected, the Intel® Local Control

Panel downloads the SEL from the system. This download may take several seconds, depending on the

number of SEL entries. The Intel® Local Control Panel displays the SEL entries in order, with the most

recent entries at the top of the display. An hourglass icon indicates that the entries are loading.

The Intel® Local Control Panel translates the standard IPMI SEL entries form HEX format. Due to the

limited display area, the Intel® Local Control Panel uses special icons to translate frequently used

translation terms. For example: an SEL event indicating a sensor has crossed its upper non-critical

threshold uses the icon . See the Help Symbols Table for a selection of icons.

The Intel® Local Control Panel can display up to two translated SEL entries on the screen at a time. The

SEL entry at the top of the Intel® Local Control Panel display is the active SEL entry. Pressing the Enter

button on the Intel® Local Control Panel on the active SEL entry causes the Intel® Local Control Panel to

display the raw SEL data for the entry in HEX.

NOTE: The Intel® Local Control Panel does not provide an option to clear the SEL. Use the

current Intel® System Management software tools to clear the SEL. Some Intel® servers also

provide the capability to clear the SEL in BIOS setup.

Page 18 of 90

8. Intel® Local Control Panel Menus (continued)

8.4.1 Navigating the SEL on the Intel® Local Control Panel

Step 1 Choose Server

Monitoring.

Step 2 Choose System Event Log.

Step 3 View System Event Log

contents.

Page 19 of 90

9. Symptoms of a Failed Local Control Panel

•Nothing on the display at all.

•Display is not readable.

•System will not power on (power button).

•System will power but no LEDs light.

Page 20 of 90

10. FRU 2U Base Chassis – System Status LED

The SIEM 9750 uses an LED on

the front of the control panel to

indicate System Faults. This LED

is called the System Status LED

and is represented by a triangle

with an exclamation mark in the

middle of it.

The Control Panel LED

Operation table shown denotes

the possible System Status LED

color states and their meanings.

Table of contents

Popular Chassis manuals by other brands

Turin Networks

Turin Networks MASTER series quick start guide

Tiger Technology

Tiger Technology Tiger Box 4U24 Assembly guide

ICP Electronics

ICP Electronics EC-1040 user manual

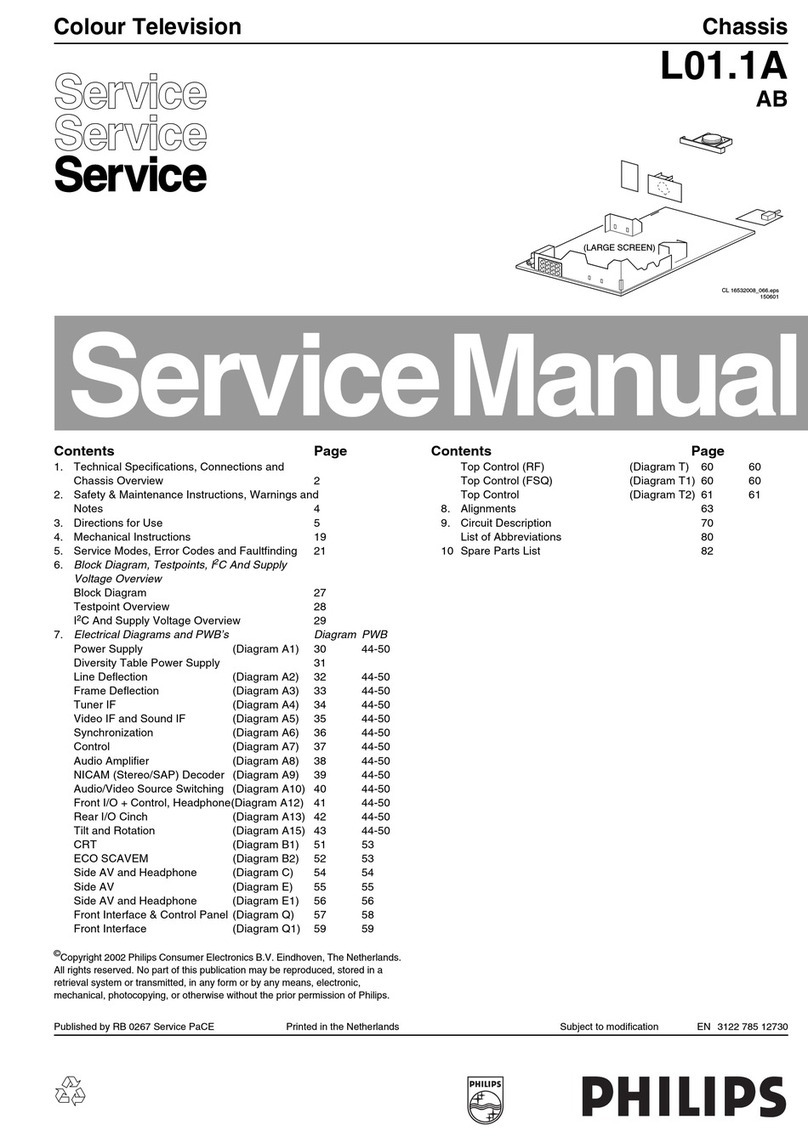

Philips

Philips L01.1A Service manual

Transition Networks

Transition Networks PointSystem CPSMC0200-2x0 user guide

SilverStone

SilverStone CS351 manual