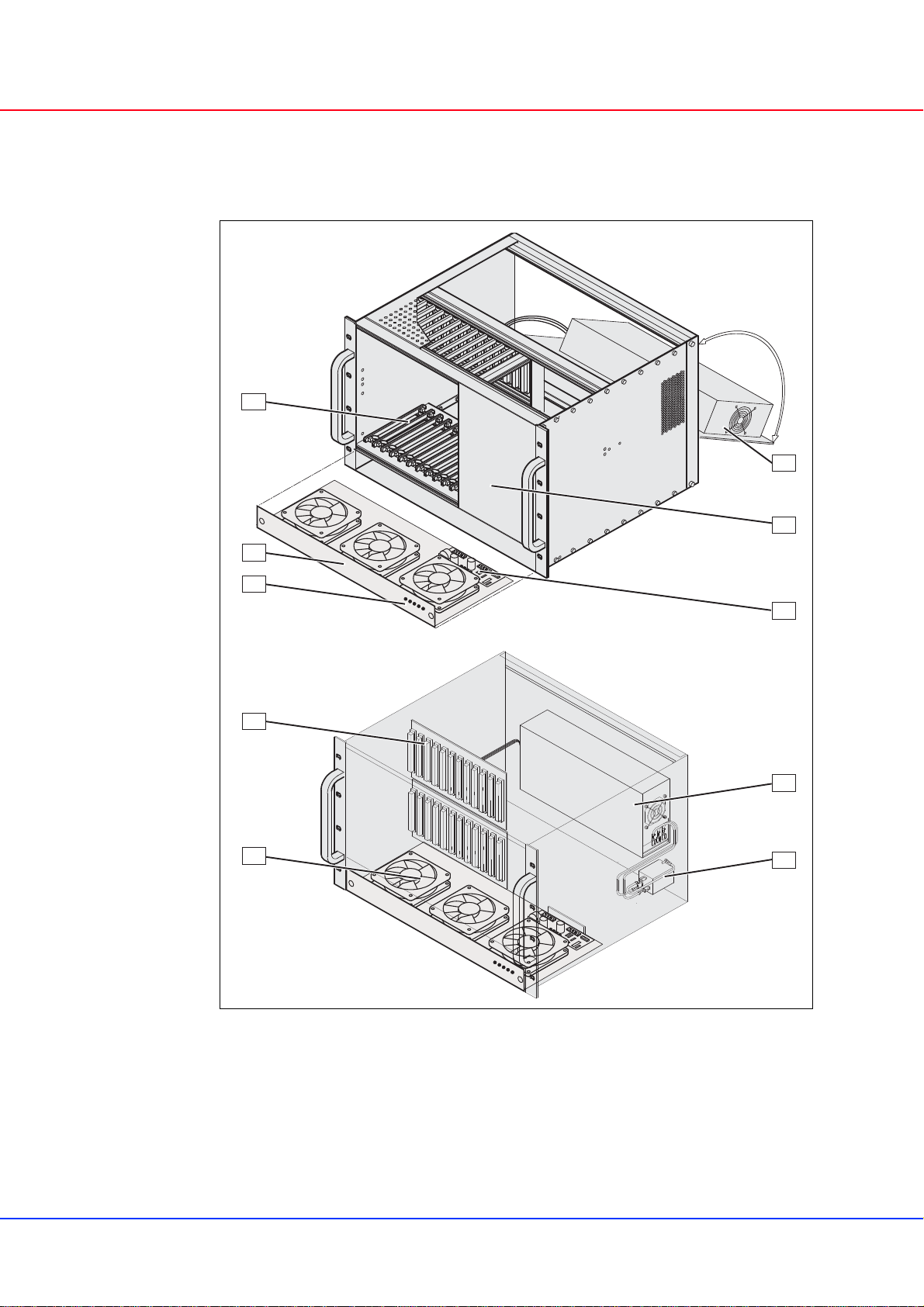

VME Subrack System 7 U

20836-715/-718

www.schroff.biz I R1.1, November 14, 2008

Table of Contents

1 Safety................................................................................................................. 1

1.1 Intended Application............................................................................................ 1

1.2 Safety Instructions............................................................................................... 2

1.3 Safety Symbols used in this document................................................................ 2

1.4 General Safety Precautions................................................................................. 2

1.5 References and Architecture Specifications........................................................ 3

2 Product Definition............................................................................................. 4

2.1 Mechanical Overview........................................................................................... 5

2.2 Subrack................................................................................................................ 6

2.3 VME Backplane................................................................................................... 6

2.4 Power Supply....................................................................................................... 7

2.4.1 Grounding.............................................................................................. 7

2.5 Thermals............................................................................................................ 10

2.6 Fan Control Module (FCM)................................................................................ 11

2.7 Chassis Monitoring Module (CMM) -optional- ................................................... 12

2.8 Display Module.................................................................................................. 13

3 Installation....................................................................................................... 14

3.1 Unpacking.......................................................................................................... 14

3.1.1 Ensuring Proper Airflow....................................................................... 14

3.2 Rack-Mounting................................................................................................... 15

3.3 Assembly of additional Backplanes................................................................... 16

3.4 Basic Functional Check..................................................................................... 17

4 Service............................................................................................................. 18

4.1 Technical support and Return for Service Assistance....................................... 18

4.2 Declaration of Conformity.................................................................................. 18

4.3 Scope of delivery............................................................................................... 19

4.4 Accessories ....................................................................................................... 19

4.5 Spare Parts........................................................................................................ 19

5 Technical Data ................................................................................................ 20

6 Mechanical Dimensions................................................................................. 21