using seamless steel pipe

(Mannesmann type), galvanized and

with threaded joints provided with

gaskets, excluding three-piece connec-

tions, except for initial and end connec-

tions. Where the piping has to pass

through walls, a suitable insulating

sleeve must be provided.

When sizing gas piping, from the

meter to the boiler, take into account

both the volume flow rates (consump-

tion) in m3/h and the relative density of

the gas in question.

The sections of the piping making up

the system must be such as to gua-

rantee a supply of gas sufficient to

cover the maximum demand, limiting

pressure loss between the gas meter

and any apparatus being used to not

greater than:

1.0 mbar for family II gases (natural

gas);

2.0 mbar for family III gases (butane

or propane).

An adhesive data plate is sticked inside

the front panel; it contains all the tech-

nical data identifying the boiler and the

type of gas for which the boiler is

arranged.

2.2.1 Filter on the gas pipe

The gas valve is supplied ex factory

with an inlet filter, which, however, is

not adequate to entrap all the impuri-

ties in the gas or in gas main pipes.

To prevent malfunctioning of the valve,

or in certain cases even to cut out the

safety device with which the valve is

equipped, install an adequate filter on

the gas pipe.

2.3 CHARACTERISTICS

OF FEEDWATER

It is absolutely essential that the water

for the central heating system is to be

treated in the following cases:

Very extensive system (with high

contents of feedwater).

Frequent addition of makeup water

into the system.

Should it be necessary to empty the

system either partially or totally.

2.4 SYSTEM FILLING

The filling shall be made slowly so that

air bubles are eliminated through the

vents. The charge pressure, with the

system cold, must between 1 and 1,2

bar. The system loading pipe can be

connected with the 1/2” coupling on

the back header or, on the “PVA”

models, on the cross coupling connec-

ted to the expansion tank.

2.5 FLUE

A flue for the discharge into the atmo-

sphere of the products of combustion

of natural draught plants must have

the following characteristics:

be sealed against the products of

combustion, waterproof and insu-

lated;

be made of materials capable of

withstanding normal mechanical

stresses, heat and the action of the

products of combustion and their

condensate;

be vertical and with no narrowing

throughout its whole length;

be properly insulated to avoid flue

gases condensing or cooling, espe-

cially if it is placed outside a building

or in rooms with no heating;

be kept at a safe distance from com-

bustible and easily inflammable

materials by an air space or any

other suitable insulating material;

have a chamber collecting solid

materials and condensates below

the mouth of the first flue; this

chamber must be at least 500 mm

high. Access to this chamber must

be ensured through a hole with an

airtight metal door;

its inner section must be round, squa-

re or rectangular; if it is square of

rectangular, the corners must be

round and have a radius of 20 mm

minimum; however, hydraulically equi-

valent sections are also permitted;

be topped by a chimneypot having its

outlet outside the reflux area in

order to avoid back pressures which

may obstruct the free discharge of

flue gas into the air;

there must be no mechanical suc-

tion equipment at the top of the pipe;

there must be no overpressure in

stacks placed inside or adjacent to

inhabited rooms.

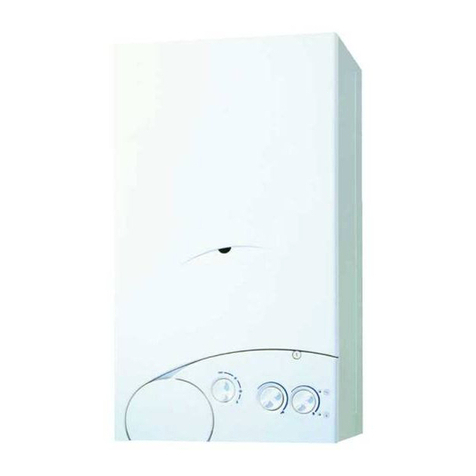

2.5.1 Flue connection

Fig. 3 refers to the boiler connection

to the flue or to the stack through flue

ducts. In making the connection obser-

ve the dimensions given and use sea-

ling materials capable of withstanding

mechanical stresses and flue heat

over time.

At any point of the flue the burnt gas

temperature shall not exceed the dew

point temperature. Maximum three

changes of direction can be made,

including the union to the stack/flue.

For changes of direction, use only cur-

ved components.

2. ELECTRIC CONNECTION

The boiler is equipped with an electric

cable with plug and shall be supplied

with 230 V - 50 Hz single-phase cur-

rent through a fuse protected switch

having a minimum distance of 3 mm

between the pins.

The room thermostat (class II accor-

ding to EN 60730.1), which should be

installed to ensure a good temperatu-

re control, must be connected to ter-

minals 1 and 4 after the existing brid-

ge has been removed.

NOTA: SIME refuses all responsibility

for damage to people or things due to

non-earthing of the boiler.

48

Fig. 3