Simex multicon cmc-99 User manual

Assisting the automation

industry since 1986

User manual

CONTROLLER/ ATA RECOR ER

MultiCon CMC-99/141

•Firmware: v.2.27.0 or higher

Read the user's manual carefully before starting to use the unit or software.

Producer reserves the right to implement changes without prior notice.

2016.06.01 ultiCon C C-99/141_INSSXEN_v.1.17.015

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

CONTENTS

1. BASIC REQUIREMENTS AND USER SAFETY.......................................................................................5

1.1. THE USE OF TOUCH-SCREEN.......................................................................................................6

2. GENERAL CHARACTERISTICS...............................................................................................................6

3. TECHNICAL DATA....................................................................................................................................9

4. DEVICE INSTALLATION.........................................................................................................................10

4.1. UNPACKING...................................................................................................................................11

4.2. ASSEMBLY.....................................................................................................................................12

4.3. CONNECTION METHOD...............................................................................................................14

4.3.1. Avai ab e modu es..................................................................................................................17

4.4. MAINTENANCE..............................................................................................................................31

5. INTRODUCTION TO MULTICON CMC-99 141.......................................................................................31

5.1. UNDERSTANDING CONTROLLER/DATA RECORDER MULTICON CMC-99/141.....................31

5.1.1. Logica channe s....................................................................................................................32

5.1.2. Groups...................................................................................................................................34

5.2. HARDWARE CONFIGURATIONS ................................................................................................35

6. WORKING WITH THE MULTICON CMC-99 141....................................................................................36

6.1. MULTICON CMC-99/141 POWER UP...........................................................................................36

6.2. THE USE OF THE TOUCH-SCREEN............................................................................................36

6.3. DISPLAY.........................................................................................................................................36

6.3.1. Information bar.......................................................................................................................37

6.3.2. Navigation bar........................................................................................................................38

6.3.3. Data pane s............................................................................................................................39

6.3.4. Important messages..............................................................................................................42

7. CONFIGURATION OF THE MULTICON CMC-99 141...........................................................................43

7.1. EDIT DIALOGUES..........................................................................................................................43

7.2. MAIN MENU SELECTION PANEL.................................................................................................46

7.3. FILES MANAGEMENT...................................................................................................................47

7.4. DEVICE INFORMATION, LICENCE, FIRMWARE UPDATE, REMOTE DISPLAY, EXPORT

MANUAL AND RENEW CONFIGURATION..........................................................................................53

7.5. DEVICE CONFIGURATION............................................................................................................56

7.6. CONFIGURATION MENU STRUCTURE.......................................................................................59

7.7. GENERAL SETTINGS....................................................................................................................63

7.8. LOGICAL CHANNELS....................................................................................................................67

7.8.1. Logica Channe s - Genera settings.....................................................................................67

7.8.2. Logica channe s - Hardware input mode..............................................................................84

7.8.3. Logica Channe s - Hardware output monitor mode..............................................................87

7.8.4. Logica Channe s - Modbus mode.........................................................................................89

7.8.5. Logica Channe s - Set point va ue mode..............................................................................92

7.8.6. Logica Channe s - Math function mode................................................................................95

7.8.7. Logica Channe s - Contro er mode....................................................................................105

7.8.8. Logica Channe s - Profi e/timer mode.................................................................................107

7.8.9. Logica Channe s - Profi e/timer (cyc e counter) mode........................................................109

7.8.10. Logica Channe s - Data from other channe mode...........................................................110

7.8.11. Examp es of Logica Channe s configuration....................................................................111

7.8.11.1. App ication of Logica channe in the Hardware input mode for UI4 modu e...111

7.8.11.2. App ication of Logica channe in the Hardware input mode for TC4 modu es 118

7.8.11.3. App ication of Logica channe in the Hardware input mode for RT4 modu es 121

7.8.11.4. App ication of Logica channe in the Hardware output monitor mode for R45

modu es.............................................................................................................................123

7.8.11.5. App ication of Logica channe in the Modbus mode........................................125

7.8.11.6. App ication of Logica channe in the Hardware input for TC8 modu es..........127

7.8.11.7. App ication in Math function mode....................................................................129

7.8.11.8. App ication of Logica channe in the Contro er mode.....................................131

7.8.11.9. App ication of Logica channe in the Profi e/timer mode.................................133

7.8.11.10. App ication of Logica channe in the Hardware input mode and Data from

2

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

other channe for FT4 modu e...........................................................................................135

7.9. BUILT-IN INPUTS.........................................................................................................................137

7.9.1. Bui t-in inputs - Genera settings.........................................................................................137

7.9.2. Bui t-in inputs - Input modu es.............................................................................................139

7.9.3. Bui t-in inputs - Binary input Inp.X2 : Digita 24V................................................................139

7.9.4. Bui t-in inputs - Demo input numbered X3, X4, X5..............................................................140

7.9.5. Bui t-in inputs – Modu es.....................................................................................................141

7.9.5.1. Vo tage and current measurement modu es........................................................141

7.9.5.2. Mixed UIN/UID modu es......................................................................................141

7.9.5.3. Iso ated current inputs modu e.............................................................................143

7.9.5.4. Ana ogue f owmeter modu es..............................................................................143

7.9.5.5. Pu se f owmeter modu es.....................................................................................144

7.9.5.6. Thermocoup es sensor measurement modu es..................................................145

7.9.5.7. RTD measurement modu es................................................................................147

7.9.5.8. Iso ated universa inputs modu es.......................................................................147

7.9.5.9. Optoiso ated digita inputs modu es.....................................................................148

7.9.5.10. Optoiso ated universa counters modu es.........................................................148

7.9.5.11. Optoizo ated hourmeters modu es.....................................................................150

7.10. BUILT-IN OUTPUTS...................................................................................................................152

7.10.1. Bui t-in outputs - Genera settings.....................................................................................152

7.10.2. Bui t-in Output - Re ays, Sound signa , Virtua re ays.......................................................154

7.10.3. Bui d-in output - PWM (Pu se-width modu ation) mode for SSR re ay output..................158

7.10.4. Bui t-in output - Current output..........................................................................................160

7.10.5. Examp es of bui d-in output configurations.......................................................................162

7.10.5.1. App ication of the output for R45 modu es.......................................................162

7.10.5.2. App ication of output for IO modu es................................................................164

7.11. EXTERNAL OUTPUTS...............................................................................................................165

7.11.1. Externa outputs - Genera settings...................................................................................165

7.11.2. Externa outputs - Contro type: as a re ay........................................................................167

7.11.3. Externa outputs - Contro type: as a inear output............................................................169

7.11.4. Examp es of externa output configurations......................................................................171

7.11.4.1. App ication of externa output for protoco Modbus in the MASTER mode.......171

7.12. PROFILES/TIMERS....................................................................................................................174

7.12.1. Profi e/timer - Genera settings..........................................................................................174

7.12.2. Profi es/timers - Triggering mode: eve (gate), edge (once), edge (retrig.)......................178

7.12.3. Profi es/timers - Triggering mode: on time........................................................................180

7.12.4. Examp es of Profi e/timer configurations...........................................................................182

7.12.4.1. App ication of the Profi es/timers......................................................................182

7.12.4.2. App ication of the Profi es/timers triggered on time..........................................184

7.13. CONTROLLERS.........................................................................................................................186

7.13.1. Contro ers - Genera settings............................................................................................186

7.13.2. Examp es of Contro er configurations...............................................................................189

7.13.2.1. App ication of the Contro ers............................................................................189

7.13.2.2. App ication of the Contro ers in cooperation with heater which is contro ed by

SSR output........................................................................................................................190

7.14. GROUPS.....................................................................................................................................193

7.14.1. Groups - Genera settings..................................................................................................193

7.14.2. Groups - Logging options..................................................................................................198

7.14.3. Groups - Examp es of visua isations of groups.................................................................200

7.14.3.1. Sing e channe - one big need e.......................................................................200

7.14.3.2. Three channe s view - one bigger, two sma er................................................201

7.15. MODBUS.....................................................................................................................................202

7.15.1. Modbus - Genera settings................................................................................................203

7.15.2. Modbus - SLAVE mode.....................................................................................................203

7.15.2.1. Modbus SLAVE - Modbus Temp ates for SLAVE mode...................................204

7.15.2.2. Modbus SLAVE - Device channe s for SLAVE mode.......................................205

7.15.2.3. Modbus SLAVE - The Modbus protoco hand ing.............................................207

3

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

7.15.2.4. Modbus SLAVE - List of registers.....................................................................207

7.15.2.5. Modbus SLAVE - Transmission errors hand ing...............................................209

7.15.2.6. Modbus SLAVE- Examp e of query/answer frames..........................................209

7.15.3. Modbus - MASTER mode..................................................................................................210

7.15.3.1. Modbus MASTER - Device temp ates parameter b ock....................................211

7.15.3.2. Modbus MASTER - Device channe s parameter b ock.....................................212

7.15.3.3. Modbus MASTER - Register settings................................................................214

7.15.3.4. Modbus MASTER - Register b ocks parameter b ock.......................................215

7.15.4. Modbus - Examp e of Modbus protoco configuration in the device.................................217

7.15.4.1. Input configuration of Modbus protoco in MASTER mode..............................217

7.15.4.2. Configuration of the Modbus Input in the MASTER mode...............................220

7.16. NETWORK AND REMOTE DISPLAY SETTINGS.....................................................................223

7.17. ACCESS OPTIONS....................................................................................................................225

7.18. PRINTOUTS................................................................................................................................229

7.19. NOTIFICATIONS.........................................................................................................................231

8. APPENDICES.........................................................................................................................................234

8.1. PS3, PS4, PS32, PS42 - POWER SUPPLY MODULE................................................................234

8.2. UI4, UI8, UI12, U16, U24, I16, I24 – VOLTAGE AND CURRENT MEASUREMENT MODULES

..............................................................................................................................................................235

8.3. UI4N8, UI4D8, UI8N8, UI8D8 – MIXED UIN/UID MODULES......................................................241

8.4. IS6 – ISOLATED CURRENT INPUTS MODULE.........................................................................244

8.5. FI2. FI4, FT2, FT4 – FLOWMETER MODULES..........................................................................246

8.6. TC4, TC8, TC12 – THERMOCOUPLE SENSOR MEASUREMENT MODULES........................249

8.7. RT4 , RT6 – RTD MEASUREMENT MODULES..........................................................................252

8.8. UN3, UN5 – OPTOISOLATED UNIVERSAL INPUTS MODULES..............................................255

8.9. D8, D16, D24 – OPTOISOLATED DIGITAL INPUTS MODULE..................................................261

8.10. CP2, CP4 – OPTOISOLATED UNIVERSAL COUNTERS MODULES......................................263

8.11. HM2, HM4 – OPTOIZOLATED HOURMETERS MODULES.....................................................266

8.12. S8, S16, S24 - SOLID STATE RELAY DRIVERS MODULES...................................................268

8.13. R45, R81, R65, R121 - RELAY MODULES................................................................................272

8.14. IO2, IO4, IO6, IO8 – PASSIVE CURRENT OUTPUT................................................................274

8.15. COMMUNICATION MODULES..................................................................................................278

8.16. MULTIPINT MLP-149 – EXTERNAL PRINTER.........................................................................279

8.16.1. Genera characteristic........................................................................................................279

8.16.2. Technica data....................................................................................................................279

8.16.3. Working with Mu tiPrint MLP-149......................................................................................280

8.17. DATA FORMAT...........................................................................................................................285

8.18. DIRECT ACCESS TO LOG FILES USING HTTP PROTOCOL................................................294

4

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Explanation of symbols used in the manual:

- This symbo denotes especia y important guide ines concerning the insta ation and

operation of the device. Not comp ying with the guide ines denoted by this symbo

may cause an accident, damage or equipment destruction.

IF THE DEVICE IS NOT USED ACCORDING TO THE MANUAL THE USER IS

RESPONSIBLE FOR POSSIBLE DAMAGES.

- This symbo denotes especia y important characteristics of the unit.

Read any information regarding this symbo carefu y

1. BASIC REQUIREMENTS AND USER SAFETY

- The manufacturer is not responsible for any damages caused by inappropriate

installation, not maintaining the proper environmental conditions and using the

unit contrary to its assignment.

- Installation should be conducted by qualified personnel . During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and E C

regulations.

- GND input of device should be connected to PE wire;

- The unit must be properly set-up, according to the application. Incorrect

configuration can cause defective operation, which can lead to unit damage or

an accident.

- If in the case of a unit malfunction there is a risk of a serious threat to the

safety of people or property additional, independent systems and solutions

to prevent such a threat must be used.

- The unit uses dangerous voltage that can cause a lethal accident. The

unit must be switched off and disconnected from the power supply prior to

starting installation of troubleshooting (in the case of malfunction).

- Neighbouring and connected equipment must meet the appropriate of

appropriate standards and regulations concerning safety and be equipped with

adequate overvoltage and interference filters.

- Do not attempt to disassemble, repair or modify the unit yourself. The unit has

no user serviceable parts. Defective units must be disconnected and submitted

for repairs at an authorized service centre.

- In order to minimize fire or electric shock hazard, the unit must be protected

against atmospheric precipitation and excessive humidity.

- Do not use the unit in areas threatened with excessive shocks, vibrations, dust,

humidity, corrosive gasses and oils.

- Do not use the unit in areas where there is risk of explosions.

5

i

!

!

!

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

- Do not use the unit in areas with significant temperature variations, exposure to

condensation or ice.

- Do not use the unit in areas exposed to direct sunlight.

- ake sure that the ambient temperature (e.g. inside the control box) does not

exceed the recommended values. In such cases forced cooling of the unit must

be considered (e.g. by using a ventilator).

The unit is designed for operation in an industrial environment and must

not be used in a household environment or similar.

1.1. THE USE OF TOUCH-SCREEN

Do not use pointers with sharp edges (like tips of pencils and pens, knifes, scissors,

needles, wires, nails, screws, bolts etc.) while working with touch-screen. It is strongly

recommended to use a special stylus made of plastic or another soft material with round ends

(for example the stylus delivered with the device). The display of the MultiCon CMC 99/141

should also be protected against aggressive substances and extremely high and low

temperatures (see Chapter 3. TECHNICAL DATA).

2. G ENERAL CHARACTERISTICS

The MultiCon CMC 99/141 is a sophisticated multichannel unit which allows

simultaneous measurement, visualisation and control of numerous channels. This device can

operate autonomously or with cooperation with external measurement devices and actuators.

Essential features of MultiCon CMC 99/141 are listed and briefly described below.

• Advanced processing unit and system based on LINUX

The powerful MultiCon CMC 99/141 processor allows the device to run under the control

of a LINUX operating system. Such a solution makes the firmware flexible and gives the

possibility of simultaneous operation of many processes (like: measurement,

communication, visualisation). The use of LINUX also makes software independent of

installed hardware.

• Color TFT display with Touch-panel

The MultiCon CMC 99/141 displays all data and dialogue on a legible, 320x240 pixels,

color TFT screen. Full control of the device is realised using the built-in touch-panel which

makes operating the MultiCon CMC 99/141 easy and intuitive.

• Hardware flexibility and a large variety of possible configurations

MultiCon CMC 99/141 is designed as modular device consisting of a base and optional

input and output modules. The base contains:

– main processor,

– display with touch-screen,

– Switch ode Power Supply

• 19V...24...50V DC, 16V...24...35V AC

• 85V...230...260V,

– basic communication interfaces (USB and RS485).

– three slots (marked as A, B, C) designed for installation of measurement and/or

output modules.

!

!

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

– one slot (marked as D) used for advanced communication module (additional USB

Host, RS-485, RS-485/RS-232 and Ethernet).

All measurement and output modules are optional and can be installed inside the device

according to the customer's needs.

Input modules that can be installed:

– 4/8/16/24x Voltage/Current input module,

– 16/24x NTC/Voltage/Current/Digital mixed inputs module,

– 6x Isolated current input module,

– 4/6x RTD input module,

– 4/8/12x TC input module,

– 8/16/24x Optoisolated digital input,

– 3/5x universal input module,

– 2/4x universal counter module,

– 2/4x hourmeter module,

– 2/4x flowmeter input + 2/4x current input module.

– 2/4x pulse input + 2/4x current input module

Output modules that can be installed:

– 8/16/24x SSR driver module,

– 4/6x Relay module 5A/250V,

– 8/12x Relay module 1A/250V,

– 2/4/6/8x Passive current output module.

• Full freedom of data sources, presentation modes and controlling methods

The multi level structure of the MultiCon CMC 99/141 firmware allows for selection of

presented data sources, presentation modes and controlling methods. The MultiCon

CMC 99/141 displays the values of virtual logical channels which can be fed with:

– measurement data from built-in physical channels,

– measurement data from remote channels (other devices connected to the MultiCon

CMC 99/141 by RS-485 interface),

– output states and quantities (looped back results of controlling processes),

– generate profiles/timers or also the mathematical combination of one or more

logical channels.

All of these can be freely named and described by the user, and presented in many

forms:

– as numerical values,

– vertical and horizontal charts,

– vertical and horizontal bars,

– as needle graphs.

Every logical channel (visualised or not) can be used as input data for one or more

controlling process. The MultiCon CMC 99/141 implements many different controlling

methods:

– above defined level,

– below defined level,

– inside defined range,

– outside of defined range,

– PID control.

7

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Fig. 2.1. Basic structure of the mu tichanne device

Process control with built-in outputs can be done with programmable hysteresis and

delays of the outputs control. It is possible to control (linearly or bistably) remote

modules. Controlling processes can drive built-in physical outputs or virtual outputs

which can be used as inputs to logical channels.

8

Build-in analog input

Buid-in binary input

External input (RS-485)

Profiles/timers

Controller

athematical & logical combination data

States of hardware & virtual outputs

Set point values

Display

Numeric, logical or text values

Charts & bars

Needles indicators

Grouping data

Interface

Build-in analog output

Build-in binary output

External output (RS-485)

Interface

Reading data via Ethernet

Reading data stored on the

flash drive

Interface

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

3. TECHNICAL DATA

Power supply voltage

(depending on version)

External Fuse (required)

Power consumption

85...230...260V AC/DC; 50 ÷ 60 Hz

or 19...24...50V DC; 16V...24...35V AC

T - type, max. 2 A

typically 15 VA; max. 20 VA

Display (depending on version) 3.5” or 5.7”, TFT color graphic display, 320 x 240

pixels, with LED backlight

Sensor power supply output 24V DC ± 5% / max. 200 mA,

Basic communication interfaces RS 485, 8N1/2, odbus RTU, 1200 bit/s ÷ 115200 bit/s

USB Host port, USB Device port

Digital input 1 input 0/15..24V DC, galvanic isolation (low state:

0÷1V, high state:8÷24V)

power consumption: 7,5 mA / 24V,

isolation: 1min @ 500V DC.

Optional communication module* Second USB Host port

Serial RS-485 and RS-485/RS-232

Ethernet 10 RJ-45

Optional input modules* 4/8/16/24x Voltage (0÷10V) / Current (0÷20mA)**

16/24x NTC (0÷100k)/ Voltage (0÷10V)/

Current (0÷20mA)/ Digital (TTL,HTL)**

6x Isolated current (4÷20mA),

4/6x RTD (Pt100, Pt500, Pt1000, Cu50, Cu100)**

4/8x/12 TC (J, K, S, T, N, R, E, L(GOST), B, C**

8/16/24x Digital input**

3/5x Universal input**

2/4x Universal counter input**

2/4x Hourmeter module**

2/4x Flowmeter + 2/4x Current input**

2/4x Pulse input + 2/4x Current input**

Optional output modules* 4/6x Relay 5A/250V (cos ϕ = 1)**

8/12x Relay 1A/250V (cos ϕ = 1)**

8/16/24x SSR driver (10÷15V, up to 100mA per

output)**

2/4/6/8x IO Passive current output (4÷20mA)**

Protection level

USB interface on rear panel

USB interface from front

IP 65 (from front, after using waterproof frame)

IP 54 (from front, with transparent door)

IP 40 (from front, standard)

IP 20 (housing and connection clips)

IP 54 (from front, with transparent door)

IP 40 (from front, standard)

IP 20 (housing and connection clips)

Housing type

Housing material

panel

NORYL - GFN2S E1

9

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Housing dimensions 96 x 96 x 100 mm (small housing - 3,5” Display)

or 144 x 144 x 100 mm (big housing - 5,7” Display)

ounting hole 90.5 x 90.5 mm (small housing - 3,5” Display)

or 137 x 137 mm (big housing - 5,7” Display)

Assembly depth

Panel thickness

102 mm

max. 5 mm

Operating temperature

(depending on version)

0°C to +50°C

or -20°C to +50°C

Storage temperature

(depending on version)

-10°C to +70°C

or -20°C to +70°C

Humidity

Altitude

5 to 90% no condensation

up to 2000 meters above sea level

Screws tightening max. torque 0,5 Nm

ax. connection leads diameter 2,5 mm2

Safety requirements according to: PN-EN 61010-1

installation category: II

pollution degree: 2

voltage in relation to ground: 300V AC

isolation resistance: >20 Ω

isolation strength between power supply and

input/output terminal: 1min. @ 2300V (see Fig. 4.1)

E C PN-EN 61326-1

Weight 340g (only base, see Fig. 4.8)

* check the current list of measurement modules at producer's website

** see the full specification in the Appendices

4. DEVICE INSTALLATION

The unit has been designed and manufactured in a way assuring a high level of user

safety and resistance to interference occurring in a typical industrial environment. In order to

take full advantage of these characteristics installation of the unit must be conducted correctly

and according to the local regulations.

- Read the basic safety requirements on page 5 prior to starting the installation.

- Ensure that the power supply network voltage corresponds to the nominal

voltage stated on the unit’s identification label.

- The load must correspond to the requirements listed in the technical data.

- All installation works must be conducted with a disconnected power supply.

- Protecting the power supply connections against unauthorized persons must

be taken into consideration.

10

!

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

This is a class A unit. Class A equipment is suitable for use in all

establishments other than domestic and those directly connected to a low

voltage power supply network which supplies buildings used for domestic

purposes.

This is group 1 unit. Group 1 contains all equipment in the scope of this

standard which is not classified as group 2 equipment. Group 2 contains

all ISM RF equipment in which radio frequency energy in the frequency

range 9 kHz to 400 GHz is intentionally generated and used or only used, in

the form of electromagnetic radiation, inductive and/or capacitive

coupling, for the treatment of material or inspection/analysis purposes.

Carefully check that the isolation used with the unit (Fig. 4.1) meets the

expectations and if necessary use appropriate measures of over voltage protection.

Additionally, insure the appropriate air and surface insulation gaps when installing.

Fig. 4.1. Schematic diagram showing the isolation between individual circuits of the unit.

4.1. UNPACKING

After removing the unit from the protective packaging, check for transportation damage.

Any transportation damage must be immediately reported to the carrier. Also, write down the

unit serial number located on the housing and report the damage to the manufacturer.

Attached with the unit please find:

– assembly brackets - 2 pieces,

– pointer for touch screen,

– user’s manual for MultiCon CMC 99/141 unit (device) in pdf.,

11

!

!

Internal circuits

External sensor

supply output Measurement inputs RS 485

interface

and

digital input

Isolation strength 1min @ 2300V AC

Isolation strength 1min @ 500V AC

No isolation

Outputs circuits

Power supply

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

4.2. ASSEMBLY

- The unit is designed for mounting inside housings (control panel, switchboard)

insuring appropriate protection against surges and interference. etal

housings must be connected to ground in a way that complies with the

governing regulations.

- Disconnect the power supply prior to starting assembly.

- Check the connections are wired correctly prior to switching the unit on.

- In order to install the unit, a mounting hole must be prepared according to

Fig. 4.2. The thickness of the material of which the panel is made must not

exceed 5mm. When preparing the mounting hole take the grooves for catches

located on both sides of the housing into consideration (Fig. 4.2). Place the

unit in the mounting hole inserting it from the front side of the panel, and then

fix it using the brackets (Fig. 4.4). The minimum distances between the centre

points of multiple units - due to the thermal and mechanical conditions of

operation - are shown on Fig. 4.3.

96 x 96 housing:

H, W = 90.5 mm

h = 16 mm

144 x 144 housing:

H, W = 137 mm

h= 38.5 mm

Fig. 4.2. Mounting ho e dimensions

12

W

h

8 mm

8 mm

h

1 mm max. 5 mm

H

1 mm

!

!

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

To avoid connectors slots destruction use the method shown on Fig. 4.5

Fig. 4.5. Connectors removing method

4.3. CONNECTION METHOD

Caution

- Installation should be conducted by qualified personnel. During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and E C

regulations.

- The unit is not equipped with an internal fuse or power supply circuit breaker.

Because of this an external time-delay cut-out fuse with a small nominal current

value must be used (recommended bipolar, max. 2A) and a power supply circuit-

breaker located near the unit (Fig. 4.6). In the case of using a monopolar fuse it

must be mounted on the active wire (L).

- The power supply network cable diameter must be selected in such a way that in

the case of a short circuit of the cable from the side of the unit the cable shall be

protected against destruction with an electrical installation fuse.

- Wiring must meet appropriate standards and local regulations and laws.

- In order to secure against accidental short circuit the connection cables must be

terminated with appropriate insulated cable tips.

14

back side

of device

connector

GOOD

back side

of device

connector

WRONG

!

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

- Tighten the clamping screws. The recommended tightening torque is 0.5 Nm.

Loose screws can cause fire or defective operation. Over tightening can lead to

damaging the connections inside the units and breaking the thread.

- In the case of the unit being fitted with separable clamps they should be inserted

into appropriate connectors in the unit, even if they are not used for any

connections.

Unused terminals (marked as n.c.) must not be used for connecting any

connecting cables (e.g. as bridges), because this can cause damage to the

equipment or electric shock.

- If the unit is equipped with housing, covers and sealing to protecting against

water intrusion, pay special attention to their correct tightening or clamping. In the

case of any doubt consider using additional preventive measures (covers, roofing,

seals, etc.). Carelessly executed assembly can increase the risk of electric shock.

- After the installation is completed do not touch the unit’s connections when it is

switched on, because it carries the risk of electrical shock.

Due to possible significant interference in industrial installations appropriate measures

assuring correct operation of the unit must be applied. To avoid the unit of improper

indications keep recommendations listed below.

Depending on version:

85...230...260V AC/DC or

19...24...50V DC; 16...24...35V AC

Fig. 4.6. Connection of power supp y

• Avoid running signal cables and transmission cables together with power supply cables

and cables controlling inductive loads (e.g. contactors). Such cables should cross at a

right angle.

• Contactor coils and inductive loads should be equipped with interference protection

systems, e.g. RC-type.

• Use of screened signal cables is recommended. Signal cable screens should be

connected to the earthing only at one of the ends of the screened cable.

• In the case of magnetically induced interference the use of twisted pair signal cables is

recommended. Twisted pair (best if shielded) must be used with RS-485 serial

transmission connections.

• In the case of measurement or control signals are longer than 30m or go outside of the

building then additional safety circuits are required.

• In the case of interference from the power supply side the use of appropriate interference

filters is recommended. Bear in mind that the connection between the filter and the unit

should be as short as possible and the metal housing of the filter must be connected to

the earth with the largest possible surface. The cables connected to the filter output must

not be run with cables with interference (e.g. circuits controlling relays or contactors).

15

!

!

FUSE

N

L

N

L

1

2

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Connections of power supply voltage and measurement signals are executed using the

screw connections on the back of the unit’s housing.

Fig. 4.7. Method of cab e iso ation rep acing and cab e termina s dimensions

All connections must be made while power supply is disconnected !

Fig. 4.8. Termina s description

The basic performance of the device (see Fig. 4.8) contains only the extreme left

terminals:

– Power supply,

– SERVICE,

– Sensor supply output +24V DC Imax=200mA,

– Digital input 0V...15...24V DC (low state: 0÷1V, high state:8÷24V)

– Interface RS-485,

1

!

5-6 mm

max. 1.5 mm

Slot D

Power supply

(depending on version)

1

2

Slot B

8

5

6

7

3

4

Slot A

Slot C

+24V DC ±5%

Imax. = 200mA

digital input

0/15..24V DC

RS 485

GND

GND

A+

B

iso ated

SERVICE

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

– If the UN3 or UN5 module is installed, the +24V DC output is available only in

devices equipped with PS42 power supply module. In other cases there is

no +24V DC output available and these terminals remain disconnected.

Depending on customer's needs, the basic version of the device can be upgraded with up to:

– three I / O modules (installed in a place designated as Slot A, Slot B, Slot C),

– advanced communication module (additional serial, USB and Ethernet interfaces

installed in Slot D).

According to the order these terminals can look different than shown in Fig. 4.8 or be not

present. Terminals and connections of available modules are shown in Fig. 4.9÷Fig. 4.21 in

Section 4.3.1. .

Shown below is an example of a configuration of the installed modules:

– base,

– Slot A - UI8 module (8 current input & 8 voltage input),

– Slot B - RT4 module (4 RTD input),

– Slot C - R81 module (8 relay output 1A/250V),

– Slot D - AC module (additional serial, USB and Ethernet interfaces).

4.3.1. Available modules

Fig. 4.9. Vo tage and current input modu es

17

i

U16

16 voltage inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15 GND

IN9

IN10

IN11

IN12

4 x 0 10V

GND

IN13

IN14

IN15

IN16

4 x 0 10V

GND

IN1

IN2

IN3

IN4

4 x 0 10V

GND

IN5

IN6

IN7

IN8

4 x 0 10V

I16

16 current inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 20mA

GND

IN9

IN10

IN11

IN12

4 x 0 20mA

GND

IN13

IN14

IN15

IN16

4 x 0 20mA

UI4

4 current

+ 4 voltage inputs

n08

n09

n10

n04

n05

n06

n07

n01

n02

n03

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 10V

UI8

8 current

+ 8 voltage inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 20mA

GND

IN9

IN10

IN11

IN12

4 x 0 10V

GND

IN13

IN14

IN15

IN16

4 x 0 10V

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Fig. 4.10. Vo tage and current input modu es contd.

18

UI12

12 current

+ 12 voltage inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15

n21

n22

n30

n26

n27

n28

n29

n23

n24

n25

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 20mA

GND

IN21

IN22

IN23

IN24

4 x 0 10V

GND

IN13

IN14

IN15

IN16

4 x 0 10V

GND

IN17

IN18

IN19

IN20

4 x 0 10V

GND

IN9

IN10

IN11

IN12

4 x 0 20mA

U24

24 voltage inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15

n11

n12

n20

n16

n17

n18

n19

n13

n14

n15

n21

n22

n30

n26

n27

n28

n29

n23

n24

n25

GND

IN9

IN10

IN11

IN12

4 x 0 10V

GND

IN13

IN14

IN15

IN16

4 x 0 10V

GND

IN1

IN2

IN3

IN4

4 x 0 10V

GND

IN5

IN6

IN7

IN8

4 x 0 10V

GND

IN17

IN18

IN19

IN20

4 x 0 10V

GND

IN21

IN22

IN23

IN24

4 x 0 10V

I24

24 current inputs

n08

n09

n10

n11

n12

n04

n05

n06

n07

n01

n02

n03

n20

n16

n17

n18

n19

n13

n14

n15

n21

n22

n30

n26

n27

n28

n29

n23

n24

n25

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 20mA

GND

IN9

IN10

IN11

IN12

4 x 0 20mA

GND

IN13

IN14

IN15

IN16

4 x 0 20mA

GND

IN17

IN18

IN19

IN20

4 x 0 20mA

GND

IN21

IN22

IN23

IN24

4 x 0 20mA

User Manual For - CONTROLLER/DATA RECORDER MultiCon CMC-99/141

Fig. 4.11. Mixed input modu es

19

n01

n02

n03

n04

n05

n06

n07

n08

n09

n10

n11

n12

n13

n14

n15

n16

n17

n18

n19

n20

GND

IN9

IN10

IN11

IN12

4 x 0 20mA

GND

IN5

IN6

IN8

IN7

4 x 0 100kΩ

IN1

IN2

IN4

IN3

GND

4 x 0 100kΩ

UI4N8

8 resistance

+ 4 current and 4 voltage inputs

GND

IN13

IN14

IN15

IN16

4 x 0 10V

n01

n02

n03

n04

n05

n06

n07

n08

n09

n10

n11

n12

n13

n14

n15

n16

n17

n18

n19

n20

UI4D8

4 current and 4 voltage

+ 8 digital inputs

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 10V

COM 9 12

IN9

IN10

IN11

IN12

IN17

COM 13 16

IN13

IN14

IN15

IN16

IN18

n01

n02

n03

n04

n05

n06

n07

n08

n09

n10

n11

n12

n13

n14

n15

n16

n17

n18

n19

n20

n21

n22

n23

n24

n25

n26

n27

n28

n29

n30

GND

IN9

IN10

IN11

IN12

4 x 0 20mA

GND

IN13

IN14

IN15

IN16

4 x 0 20mA

GND

IN5

IN6

IN8

IN7

4 x 0 100kΩ

IN1

IN2

IN4

IN3

GND

4 x 0 100kΩ

UI8N8

8 resistance

+ 8 current and voltage inputs

GND

IN17

IN18

IN19

IN20

4 x 0 10V

GND

IN21

IN22

IN23

IN24

4 x 0 10V

n01

n02

n03

n04

n05

n06

n07

n08

n09

n10

n11

n12

n13

n14

n15

n16

n17

n18

n19

n20

n21

n22

n23

n24

n25

n26

n27

n28

n29

n30

GND

IN1

IN2

IN3

IN4

4 x 0 20mA

GND

IN5

IN6

IN7

IN8

4 x 0 20mA

UI8D8

8 current and voltage

+ 8 digital inputs

GND

IN9

IN10

IN11

IN12

4 x 0 10V

GND

IN13

IN14

IN15

IN16

4 x 0 10V

COM 17 20

IN17

IN18

IN19

IN20

IN25

COM 21 24

IN21

IN22

IN23

IN24

IN26

This manual suits for next models

1

Table of contents

Other Simex Controllers manuals

Popular Controllers manuals by other brands

PenMount

PenMount Touchscreen 6000 Installation guides

Hypertherm

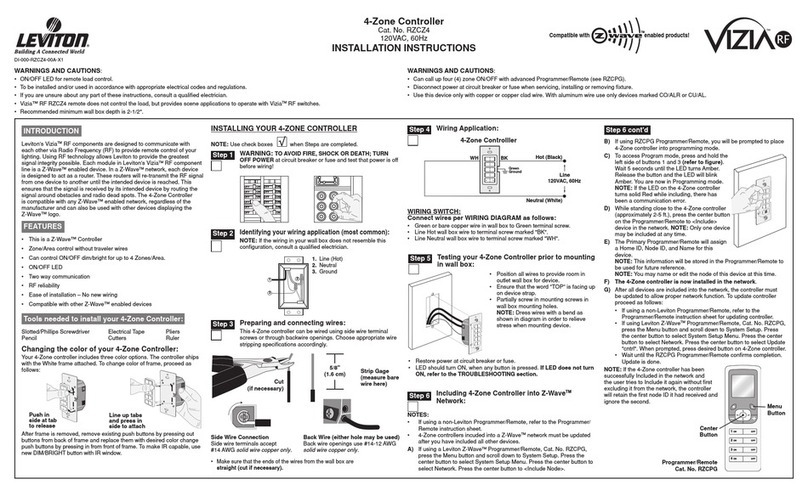

Hypertherm MicroEdge Field Service Bulletin

NOVAK

NOVAK GTS PRO SPORT manual

Varian

Varian XGS-600 instruction manual

Nordmann Engineering

Nordmann Engineering SBC Installation and operating instructions

Angry Audio

Angry Audio BUTTON GIZMO Preliminary user guide

ADLINK Technology

ADLINK Technology ROScube-Pico TGL RQP-T37 user manual

CoolBot

CoolBot CoolBot Pro manual

Regin

Regin RDAS7S Series Mounting instructions

BRONKHORST

BRONKHORST IQ+Flow series instruction manual

Hitachi

Hitachi ECO COMPACT PC-ARC-E instruction manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series user manual