Nordmann Engineering SBC User manual

INSTALLATION AND OPERATING INSTRUCTIONS

NORDMANN

ENGINEERING

NORDMANN

ENGINEERING

Dampfluftbefeuchter econoVap

2557030 EN 1501

Steam bath control

Nordmann SBC

3

Contents

1 General Information 4

1.1 Information on the installation and operating manual 4

1.2 Explanations of symbols 5

1.3 Liability limitation 5

1.4 Copyright 6

1.5 Scope of delivery 6

1.6 Spare parts 6

1.7 Customer service 7

2 Safety 8

2.1 Intended use 8

2.2 Request for public steambaths 8

2.3 Modicationsandalterations 8

2.4 Demands on technical personnel 9

2.5 Operational safety and special dangers 10

3 Identication 11

3.1 Type plate 11

4 Technicaldata 12

4.1 General information 12

4.2 Cables 13

4.3 Voltage and switching capacity - electrical load 14

4.4 Light and blower 15

4.4.1 Deactivate phase cutting of light and/or blower 15

5 Goodsreceipt,TransportandStorage 16

5.1 Safety 16

5.2 Goods receipt 16

5.3 Packing 16

5.4 Storage 16

6 Installation 17

6.1 Protect against ESD 17

6.2 Installation of steam bath control device 17

6.3 Mounting the operating panel “Design” 18

6.4 Installation of interior cabin display 20

6.5 Checking the installation 21

7 Electricalconnection 22

7.1 Safety 22

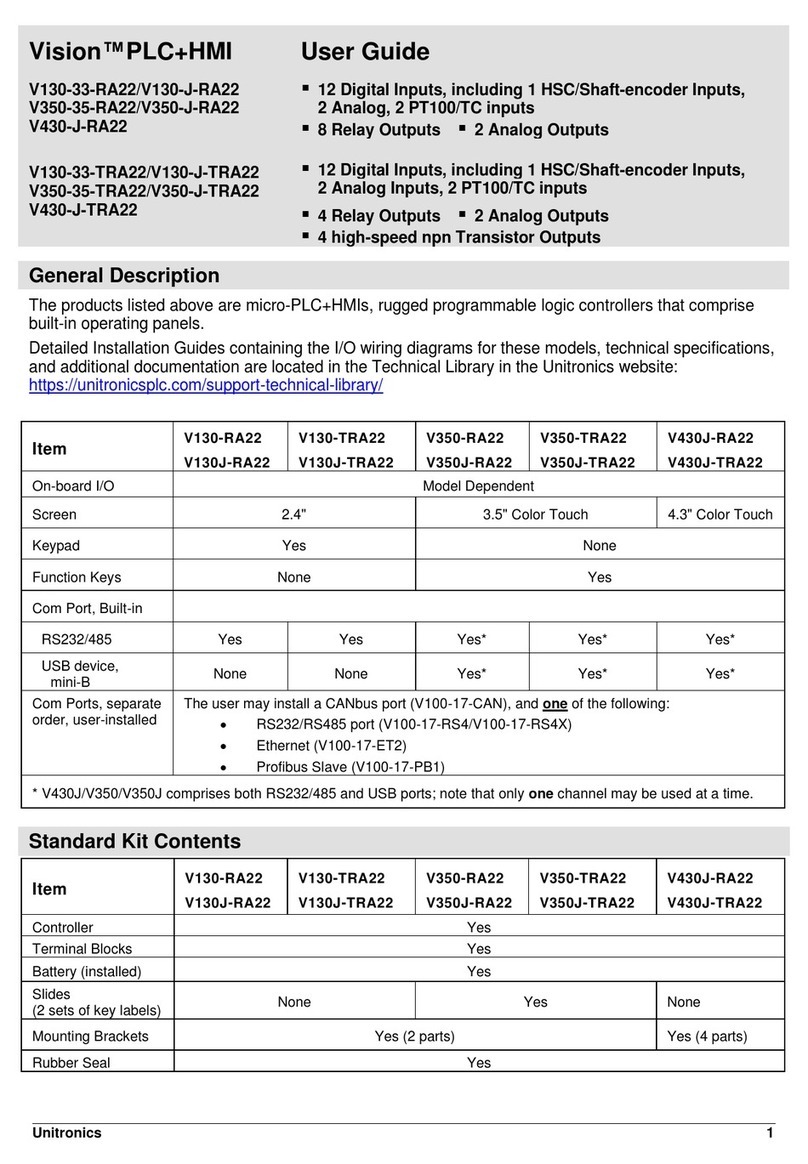

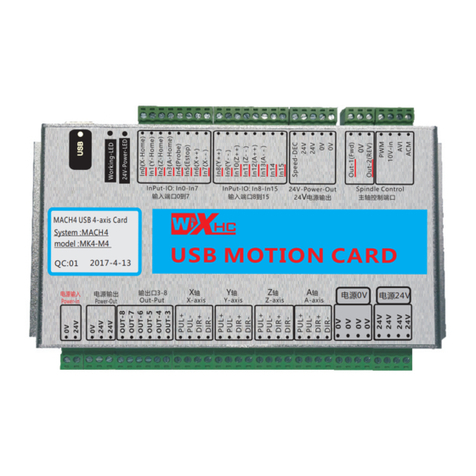

7.1.1 Connecting the control device, consumers and sensor 23

7.2 Installing the temperature sensors 25

7.2.1 Rod sensor for bench heating 25

7.2.2 Steam bath sensor 26

7.2.3 Characteristic curve rod sensor bench heating and steam bath sensor (KTY 81-110) 28

7.3 Fragrance pump 29

7.4 Checking the electrical connection 29

8 Commissioning 30

8.1 Safety instructions and notes 30

8.2 Checks before the initial commissioning 31

8.3 Switching on and off the steam bath control 31

8.4 Functional test of the steam bath control device and the electrical consumers 32

8.4.1 Functional test of the sensor 32

9 Appendix 33

9.1 Wiring diagram 33

4

1.1 Informationontheinstallationandoperatingmanual

An operating manual as well as an installation and operating manual are

available for the NORDMANN steam bath control.

The operating manual is meant for the user and gives important instructions

for handling the NORDMANN steam bath control.

The installation and operating manual describes the assembly, installation,

commissioning, rectication of defects and repair and is provided exclusively

for the technical personnel.

To ensure safe operation and working practices, all the prescribed safety

instructions and guidelines have to be followed.

Furthermore, the local accident prevention regulations and general safety

regulations applicable for the elds of use of the steam bath control are to

be adhered to.

The operating manual must be read carefully before switching on the device.

The operating manual as well as the installation and operating manual are

an integral part of the product and must be kept in the immediate vicinity of

the steam bath control so that they are always accessible.

The number of available connections and functions depends on the version

of the device. The keys and the display text can be customized depending on

the particular model and can differ from the gure shown on the rst page.

If you pass on the steam bath control to a third party, make sure you hand

over also the operating manual and the installation and operating manual.

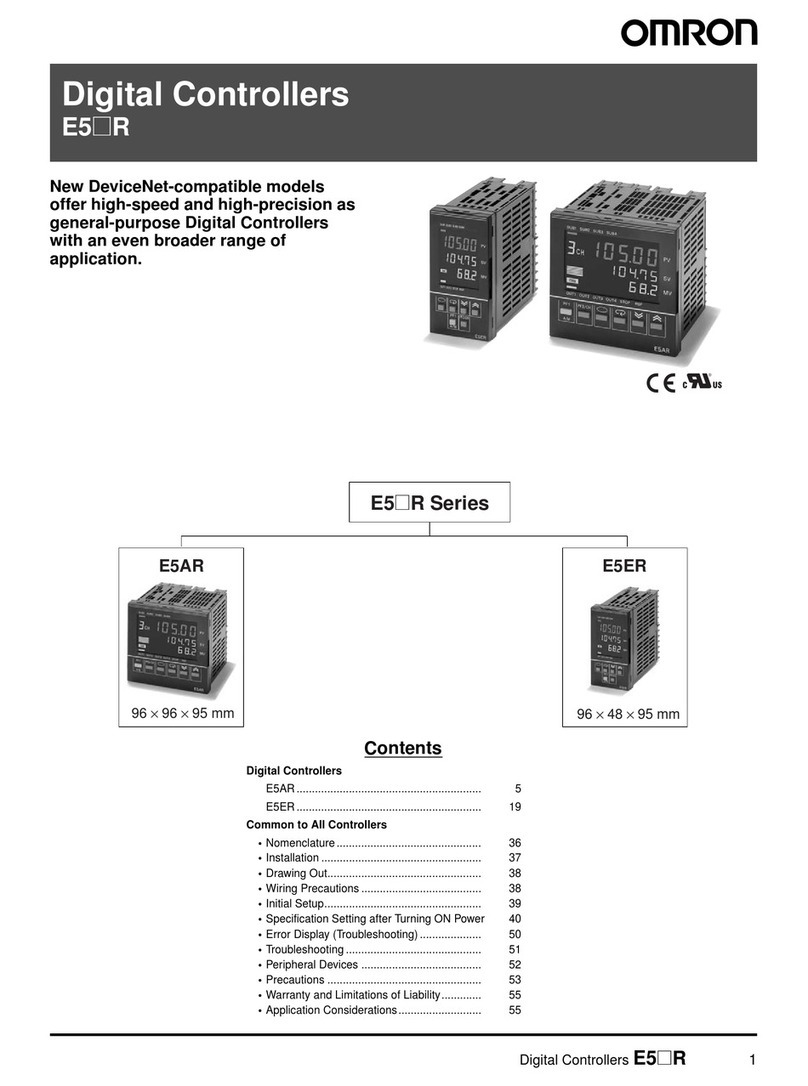

Components from other suppliers have their own operating manuals, safety

regulations and guidelines, which must be followed as well.

1 General Information

5

1.2 Explanationsofsymbols

Identications of Warnings

Warnings in this installation and operating manual are indicated through

symbols. The instructions are introduced through signal words, which ex-

press the degree of danger.

Adhere strictly to the instructions and be careful to avoid accidents, personal

injuries and property damage.

DANGER!

… indicates and imminent dangerous situation, which could lead to loss

of life or cause serious injuries if not avoided.

WARNING!

… indicates a possible dangerous situation, which can be fatal or cause

serious injuries if not avoided.

CAUTION!

… indicates a possible dangerous situation, which could lead to small or

slight injuries if not avoided.

ATTENTION!

… indicates a possible dangerous situation, which could lead to property

damage if not avoided.

Identications of tips and recommendations

NOTE!

…highlights useful tips and recommendations as well as information for

an efcient and smooth operation.

1.3 Liabilitylimitation

All the details and instructions in this manual have been compiled taking

into consideration the relevant standard specications and stipulations and

the state-of-the-art technology as well as our knowledge and experience

of many years.

The manufacturer does not take any liability for damages caused by:

– Non-adherence to the operating manual and to the installation and

operating manual

– Improper use

– Unauthorized alterations

– Technical changes

– Use of own assembly aids (only the assembly aids provided are admis-

sible)

– Use of not approved spare parts and wear and tear parts.

The actual scope of delivery can deviate from the explanations and the

presentation given here in case of special designs, additional orders or

technical updates.

Otherwise the obligations agreed upon in the delivery contract, the general

business conditions as well as the delivery terms of the manufacturer and the

legal regulations valid at the time of concluding the agreement are applicable.

6

Guarantee

The guarantee period of the manufacturer starts from the time of dispatch

by the manufacturer and is valid for 24 months. The delivery date can be

determined from the device number on the nameplate.

The manufacturer assumes no liability for any other guarantee commitments

deviating from this regulation. Guarantee claims must be submitted to the

steam bath manufacturer or dealer.

1.4 Copyright

Handing over the installation and operating manual to a third party without

the written consent of the manufacturer is not permitted.

NOTE!

The details, texts, drawings, pictures and other representations in this ma-

nual are protected by copyright and subjected to the industrial proprietary

laws. Any misuse is liable to punishment.

Copying in any form - even as excerpt - as well as use and/or conveying

of the content without written consent of the manufacturer is not permitted.

1.5 Scopeofdelivery

For information on the scope of delivery, pl. see the delivery note.

1.6 Spareparts

CAUTION!

Danger of injury due to incorrect spare parts!

Incorrect or defective spare parts can lead to damage, incorrect function-

ing or total breakdown and can impair the safety.

Therefore:

– Use only original spare parts of the manufacturer.

– Repairs of the steam bath control should be carried out only by techni-

cal experts.

Order the spare parts from the installer or the dealer of the steam bath unit.

For address see the invoice, delivery note or the back page of this manual.

7

1.7 Customerservice

Your dealer or the installer of the steam bath unit can provide technical

information on request.

The address you can nd on the invoice, delivery note or the back page of

this manual.

NOTE!

For quick processing, before calling note down the data on the nameplate

as well as the model, serial number, version etc.

8

2 Safety

2.1 Intendeduse

All NORDMANN steam bath controls are exclusively meant for operation

and control of steam bath cabins. The control devices are permitted for

domestic and commercial application.

WARNING!

Danger if not used correctly

Any improper use of the steam bath control can lead to dangerous situ-

ations.

Therefore:

– Use the steam bath control as instructed.

– Operate the steam bath control only within the permissible room

temperature and moisture range. → See chapter 4.

– All the specications in the operating manual and the installation and

operating manual must be strictly adhered to.

Claims of any type due to damages caused by improper use will not be ac-

cepted. Only the user is responsible for damages caused by improper use.

2.2 Requestforpublicsteambaths

In accordance with VDE the control room of the supervisor of a public

steam bath must be equipped with a control lamp, which displays when the

evaporator is switched on.

This control lamp is to be connected to the “Steam” terminals of the oper-

ating and fault remote indication board inside the evaporator (see wiring

diagram of the evaporator).

2.3 Modicationsandalterations

Modications and alterations of the steam bath control or installation can

lead to unforeseen dangers.

All technical modications and add-ons to the steam bath control require

the written permission of the manufacturer.

9

2.4 Demandsontechnicalpersonnel

The assembly, installation, commissioning as well as rectication of defects

and repairs must be carried out by qualied persons only unless otherwise

mentioned.

Inadequate Qualication

WARNING!

Danger of injury due to inadequate qualication!

Improper handling can lead to signicant personal injuries and material

damage.

Therefore: The assembly, installation, commissioning as well as rectica-

tion of defects, maintenance and repairs must be carried out by qualied

persons only unless otherwise mentioned.

– Technical personnel

due to their technical training, knowledge and experience as well as the

knowledge of the relevant regulations these persons are in a position to

carry out the tasks assigned to them and to identify possible dangers

on their own.

– Certied electricians

due to their technical training, knowledge and experience as well

as the knowledge of the relevant standard specications and

regulations these experts are in a position to carry out jobs on

the electrical unit and to identify possible dangers on their own.

In Germany certied electricians have to full the stipulations of the

accident prevention regulation BGV A3 (e.g. master electrician). In

other countries corresponding stipulations are applicable that have to

be followed.

10

2.5 Operationalsafetyandspecialdangers

Pay attention to the safety and warning notes in the following chapters of

this manual to minimize health hazards and to avoid dangerous situations.

The following instructions are to be adhered to for your own safety

and the safety of the unit:

DANGER!

Danger to life due to electric potential!

Contact with live components can be fatal.

Damage of the insulation of the individual components can be dangerous

to life.

Therefore:

– For switching off the mains, the power supply cable must be equipped

with a fuse having a contact opening width corresponding to the require-

ments of the excess voltage category III for total disconnection.

– Disconnect the unit from the mains before carrying out any work on it

(switch off the fuse in the distribution box) and secure against restarting.

Check for zero potential. The control device should be disconnected

from the mains before opening the casing.

– In case of damage to the insulation, switch off the power supply im-

mediately and carry out the repair.

– Work on electrical unit should be carried out by certied electricians

only.

– Never bypass fuses or switch them off.

– While changing the fuses, pay attention to correct current specica-

tions.

– Keep moisture away from live components, since it can lead to short

circuit.

WARNING!

If a short circuit occurs in a 230V/400V appliance, the high short-circuit

current can cause the contact of a relay to fuse. If the unit is switched

on again before the short circuit has been rectied, the safety relay can

also fuse. This will then cause the appliance to run continuously. Switch

off the circuit breaker in the junction box. Return the device to the factory

for testing/repair.

11

3 Identication

3.1 Typeplate

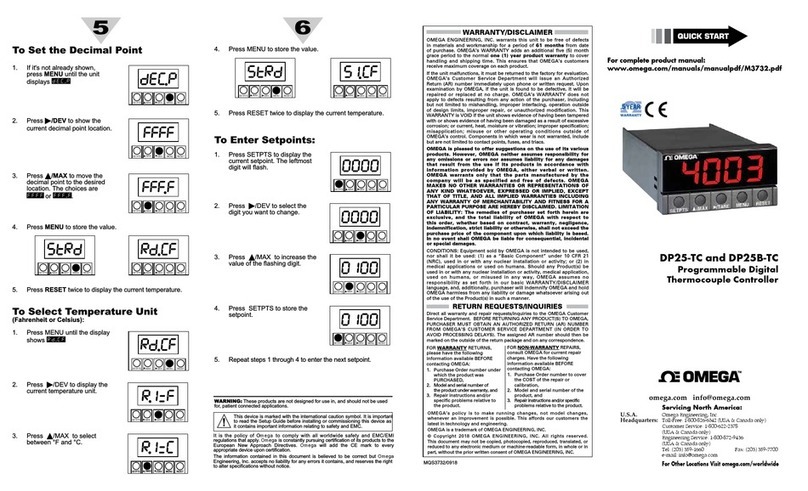

The type plate is located on the control unit on the left side:

Fig.1: control unit type plate

1 Type designation

2 Company logo

3 Article number

4 Voltage and max. power

5 Device number

6 Barcode

7 Article number

8 Barcode Article number

9 VDE mark (for devices that are approved by VDE)

10 RoHS marking

11 CE mark

12 Protection category

RoHS

conform

1

3

4

5

6

7

8

2

10

9

11

12

12

4.1 General information

Designation

Dimensions steam bath

control “compact”

247 mm x 285 mm x 86,5 mm

(Height x Width x Depth)

Dimensions operating

element “design”

197,5 mm x 122,5 mm x 35 mm

(Height x Width x Depth)

Max. distance between

basic device to operating

element

100 m

Voltage supply see type plate (V AC / Hz)

Ambient temperature 0 to +40 °C

Rel. humidity max.80 % relative humidity,

non-condensing

Storing temperature –10 °C bis +60 °C

Rel. humidity, storage max.80 % relative humidity,

non-condensing

Protection category see type plate

Table 1: Technical Data – General

Connecting cable

control device to operating element

The patch cable can be delivered

with a standard length of 5 or 10m.

If another length is desired then the

cable must be congured by the

electrician. Another option would be

to bridge a stretch by installing two

network sockets (CAT 5).

Specication of the patch cable – Minimum AWG26

– Minimum CAT 5

– Plugs should have no rubber

covering over the locking mecha-

nism

– Pin 1 to Pin 1 cable conguration

(straight through)

4 Technicaldata

13

4.2 Cables

Use of inappropriate cables – Electric potential

DANGER!

Danger to life due to electric potential!

Use of inappropriate cables can lead to short circuits and subsequent

res.

Damage to the insulation can be dangerous to life.

Therefore:

– All the cables, which lead to the steam bath, must be designed for at

least 150 °C.

– Use cables as per specications in table 2 and electrical wiring dia-

gram (see chapter 9.1). The specied cross sections are designed for

copper cables. In case of aluminium cables the cross sections should

be appropriately increased.

– The cross sections can increase due to the length of the cables, the

type of cable laying or special regulations.

Designation

Power supply cables Type / Cross

section /

Number of leads

H07RN-FG2,5

(heavy rubber hose 5 x 2,5 mm2)

Power supply cables must be polychloroprene-coated

and should not be lighter than heavy polychloroprene-

coated exible cables.

Signal cables for sensors Type – In case of longer distances: LiYCY

(exible, shielded cable)

– Within the cabin: heat resistant,

minimum 150 °C

Cross section → See also installation plans in chapter 7.3.

Number of leads → See also installation plans in chapter 7.3.

230 / 400V cables for sup-

ply to evaporator, blower,

light etc.

Type Heat resistant, at least 150 °C

Cross section → See wiring diagram, chapter 9.1

Number of leads → See wiring diagram, chapter 9.1

Table 2: Technical data– cables

14

4.3 Voltageandswitchingcapacity-electricalload

Designation Switching capacity

Nominal voltage 230 V 1 N ~ 50Hz

Seat heating 230 V~ max. 2 kW

Supply fan

(steam) 230 V~ max. 60 W

Supply fan

(permanent)

Exhaust fan 230 V~ max. 120 W

Cabin light 230 V~ max. 120 W

Cleaning light 230 V~ max. 120 W

OUT 1 … OUT 4 1)

OUT 5 … OUT 12 1)

Potential free, safety extra low voltage

max. 50 V / 1 A, 230 V~ / max. 120 W per relay;

total capacity see circuit diagram

IN 1 … IN 4 1)

IN 5 … IN 8 1)

IN 9 … IN 12 1)

Safety extra low voltage approx. 15 V,

switching current approx. 10 mA, 230 V~ 50 Hz,

all inputs same phase

1) option

Table 3: Technical data – voltages and switching capacity consumer

ATTENTION!

Light and fan:

At the dimmable outputs of light and fan, only 230V consumer, or for low

voltage iron core transformer which are suitable for phase cut on, will be

permitted.

Electronic transformer for phase cut off may not be connected.

15

4.4 Lightandblower

ATTENTION!

Light and blower:

At the dimmable outputs of light and blower, only 230V appliances or,

for low voltage, only ferrite core transformers or electronic transformers

suitable for phase cutting may be used.

Electronic transformers for phase cutting control may not be connected.

4.4.1 Deactivatephasecuttingoflightand/orblower

DANGER!

Danger to life from electrical voltage!

All poles of the device must be disconnected from the mains!

CAUTION!

Protect against ESD!

In order to protect against ESD, do not touch electrically conductive parts.

Take appropriate precautions. As a minimum precaution, touch an earthed

metallic item in order to discharge the static electricity.

If the light and/or blower are not suitable for phase cut-

ting, you can deactivate this function.

Blower adjustment (Terminal 1) activated

Blower adjustment deactivated, only ON/OFF

Light dimming (Terminal 3) activated

Dimming deactivated, only ON/OFF

The jumpers are only tted onto one pin (as shown

in the diagram above) or they are in the accessory kit

supplied with the control unit.

Deactivate the user menus for blower/light settings by

means of “DIP switch S1”.

DIP 4=ON, blower adjustment menu deactivated

DIP 5=ON, light dimming menu deactivated

If the light dimmer no longer works because of a fault in the lamp, then triac

“Tri2” and possibly fuse “Si2” may be irreparably damaged. When replacing

the triac (there is 1 spare triac in the accessory kit), ensure that the new

component is seated correctly on the base (check the metal lug). Make sure

that all connections are inserted correctly into the base and then press it

carefully into place.

If the blower adjustment has been permanently damaged as a result of a

fault, then the same applies to triac “Tri1”.

16

5 Goodsreceipt,TransportandStorage

5.1 Safety

Inappropriate Transport

ATTENTION!

Damage to the control due to inappropriate transport!

The control is a highly sensitive electronic device. It can get damaged due

to inappropriate transport.

Therefore: Remove the packing only just before starting the installation

5.2 Goodsreceipt

After the receipt the consignment should be immediately checked for any

transport damages.

In case of damages which are visible from outside, the following course of

action should be taken:

– The consignment should not be accepted or accepted conditionally only.

– Note down the scope of damage on the transport documents or on the

delivery note of the transporter.

– Initiate claim.

NOTE!

Claim damages as soon as they are identied. Claims for damages can

be lodged only within the valid claim period.

5.3 Packing

The packing should provide protection against transport damages to the

individual components till the time of installation. Therefore remove the

packing only just before installation.

5.4 Storage

Store the control under the following conditions:

– Do not store in open place, store in a dry dust free place.

– Do not subject to any aggressive media.

– Protect against sunlight.

– Avoid mechanical shocks.

– Storage temperature: –10 to +60 °C

– Relative humidity: max. 80 %, non-condensing

17

6.1 ProtectagainstESD

CAUTION!

Protect against ESD!

In order to protect against ESD, do not touch any electrically conductive

parts and when assembling the circuit board, only touch the plastic hous-

ing or the edge from the side!

Similarly, only touch the cable that connects to the board at the connector,

without touching the contact surfaces.

Therefore: Take appropriate precautions.As a minimum precaution, touch

an earthed metallic item in order to discharge the static electricity.

6.2 Installationofsteambathcontroldevice

The steam bath control device should be installed at a distance of at least

5 cm from the walls or other equipment. There should be a distance of 10 cm

between two steam bath control devices.

The control unit must be mounted in such a way that it is always accessible

(e.g. for maintenance purposes or replacing wear parts and fuses, etc.).

6 Installation

18

6.3 Mountingtheoperatingpanel“Design”

The operating control can be installed maximum 100 m away from the basic

control device.

Installation opening of operating panel “Design”

103 mm

25 mm

51.5 mm

9.5 mm

167 mm

ø 8 mm

8 mm

36 mm

70 mm

106 mm

36 mm

53 mm

70 mm

106 mm

1 mm

182.6 mm

23 mm

7.5 mm

198.1 mm

143.5 mm

83.5 mm

30 mm

5 mm

26 mm

Overall width 124 mm

Steam bath exterior

wall min. 12 mm

Cavity ll with

insulation

Housing trough

Push-Out for

control cable

Push-Out for

power switch

Installation opening for

the housing trough

Recess 5 mm

deep for

sleeve

Cutout (dotted)

Fig. 2: Installation opening operating panel “Design“

At this point

provide a re-

cess (5 mm

deep) for the

sleeve

top

bottom

19

Mounting/removing the “Design” operating panel

Fig. 3: Mounting / removing the “Design” operating panel

ATTENTION!

Damage or malfunction of the operating panel “Design” by steam,

humidity or water!

Therefore: Make sure the operating panel does get in touch with steam,

humiditiy or water.

20

6.4 Installationofinteriorcabindisplay

ATTENTION!

Damage of the cab interior may occur due of excess temperatures!

Therefore:

– Do not install the interior cabin display above or directly adjacent to

the steam outlet.

– The interior cabin display must be installed in such a way that it is

steam-tight (seal with silicone).t eingebaut werden (mit Silikon abdi-

chten).

Interior cabin display must be mounted on a maximum height of 1.6 m

above oor.

Fig. 4: Installation examples interior display

Evaporator

Interior display

Abb. 5: Dimenisons interior cabin display

Other manuals for SBC

1

Table of contents

Other Nordmann Engineering Controllers manuals